AlSi7Mg-pulver

AlSi7Mg-pulver är ett aluminiumlegeringspulver som främst består av aluminium (Al), kisel (Si) och magnesium (Mg). "7" i namnet står för andelen kisel, medan "Mg" står för magnesiuminnehållet. Detta pulver uppvisar utmärkt styrka, låg densitet och imponerande termiska egenskaper, vilket gör det till ett förstahandsval i flera branscher.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt över AlSi7Mg-pulver

AlSi7Mg eller A357-legering är en mångsidig gjuterilegering som har egenskaper mellan ren aluminium och hypereutektiska legeringar med hög kiselhalt. Kiseltillsatserna förbättrar gjutbarheten och förbättrar de mekaniska egenskaperna medan magnesium förbättrar hållfastheten.

Viktiga egenskaper hos AlSi7Mg-pulver inkluderar:

- God hållfasthet och hårdhet

- Utmärkt flytbarhet och gjutbarhet

- God bearbetbarhet och polerbarhet

- Hög värmeledningsförmåga

- God korrosionsbeständighet

- Låg värmeutvidgningskoefficient

- Finns i en rad olika partikelstorlekar

AlSi7Mg-pulver används för tillverkning av fordonskomponenter, hydrauliska delar och andra precisionsgjutgods som kräver balanserade egenskaper.

Kemisk sammansättning av AlSi7Mg-pulver

Den typiska kemiska sammansättningen av AlSi7Mg-pulver är:

| Element | Vikt % |

|---|---|

| Aluminium (Al) | Balans |

| Kisel (Si) | 6-8% |

| Magnesium (Mg) | 0.4-0.8% |

| Järn (Fe) | 0.15-0.5% |

| Mangan (Mn) | 0,1% max |

| Koppar (Cu) | 0,1% max |

| Zink (Zn) | 0,1% max |

| Titan (Ti) | 0,25% max |

Kisel är det viktigaste legeringsämnet medan magnesium förbättrar hållfastheten och gjutbarheten. Järn, mangan och titan har mindre effekter. Sammansättningen skräddarsys för att uppfylla kraven på mekaniska egenskaper.

Egenskaper hos AlSi7Mg-pulver

AlSi7Mg-pulver har följande egenskaper:

| Fastighet | Värde |

|---|---|

| Täthet | 2,68 g/cm3 |

| Smältpunkt | ~600°C |

| Termisk konduktivitet | 130-160 W/mK |

| Elektrisk resistivitet | 3-5 μΩ.cm |

| Young's modul | 70-80 GPa |

| Poissonförhållande | 0.33 |

| Draghållfasthet | 250-300 MPa |

| Utbyteshållfasthet | 140-180 MPa |

| Töjning | 4-8% |

| Hårdhet | 80-100 Brinell |

Kiseltillsatserna ökar hållfastheten samtidigt som duktiliteten och bearbetbarheten bibehålls. Legeringen har utmärkt gjutbarhet och termiska egenskaper.

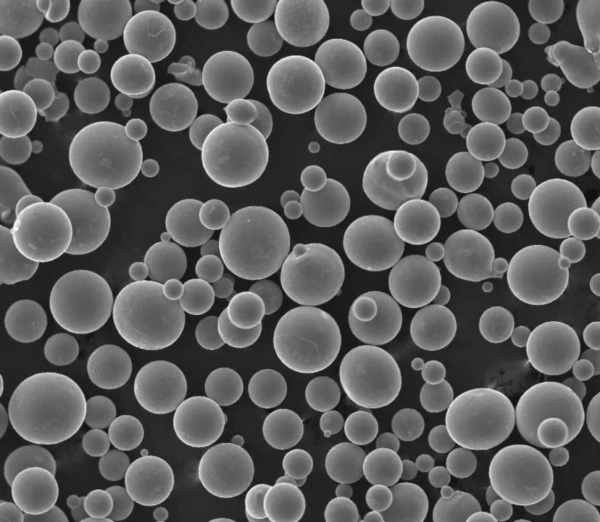

Produktionsmetod för AlSi7Mg-pulver

Kommersiella produktionsprocesser som används för AlSi7Mg-pulver inkluderar:

- Atomisering av gas - Smält legeringsström bryts ned till fina droppar av inerta gasstrålar. Producerar sfäriskt pulver.

- Atomisering av vatten - Högtrycksvattenstråle träffar smält metall och ger fina pulver. Kostnadseffektiv men högre syreupptagningsförmåga.

- Mekanisk legering - Kulfräsning av aluminium- och kiselpulver följt av kallkompaktering och sintring.

Gasatomisering ger störst kontroll över pulveregenskaper som partikelstorleksfördelning, morfologi och mikrostruktur.

Användningsområden för AlSi7Mg-pulver

De viktigaste användningsområdena för AlSi7Mg-pulver inkluderar:

- Formsprutning av metall - För tillverkning av små komplicerade detaljer med snäva toleranser och goda mekaniska egenskaper.

- Additiv tillverkning - Används i binder jetting, lasersmältning och andra AM-processer för att tillverka komplexa komponenter.

- Gjutgods - Tillsätts i smältor för att förbättra flytförmågan. Används för att tillverka bildelar som kräver hållbarhet.

- Pulvermetallurgi - Press- och sintringsprocess för att skapa högpresterande delar.

- Termisk sprutning - Deponeras som skyddande beläggningar på metallytor för att ge slitage- och korrosionsbeständighet.

- Fyllmedel för svetsning - För sammanfogning av aluminiumkomponenter med bibehållen svetsstyrka.

