Refrakter Toz Malzemeler

İçindekiler

Refrakter Toz Malzemeler, zorlu endüstrilerde kullanılan son derece yüksek ısı direnci sergileyen özel bir inorganik metalik olmayan malzeme sınıfını temsil eder. Bu kapsamlı kılavuz, tipik bileşimi, kritik özellik verilerini, üretim süreçlerini, uygulamaları, spesifikasyonları ve tedarikçileri kapsayan refrakter tozların tüm temel özelliklerini anlayan teknik profesyonellere ve alıcılara hizmet eder.

Refrakter Toz Malzemelere Genel Bakış

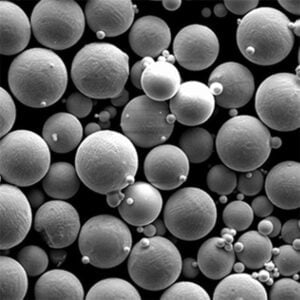

Refrakter tozlar, 1000°C'yi aşan yüksek sıcaklıklarda mukavemet ve formunu koruyarak olağanüstü termal stabilite gösteren ince bölünmüş inert metalik olmayan malzemelerden oluşur. Temel alt sınıflar arasında oksitler, karbürler, nitrürler ve seramikler bulunur.

Kritik Özellikler:

- 1000°C'nin üzerinde ısı direnci

- Termal şoka dayanıklı

- Korozyona karşı dayanıklı

- Yüksek erime noktası

- Yapısal bütünlüğü koruyun

Olağanüstü yetenekleri, geleneksel malzemelerin hızla bozulduğu fırınlar, kazanlar, fırınlar, reaktörler ve diğer aşırı termal ortamlarda performansı güçlendirir.

Tipik Kompozisyon

| Malzeme | Rol | Wt% Aralığı |

|---|---|---|

| Alümina | Termal özellikler | 40-100% |

| Silika | Matrisi bağlayın | 0-60% |

| Magnezya | Bozulmaya karşı dirençli | 0-20% |

| Grafit | Termal şok direncini artırın | 0-15% |

Temel bileşenlerin dengelenmesi ısı kapasitesi, yalıtım, erozyon direnci, erime noktası ve maliyet gibi özelliklerin optimize edilmesini sağlar.

Başlıca Refrakter Toz Türleri

| Tip | Açıklama |

|---|---|

| Kaynaşmış | Aşırı saflık, 1800°C'nin üzerinde dayanım |

| Sinterlenmiş | Toz presleme/ateşleme, daha düşük maliyet |

| Silisyum karbür | Yüksek ısı iletkenliğine sahip seramik |

| Kromit | Cüruf ve metal penetrasyonuna karşı dirençli |

| Zirkonya | Termal şok direnci |

Refrakter Toz Malzeme Üretim Süreçleri

| Fayda | Açıklama | Etki |

|---|---|---|

| Yüksek Yoğunluklu, Ağ Şekline Yakın Parçalar | EBM, kullanılan metal tozunun teorik yoğunluğunun 99,5%'sini aşan bir yoğunluğa sahip parçalar oluşturur. Bu, diğer eklemeli üretim yöntemlerinde yaygın olan gözenekliliği (küçük hava cepleri) ortadan kaldırarak olağanüstü mukavemet, yorulma direnci ve boyutsal doğruluğa sahip parçalar elde edilmesini sağlar. | Bu, havacılık (türbin kanatları, motor gövdeleri), tıp (diş implantları, protezler) ve otomotiv (hafif, yüksek performanslı parçalar) endüstrilerindeki zorlu uygulamalar için işlevsel metal bileşenlerin oluşturulmasını sağlar. |

| Üstün Mekanik Özellikler | EBM'deki yüksek vakumlu ortam ve hassas eritme işlemi oksidasyonu ve kontaminasyonu en aza indirerek metal tozunun doğal özelliklerini korur. Bu da mükemmel gerilme mukavemeti, sürünme direnci (yüksek sıcaklıklarda stres altında deformasyona dayanma yeteneği) ve kırılma tokluğuna sahip parçalar anlamına gelir. | EBM ile üretilen parçalar önemli yükleri kaldırabilir, yüksek sıcaklıklarda etkili bir şekilde çalışabilir ve çatlak yayılmasına karşı koyabilir, bu da onları zorlu ortamlarda dayanıklılık ve yapısal bütünlük gerektiren uygulamalar için ideal hale getirir. |

