Prášek ze slitiny niklu pro 3d tisk

Vše, co potřebujete vědět o prášku ze slitiny niklu pro 3d tisk

kategorie produktů

Přehled práškových niklových slitin pro 3D tisk

3D tisk, známý také jako aditivní výroba, způsobila revoluci v designu a výrobě výrobků v odvětvích, jako je letectví, automobilový průmysl, zdravotnictví a spotřební zboží. Na rozdíl od tradiční subtraktivní výroby, při níž se materiál odebírá, 3D tisk vytváří komponenty vrstvu po vrstvě na základě digitálního 3D modelu.

Jednou z nejoblíbenějších technologií 3D tisku kovů je tavení v práškovém loži, kdy zdroj tepelné energie selektivně taví oblasti práškového lože. Bezkonkurenční svoboda při navrhování, poměr "buy-to-fly" a ekonomická výroba složitých dílů vedly k obrovskému rozšíření technologií práškového lože, jako je např. selektivní laserové tavení (SLM), přímého laserového spékání kovů (DMLS), a tavení elektronovým paprskem (EBM).

Slitiny niklu jsou univerzální třídou materiálů s vlastnostmi, jako je vysoká pevnost, odolnost proti korozi a tepelná odolnost, které z nich činí ideální kandidáty pro 3D tisk. Mezi nejběžnější práškové niklové slitiny používané při fúzi v práškovém loži patří superslitiny Inconel, nerezové oceli, Hastelloys, Nimonics, Kovar, Invar, Monel, slitiny niklu a titanu a superslitiny na bázi niklu.

Složení prášků ze slitin niklu

Vlastnosti slitin niklu vyplývají z jejich prvkového složení a mikrostruktury. Obsah niklu se u různých slitin pohybuje od 2% do 99%. Nikl propůjčuje slitinám vlastnosti, jako je odolnost proti korozi, oxidační odolnost a pevnost při vysokých teplotách. Legující prvky se přidávají pro zlepšení specifických vlastností v závislosti na použití.

Složení prášku ze slitiny niklu

| Rodina slitin | Obsah niklu | Legující prvky |

|---|---|---|

| Inconel | 30-80% | Cr, Mo, Nb, Ta, Al, Ti, Fe |

| Nerezová ocel | 2-20% | Cr, Mo, Mn, Si, C |

| Hastelloy | 35-60% | Mo, Cr, W, Fe, Co |

| Nimonic | Nad 50% | Cr, Ti, Al, Mo |

| Kovar | 17% | Fe, Co, Mn, Si |

| Invar | 36% | Fe |

| Monel | Nad 67% | Cu, Fe, Mn, Si, C |

| Nikl-titan | 55% Ni, 45% Ti | – |

| Niklové superslitiny | Nad 50% | Cr, Co, Mo, W, Ta, Al, Ti, Nb |

Obsah chromu v nerezových ocelích a niklových superslitinách zvyšuje odolnost proti oxidaci a korozi. Molybden, wolfram a tantal zvyšují pevnost při tečení a mechanické vlastnosti při vysokých teplotách. Železo ve slitinách, jako je Kovar a Invar, řídí tepelnou roztažnost. Hliník, titan a niob se přidávají pro precipitační kalení. Mangan zlepšuje tažnost za tepla, zatímco uhlík zvyšuje pevnost a tvrdost. Křemík zlepšuje tekutost a svařitelnost.

Pochopení vlivu legování na tvorbu mikrostruktury a vlastnosti pomáhá při výběru optimálního materiálu pro danou aplikaci. Správná charakterizace a kvalifikace složení a kvality prášku je zásadní před tiskem kritických součástí.

Vlastnosti prášků ze slitin niklu

Jedinečné vlastnosti niklových slitin vytištěných z optimalizovaných prášků umožňují jejich použití v různých aplikacích a extrémních prostředích. Níže uvedená tabulka shrnuje obecné vlastnosti běžných skupin slitin.

