atomizace plazmatu

Obsah

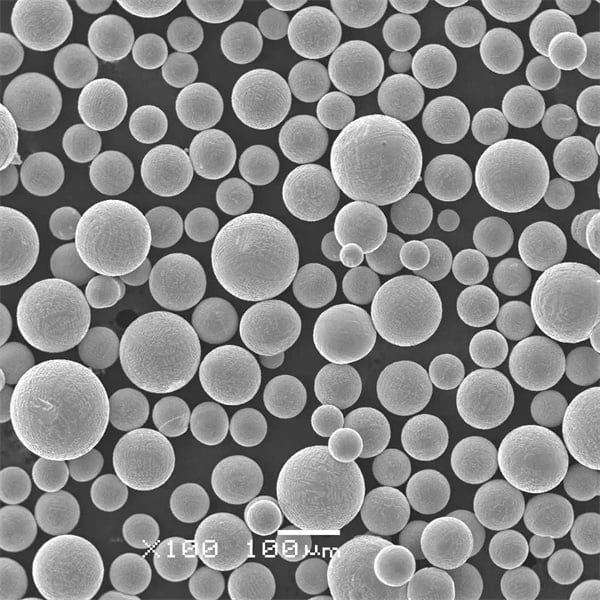

Představte si, že dokážete přeměnit pevný kov na oblak dokonale kulovitých částic, z nichž každá je mikroskopická, ale nesmírně silná. To je kouzlo atomizace plazmatu, revoluční technologie, která přetváří svět kovových prášků. Ale co to přesně je a jak to funguje? Připoutejte se, protože se chystáme ponořit se do fascinujícího světa tohoto high-tech procesu.

Od roztaveného kovu k mikroskopickým zázrakům

Plazmová atomizace odebírá surovinu kovu, obvykle ve formě drátu, a stříká ji intenzivně horkým proudem plazmy – představte si teploty přesahující 10 000 °C (18 000 °F)! Toto intenzivní teplo okamžitě roztaví kov a přemění ho na roztavenou kapku. Tím ale příběh nekončí. Proces pak využívá různé atomizační techniky, jako je plyn nebo odstředivá síla, k rozbití této roztavené kapičky na jemnou mlhu drobných kovových částic. Tyto částice rychle tuhnou, když se ve vzduchu ochlazují, což vede ke sbírce téměř dokonalých kuliček – kýženého kovového prášku.

Síla atomizace plazmatu

Plazmová atomizace se odlišuje od jiných metod výroby kovových prášků, jako je atomizace vodou nebo plynem, díky své schopnosti vytvářet výjimečně vysoce kvalitní prášky. Zde je důvod:

- Síla čistoty: Vysoké teploty dosahované při plazmové atomizaci minimalizují riziko kontaminace z okolního prostředí, což vede k výjimečně čistým kovovým práškům. To je zásadní pro aplikace, kde i stopové množství nečistot může významně ovlivnit výkon.

- Sférická nadřazenost: Díky silám povrchového napětí působících na roztavené kapičky během tuhnutí vytváří plazmová atomizace vysoce kulovité částice. Tento konzistentní tvar se promítá do vynikající tekutosti a hustoty balení, díky čemuž je prášek ideální pro aditivní výrobní procesy, jako je 3D tisk.

- Jemné doladění síly: Přesné ovládání parametrů plazmového hořáku a atomizace umožňuje vytvářet prášky s úzkou distribucí velikosti. Tato konzistence je nezbytná pro mnoho aplikací, kde je pro optimální výkon rozhodující jednotná velikost částic.

Specifické kovové prášky

Nyní se pojďme ponořit hlouběji a prozkoumat některé šampiony kovového prášku vytvořené pomocí atomizace plazmy:

1. Titanové prášky: Titanové prášky, známé pro svůj výjimečný poměr pevnosti k hmotnosti a vynikající odolnost proti korozi, jsou tou volbou pro letecký průmysl, lékařské implantáty a vysoce výkonné sportovní zboží. Plazmově atomizované titanové prášky se mohou pochlubit vynikající čistotou a konzistentní sférickou morfologií, díky čemuž jsou ideální pro aplikace aditivní výroby, kde jsou tyto vlastnosti prvořadé.

2. Niklové prášky: Nikl, všestranný kov, si našel cestu do bezpočtu aplikací, od ražení mincí a baterií až po superslitiny používané v proudových motorech. Plazmově atomizované niklové prášky nabízejí výjimečnou tekutost a hustotu balení, což je zásadní pro procesy, jako je prášková metalurgie, kde je nezbytná přesná kontrola vlastností materiálu.