| Refrakter ve Reaktif Metallerin İşlenmesi | Yüksek erime noktaları ve reaktivite ile sınırlı geleneksel üretim yöntemlerinin aksine, EBM titanyum alaşımları, tantal ve Inconel gibi zorlu malzemeleri işlemede mükemmeldir. Vakum ortamı oksidasyonu önler ve eritme işleminin hassas bir şekilde kontrol edilmesini sağlayarak başarılı bir üretim sağlar. | Bu, bileşenlerin olağanüstü güç-ağırlık oranları, biyouyumluluk (canlı doku ile uyumluluk) ve yüksek sıcaklık performansı gerektirdiği havacılık ve biyomedikal gibi endüstriler için tasarım olanaklarını genişletir. |

| Karmaşık Geometriler için Tasarım Özgürlüğü | EBM'nin katman katman yaklaşımı, geleneksel tekniklerle mümkün olmayan karmaşık iç özelliklerin, kanalların ve kafes yapıların oluşturulmasına olanak tanır. Bu tasarım esnekliği ağırlık dağılımını optimize eder, ısı transferini iyileştirir ve üstün işlevselliğe sahip bileşenlerin oluşturulmasını sağlar. | Bu avantaj, karmaşık soğutma kanallarına sahip hafif, yüksek mukavemetli bileşenlerin motor verimliliği için çok önemli olduğu havacılık ve uzay gibi sektörlerde ürün tasarımında devrim yaratıyor. Ayrıca, hastanın anatomisine mükemmel şekilde uyan özelleştirilmiş tıbbi implantların oluşturulmasına da olanak tanır. |

| Minimal Destek Yapıları | EBM ile üretilen parçaların yüksek doğal mukavemeti nedeniyle, yapım süreci sırasında minimum destek yapılarına ihtiyaç duyulur. Bu, işlem sonrası süreyi ve malzeme israfını azaltmanın yanı sıra destek yapısının nihai bileşene zarar verme riskini de azaltır. | Bu, daha hızlı üretim süreleri, daha düşük toplam maliyetler ve geleneksel yöntemlerle desteklenmesi zor veya imkansız olan karmaşık geometriler oluşturma yeteneği anlamına gelir. |

| Azaltılmış Malzeme Atığı | EBM eklemeli bir üretim sürecidir, yani istenen şekli oluşturmak için malzeme katman katman eklenir. Bu, nihai formu elde etmek için hammaddenin önemli bir kısmının çıkarıldığı talaşlı imalat gibi eksiltici tekniklere kıyasla malzeme israfını en aza indirir. | Bu avantaj, sürdürülebilirliği teşvik eder ve malzeme kullanımını en üst düzeye çıkararak üretim maliyetlerini azaltır. Ayrıca, yapı haznesindeki kullanılmayan toz genellikle sonraki yapılar için yeniden kullanılabilir ve atıkları daha da en aza indirir. |

Refrakter Toz Malzemelerin Özellikleri

| Mülkiyet | Tipik Değer |

|---|---|

| Erime Noktası | 1600°C'nin üzerinde |

| Yoğunluk | 2 - 6 g/cm3 |

| Basınç Dayanımı | 20 - 100 MPa |

| Eğilme Dayanımı | 10 - 60 MPa |

| Kırılma Tokluğu | 2 - 10 MPa-m^1/2 |

| Termal İletkenlik | 20 - 100 W/m-K |

| Elektriksel Dirençlilik | 10^8 - 10^13 Ohm-cm |

| Maksimum Servis Sıcaklığı | 1200°C - 2000°C |

Erime noktası, ısı kapasitesi, termal şok direnci, yalıtım değeri, kimyasal atalet ve maliyet gibi gereksinimlerin dengelenmesi seçimi belirler.

