Ti6Al4V Pulver Titanbaserat metallpulver för additiv tillverkning

Ti6Al4V pulver för 3D-utskrift prislista :

| Metallpulver | Storlek | Kvantitet | Pris/kg | Storlek | Kvantitet | Pris/kg |

| TiAl6V4 gr.23 | 20-63 μm | 1KG | 138 | 0-45 μm | 1KG | 144 |

| 10KG | 109 | 10KG | 124 | |||

| 100KG | 105 | 100KG | 117 |

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt över Ti6Al4V-pulver

Ti6Al4V-pulver, även kallat Grade 5 titanlegering, är ett av de mest populära titanlegeringspulver. Den innehåller 6% aluminium och 4% vanadin som de viktigaste legeringselementen tillsammans med återstoden titan.

Sfäriskt pulver ti6al4v erbjuder en exceptionell kombination av hög hållfasthet, låg vikt och korrosionsbeständighet, Biokompatibilitetoch bearbetbarhet.

Viktiga egenskaper och fördelar med Ti6Al4V-pulver:

Egenskaper och kännetecken för Ti6Al4V-pulver

| Fastigheter | Detaljer |

|---|---|

| Sammansättning | Ti-6Al-4V-legering |

| Täthet | 4,43 g/cc |

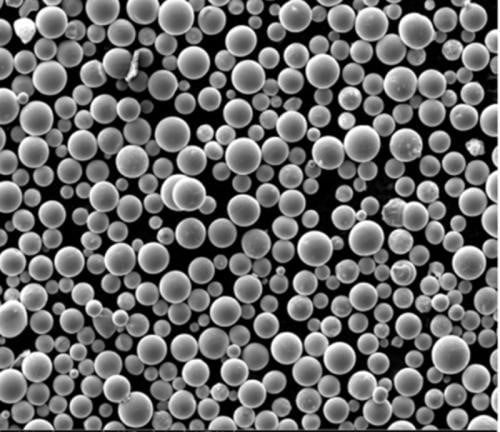

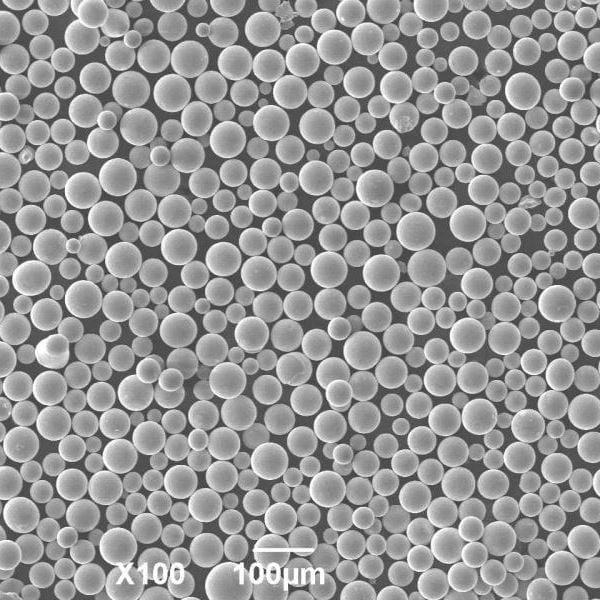

| Partikelns form | Övervägande sfärisk |

| Storleksintervall | 15-45 mikrometer |

| Skenbar densitet | Upp till 60% av verklig densitet |

| Flytbarhet | Bra |

| Styrka | Hög för en titanlegering |

| Korrosionsbeständighet | Utmärkt |

Ti6Al4V används ofta inom flyg-, medicin-, fordons-, kemi- och konsumentindustrin på grund av sin välbalanserade egenskapsprofil.

