Rostfritt stål OP431 Pulver

OP431-pulver av rostfritt stål är en pulverform av rostfritt stål som består av järn, krom, nickel och andra legeringselement. Det tillverkas genom en specialiserad process som kallas atomisering, där smält rostfritt stål snabbt kyls med hjälp av gas eller vatten, vilket resulterar i bildandet av fina metallpartiklar.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt över OP431-pulver i rostfritt stål

OP431 rostfritt stål tillhör de ferritiska stålsorterna som innehåller krom som huvudsakligt legeringselement. Tillsats av aluminium förbättrar oxidations- och korrosionsbeständigheten vid höga temperaturer.

Viktiga egenskaper hos OP431-pulvret är bl.a:

- Utmärkt oxidations- och korrosionsbeständighet upp till 1150°C

- Bra krypmotstånd och termisk utmattningshållfasthet

- Utmärkt termomekanisk stabilitet

- Hög värmeledningsförmåga och låg värmeutvidgning

- Kostnadseffektivt jämfört med austenitiska rostfria stål

- Finns i olika partikelstorleksfördelningar

OP431-pulvret är idealiskt för applikationer som kräver oxidationsbeständighet, termisk stabilitet och måttlig hållfasthet vid förhöjda temperaturer.

Kemisk sammansättning av OP431-pulver

OP431-pulvret har följande nominella sammansättning:

| Element | Vikt % |

|---|---|

| Järn (Fe) | Balans |

| Krom (Cr) | 16-18% |

| Aluminium (Al) | 3-5% |

| Yttrium (Y) | 0.2-0.5% |

| Kol (C) | 0,03% max |

| Kisel (Si) | 1% max |

| Mangan (Mn) | 1% max |

Krom ger korrosionsbeständighet medan aluminium ger utmärkt oxidationsbeständighet genom bildandet av ett skyddande aluminiumoxidskikt vid höga temperaturer. Yttrium förfinar kornstorleken för ytterligare styrka.

Egenskaper för OP431-pulver

Viktiga egenskaper hos OP431-pulver är bl.a:

| Fastighet | Värde |

|---|---|

| Täthet | 7,3 g/cm3 |

| Smältpunkt | 1400-1450°C |

| Termisk konduktivitet | 29 W/mK |

| Elektrisk resistivitet | 0,6 μΩ.cm |

| Young's modul | 200 GPa |

| Poissonförhållande | 0.27-0.30 |

| Draghållfasthet | 450-650 MPa |

| Utbyteshållfasthet | 280-480 MPa |

| Töjning | 15-20% |

| Oxideringsbeständighet | Utmärkt upp till 1150°C |

Egenskaper som hållfasthet vid höga temperaturer, oxidationsbeständighet och termisk stabilitet gör OP431 lämplig för krävande applikationer.

Produktionsmetod för OP431-pulver

OP431-pulver kan produceras via:

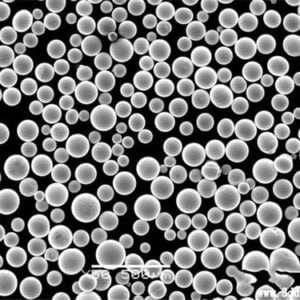

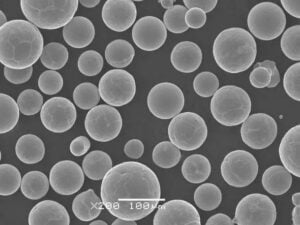

- Atomisering av gas - Inert gas under högt tryck används för att atomisera den smälta legeringen, vilket resulterar i ett fint sfäriskt pulver som är idealiskt för AM.

- Atomisering av vatten - Vattenstråle med hög hastighet bryter upp den smälta strömmen och producerar oregelbundna pulverpartiklar. Lägre kostnad men högre syreupptagningsförmåga.

- Mekanisk legering - Kulfräsning av blandade elementpulver följt av sintring och sekundär atomisering.

Gasatomisering ger utmärkt kontroll över partikelstorleksfördelning, morfologi, syreupptagningsförmåga och mikrostruktur.

Användningsområden för OP431-pulver

Typiska användningsområden för OP431-pulver är

- Additiv tillverkning - Selektiv lasersmältning för tillverkning av komplexa delar som kräver oxidationsbeständighet vid höga temperaturer.

- Beläggningar för termisk sprutning - Appliceras via bågsprutning för att ge skyddande beläggningar på komponenter som arbetar i över 1000°C.

- Fyllmedel för lödning - För sammanfogning av delar av ferritiskt rostfritt stål i högtemperaturtillämpningar.

- Tändare för fast bränsle - Tändstift av pulvermetallurgi som används i industriugnar och turbiner.

- Bearbetning av smält metall - Transportrullar för pulvermetallurgi, tundrar och skänkar som används vid hantering av smält metall.

Specifikationer för OP431 Pulver

OP431-pulver finns i olika storleksintervall, former och kvaliteter:

- Partikelstorlek: Från 15-45 μm för AM-metoder, upp till 150 μm för termiska sprutprocesser.

- Morfologi: Sfäriska, oregelbundna och blandade former. Sfäriskt pulver har utmärkt flytbarhet.