Vlastnosti rodin práškových slitin niklu

| Rodina slitin | Hustota | Bod tání | Pevnost v tahu | Tepelná vodivost | Tepelná roztažnost | Odolnost proti oxidaci | Odolnost proti korozi |

|---|---|---|---|---|---|---|---|

| Inconel | 8,2-8,4 g/cc | 1300-1450°C | 750-1380 MPa | 11-16 W/mK | 12-16 μm/m°C | Vynikající | Vynikající |

| Nerezová ocel | 7,5-8,1 g/cc | 1375-1500°C | 450-1100 MPa | 15-30 W/mK | 10-18 μm/m°C | Dobrý | Dobrý-výborný |

| Hastelloy | 8,1-9,2 g/cc | 1260-1350°C | 550-1000 MPa | 6-22 W/mK | 12-16 μm/m°C | Dobrý-výborný | Vynikající |

| Nimonic | 8,1-8,7 g/cc | 1260-1400°C | 500-1200 MPa | 10-30 W/mK | 12-17 μm/m°C | Dobrý | Dobrý |

| Kovar | 8,2 g/cc | 1450°C | 550 MPa | 17 W/mK | 5,9 μm/m°C | Špatný | Špatný |

| Invar | 8 g/cm3 | 1427°C | 200-450 MPa | 10,5 W/mK | 1,2 μm/m°C | Veletrh | Veletrh |

| Monel | 8,8 g/cc | 1350-1370°C | 550-950 MPa | 21-48 W/mK | 13-17 μm/m°C | Veletrh | Vynikající |

| Nikl-titan | 6,4 g/cc | 1240-1310°C | 600-900 MPa | 8-18 W/mK | 11 μm/m°C | Veletrh | Vynikající |

| Niklové superslitiny | 8-9 g/cc | 1260-1350°C | 750-1400 MPa | 11-61 W/mK | 12,5-17 μm/m°C | Dobrý-výborný | Slušně-dobře |

Vysoký bod tání niklových slitin zabraňuje deformaci nebo zkroucení dílů během zpracování. Pevnost v širokém teplotním rozsahu umožňuje konstrukční aplikace, které nesou zatížení. Řízené chování při teplotní roztažnosti umožňuje výrobu přesných součástí s malými tolerancemi. Vynikající odolnost proti korozi a oxidaci usnadňuje použití v náročných prostředích, jako jsou námořní, chemické a ropné a plynové provozy.

Přizpůsobením složení prášku a procesních parametrů lze optimalizovat vlastnosti materiálu pro požadavky konstrukce. Anizotropní povaha aditivní výroby však může mít za následek směrově závislé vlastnosti. Pro dosažení požadovaných vlastností je klíčový správný návrh a zajištění kvality.

Aplikace prášků ze slitin niklu

Niklové slitiny jsou díky své univerzálnosti vhodné pro nejrůznější aplikace v letectví, obraně, automobilovém a námořním průmyslu, při zpracování ropy a plynu, v chemickém průmyslu, energetice, zdravotnictví, při výrobě nástrojů a v dalších oblastech všeobecného strojírenství.

Průmysl Aplikace prášku ze slitiny niklu Rodiny

| Rodina slitin | Průmyslové aplikace |

|---|---|

| Inconel | Letectví, obrana, automobilový průmysl, chemické zpracování, ropa a plyn, výroba energie, raketová technika, rakety, jaderná energie. |

| Nerezová ocel | Letectví, obrana, automobilový průmysl, lékařství, námořní průmysl, architektura, chemický průmysl, potravinářství, nástroje, formy. |

| Hastelloy | letectví, obrana, chemické zpracování, kontrola znečištění, výroba energie, ropa a plyn |

| Nimonic | Letectví, obrana, energetika, chemické zpracování, nástroje |

| Kovar | Elektronika, polovodiče, integrované obvody, balení |

| Invar | Elektronika, optika, přesné přístroje, letectví a kosmonautika |

| Monel | Námořní doprava, zpracování ropy a zemního plynu, chemické zpracování, výroba energie, výroba celulózy a papíru. |

| Nikl-titan | Zdravotnické přístroje, aktuátory, senzory, letectví, ropný a plynárenský průmysl |

| Niklové superslitiny | Letectví, obrana, energetika, ropa a plyn, automobilový průmysl, nástroje |