3. Hliníkové prášky: Lehké a snadno tvarovatelné hliníkové prášky nacházejí stále větší uplatnění v automobilovém a leteckém průmyslu pro snížení hmotnosti. Plazmová atomizace zajišťuje vysokou čistotu a úzkou distribuci velikosti v hliníkových prášcích, což vede ke komponentám s předvídatelnými mechanickými vlastnostmi.

4. Kobaltové prášky: Kobaltové prášky, klíčová složka superslitin a odolných řezných nástrojů, ohromně těží z plazmové atomizace. Tento proces poskytuje vysoce čisté prášky s vynikající tekutostí, což umožňuje vytvoření robustních a otěruvzdorných součástí.

5. Měděné prášky: Vysoce vodivý kov, měď, je základem v elektrických aplikacích. Plazmově atomizované měděné prášky nabízejí vynikající tekutost a hustotu balení, díky čemuž jsou ideální pro procesy, jako je vstřikování kovů (MIM) používané k vytváření složitých elektronických součástek.

6. Prášky z nerezové oceli: Prášky z nerezové oceli, které nabízejí kombinaci pevnosti, odolnosti proti korozi a cenové dostupnosti, jsou široce používány v různých průmyslových odvětvích. Plazmová atomizace zajišťuje konzistentní velikost částic a morfologii v těchto prášcích, což vede k předvídatelným mechanickým vlastnostem konečného produktu.

7. Prášky Inconel: Prášky Inconel, řada vysoce výkonných nikl-chromových superslitin, jsou životně důležité pro aplikace vyžadující mimořádnou pevnost a tepelnou odolnost, jako jsou součásti proudových motorů. Plazmová atomizace zajišťuje, že tyto prášky mají vysokou čistotu a přesnou strukturu zrna potřebnou k tomu, aby vydržely extrémní podmínky.

8. Wolframové prášky: Husté a neuvěřitelně tvrdé wolframové prášky se používají pro aplikace, jako je pancéřování a vysoce výkonné řezné nástroje. Plazmová atomizace poskytuje wolframové prášky s minimálními nečistotami a řízenou distribucí velikosti částic, což je klíčové pro dosažení požadované tvrdosti a odolnosti proti opotřebení.

9. Molybdenové prášky: Další kov s vysokou teplotou tání, molybden, nachází využití v topných prvcích a dalších vysokoteplotních aplikacích. Plazmová atomizace zajišťuje výjimečnou čistotu a řízenou velikost částic v molybdenových prášcích, což vede ke komponentám s předvídatelnými tepelnými a mechanickými vlastnostmi.

10. Tantalové prášky: Tantalové prášky vysoce odolné vůči korozi a biokompatibilní nacházejí stále větší uplatnění v lékařských implantátech a kondenzátorech. Plazmová atomizace poskytuje vysoce čisté tantalové prášky s řízenou strukturou zrna, která je nezbytná pro zajištění dlouhodobého výkonu a biokompatibility zdravotnických prostředků.

Beyond the Big 10: Universe of Metal Powders

Krása atomizace plazmatu spočívá v její všestrannosti. Tento proces lze použít k vytvoření prášků z široké škály kovů, včetně:

- Zirkonium: Používá se v jaderných reaktorech díky svým výjimečným vlastnostem absorpce neutronů. Plazmová atomizace zajišťuje vysokou čistotu zirkoniových prášků, což je klíčové pro bezpečný a efektivní provoz reaktoru.

- niob: Cenný legující prvek známý svou pevností a supravodivostí při nízkých teplotách. Plazmově atomizované niobové prášky nabízejí přesnou kontrolu nad velikostí a morfologií částic, což vede k vynikajícímu výkonu v supravodivých aplikacích.

- Hořčík: Hořčík, nejlehčí konstrukční kov, získává na trakci v aplikacích citlivých na hmotnost, jako je letecký průmysl. Plazmová atomizace zajišťuje vysokou čistotu a řízenou poréznost v hořčíkových prášcích a optimalizuje jejich poměr pevnosti k hmotnosti.

Odhalení nuancí kovových prášků

Pokud jde o kovové prášky, ďábel se skrývá v detailech. Zde je rozpis některých klíčových parametrů, které je třeba vzít v úvahu:

| Parametr | Popis | Význam pro plazmou atomizované prášky |

|---|---|---|

| Distribuce velikosti částic | Rozsah velikostí přítomných v prášku | Plazmová atomizace nabízí přesnou kontrolu, což vede ke konzistentním a předvídatelným vlastnostem konečného produktu. |

| Kulovitost | Jak moc se částice podobají dokonalým koulím | Vysoká kulovitost u plazmou atomizovaných prášků zajišťuje vynikající tekutost a hustotu balení. |