- Pyroteknik - Tillsatt till pyrotekniska kompositioner som en bränslebeståndsdel.

Specifikationer för AlSi7Mg-pulver

AlSi7Mg-pulver finns i olika storleksintervall, kvaliteter och renhetsgrader:

- Partikelstorlek: Från 10 - 150 mikrometer för AM, under 45 mikrometer för MIM.

- Morfologi: Sfäriska, granulära och oregelbundna partikelformer. Slätt pulver flyter bättre.

- Renhet: Från kommersiella kvaliteter till hög renhet (99,9%).

- Syrehalt: Nivåerna varierar från 400 - 1500 ppm för olika produktionsmetoder.

- Flytbarhet: Pulver anpassat för utmärkta flödeshastigheter på 25 s/50 g eller bättre.

- Betyg: Anpassad legeringskemi och pulveregenskaper erbjuds.

Globala leverantörer av AlSi7Mg-pulver

Några av de största leverantörerna av AlSi7Mg-pulver globalt är:

- PyroGenesis Kanada

- Sandvik Osprey Storbritannien

- Valimet Inc. USA

- Makin Metallpulver UK

- Shanghai Chaowei Nanoteknologi Kina

- Agni Metall USA

- Titanpulver Kanada

Dessa företag producerar AlSi7Mg-pulver med hjälp av olika metoder som lämpar sig för additiv tillverkning, formsprutning av metall, termisk sprutning och andra tillämpningar.

Priser för AlSi7Mg-pulver

Prissättningen av AlSi7Mg-pulver beror på faktorer som:

- Renhetsnivåer

- Partikelns egenskaper

- Produktionsmetod

- Ordervolym

- Ytterligare bearbetning

- Leverantör och plats

| Betyg | Prisintervall |

|---|---|

| Kommersiell | $5-15 per kg |

| Hög renhet | $15-30 per kg |

| Ultrafin | $30-60 per kg |

| Särskild klass | $50-120 per kg |

I allmänhet har gasatomiserade och kontrollerade pulver mycket högre priser än enkla kommersiella kvaliteter.

Hantering och lagring av AlSi7Mg-pulver

AlSi7Mg-pulver ska hanteras och förvaras på rätt sätt för att förhindra:

- Fuktkontakt som leder till oxidation

- Brandfara på grund av ansamling av damm

- Hälsorisker vid inandning av fina pulver

- Säkerhetsrutiner som rekommenderas av leverantören ska följas

Förslutna behållare under inert atmosfär tillsammans med korrekt jordning och personlig skyddsutrustning rekommenderas.

Test- och karakteriseringsmetoder

Viktiga testmetoder för AlSi7Mg-pulver inkluderar:

- Kemisk analys med hjälp av OES eller XRF för sammansättning

- Partikelstorleksfördelning enligt ASTM B822-standarden

- Morfologisk analys genom SEM

- Mätning av flödeshastighet med Hall-flödesmätare

- Densitetsbestämning med heliumpyknometri

- Föroreningsnivåer testade med ICP-MS

- Mikrostrukturen undersöktes med XRD-fasanalys

Grundliga tester säkerställer att pulverkvaliteten uppfyller applikationskraven.

Jämförelse av AlSi7Mg- och AlSi10Mg-pulver

AlSi7Mg och AlSi10Mg är två aluminiumlegeringspulver som jämförs:

| Parameter | AlSi7Mg | AlSi10Mg |

|---|---|---|

| Innehåll av kisel | 6-8% | 9-11% |

| Styrka | Lägre | Högre |

| Gjutbarhet | Jämförbar | Jämförbar |

| Korrosionsbeständighet | Bra | Utmärkt |

| Kostnad | Lägre | Högre |

| Tillämpningar | Gjutgods, MIM | Flyg- och rymdindustrin, AM-delar |

| Tillgänglighet | Lättillgänglig | Måttlig |

AlSi10Mg ger högre hållfasthet men till en högre kostnad. AlSi7Mg ger välbalanserade egenskaper till lägre kostnad där hög hållfasthet inte är avgörande.

Vanliga frågor om AlSi7Mg-pulver

F: Hur produceras AlSi7Mg-pulver?

S: AlSi7Mg-pulver tillverkas kommersiellt med hjälp av gasatomisering, vattenatomisering eller mekanisk legering följt av sintring. Gasatomisering ger bättre kontroll över partikelegenskaperna.

F: Vilka är de viktigaste användningsområdena för AlSi7Mg-pulver?

A: De viktigaste användningsområdena för AlSi7Mg-pulver är formsprutning av metall, pressgjutning av aluminium, additiv tillverkning, pulvermetallurgi, beläggningar för termisk sprutning och tillsatsmaterial för svetstråd.

F: Vilken är den typiska partikelstorleken som används för AlSi7Mg-pulver i AM?

S: För de flesta 3D-utskriftsprocesser för metall som DMLS och bindemedelsjetting är det vanliga partikelstorleksintervallet för AlSi7Mg-pulver 20-45 mikron.

F: Kräver AlSi7Mg-pulver några särskilda försiktighetsåtgärder vid hantering?

A: Ja, det rekommenderas att hantera aluminiumpulver under inert atmosfär med korrekt jordning, ventilation och PPE för att förhindra brand- och explosionsrisker.

F: Var kan jag köpa AlSi7Mg-pulver som är lämpligt för tillverkning av precisionsgjutgods?

S: Ledande pulverleverantörer som Valimet, Makin Metal Powders och PyroGenesis tillhandahåller AlSi7Mg-pulver som lämpar sig för gjuteritillämpningar som precisionsgjutgods.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731