Mezi příklady dílů ze slitiny niklu vyrobených 3D tiskem patří:

- Letectví a kosmonautika: Lopatky turbín, trysky, spalovací motory, ventily, držáky, termofluidní komponenty.

- Automobilový průmysl: rotory turbodmychadel, rozvody, ventily, díly hnacího ústrojí.

- Zdravotnictví: Implantáty, protézy, chirurgické nástroje, specifické přístroje pro pacienty.

- Ropa a plyn: Nástroje pro hlubinné vrty, ventily, součásti ústí vrtů, potrubní armatury.

- Nástroje: Vstřikovací formy, vytlačovací formy, přípravky a přípravky, lisovací nástroje.

- Obecné informace: Výměníky tepla, díly pro manipulaci s kapalinami, spojovací materiál, pouzdra, skříně.

Díky vynikajícím vlastnostem materiálu, složitým geometriím, kratším dodacím lhůtám, nižším nákladům a flexibilitě konstrukce, které 3D tisk niklových slitin umožňuje, jsou velmi atraktivní volbou pro mnoho kritických aplikací.

Specifikace prášku ze slitiny niklu

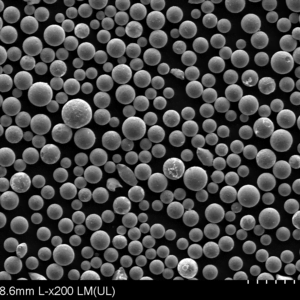

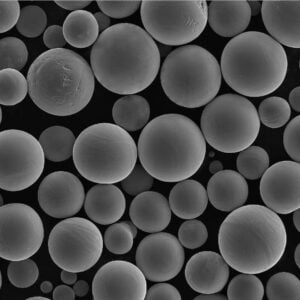

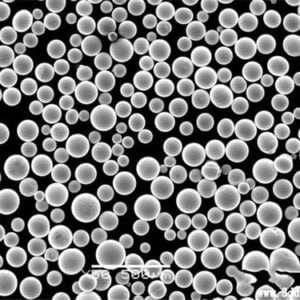

Prášky ze slitin niklu jsou komerčně dostupné v různých rozměrech, morfologiích a úrovních kvality přizpůsobených požadavkům 3D tisku. Níže jsou uvedeny běžné specifikace:

Typické specifikace prášku ze slitiny niklu

| Vlastnictví | Typické hodnoty |

|---|---|

| Složení slitiny | Vlastní slitiny, třída podle ASTM/ASME |

| Tvar částic | Sférické, téměř sférické |

| Velikost částic | 10-45 mikronů |

| Distribuce velikosti částic | D10: 15-25 μm, D50: 25-35 μm, D90: 35-45 μm |

| Zdánlivá hustota | 2,5-5,5 g/cc |

| Hustota poklepání | 4-8 g/cc |

| Tekutost | Vynikající na Hallův průtokoměr |

| Zbytkový kyslík | 100-400 ppm |

| Zbytkový dusík | 50-150 ppm |

| Zbytkový uhlík | 100-300 ppm |

Sférická morfologie a úzká distribuce velikosti částic s hodnotami D10, D50 a D90 v ideálním rozmezí pro konkrétní tiskový proces pomáhají dosáhnout dobré hustoty a mechanických vlastností. Vysoká tekutost zabraňuje aglomeraci prášku a problémům s roztíratelností při přelakování. Nízký obsah zbytkového kyslíku, dusíku a uhlíku minimalizuje kontaminaci a pórovitost.