Ti6Al4V pulver sammansättning

Typisk sammansättning av Ti6Al4V-pulver:

Ti6Al4V pulver sammansättning

| Element | Vikt % |

|---|---|

| Titan | Balans |

| Aluminium | 5.5-6.75% |

| Vanadin | 3.5-4.5% |

| Syre | <0,2% |

| Kol | <0,1% |

| Kväve | <0,05% |

| Väte | <0,015% |

| Järn | <0,3% |

- Titan bildar matrisen som ger styrka och korrosionsbeständighet

- Aluminium stabiliserar alfafasen och ökar styrkan

- Vanadin stabiliserar betafasen och förbättrar bearbetbarheten

- Andra element begränsade som orenheter

De optimerade Ti-Al-V-kvoterna ger en exceptionell kombination av styrka, duktilitet, brottseghet och utmattningshållfasthet.

Ti6Al4V Pulver Fysikaliska egenskaper

Ti6Al4V Pulver Fysikaliska egenskaper

| Fastighet | Värden |

|---|---|

| Täthet | 4,43 g/cc |

| Smältpunkt | 1604-1660°C |

| Termisk ledningsförmåga | 6,7 W/mK |

| Elektrisk resistivitet | 170 μΩ-cm |

| Koefficient för termisk expansion | 8,4 x 10^-6 /K |

| Maximal driftstemperatur | 400°C |

- Låg densitet jämfört med stål

- Hög smältpunkt möjliggör användning vid måttligt förhöjda temperaturer

- Låg värmeledningsförmåga kräver designöverväganden

- Hög elektrisk resistivitet lämplig för korrosionsbeständiga fästelement

- CTE lägre än stål och nickellegeringar

Dessa egenskaper gör Ti6Al4V väl lämpad för många lättviktsapplikationer inom olika branscher.

Ti6Al4V pulver Mekaniska egenskaper

Ti6Al4V pulver Mekaniska egenskaper

| Fastighet | Värden |

|---|---|

| Draghållfasthet | 950 - 1050 MPa |

| Sträckgräns | 860 - 950 MPa |

| Töjning | 10 – 18% |

| Hårdhet | 330 - 380 HB |

| Elasticitetsmodul | 110 - 120 GPa |

| Utmattningshållfasthet | 400 - 500 MPa |

- Utmärkt kombination av hög hållfasthet och rimlig duktilitet

- Hållfastheten överstiger andra titankvaliteter som kommersiellt ren titan

- Hårdhet högre än olegerad titan

- Enastående utmattningslivslängd gör den lämplig för cyklisk belastning

Dessa egenskaper gör Ti6Al4V lämplig för krävande applikationer som kräver hög specifik hållfasthet och utmattningshållfasthet.

Ti6Al4V Pulver Tillämpningar

Ti6Al4V-pulver används i stor utsträckning inom olika branscher:

Ti6Al4V Pulver Tillämpningar

| Industri | Användningsområden |

|---|---|

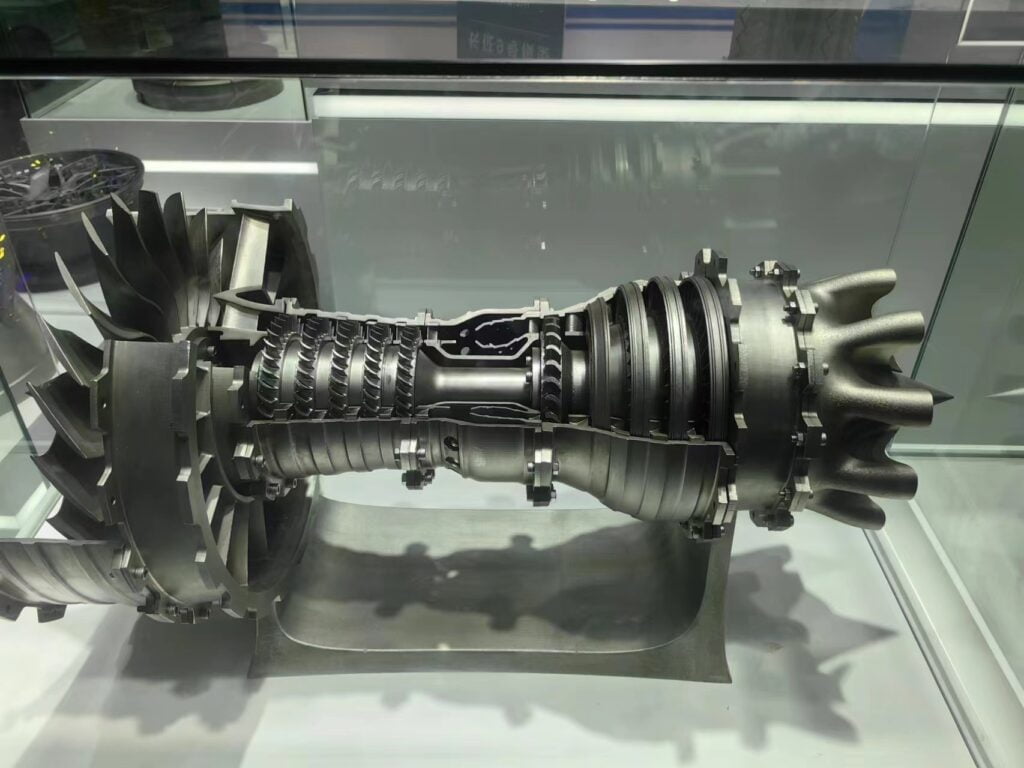

| Flyg- och rymdindustrin | Strukturella flygplansdelar, motorkomponenter |

| Biomedicinsk | Ortopediska och dentala implantat |

| Fordon | Kopplingsstavar, ventiler, fjädrar |

| Kemisk | Tankar, kärl, värmeväxlare |

| Konsument | Sportartiklar, klockfodral, mobilskal |

| 3D-utskrift | Komponenter för flyg- och medicinteknik |

Några specifika produktapplikationer inkluderar:

- Benplattor, implantat för ledproteser

- Strukturella komponenter för flygplan och helikoptrar

- Ventiler och vevstakar till bilmotorer

- Kemisk utrustning som rör, pumpar, ventiler

- Sportartiklar inklusive golfklubbor och cykelramar

- Additiv tillverkning av lättviktsstrukturer

Ti6Al4V ger det bästa förhållandet mellan styrka och vikt och är biokompatibelt för kritiska konstruktionsdelar inom dessa krävande sektorer.

Tillämpningar av Ti6Al4V-pulver vid 3D-utskrift av metall

Ti6Al4V-pulver är ett mycket använt material för 3D-utskrift av metall tack vare dess exceptionella mekaniska egenskaper, biokompatibilitet och korrosionsbeständighet. Det är särskilt väl lämpat för applikationer inom flyg-, medicin- och fordonsindustrin. Här är några av de 3D-utskriftsmetoder för metall som kan använda Ti6Al4V-pulver:

1. Selektiv lasersmältning (SLM): SLM är en PBF-teknik (Powder Bed Fusion) som använder en högeffektslaser för att selektivt smälta och smälta samman fina lager av Ti6Al4V-pulver. Denna metod ger högdensitetsdelar med hög hållfasthet och komplexa geometrier.

2. Smältning med elektronstråle (EBM): EBM är en annan PBF-teknik som använder en fokuserad elektronstråle för att smälta Ti6Al4V-pulver. Tekniken är känd för sin förmåga att tillverka detaljer med utmärkt ytkvalitet och fina detaljer.

3. Deposition med riktad energi (DED): DED är en additiv tillverkningsprocess där material deponeras genom ett munstycke samtidigt som det smälts med en laser- eller elektronstråle. Ti6Al4V-pulver kan användas i DED för att skapa storskaliga, nästan nätformade komponenter.

4. Binder Jetting (BJ): BJ är en PBF-teknik som använder ett flytande bindemedel för att selektivt fästa Ti6Al4V-pulverpartiklar vid varandra. Det obundna pulvret avlägsnas sedan och kvar blir en förformad del som sintras för att uppnå full densitet.