Refrakter Toz Malzemelerin Uygulamaları

| Endüstri | Uygulama | Malzeme | Kullanılan Özellikler |

|---|---|---|---|

| Havacılık ve Uzay | * Türbin Kanatları * Roket Nozulları * Isı Kalkanları | * Tungsten * Tantal * Renyum | * Yüksek Erime Noktaları (>3000°C) * Yüksek Sıcaklıklarda Mükemmel Mekanik Dayanım * Üstün Oksidasyon Direnci |

| Otomotiv | * Buji Elektrotları * Egzoz Valfleri * Turboşarj Bileşenleri | * Tungsten * Molibden * Nikel Alaşımları | * Yüksek Elektriksel İletkenlik * Aşınma Direnci * Termal Şok Direnci |

| Elektronik | * Yüksek Sıcaklık Dirençleri * Kondansatörler * Elektrik Kontakları | * Tungsten * Molibden * Gümüş | * Yüksek Erime Noktaları * Düşük Dirençlilik * Ark Erozyon Direnci |

| Enerji | * Enerji Santrallerindeki Fırınlar için Astarlar * Erimiş Tuz Reaktörleri | * Silisyum Karbür * Alümina * Zirkonya | * Mükemmel Termal İletkenlik * Yüksek Kimyasal Kararlılık * Erimiş Tuzlara Karşı Direnç |

| Tıbbi | * Kalça ve Diz Protezleri * Diş İmplantları * Radyasyon Kalkanı | * Titanyum Alaşımları * Tantal * Tungsten | * Biyouyumluluk * Yüksek Mukavemet-Ağırlık Oranı * X-Işını Opaklığı |

| Kimyasal İşleme | * Zorlu Kimyasal Ortamlar için Reaktörler * Yüksek Sıcaklık Boru Tesisatı * Isı Eşanjörleri | * Tantal * Zirkonyum * Nikel Alaşımları | * Korozyon Direnci * Yüksek Sıcaklıklarda Yüksek Mukavemet * Mükemmel Şekillendirilebilirlik |

| Aletler | * Yüksek Mukavemetli Malzemeler için Kesici Takımlar * Metal Şekillendirme Kalıpları * Cam ve Seramik için Kalıplar | * Tungsten Karbür * Bor Nitrür * Elmas Tozları | * Olağanüstü Sertlik * Yüksek Aşınma Direnci * Düşük Termal Genleşme |

| Katmanlı Üretim | * Karmaşık Metal Bileşenlerin 3D Baskısı * Aşınmış veya Hasarlı Parçaların Onarımı | * Inconel Tozları * Kobalt Krom Alaşımları * Titanyum Tozları | * Hassas Baskı için Yüksek Toz Akışkanlığı * Mükemmel Sinterleme Özellikleri * Belirli Uygulamalar için Özel Mikroyapılar |

Özellikler ve Sınıflar

| Mülkiyet | Açıklama | Seçim için Önemli Hususlar |

|---|---|---|

| Kimyasal Bileşim | Tozun birincil yapı taşları, tipik olarak metal oksitler, karbürler, nitrürler veya seramiklerdir. | * Baskın Oksit: Alümina (Al2O3) mükemmel yüksek sıcaklık dayanımı sunar ancak termal şok direnci daha düşüktür. Silika (SiO2) iyi kimyasal direnç sağlar ancak refrakterliği düşüktür. Magnezya (MgO) cüruf saldırısına direnmede üstündür ancak kolayca hidratlaşır. * İkincil Katkı Maddeleri: Kalsiya (CaO) cüruf direncini artırırken, krom (Cr2O3) aşınma direncini artırır. * Saflık: Daha yüksek saflık genellikle daha iyi performans anlamına gelir, ancak maliyet artışına neden olabilir. |

| Parçacık Boyutu Dağılımı | Toz içindeki münferit partikül boyutlarının aralığı ve yayılımı. | * Ortalama Parçacık Boyutu: Daha ince tozlar, yapıştırma için üstün paketleme yoğunluğu ve yüzey alanı sunar, ancak aglomerasyona (topaklanma) daha duyarlı olabilir ve akış özelliklerini engelleyebilir. * Parçacık Boyutu Dağılımı: Dar bir dağılım tutarlı bir paketleme sağlar ve işleme sırasında ayrışmayı en aza indirir. Daha geniş dağılımlar boşlukları doldurmak ve paketleme verimliliğini artırmak için faydalı olabilir. * Özel Uygulamalar: 3D baskı gibi süreçler, optimum akış ve basılabilirlik için genellikle daha sıkı boyut kontrolü gerektirir. |