Kvalita prášku, velikostní parametry a další charakteristiky významně ovlivňují konečné vlastnosti dílů a musí být v souladu s požadavky tiskárny a aplikace. Většina dodavatelů poskytuje vlastní složení slitin a optimalizaci částic tak, aby splňovaly specifikace uživatele.

Metody 3D tisku z práškové niklové slitiny

Mezi nejběžnější metody aditivní výroby používané ke zpracování práškových niklových slitin patří:

Procesy tisku práškových niklových slitin

| Metoda | Popis |

|---|---|

| Selektivní laserové tavení (SLM) | Práškové lože natavené fokusovaným laserovým paprskem |

| Přímé laserové spékání kovů (DMLS) | Podobně jako SLM, ale s nižším výkonem laseru |

| Tavení elektronovým paprskem (EBM) | Práškové lože natavené elektronovým paprskem ve vakuu |

| Laserové nanášení kovů (LMD) | Prášek vstřikovaný do roztaveného bazénu vytvořeného laserem |

| Usměrněná depozice energie (DED) | Podobně jako LMD s práškovým nebo drátěným posuvem |

| Tryskání pojiva | Tekuté pojivo selektivně natištěné na práškové lože |

SLM a DMLS využívají laser s vysokou hustotou výkonu k úplnému roztavení kovového prášku do hustých vrstev. EBM používá jako zdroj energie elektronový paprsek, který vytváří díly ve vakuu. LMD s drátovým napájením taví vstupní kovový drát pomocí fokusovaného laseru. Binder jetting vytiskne kapalné pojivo pro vytvoření dílu, po kterém následuje spékání.

Konkrétní zvolená technika závisí na faktorech, jako je velikost dílu, složitost geometrie, kvalita povrchu, rozlišení prvků, rychlost výroby a náklady. Každý proces vyžaduje optimalizaci nastavení tiskárny a parametrů přizpůsobených složení práškové slitiny.

Parametry procesu zpracování niklové slitiny v prášku

Mezi kritické parametry tiskárny pro niklové slitiny, které vyžadují optimalizaci z hlediska hustoty, pevnosti, přesnosti a povrchové úpravy, patří:

Typické parametry procesu SLM/DMLS

| Parametr | Typický rozsah |

|---|---|

| Tloušťka vrstvy | 20-60 μm |

| Výkon laseru | 100-400 W |

| Rychlost skenování | 400-1200 mm/s |

| Rozteč poklopů | 80-200 μm |

| Velikost paprsku | 50-200 μm |

| Strategie skenování | Šachy, pruh, obrys |

| Podpůrná struktura | Pravidelné, roztříštěné, hybridní |

Typické parametry procesu EBM

| Parametr | Typický rozsah |

|---|---|

| Tloušťka vrstvy | 50-200 μm |

| Výkon elektronového svazku | 3-15 kW |

| Funkce rychlosti | 20-200 mm/s |

| Posun řádku | 0,1-0,3 mm |

| Zaostřovací posun | 15-35 mA |

| Strategie skenování | Jednosměrný, obousměrný |

| Podpůrná struktura | Pravidelné, těžké |

Menší tloušťka vrstvy a velikost paprsku ve spojení s vyšší rychlostí skenování zvyšují rozlišení, přesnost a kvalitu povrchu. Běžně se používají šachové nebo pásové skenovací vzory. Obvodové kontury zlepšují kvalitu hran. Optimalizované podpůrné struktury zabraňují deformaci, ale snáze se odstraňují. Předehřev a recyklace prášku mohou podpořit hustotu a kvalitu materiálu.