Ytterligare överväganden:

-

Valet av 3D-utskriftsmetod för Ti6Al4V-pulver beror på de specifika applikationskraven, t.ex. detaljgeometri, mekaniska egenskaper och ytfinish.

-

Varje 3D-utskriftsmetod har sina egna fördelar och begränsningar, och det är viktigt att noggrant utvärdera dessa faktorer innan man väljer den mest lämpliga tekniken.

-

Korrekt hantering och förvaring av Ti6Al4V-pulver är avgörande för att säkerställa kvaliteten på 3D-utskrivna delar och för att minimera säkerhetsriskerna.

Ti6Al4V-pulver fortsätter att vara ett värdefullt material för 3D-printing av metall, vilket möjliggör tillverkning av högpresterande komponenter för olika branscher. I takt med att 3D-utskriftstekniken utvecklas förväntas användningsområdena för Ti6Al4V-pulver bli ännu fler.

Specifikationer för Ti6Al4V-pulver

Viktiga specifikationer och standarder för Ti6Al4V-pulver:

Ti6Al4V pulver standarder

| Standard | Beskrivning |

|---|---|

| ASTM F2924 | Additiv tillverkning Ti6Al4V-legering |

| ASTM F3001 | Specifikationer för gasatomiserat Ti-legeringspulver för AM |

| AMS 4954 | Gränsvärden för sammansättningen av Ti-6Al-4V-pulver för additiv tillverkning |

| ASTM B348 | Specifikationer för pulver av Ti och Ti-legeringar |

| ASTM F1472 | Smidd Ti6Al4V-legering för kirurgiska implantat |

Dessa definierar:

- Intervall för kemisk sammansättning

- Nödvändiga mekaniska egenskaper

- Pulverproduktionsmetod - atomisering med inert gas

- Föroreningsgränser som O, N, C, Fe

- Partikelstorleksfördelning och morfologi

- Testmetoder för att verifiera pulverkvalitet

Certifierat Ti6Al4V-pulver som uppfyller dessa specifikationer säkerställer optimala egenskaper och prestanda för olika applikationer i olika branscher.

Ti6Al4V pulver Partikelstorlekar

Partikelstorleksfördelning för Ti6Al4V-pulver

| Partikelstorlek | Egenskaper |

|---|---|

| 15-45 mikrometer | Storleksintervall för allmänna ändamål |

| 45-100 mikrometer | Optimerad för kallsprutning |

| 5-25 mikrometer | Finare storlekar används i laser AM-processer |

- Finare pulver ger högre upplösning och ytfinish

- Grovare pulver lämpar sig för metoder med hög deponeringshastighet, t.ex. kallsprutning

- Storleksintervallet anpassas utifrån den produktionsmetod som används

- Sfärisk morfologi bibehålls i alla storleksintervall

Kontroll av partikelstorleksfördelning och morfologi är avgörande för hög pulverpackningsdensitet, flytbarhet och slutliga detaljegenskaper.

Ti6Al4V pulver skenbar densitet

Ti6Al4V pulver skenbar densitet

| Skenbar densitet | Detaljer |

|---|---|

| Upp till 60% av verklig densitet | För sfärisk pulvermorfologi |

| 2,6 - 3,0 g/cc | Förbättras med högre packningstäthet |

- Högre skenbar densitet förbättrar pulverflödesförmågan och effektiviteten vid formfyllning

- Värden upp till 65% är möjliga med optimerat sfäriskt pulver

- Hög skenbar densitet minimerar presscykeltiden

Maximering av den skenbara densiteten möjliggör effektiv automatiserad pulverpressning och sintring till full densitet.