| Parçacık Morfolojisi | Tek tek parçacıkların şekli ve biçimi. | * Şekil: Küresel partiküller tipik olarak daha verimli bir şekilde paketlenirken, köşeli partiküller daha iyi mukavemet için mekanik bir kenetlenme etkisi yaratabilir. * Yüzey Alanı: Daha yüksek yüzey alanlı tozlar daha iyi bağlanma potansiyeli sunar ancak reaktiviteyi de artırabilir. * Morfoloji Kontrolü: Bazı uygulamalar, gelişmiş termal iletkenlik için trombositler gibi belirli şekillere öncelik verebilir. |

| Görünür Yoğunluk | Gevşek, sıkıştırılmamış haliyle birim hacim başına toz kütlesi. | * Paketleme Verimliliği: Daha yüksek görünür yoğunluk daha iyi paketleme verimliliğini gösterir ve malzeme kullanımını azaltabilir. * Akışkanlık: Düşük görünür yoğunluğa sahip tozlar, daha kolay kullanım ve işleme için tipik olarak daha iyi akış özellikleri sergiler. * Yeşil Güç: Görünür yoğunluk, şekillendirilmiş bileşenlerin yeşil mukavemetini (ön ateşlemeli) etkileyebilir. |

| Yığın Yoğunluğu | Standartlaştırılmış bir kılavuz çekme veya titreşim prosedüründen geçtikten sonra birim hacim başına toz kütlesi. | * Sıkıştırma Verimliliği: Yığın yoğunluğu, tozun ne kadar iyi sıkıştırılabileceğini yansıtır ve nihai ürün yoğunluğunu ve özelliklerini etkiler. * Gözeneklilik: Düşük yığın yoğunluğu, ısı yalıtım özelliklerini etkileyebilen ancak mekanik mukavemeti azaltabilen daha yüksek gözenekliliği gösterir. * Malzeme Taşıma: Yığın yoğunluğu, belirli bir hacimde ne kadar tozun verimli bir şekilde depolanabileceğini veya taşınabileceğini etkiler. |

| Özgül Ağırlık | Bir malzemenin yoğunluğunun suyun yoğunluğuna oranı. | * Refrakter Seçimi: Yüksek özgül ağırlıklı malzemeler genellikle üstün ısı direnci sunar, ancak daha fazla ağırlık dikkate alınabilir. * Maliyet-Etkinlik: Daha düşük özgül ağırlığa sahip daha hafif malzemelerin taşınması ve elleçlenmesi daha uygun maliyetli olabilir. |

| Refrakterlik | Bir malzemenin erimeden veya yapısal bütünlüğünü kaybetmeden dayanabileceği maksimum sıcaklık. | * Başvuru Koşulları: Refrakter tozun nihai uygulamada beklenen çalışma sıcaklığını aşması gerekir. * Kimyasal Ortam: Belirli atmosferler refrakterliği etkileyebilir. Örneğin, indirgeyici ortamlar bazı oksitleri bozabilir. |

| Termal İletkenlik | Malzemenin ısıyı iletme kabiliyeti. | * Isı Transferi Yönetimi: Yüksek ısı iletkenliği, ısı eşanjörleri gibi verimli ısı transferi gerektiren uygulamalar için faydalı olabilir. * Isı Yalıtımı: Düşük ısı iletkenliği, fırın kaplamaları gibi ısıyı tutması gereken uygulamalar için arzu edilir. |

| Termal Genleşme | Bir malzemenin ısındığında genleştiği miktar. | * Termal Şok Direnci: Daha düşük termal genleşmeye sahip malzemeler genellikle hızlı sıcaklık değişimleri nedeniyle çatlama ve dökülmeye karşı daha dayanıklıdır. * Boyutsal Kararlılık: Refrakter tozun termal genleşme katsayısının alt tabaka malzemesiyle eşleştirilmesi, termal döngü sırasında stres gelişimini en aza indirir. |

| Kimyasal Direnç | Malzemenin aşındırıcı kimyasalların ve erimiş metallerin/cürufların saldırısına dayanma kabiliyeti. | * Spesifik Agresif Ajanlar: Seçim, refrakterin uygulamada karşılaşacağı kimyasal türlerini dikkate almalıdır. * Asitlik/Alkali: Asidik veya bazik ortamlar belirli refrakter malzemeleri bozabilir. |

| Diğer Performans Özellikleri | Özel uygulamaya bağlı olarak erozyon direnci, elektrik iletkenliği veya aşınma direnci gibi ek özellikler. | * İhtiyaçlara Odaklanın: Amaçlanan kullanım durumu için kritik performans faktörlerini belirleyin ve bu alanlarda üstün olan bir toz seçin. * Değiş tokuşlar: Genellikle, çeşitli özellikler arasında ödünleşimler olacaktır. En uygun malzemenin seçilmesi, en ilgili özelliklere öncelik verilmesini gerektirir. |

