Лучшее аддитивное производство в аэрокосмической отрасли в Гамбурге: полное руководство для B2B-покупателей

Оглавление

1. Introduction to Aerospace Additive Manufacturing in Hamburg

Hamburg is a key hub for aerospace manufacturing in Europe, home to leading companies such as Airbus and Lufthansa Technik. With the growing demand for lightweight, high-performance parts, additive manufacturing (AM) in aerospace has gained significant traction in the region.

Aerospace additive manufacturing involves 3D printing metal and polymer components to enhance aircraft performance, reduce material waste, and accelerate production timelines. This technology is widely used for engine components, structural parts, and intricate geometries that are difficult to manufacture using traditional methods.

Key Benefits of Aerospace 3D Printing

✅ Снижение веса – Optimized part designs reduce overall aircraft weight, improving fuel efficiency.

✅ Экономия средств – Minimizes material waste and reduces production costs for complex components.

✅ Более короткие сроки выполнения – Rapid prototyping and on-demand production accelerate time-to-market.

✅ Повышенная производительность – AM enables the creation of high-strength, intricate parts with superior durability.

As aerospace manufacturers in Hamburg increasingly adopt аддитивное производство металлов, sourcing the right 3D printing suppliers and materials is crucial for success.

2. Market Trends and Growth Potential in Aerospace 3D Printing

The aerospace additive manufacturing market is experiencing rapid growth, driven by advancements in metal 3D printing technologies, high-performance materials, and automated production processes.

Ключевые тенденции рынка

📈 Increased Adoption of Metal 3D Printing – Aerospace companies favor металлические порошки like titanium, aluminum, and superalloys for critical components.

📈 Инициативы в области устойчивого развития – Additive manufacturing reduces waste and supports greener production practices.

📈 Customization & On-Demand Production – Airlines and manufacturers leverage on-demand 3D printing for spare parts, reducing inventory costs.

📈 Regulatory Approvals & Certifications – Aerospace AM suppliers must meet strict industry standards like AS9100 and Nadcap certification.

| Статистика роста рынка | Figures |

|---|---|

| Global Aerospace AM Market Size (2023) | $3.5 миллиарда |

| Projected CAGR (2023-2030) | 19.8% |

| Adoption Rate Among Aerospace OEMs | 85% |

| Reduction in Lead Time via AM | 50-70% |

С Hamburg’s strong aerospace ecosystem, companies are investing in advanced технологии аддитивного производства to enhance production efficiency and competitiveness.

3. Ключевые факторы, которые следует учитывать при выборе поставщика аэрокосмической 3D-печати

Выбор правильного aerospace additive manufacturing supplier in Hamburg requires careful evaluation of several critical factors:

1️⃣ Experience & Certifications

Ensure the supplier has aerospace industry experience and meets stringent certifications such as:

✔ Сертификация AS9100 – Quality management standard for aerospace manufacturers.

✔ Nadcap Accreditation – Ensures compliance with aerospace additive manufacturing processes.

✔ Сертификация по ISO 9001 – Demonstrates quality control and consistency in production.

2️⃣ Material & Technology Capabilities

Оцените Технологии 3D-печати и metal powder materials the supplier offers:

- Лазерно-порошковое наплавление (ЛПНП) – Ideal for high-precision metal components.

- Электронно-лучевое плавление (ЭЛП) – Suitable for high-strength aerospace parts.

- Прямое энергетическое осаждение (DED) – Used for repair and refurbishment of aircraft components.

🔹 Common Aerospace 3D Printing Materials:

- Титановые сплавы (Ti6Al4V) – Lightweight and corrosion-resistant.

- Nickel-Based Superalloys (Inconel 718, 625) – High-temperature resistance.

- Алюминиевые сплавы (AlSi10Mg) – Excellent strength-to-weight ratio.

- Нержавеющая сталь (316L, 17-4PH) – High durability and wear resistance.

3️⃣ Production Capabilities & Lead Times

✔ Can the supplier handle крупносерийное производство?

✔ What are the lead times for prototyping vs. full-scale production?

✔ Do they offer on-demand production for spare parts?

4️⃣ Cost & Scalability

Compare pricing models based on:

💲 Материальные затраты – Metal powders can vary in price depending on composition and purity.

📦 Производственные затраты – Evaluate per-part pricing for small vs. large production runs.