Výhody 3D tisku ze slitin niklu

Aditivní výroba s použitím optimalizovaných prášků ze slitin niklu nabízí mnoho výhod oproti tradiční výrobě:

- Svoboda designu: Složité geometrie, které nelze opracovat obráběním

- Snížení hmotnosti: Lehčí komponenty díky optimalizaci topologie

- Konsolidace části: Zkrácená montáž pomocí tištěných složitých tvarů

- Přizpůsobení: Zdravotnické prostředky přizpůsobené pacientům, nástroje

- Snížení množství odpadu: Pouze požadovaný objem použitého materiálu

- Kratší doba realizace: Týdny versus měsíce pro výrobu nástrojů

- Flexibilita procesu: Snadné iterace návrhu a optimalizace

- Výhody výkonu: Anizotropní pevnosti, vložené prvky

- Snížení nákladů: Eliminace nákladů na nástroje, malosériová výroba

- Poměr nákupů a letů: Tisk pouze finálního dílu versus obrábění z bloku

3D tisk rozšiřuje možnosti konstrukce a umožňuje výrobu nových dílů ze slitin niklu, které nejsou proveditelné nebo ekonomicky výhodné při použití běžných technik. Přináší revoluci do výroby v leteckém, lékařském, automobilovém a dalších odvětvích.

Dodavatelé práškových niklových slitin

Většina významných výrobců kovových prášků nyní nabízí řadu prášků ze slitin niklu optimalizovaných pro aditivní výrobu. Mezi přední dodavatele patří např:

Klíčoví dodavatelé niklových slitin

| Dodavatel | Klíčové třídy slitin |

|---|---|

| Met3DP | Inconel 625, 718, Hastelloy X, nerezové oceli |

| Sandvik | Osprey nerezové oceli, superslitiny, slitiny titanu |

| Praxair | Inconel 718, 625, Hastelloy X, nerezové oceli |

| AP&C | Inconel 718, 625, nerezové oceli |

| Technologie LPW | Inconel 718, nerezové oceli, niklové superslitiny |

| Řešení SLM | Nerezová ocel 316L, 17-4PH, niklové superslitiny |

| Přísady GE | Nerezová ocel 316L, Inconel 718, 625, Hastelloy |

Dodavatelé nabízejí různé rozdělení velikostí, vynikající sypkost prášku, nízký obsah kyslíku a vlhkosti, sledovatelnost šarží a slitiny na míru požadavkům procesu a aplikace. Většina z nich poskytuje specializovanou charakterizaci, která zajišťuje konzistentní vysokou kvalitu prášku.

Náklady na prášek ze slitiny niklu

Průměrné náklady na běžné práškové slitiny niklu jsou shrnuty níže:

Náklady na prášek ze slitiny niklu

| Materiál | Náklady na kg |

|---|---|

| Inconel 718 | $75-150 |

| Inconel 625 | $60-120 |

| Nerezová ocel 316L | $35-70 |

| Nerezová ocel 17-4PH | $45-90 |

| Hastelloy X | $85-170 |

| Niklové superslitiny | $90-200 |

Vysoce výkonné slitiny, jako je Inconel 718 a Hastelloy X, jsou dražší, zatímco nerezové oceli bývají nejlevnější variantou. Náklady na materiál jsou však pouze jednou ze složek celkových nákladů na díl. Přidaná hodnota plynoucí z konstrukční flexibility, výkonnostních výhod a zkrácení doby přípravy často kompenzuje vyšší ceny prášků pro malosériovou výrobu.

Nákup prášku ve velkém množství může snížit náklady. Mnoho dodavatelů také nabízí služby opakovaného použití a recyklace prášku. Celkově musí kupující při výběru vhodné práškové slitiny niklu zhodnotit celkové náklady včetně nákladů na pracovní sílu, následné zpracování, využití materiálu, mechanické vlastnosti a další faktory.