Refrakter Toz Malzeme Tedarikçileri

| Şirket | Konum |

|---|---|

| Saint-Gobain | Küresel |

| RHI Magnesita | Brezilya, Avusturya, Çin |

| Krosaki Harima | Japonya |

| Vezüv | Avrupa, Amerika Birleşik Devletleri |

| Morgan İleri Malzemeler | Birleşik Krallık, Amerika Birleşik Devletleri |

Fiyatlandırma Tahminleri

| Sınıf | Kg başına fiyat |

|---|---|

| Tabular Alümina | $10-30 |

| Silisyum Karbür | $50-150 |

| Zirkonya | $100-500 |

| Diğerleri | $20-100 |

Ölçek ekonomileri maliyetleri etkilemektedir - özelleştirilmiş bileşimler ve katı kalite gereksinimleri primlere hükmetmektedir.

Artıları ve Eksileri

| Artıları | Eksiler |

|---|---|

| Eşsiz Isı Direnci: Refrakter tozlar, erime veya bozulma olmaksızın 1500°C'yi (2732°F) aşan sıcaklıklara dayanabilen olağanüstü termal kararlılığa sahiptir. Bu da onları, geleneksel malzemelerin hızla yenik düşeceği fırınlar, fırınlar, reaktörler ve diğer yüksek ısı uygulamaları için ideal hale getirir. | Kırılganlık ve Dökülme: Sert yapıları nedeniyle refrakter tozlar, özellikle hızlı sıcaklık dalgalanmaları (termal şok) altında çatlamaya ve ufalanmaya karşı hassas olabilir. Bu dökülme, astarın bütünlüğünü tehlikeye atarak onarım veya değiştirme gerektirebilir. |

| Özel Performans: Mühendisler, farklı refrakter toz türlerini (örn. alümina, zirkonya, magnezya) dikkatlice seçip karıştırarak belirli özelliklere sahip özelleştirilmiş malzeme formülasyonları oluşturabilir. Bu, ısı direnci, kimyasal uyumluluk ve aşınma direnci gibi faktörlerin uygulamanın taleplerine tam olarak uyacak şekilde optimize edilmesini sağlar. | Karmaşık Kurulum: Önceden şekillendirilmiş tuğlaların veya şekillerin aksine, refrakter tozlar daha kapsamlı bir kurulum süreci gerektirir. Bu genellikle döküm, tabanca veya vibro-döküm gibi teknikleri içerir ve yoğun, düzgün bir astar elde etmek için özel ekipman ve vasıflı işçilik gerektirir. |

| Biçim ve İşlevde Çok Yönlülük: Refrakter tozlar, önceden imal edilmiş bileşenlere kıyasla üstün tasarım esnekliği sunar. Karmaşık şekillerde kalıplanabilme yetenekleri, karmaşık fırın astarlarının, potaların ve diğer ısmarlama refrakter elemanların oluşturulmasını sağlar. | Maliyet Değerlendirmeleri: Yüksek performanslı refrakter tozların üretiminde kullanılan hammaddeler ve işleme teknikleri, bazı geleneksel refrakter malzemelere kıyasla daha yüksek bir başlangıç maliyeti anlamına gelebilir. |

| Hafiflik Avantajı: Refrakter tozlar, geleneksel tuğla kaplamalara kıyasla ağırlıkta önemli bir azalmaya katkıda bulunur. Bu, özellikle daha hafif ağırlığın gelişmiş enerji verimliliği, azaltılmış yapısal yük ve kurulum sırasında daha kolay kullanım anlamına geldiği uygulamalarda faydalıdır. | Potansiyel Sağlık Riskleri: Bazı refrakter toz bileşimleri, özellikle silika veya kromit içerenler, solunduğunda sağlık riskleri oluşturabilir. Taşıma ve kurulum sırasında uygun güvenlik protokollerinin uygulanması ve uygun kişisel koruyucu ekipmanların (KKE) kullanılması çok önemlidir. |