🚀 Масштабируемость – Can the supplier scale production based on demand fluctuations?

By carefully considering these factors, aerospace manufacturers in Hamburg can select the best 3D printing partner to support their production needs.

4. Top Aerospace Additive Manufacturing Companies in Hamburg

Hamburg is a major hub for aerospace innovation, home to ведущие компании по производству аддитивных материалов которые специализируются на metal 3D printing for aircraft and spacecraft components. Below are some of the top aerospace additive manufacturing providers in the region:

🔝 Leading Aerospace 3D Printing Suppliers in Hamburg

| Название компании | Ключевые возможности | Сертификаты | Специализация |

|---|---|---|---|

| Airbus Additive Manufacturing | Metal & polymer 3D printing, prototyping, production | AS9100, Nadcap | Элементы конструкции самолета |

| Lufthansa Technik | Repair & maintenance via metal 3D printing | EASA, FAA, AS9100 | Spare parts & engine components |

| Materialise | Aerospace-grade metal & polymer printing | ISO 9001, AS9100 | Lightweight aircraft parts |

| FIT Additive Manufacturing Group | High-end metal 3D printing, complex geometries | AS9100, ISO 13485 | Aircraft & space applications |

| Metal3DP | Высокопроизводительный SEBM & LPBF metal 3D printing, современные металлические порошки | ISO 9001, Industry-leading expertise | Titanium, superalloys, aerospace-grade materials |

Each of these suppliers brings unique strengths to aerospace additive manufacturing. Однако, Metal3DP stands out with its specialized focus on metal powders and high-precision 3D printing solutions that meet the rigorous demands of aerospace.

5. Why More Aerospace Manufacturers Are Adopting Additive Manufacturing

Принятие metal 3D printing in aerospace is accelerating as manufacturers recognize its numerous advantages over traditional production methods.

🚀 Key Reasons for Adoption

✅ Lightweight Design for Fuel Efficiency

- 3D printing enables the creation of hollow lattice structures и topology-optimized parts, significantly reducing weight.

- Lighter aircraft consume less fuel, improving operational efficiency and sustainability.

✅ Reduced Waste & Sustainability

- При традиционной обработке отходы составляют до 80% of raw materialтогда как additive manufacturing uses only the necessary material.

- Closed-loop recycling systems allow manufacturers to reuse metal powder, reducing overall waste.

✅ Быстрое прототипирование и ускоренное производство

- Traditional aerospace parts take months to produce due to complex supply chains.

- С аддитивное производство, production cycles are cut by 50-70%, enabling faster iteration and market readiness.

✅ On-Demand Spare Parts Production

- Airlines and MRO (Maintenance, Repair, Overhaul) providers can 3D print spare parts on demand, что снижает затраты на инвентаризацию.

- This is particularly useful for rare, discontinued, or customized aircraft components.

✅ Superior Material Properties

- 3D-печать по металлу производит высокопрочные, коррозионностойкие компоненты that outperform traditionally manufactured parts.

- Advanced alloys such as Ti6Al4V, Inconel 718, and CoCrMo широко используются в jet engines, landing gear, and structural components.

As the aerospace industry continues to evolve, companies that integrate additive manufacturing into their production workflows gain a competitive edge in cost, speed, and innovation.

6. Why Choose Metal3DP as Your Aerospace 3D Printing Partner?

Когда дело доходит до high-performance aerospace additive manufacturing, Metal3DP is a trusted partner for OEMs, Tier-1 suppliers, and research institutions.

🔹 What Sets Metal3DP Apart?

1️⃣ Industry-Leading Metal 3D Printing Technologies

- Селективное электронно-лучевое плавление (SEBM) – Ideal for high-precision titanium and superalloy parts.

- Лазерно-порошковое наплавление (ЛПНП) - Обеспечивает tight tolerances and fine surface finishes for aerospace components.

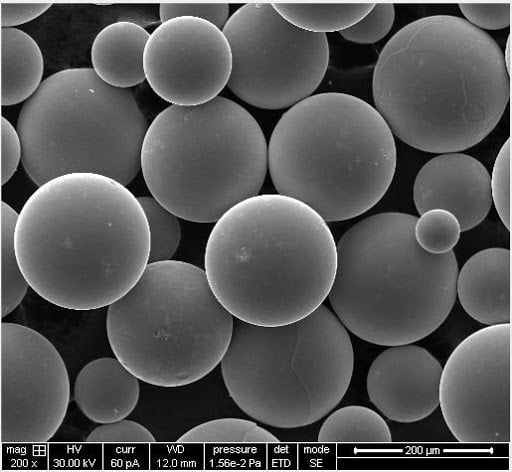

2️⃣ High-Quality Metal Powders for Aerospace Applications

- Our company manufactures aerospace-grade metal powders используя Газовое распыление и технология PREP.

