Bästa rostfritt stål 316L pulver för 3D-utskrift

Rostfritt stål 316L-pulver är ett mångsidigt material som används i många olika branscher. Dess unika egenskaper gör det lämpligt för tillämpningar som sträcker sig från 3D-utskrifter till biomedicinska implantat. I den här artikeln kommer vi att utforska egenskaper, användningsområden, tillverkningsprocess och fördelar med rostfritt stål 316L-pulver.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt över rostfritt stål 316L pulver

316L rostfritt stål tillhör den austenitiska klassen av rostfritt stål. Tillsatsen av 2-3% molybden tillsammans med nickel och krom ger utmärkt grop- och spaltkorrosionsbeständighet i tuffa miljöer. 'L' betecknar lägre kolhalt för att undvika karbidutfällning under svetsning.

Viktiga egenskaper hos 316L pulver inkluderar:

- Utmärkt korrosionsbeständighet i tuffa miljöer

- Hög oxidations- och sulfideringsbeständighet vid förhöjda temperaturer

- Mycket god svetsbarhet och formbarhet

- Icke-magnetisk austenitisk struktur

- Tillgänglig i en rad olika partikelstorleksfördelningar

316L pulver är lämpligt för applikationer som kräver utmärkt korrosionsbeständighet som kemisk bearbetning, läkemedel, mat och dryck, marin utrustning och biomedicinska implantat. Den här artikeln ger en detaljerad översikt över 316L pulver.

Kemisk sammansättning av 316L pulver

Den typiska sammansättningen av 316L pulver är:

| Element | Vikt % |

|---|---|

| Järn (Fe) | Balans |

| Krom (Cr) | 16-18% |

| Nickel (Ni) | 10-14% |

| Molybden (Mo) | 2-3% |

| Mangan (Mn) | ≤ 2% |

| Kisel (Si) | ≤ 1% |

| Kol (C) | ≤ 0,03% |

| Fosfor (P) | ≤ 0,045% |

| Svavel (S) | ≤ 0,03% |

Nickel förbättrar korrosionsbeständigheten medan tillsats av molybden förbättrar motståndskraften mot gropfrätning och spaltkorrosion i miljöer som innehåller klorider. Låg kolhalt undviker karbidutfällning under svetsning.

Egenskaper för 316L pulver

316L pulver har följande egenskaper:

| Fastighet | Värde |

|---|---|

| Täthet | 7,9-8,1 g/cm3 |

| Smältpunkt | 1370-1400°C |

| Termisk konduktivitet | 16 W/mK |

| Elektrisk resistivitet | 0,75 μΩ.cm |

| Young's modul | 190-210 GPa |

| Poissonförhållande | 0.27-0.30 |

| Draghållfasthet | 485-620 MPa |

| Utbyteshållfasthet | 170-310 MPa |

| Töjning | 40-50% |

| Hårdhet | 79-95 HRB |

316L erbjuder utmärkt korrosionsbeständighet kombinerat med god formbarhet och svetsbarhet. Den austenitiska strukturen ger god seghet och duktilitet.

Produktionsmetod för 316L pulver

Vanliga produktionsmetoder för 316L pulver inkluderar:

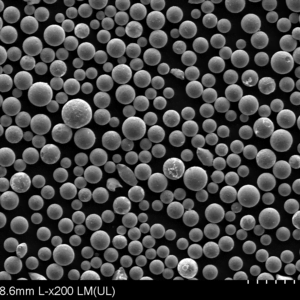

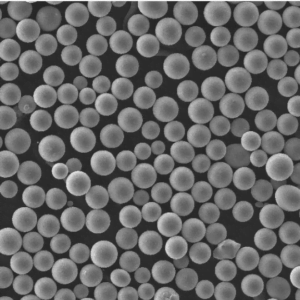

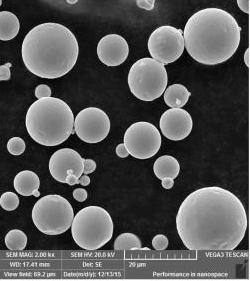

- Atomisering av gas – Inerta gasstrålar sönderdelar smält 316L legeringsström till fina sfäriska pulver med kontrollerad storleksfördelning.

- Atomisering av vatten – Högtrycksvattenstråle slår mot och sönderdelar smält metall för att producera fina oregelbundna pulverpartiklar.

- Mekanisk legering - Kulfräsning av blandade elementpulver följt av sintring och sekundär atomisering.

Gasatomisering tillåter utmärkt kontroll över partikelegenskaper som storlek, form, syreupptagning och mikrostruktur.

Användningsområden för 316L-pulver

Typiska tillämpningar av 316L pulver inkluderar:

- Additiv tillverkning – Pulverbäddsfusion, bindemedelssprutningsprocesser använder 316L pulver för kemiska, marina, biomedicinska delar.

- Formsprutning av metall – För att tillverka små komplexa komponenter som behöver korrosionsbeständighet.

- Beläggningar för termisk sprutning – Spraydeponering av trådbåge för att producera skyddande beläggningar i tuffa miljöer.

- Förbrukningsmaterial för svetsning – Används som tillsatsmaterial för sammanfogning av 316L-komponenter som ger utmärkt svetshållfasthet.

- Kemisk bearbetning – Pulvermetallurgikärl, brickor, korgar som används inom kemisk och läkemedelsindustri.