| Plocha povrchu | Celková plocha povrchu částic prášku | Plazmová atomizace může ovlivnit plochu povrchu a ovlivnit faktory, jako je reaktivita a slinovací chování. |

| Zdánlivá hustota | Hmotnost prášku na jednotku objemu | Vysoká zdánlivá hustota v plazmově atomizovaných prášcích se promítá do efektivního využití materiálu a snížení výrobních nákladů. |

| Tekutost | Snadnost, s jakou prášek teče | Vynikající tekutost v plazmově atomizovaných prášcích umožňuje efektivní manipulaci a zpracování v různých aplikacích. |

| Chemické složení | Elementární make-up prášku | Plazmová atomizace minimalizuje kontaminaci, což vede k vysoce čistým práškům s předvídatelnými vlastnostmi. |

Krajina dodavatelů a cen

S rostoucí poptávkou po vysoce kvalitních kovových prášcích se zvyšuje počet atomizace plazmatu dodavatelů neustále přibývá. Tady je pohled do krajiny:

- Přední dodavatelé: Některá z prominentních jmen v průmyslu plazmové atomizace zahrnují AP&C, Höganäs a PyroGenesis. Tyto společnosti nabízejí širokou škálu kovových prášků pro různé aplikace.

- Dynamika cen: Ceny za plazmově atomizované prášky se liší v závislosti na konkrétním kovu, kvalitě prášku a množství. Obecně platí, že vysoce čisté a jemné prášky vyžadují prémiovou cenu.

Zvažování výhod a nevýhod

Zatímco plazmová atomizace nabízí řadu výhod, je důležité vzít v úvahu její omezení:

výhody:

- Výjimečná čistota: Minimalizovaná kontaminace vede k předvídatelným a spolehlivým vlastnostem materiálu.

- Vynikající sféricita: Konzistentní tvar částic zajišťuje vynikající tekutost a hustotu balení.

- Přesné ovládání: Přizpůsobené parametry procesu umožňují kontrolu nad velikostí částic a morfologií.

- Široký rozsah materiálů: Použitelné na širokou škálu kovů pro různé aplikace.

Nevýhody:

- Vysoká spotřeba energie: Intenzivní plazmové hořáky vyžadují značný energetický vstup, což má dopad na výrobní náklady.

- Komplexní vybavení: Nastavení plazmové atomizace zahrnuje sofistikované zařízení, které vede k vyšším kapitálovým investicím.

- Omezené výrobní sazby: Ve srovnání s některými jinými metodami může mít plazmová atomizace pro určité kovy nižší rychlost produkce.

Nejčastější dotazy

Zde je několik nejčastěji kladených otázek týkajících se atomizace plazmatu, zodpovězené jasnou a stručnou formou:

| Otázka | Odpovědět |

|---|---|

| Jaké jsou výhody plazmové atomizace oproti jiným metodám výroby prášku? | Plazmová atomizace nabízí vynikající čistotu, konzistentní sféricitu a přesnou kontrolu velikosti částic, což vede k vysoce výkonným práškům. |

| Jaké jsou některé aplikace plazmově atomizovaných kovových prášků? | Tyto prášky se používají v aditivní výrobě, práškové metalurgii, vstřikování kovů a různých dalších průmyslových procesech. |

| Jaké faktory ovlivňují cenu plazmou atomizovaných prášků? | Konkrétní kov, jakost prášku a množství hrají roli při stanovení ceny. |

| Je plazmová atomizace proces šetrný k životnímu prostředí? | Zatímco spotřeba energie plazmové atomizace může být značná, dochází ke zlepšení energetické účinnosti. Navíc minimální množství vznikajícího odpadu a potenciál pro recyklaci nepoužitého prášku přispívají k udržitelnějšímu přístupu. |

| Jaké jsou budoucí vyhlídky atomizace plazmatu? | Vzhledem k tomu, že poptávka po vysoce výkonných kovových prášcích roste, očekává se, že plazmová atomizace bude dále růst. Pokroky v automatizaci, optimalizaci procesů a materiálové vědě pravděpodobně dále rozšíří možnosti a efektivitu této technologie. |

Sdílet na

MET3DP Technology Co., LTD je předním poskytovatelem řešení aditivní výroby se sídlem v Qingdao v Číně. Naše společnost se specializuje na zařízení pro 3D tisk a vysoce výkonné kovové prášky pro průmyslové aplikace.

Dotaz k získání nejlepší ceny a přizpůsobeného řešení pro vaše podnikání!

Související články

Vysoce výkonné segmenty lopatek trysek: Revoluce v účinnosti turbín díky 3D tisku z kovu

Přečtěte si více "O Met3DP

Nedávná aktualizace

Náš produkt

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731