Produktionsmetod för Ti6Al4V-pulver

Produktion av Ti6Al4V-pulver

VIGA-utrustning har ett brett utbud av applikationer, främst för produktion av högpresterande järnbaserade, nickelbaserade, koboltbaserade, aluminiumbaserade, kopparbaserade och andra avancerade legeringspulvermaterial. Den används ofta inom flyg, hälsa, verktyg, bil, maskiner, elektronik, ny energi och andra områden och är också lämplig för additiv tillverkning (3D-utskrift), smältdeponering, laserplätering, termisk sprutning, pulvermetallurgi, varm isostatisk pressning och andra avancerade tillverkningsprocesser.

| Metod | Detaljer |

|---|---|

| Atomisering av gas | Inert gas under högt tryck bryter upp smält legeringsström till fina droppar |

| Smältning med vakuumbåge | Insatsmaterial med hög renhet som raffineras och smälts i vakuum |

| Flera omsmältningar | Förbättrar den kemiska homogeniteten |

| Siktning | Klassificerar pulver i olika fraktioner av partikelstorlek |

- Gasatomisering med inert gas ger rent, sfäriskt pulver

- Vakuumbearbetning minimerar gasformiga föroreningar

- Flera omsmältningar ger jämnare sammansättning

- Efterbearbetning möjliggör kontroll av partikelstorleksfördelningen

Automatiserade metoder i kombination med sträng kvalitetskontroll resulterar i tillförlitligt och konsekvent Ti6Al4V-pulver som lämpar sig för kritiska applikationer.

Priser för Ti6Al4V-pulver

Priser för Ti6Al4V-pulver

| Faktor | Påverkan på priset |

|---|---|

| Renhetsgrad | Prisökningar för högre renhetsgrad |

| Partikelstorlek | Ultrafint pulver dyrare |

| Orderkvantitet | Prisreduktion för bulkbeställningar |

| Produktionsmetod | Användning av flera omsmältningsmedel ökar kostnaderna |

| Förpackning | Argonfyllda flaskor kostar mer |

| Ledtid | Snabbare leveranstider ökar priset |

Indikativ prissättning

- Ti6Al4V för medicinska tillämpningar: $150-250 per kg

- Ti6Al4V för industriella tillämpningar: $100-150 per kg

Betydligt lägre priser gäller för bulkbeställningar i tonstorlek.

Met3DP Ti6Al4V pulver Pris:

| Metallpulver | Storlek | Kvantitet | Pris/kg | Storlek | Kvantitet | Pris/kg |

| TiAl6V4 gr.23 | 20-63 μm | 1KG | 138 | 0-45 μm | 1KG | 144 |

| 10KG | 109 | 10KG | 124 | |||

| 100KG | 105 | 100KG | 117 |

Ti6Al4V pulver leverantörer

Ti6Al4V pulver leverantörer

| Företag | Plats |

|---|---|

| AP&C | USA, Kanada |

| Snickare Tillsats | USA |

| Met3DP | Kina |

| TLS Teknik | Tyskland |

| Sandvik Osprey | STORBRITANNIEN |

| Tekna | Kanada |

Viktiga urvalsfaktorer:

- Utbud av olika renhetsgrader och partikelstorlekar

- Pulverkvalitet och jämnhet från batch till batch

- Produktionskapacitet och ledtider

- Överensstämmelse med medicinska standarder och standarder för flyg- och rymdindustrin

- Prisnivåer baserade på ordervolym

- Teknisk expertis och kundsupport

Hantering och förvaring av Ti6Al4V-pulver

Ti6Al4V Pulverhantering

| Rekommendation | Anledning |

|---|---|

| Undvik inandning | På grund av risk för skador på lungvävnaden från fina partiklar |

| Använd skyddsmask | Förhindra oavsiktligt intag |

| Hantera i ventilerade utrymmen | Minska suspensionen av luftburna partiklar |

| Säkerställ att inga antändningskällor finns | Pulver kan antändas i syrehaltig atmosfär |

| Följ antistatiska protokoll | Förhindra brand från statisk urladdning vid hantering |

| Förvara förseglade behållare i svalt, torrt utrymme | Förhindrar fuktupptagning och reaktivitet |

Även om Ti6Al4V-pulver är relativt inert, bör rekommenderade försiktighetsåtgärder vidtas under hantering och lagring för att bevara renheten.