Specifikationer för 316L pulver

316L pulver är tillgängligt under olika storleksintervall, former och renhetsnivåer:

- Partikelstorlek: Från 10-45 μm för AM-metoder, upp till 150 μm för termiska sprutprocesser.

- Morfologi: Sfäriska, oregelbundna och blandade partikelformer. Smidigt sfäriskt pulver ger optimalt flöde.

- Renhet: Från kommersiell till hög renhet (99.9%) skräddarsydd efter applikationskrav.

- Syrehalt: Nivåerna hålls på 100-1000 ppm för de flesta applikationer.

- Flödeshastighet: Pulver kundanpassat för flöden över 25 s/50 g.

Globala leverantörer av 316L pulver

Några av de stora globala leverantörerna av 316L-pulver inkluderar:

- Sandvik Osprey (Storbritannien)

- Hoganas (Sverige)

- Carpenter Powder Products (USA)

- Praxair (USA)

- Oerlikon Metco (Schweiz)

- LPW Technology (UK)

Dessa företag producerar olika kvaliteter av 316L pulver som är skräddarsydda för additiv tillverkning, termisk spray, metallformsprutning och andra applikationer.

Pris på 316L pulver

316L pulverpriser beror på faktorer som:

- Renhetsnivåer

- Partikelns egenskaper

- Orderkvantitet

- Ytterligare bearbetning

- Tillverkare och geografiskt läge

| Betyg | Prisintervall |

|---|---|

| Kommersiell | $15-25 per kg |

| Hög renhet | $25-50 per kg |

| Ultrafin | $50-120 per kg |

| Särskild klass | $120-250 per kg |

Gasfinfördelad, kontrollerad partikelstorlek, högrenhetspulver kräver mycket högre pris än vanligt kommersiellt 316L-pulver.

Förvaring och hantering av 316L pulver

316L pulver ska hanteras med försiktighet för att:

- Förhindra kontakt med fukt, syror etc. som leder till korrosion

- Undvik ansamling av fint pulver för att minimera risken för dammexplosioner

- Använd lämplig ventilation, PPE vid hantering av fina pulver

- Följ rekommenderad praxis från leverantörens säkerhetsdatablad

- Förvara förslutna behållare i en torr, inert atmosfär

Lämpliga skyddsåtgärder måste vidtas vid hantering av reaktiva legeringspulver som 316L.

Inspektion och testning av 316L pulver

Viktiga kvalitetskontrolltester utförda på 316L pulver:

- Kemisk analys med hjälp av OES eller XRF för att säkerställa att sammansättningen ligger inom angivna gränser

- Partikelstorleksfördelning enligt ASTM B822-standarden

- Morfologisk analys genom SEM-bildtagning

- Pulverflödeshastighet mätt enligt ASTM B213-standarden

- Densitetsbestämning med heliumpyknometri

- Test av orenheter med ICP-MS

- Karakterisering av mikrostruktur med röntgendiffraktion

Grundliga tester säkerställer att pulvret uppfyller de kemiska, fysiska och mikrostrukturella egenskaper som krävs för den avsedda applikationen.

Jämförelse mellan 316L och 304L pulver i rostfritt stål

316L och 304L pulver av rostfritt stål jämfört:

| Parameter | 316L | 304L |

|---|---|---|

| Sammansättning | Fe-Cr-Ni-Mo | Fe-Cr-Ni |

| Korrosionsbeständighet | Mycket bättre | Bra |

| Kostnad | Högre | Lägre |

| Temperaturbeständighet | Bättre | Bra |

| Svetsbarhet | Utmärkt | Utmärkt |

| Tillgänglighet | Måttlig | Utmärkt |

| Tillämpningar | Marin, kemisk industri | Konsumentprodukter, vitvaror |

316L erbjuder avsevärt bättre korrosionsbeständighet medan 304L är mer ekonomiskt för mindre krävande applikationer.

Vanliga frågor om 316L Powder

F: Hur produceras 316L rostfritt stålpulver?

S: 316L pulver tillverkas kommersiellt med gasförstoftning, vattenförstoftning och mekanisk legering följt av sintring. Gasförstoftning ger den bästa kontrollen av pulvrets egenskaper.

F: Vilka är de huvudsakliga användningsområdena för 316L-pulver?

S: Nyckelapplikationer för 316L-pulver inkluderar additiv tillverkning, metallformsprutning, termiska sprutbeläggningar och pulvermetallurgiska delar för kemiska, marin-, läkemedels- och livsmedelsindustrier som behöver utmärkt korrosionsbeständighet.

F: Vilken är den rekommenderade 316L pulverstorleken för bindemedelssprutning AM?

S: För bindemedelssprutningsprocessen är det typiska 316L pulverstorleksintervallet 20-45 mikron med sfärisk morfologi för optimal pulverbädddensitet och bindemedelsinfiltration.

F: Kräver 316L pulver särskilda försiktighetsåtgärder?

S: Ja, 316L är ett reaktivt legeringspulver och bör hanteras försiktigt under kontrollerad fuktighet och inert atmosfär med korrekt jordning, ventilation och personlig skyddsutrustning.

F: Var kan jag köpa 316L pulver lämpligt för biomedicinska implantat?

S: Högrent, gasatomiserat 316L-pulver som uppfyller biomedicinska specifikationer kan köpas från ledande tillverkare som Sandvik Osprey, Hoganas, Carpenter Powder Products och LPW Technology.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731