- Available materials:

✔ Титановые сплавы (Ti6Al4V, TiAl, TiNbZr) – Используется в airframes, engine parts, and landing gear.

✔ Superalloys (Inconel 718, CoCrMo, Ni-based alloys) - Идеально подходит для high-temperature jet engine components.

✔ Нержавеющие стали (316L, 17-4PH) – Corrosion-resistant and durable for aircraft interiors and structural parts.

3️⃣ Certified & Reliable Aerospace Manufacturing

- ISO 9001-certified production facility ensures the highest quality standards.

- В доме powder characterization and quality control guarantee consistent particle size, flowability, and purity.

4️⃣ Expertise in Aerospace Applications

- Десятилетия опыта в aerospace additive manufacturing.

- Close collaboration with ведущие аэрокосмические фирмы to develop cutting-edge 3D-печатные компоненты.

📌 Explore Our Metal Powders & 3D Printing Solutions:

🔗 Learn More About Metal3DP’s Metal 3D Printing Capabilities

By partnering with Metal3DP, aerospace manufacturers gain access to top-tier additive manufacturing expertise, high-performance materials, and cutting-edge printing technologies to enhance their production efficiency and competitiveness.

7. How to Source High-Quality Metal Powders for Aerospace 3D Printing

Поиск высококачественные металлические порошки is crucial for achieving precision, durability, and performance in aerospace additive manufacturing. The right metal powder ensures optimal printability, mechanical properties, and safety compliance. Here’s how aerospace manufacturers can source the best materials for their 3D-печать потребности.

🔹 Key Factors to Consider When Choosing Metal Powders

| Фактор | Почему это важно |

|---|---|

| Распределение частиц по размерам (PSD) | Affects powder flowability and layer uniformity in AM processes. |

| Powder Morphology (Shape and Surface Quality) | Spherical powders improve packing density and reduce defects. |

| Purity and Contamination Levels | High-purity powders ensure stronger, defect-free components. |

| Oxidation and Moisture Sensitivity | Oxidized powders can degrade mechanical properties. |

| Printability & Compatibility | The powder must be optimized for LPBF, SEBM, or DED processes. |

🔹 Recommended Metal Powders for Aerospace 3D Printing

| Материал | Применение в аэрокосмической отрасли |

|---|---|

| Титановые сплавы (Ti6Al4V, TiAl, TiNbZr) | Lightweight & corrosion-resistant – used in airframes, engine parts. |

| Суперсплавы на основе никеля (Инконель 718, Инконель 625) | High-temperature resistance – ideal for компоненты реактивных двигателей. |

| Кобальт-хром (CoCrMo) | High wear resistance – used in turbine blades, exhaust systems. |

| Нержавеющие стали (316L, 17-4PH) | Strong & corrosion-resistant – used in aircraft interiors, structural parts. |

🔹 Why Choose Metal3DP’s Metal Powders?

✅ Industry-Leading Purity & Quality – Изготовлено с использованием распыление газа и Технология PREP для превосходных sphericity and flowability.

✅ Сертификаты аэрокосмического класса – Compliant with ISO 9001 standardsобеспечивая high-performance, defect-free prints.

✅ Optimized for Additive Manufacturing – Powders tailored for LPBF, SEBM, and DED процессы.

📌 Explore Metal3DP’s Full Range of Metal Powders:

🔗 View Our Metal Powder Products

8. How to Order Aerospace 3D Printing Services in Hamburg

For aerospace manufacturers looking to integrate аддитивное производство into their production workflows, partnering with the right supplier is essential. Here’s how to order aerospace 3D printing services with a streamlined process.

Step-by-Step Guide to Ordering Aerospace 3D Printing Services

Шаг 1: Определите ваши требования

📌 Determine the part specifications:

- Material type (e.g., Ti6Al4V, Inconel 718)

- Print technology (LPBF, SEBM, or DED)

- Tolerance requirements

- Mechanical performance needs

Step 2: Select a Trusted Supplier

- Выберите Metal3DP для high-precision aerospace printing and advanced metal powders.