Inspektion och provning av Ti6Al4V-pulver

Testning av Ti6Al4V-pulver

| Test | Detaljer |

|---|---|

| Kemisk analys | ICP-spektroskopi används för att verifiera sammansättningen |

| Fördelning av partikelstorlek | Laserdiffraktion används för att bestämma storleksfördelningen |

| Skenbar densitet | Mätt med Hall-flödesmätare enligt ASTM B212 |

| Morfologi för pulver | SEM-bildtagning för att kontrollera partikelns sfäriskhet |

| Analys av flödeshastighet | Använda Hall flödesmätare tratt |

| Tappdensitetstest | Densitet uppmätt efter mekanisk knackning av pulverprov |

Testningen säkerställer att pulvret uppfyller kraven på kemisk sammansättning, fysiska egenskaper, morfologi, densitet och flödesspecifikationer enligt gällande standarder.

Fördelar och nackdelar med Ti6Al4V-pulver

Fördelar med Ti6Al4V-pulver

- Utmärkt förhållande mellan styrka och vikt

- Hög utmattningshållfasthet och brottseghet

- Enastående korrosionsbeständighet

- God duktilitet och formbarhet

- Hög biokompatibilitet för medicinsk användning

- Kostnadseffektiv jämfört med andra titanlegeringar

Begränsningar för Ti6Al4V-pulver

- Måttlig oxidationsbeständighet vid höga temperaturer

- Lägre hållfasthet än vissa titanlegeringar

- Hög reaktivitet kräver inert processatmosfär

- Svårt att bearbeta i helt sintrat tillstånd

- Begränsningar vid svetsning av legeringen

- Toxicitetsproblem med vanadiumelement

Jämförelse med Ti64- och Ti Grade 2-pulver

Ti6Al4V vs. Ti64 och pulver av klass 2

| Parameter | Ti6Al4V | Ti64 | Ti klass 2 |

|---|---|---|---|

| Aluminium | 6% | 6% | – |

| Vanadin | 4% | 4% | – |

| Styrka | 950-1050 MPa | 950-1050 MPa | 420-550 MPa |

| Duktilitet | 10-18% | 10-18% | 15-30% |

| Kostnad | Måttlig | Måttlig | Låg |

| Användningsområden | Flyg- och rymdindustrin, medicinteknik | Flyg- och rymdindustrin, fordonsindustrin | Industri, konsument |

- Ti6Al4V och Ti64 har i stort sett identiska egenskaper

- Ti klass 2 ger bättre duktilitet men lägre hållfasthet

- Ti6Al4V föredras för kritiska konstruktionsdelar som kräver hög hållfasthet

Vanliga frågor om Ti6Al4V-pulver

F: Vilka är de viktigaste tillämpningarna av Ti6Al4V-pulver?

A: De viktigaste användningsområdena är strukturella komponenter inom flyg- och rymdindustrin, biomedicinska implantat som höft- och knäleder, bildelar som ventiler och vevstakar, kemisk processutrustning och konsumentprodukter som sportutrustning och klockfodral.

F: Varför är Ti6Al4V den mest populära titanlegeringen?

A: Ti6Al4V ger den bästa allroundkombinationen av hög hållfasthet, låg densitet, brottseghet, korrosionsbeständighet, biokompatibilitet, svetsbarhet och måttlig kostnad.

F: Vilka försiktighetsåtgärder bör vidtas när man arbetar med Ti6Al4V-pulver?

A: Rekommenderade försiktighetsåtgärder inkluderar användning av skyddsutrustning, hantering i inert atmosfär, undvikande av antändningskällor, kontroll av statiska laddningar, användning av gnistfria verktyg och förvaring av förseglade behållare på en sval och torr plats.

F: Hur påverkar vanadin egenskaperna hos legeringen Ti6Al4V?

A: Vanadin fungerar som en betastabilisator som förbättrar bearbetbarheten. Det bidrar också till utskiljningshärdning som ger legeringen styrka och krypbeständighet vid höga temperaturer.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731