Velkoobchodní cena: $20/Kg-$200/Kg

Zobrazen 1. – 15. z 17 výsledků

-

GH3536 slitinový prášek

-

K465 slitinový prášek

-

GH3230 prášek

-

GH5188 prášek

-

GH3625 prášek Inconel 625 prášek

-

GH4169 prášek pro kovový 3D tisk

-

GH3230 prášek

-

GH 3625 prášek

-

Série vysokoteplotních slitin

-

GH4169 Prášek pro aditivní výrobu

-

K403 prášek na bázi niklu

-

Nejlepší prášek IN939 pro 3D tisk v roce 2024

-

Nejlepší prášek IN738LC pro 3D tisk v roce 2025

-

Nejlepší in718 prášek inconel 718 prášek pro kovový 3D tisk

-

Nejlepší Hastelloy X Powder丨Prášek z vysokoteplotní slitiny pro 3D tisk

Časté dotazy o 3D tisku kovového prášku

Jak mohu kontaktovat zákaznický servis Metal3DP?

Poskytujeme zákaznickou podporu 24/7. Naše kontaktní údaje najdete na stránce Kontaktujte nás, včetně telefonu, e-mailu a online chatu.

Jaké kovové práškové materiály Metal3DP nabízí?

Nabízíme různé vysoce kvalitní kovové prášky včetně nerezové oceli, vysokoteplotní slitiny, vhodné pro procesy, jako je fúze prášku laserem a elektronovým paprskem.

Jak Metal3DP zajišťuje kvalitu 3D tiskového kovového prášku?

Díky rozsáhlým odborným znalostem v oblasti výroby aditiv kovů využíváme pokročilé procesy a přísnou kontrolu kvality, abychom zajistili mechanické vlastnosti a kvalitu povrchu dílů.

V jakých průmyslových odvětvích se používají 3D tisková zařízení Metal3DP?

Naše zařízení mají širokou škálu aplikací v průmyslových odvětvích, jako je letectví, lékařství, automobilový průmysl a další, a poskytují řešení pro vysoce výkonné kovové součásti ve výrobě.

Nabízí Metal3DP vlastní možnosti slitin?

Ano, poskytujeme vlastní služby z oblasti slitin, abychom splnili specifické požadavky klientů na materiály.

Jaké jsou výhody systémů SEBM od Metal3DP?

Naše systémy SEBM vynikají ve výrobě složitých kovových dílů s výjimečnými mechanickými vlastnostmi. Mezi klíčové vlastnosti patří špičkový objem sestavení, přesnost a spolehlivost.

Mohu na webu Metal3DP najít aplikační pouzdra?

Ano, naše webové stránky předvádějí širokou škálu případů aplikací demonstrujících úspěšné implementace technologie Metal3DP v různých odvětvích.

Jak mohu začít spolupracovat s Metal3DP?

Kontaktujte nás a náš tým vám poskytne řešení a plány spolupráce na míru podle vašich potřeb.

Jaká je doba obratu u zákaznických služeb Metal3DP?

Doba zpracování zákaznických služeb se liší v závislosti na složitosti projektu. Na základě vašich požadavků vám poskytneme přesné dodací lhůty.

Jaké technologie 3D tisku Metal3DP nabízí?

Specializujeme se na selektivní laserové sintrování (SLS), selektivní laserové tavení (SLM) a selektivní tavení elektronovým paprskem (SEBM) a další technologie 3D tisku.

POŠLI NÁM

Zeptat se na další otázku?

Pokud nemůžete najít odpověď na svou otázku v našich FAQ, můžete nám vždy zanechat zprávu. Brzy vám odpovíme.

POČKEJ NA NÁS

Další krok

01. Zpracujeme návrh

Požadovaný rozsah, časový rozvrh a RPSN. Cena bude zahrnuta, pokud nám poskytnete podrobné informace o projektu.

02. Diskutujte o tom společně

Pojďme se seznámit a probrat všechny možné varianty a možnosti

03. Začněme stavět

Když je podepsána smlouva a jsou stanoveny všechny cíle, můžeme začít s prvním sprintem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731