- Ensure supplier сертификаты (AS9100, ISO 9001) align with industry standards.

Step 3: Request a Quote & Feasibility Analysis

📩 Provide a 3D CAD-файл (STEP/STL format) to Metal3DP for evaluation.

📊 Receive a technical feasibility assessment & cost estimate.

Step 4: Prototype & Testing Phase

🔬 Prototype production for functional testing and validation.

📏 Material characterization to ensure compliance with aerospace standards.

Шаг 5: Полномасштабное производство и доставка

🚀 Batch production of aerospace components using high-precision 3D printing.

📦 Quality inspection & certification before final delivery.

📌 Get Started with Aerospace Additive Manufacturing:

🔗 Contact Metal3DP for Ordering

9. FAQs: Common Questions About Aerospace Additive Manufacturing

Q1: What are the main advantages of additive manufacturing in aerospace?

Aerospace 3D printing обеспечивает:

✔ Снижение веса для повышения топливной эффективности

✔ Экономия средств by minimizing material waste

✔ Быстрое прототипирование for faster product development

✔ On-demand spare parts production

Q2: Which metal powders are best for aerospace 3D printing?

🔹 Титановые сплавы (Ti6Al4V, TiAl, TiNbZr) – Легкий, высокопрочный

🔹 Суперсплавы на основе никеля (Инконель 718, 625) – Heat-resistant, durable

🔹 Кобальт-хром (CoCrMo) – High wear resistance for turbine blades

Q3: How does Metal3DP ensure metal powder quality?

✅ Gas atomization & PREP production обеспечивает high sphericity, minimal impurities

✅ ISO-certified quality control для consistent particle size and flowability

Q4: How long does it take to produce aerospace 3D printed parts?

⏳ Lead times vary based on complexity and production volume:

- Прототипы: 1-2 недели

- Full production: 4-8 недель

Q5: How can I request a custom aerospace 3D printing project?

📩 Submit your CAD file & material requirements в Metal3DP.

📊 Receive a customized production plan & pricing estimate.

📌 Learn More About Metal3DP’s Aerospace 3D Printing Solutions:

🔗 Explore Our Metal 3D Printing Capabilities

Заключительные мысли и следующие шаги

Aerospace additive manufacturing is revolutionizing the industry, offering lighter, stronger, and more efficient parts for modern aircraft. With Hamburg’s growing Экосистема 3D-печати, manufacturers can leverage high-performance metal powders and advanced printing technologies чтобы получить конкурентное преимущество.

🚀 Почему стоит выбрать Metal3DP?

✅ Industry-leading aerospace 3D printing solutions

✅ High-purity, aerospace-grade metal powders

✅ Precision manufacturing for mission-critical components

📌 Get Started with Metal3DP Today:

🔗 Contact Us for Aerospace 3D Printing Services

By following this guide, aerospace manufacturers in Hamburg can successfully integrate additive manufacturing into their supply chainобеспечивая high-quality, cost-effective production of critical aircraft components.

Поделиться

MET3DP Technology Co., LTD - ведущий поставщик решений для аддитивного производства со штаб-квартирой в Циндао, Китай. Наша компания специализируется на производстве оборудования для 3D-печати и высокопроизводительных металлических порошков для промышленного применения.

Сделайте запрос, чтобы получить лучшую цену и индивидуальное решение для вашего бизнеса!

Похожие статьи

Высокопроизводительные сегменты сопловых лопаток: Революция в эффективности турбин с помощью 3D-печати металла

Читать далее "

3D-печатные крепления для автомобильных радарных датчиков: Точность и производительность

Читать далее "О компании Met3DP

Последние обновления

Наш продукт

CONTACT US

Есть вопросы? Отправьте нам сообщение прямо сейчас! После получения Вашего сообщения мы всей командой выполним Ваш запрос.

Получите информацию о Metal3DP

Брошюра о продукции

Получить последние продукты и прайс-лист

Металлические порошки для 3D-печати и аддитивного производства

КОМПАНИЯ

ПРОДУКТ

ИНФОРМАЦИЯ О КОНТАКТЕ

- Город Циндао, Шаньдун, Китай

- [email protected]

- [email protected]

- +86 19116340731