- Renhet: Från kommersiella till högrena kvaliteter baserat på applikationskrav.

- Syrehalt: Nivåerna hålls under 2000 ppm för de flesta tillämpningar.

- Flödeshastighet: Pulver kan anpassas för flödeshastigheter över 25 s/50 g.

Globala leverantörer av OP431-pulver

Några av de största globala leverantörerna av OP431-pulver är

- Sandvik Osprey (Storbritannien)

- Hoganas (Sverige)

- Carpenter Powder Products (USA)

- Praxair Surface Technologies (USA)

- CNPC Powder Group (Kina)

Dessa företag tillverkar olika typer av OP431-pulver som är skräddarsydda för additiv tillverkning, termisk sprayning, pulvermetallurgi och andra högtemperaturtillämpningar.

Prissättning av OP431-pulver

Priset för OP431-pulver är högre än för austenitiska kvaliteter men lägre än för exotiska legeringar:

- Kvantitet - $50-100 per kg för bulkbeställningar över 500 kg. Mindre kvantiteter prissätts betydligt högre.

- Kvalitet - Sfäriskt pulver med hög renhet och kontrollerade egenskaper kräver premiumpriser.

- Leverantör - Stora globala leverantörer erbjuder konkurrenskraftiga priser på grund av högre volymer.

- Geografi - Priserna varierar mellan olika regioner, där Europa och Nordamerika är marknader med högre priser.

För kritiska applikationer bör köpare fokusera på kvalitet snarare än lägsta kostnad när de köper OP431-pulver.

Förvaring och hantering av OP431-pulver

OP431-pulver kräver följande förvaring och hantering:

- Bör förvaras i slutna behållare under inert gas för att förhindra oxidation

- Undvik ansamling av fint pulver för att minimera risken för dammexplosion

- Använd korrekt personlig skyddsutrustning, ventilation, jordning och säkerhetsrutiner under hanteringen

- Förhindra kontakt mellan pulver och oförenliga material

- Följ säkerhetsanvisningarna i leverantörens säkerhetsdatablad

Vid hantering av detta reaktiva legeringspulver måste lämpliga skyddsåtgärder vidtas.

Inspektion och testning av OP431-pulver

Viktiga kvalitetskontrolltester som utförts på OP431-pulver inkluderar

- Kemisk analys med hjälp av OES eller XRF för att säkerställa att sammansättningen ligger inom angivna gränser

- Partikelstorleksfördelning enligt ASTM B822-standarden

- Morfologisk analys genom SEM

- Pulverflödeshastighet mätt enligt ASTM B213-standarden

- Test av syre- och kväveinnehåll genom fusion med inert gas

- Densitet bestämd med heliumpyknometri

- Karaktärisering av mikrostrukturen med XRD

Grundliga tester säkerställer att pulvret uppfyller de kemiska, fysiska och mikrostrukturella egenskaper som krävs för den avsedda applikationen.

Jämförelse mellan OP431 och 316L rostfritt stålpulver

Pulver av OP431 och 316L rostfritt stål jämförs:

| Parameter | OP431 | 316L |

|---|---|---|

| Typ | Ferritisk | Austenitisk |

| Cr-innehåll | 16-18% | 16-18% |

| Ni-halt | – | 10-14% |

| Hållfasthet vid höga temperaturer | Högre | Lägre |

| Korrosionsbeständighet | Måttlig | Utmärkt |

| Kostnad | Lägre | Högre |

| Tillämpningar | Termisk spray, tändare | Fordon, bygg- och anläggning |

| Svetsbarhet | Dålig | Utmärkt |

OP431 ger mycket bättre hållfasthet vid höga temperaturer medan 316L ger utmärkta tillverkningsegenskaper och korrosionsbeständighet.

Vanliga frågor om OP431-pulver

F: Hur produceras OP431-pulver?

S: OP431-pulver tillverkas kommersiellt med hjälp av gasatomisering, vattenatomisering och mekanisk legering följt av sintring. Gasatomisering ger den bästa kontrollen över pulvrets egenskaper.

F: Vilka är de viktigaste användningsområdena för OP431-pulver?

A: Viktiga användningsområden är beläggningar för termisk sprutning, additiv tillverkning, lödfyllnadsmaterial, tändstift för pulvermetallurgi och komponenter för hantering av smält metall vid höga temperaturer där oxidationsbeständighet krävs.

F: Vad är det typiska OP431-pulverstorleksintervallet som används i metall AM?

S: För de flesta AM-processer för metall är det idealiska pulverstorleksintervallet för OP431 15-45 mikron med sfärisk morfologi och goda pulverflödesegenskaper.

F: Kräver OP431-pulver några särskilda försiktighetsåtgärder vid hantering?

S: Ja, det rekommenderas att hantera detta reaktiva pulver försiktigt under inert atmosfär med korrekt ventilation, jordning och personlig skyddsutrustning.

F: Var kan jag köpa OP431-pulver som är lämpligt för beläggningar med termisk sprutning?

S: För applikationer med termisk sprutning som kräver oxidationsbeständighet vid höga temperaturer kan OP431-pulver köpas från ledande tillverkare, inklusive Sandvik Osprey, Hoganas, Praxair Surface Technologies och CNPC Powder Group.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731