| Geliştirilmiş Refrakter Özellikler: Refrakter tozlar, özel katkı maddeleri eklenerek veya gelişmiş üretim teknikleri kullanılarak, temel ısı direncinin ötesinde üstün özellikler sergileyecek şekilde tasarlanabilir. Bu, gelişmiş termal şok direncini, erimiş metallere veya cüruflara karşı gelişmiş kimyasal direnci ve hatta daha uzun hizmet ömrü için kendi kendini iyileştirme yeteneklerini içerebilir. | Çevresel Etki: Özel bileşim ve üretim yöntemlerine bağlı olarak, bazı refrakter tozların madenciliği, işlenmesi veya bertarafı ile ilgili çevresel kaygılar olabilir. Çevre dostu hammaddelerin seçilmesi ve sorumlu geri dönüşüm uygulamaları dikkate alınması gereken önemli faktörlerdir. |

SSS

S: Refrakter tozlar ve refrakter tuğlalar arasındaki fark nedir?

C: Tuğlalar önceden şekillendirilmiş konsolide yapılardır, tozlar ise presleme/ateşleme veya gelişmiş katkılı üretim yöntemleri yoluyla özel refrakter bileşenlerin üretilmesini sağlayan hammadde hammaddelerini temsil eder.

S: Tüm refrakter tozlar AM teknolojisi kullanılarak 3D basılabilir mi?

C: Evet - bağlayıcı püskürtme ve yönlendirilmiş enerji biriktirme baskısı, daha önce imkansız olan refrakter geometriler için termal olarak dirençli alümina, zirkonya ve silikon karbür kalitelerinin çoğuyla uyumlu olduğunu kanıtlamaktadır.

S: Hangi refrakter toz en yüksek servis sıcaklığını sunar?

A: Ultra yüksek saflıkta erimiş mullit ve zirkonya kaliteleri, alternatiflerin eridiği veya ayrıştığı en zorlu fırın, havacılık ve nükleer uygulamalar için 2000°C'nin üzerine güvenilir bir şekilde dayanır.

S: Sentetik ve doğal refrakter malzemeler arasındaki fark nedir?

C: Boksit, manyezit ve kil gibi doğal hammaddeler, sentetik mühendislik formülasyonlarıyla mümkün olan gelişmiş homojenliği ve aşırı termal direnci elde etmek için hassas bir şekilde kontrol edilen tozlar halinde kapsamlı bir şekilde işlenmelidir.

Sonuç

Bu kılavuz, refrakter tozlar hakkında bütünsel bir referans sağlamayı amaçlamaktadır - sıradan metallerin ve alaşımların en sıcak, en agresif endüstriyel ortamlardaki sınırlamalarını olağanüstü ısı direnci ile aşan özel malzemeler. Gelişmiş refrakter kalitelerini özel aşırı işleme ihtiyaçlarınıza göre uyarlamayı görüşmek için lütfen bir endüstri uzmanıyla bağlantı kurun. Olasılıklar çok geniş.

Paylaş

Facebook

Twitter

LinkedIn

WhatsApp

E-posta

MET3DP Technology Co, LTD, merkezi Qingdao, Çin'de bulunan lider bir katmanlı üretim çözümleri sağlayıcısıdır. Şirketimiz, endüstriyel uygulamalar için 3D baskı ekipmanları ve yüksek performanslı metal tozları konusunda uzmanlaşmıştır.

İşletmeniz için en iyi fiyatı ve özelleştirilmiş Çözümü almak için sorgulayın!

İlgili Makaleler

Met3DP Hakkında

Video Oynat

Son Güncelleme

Bizim Ürünümüz

BİZE ULAŞIN

Herhangi bir sorunuz var mı? Bize şimdi mesaj gönderin! Mesajınızı aldıktan sonra tüm ekibimizle talebinize hizmet edeceğiz.

3D Baskı ve Katmanlı Üretim için Metal Tozları

ÜRÜN

cONTACT BİLGİLERİ

- Qingdao Şehri, Shandong, Çin

- [email protected]

- [email protected]

- +86 19116340731