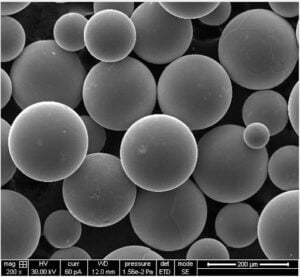

AM Powder

wszystkie kolekcje

Proszek FeCoNiCrMn: najlepszy przewodnik na rok 2025

Przegląd Proszek FeCoNiCrMn to stop o wysokiej entropii (HEA), który wykazuje wyjątkową wytrzymałość mechaniczną, wyjątkową odporność na korozję, doskonałą stabilność termiczną i doskonałą odporność na zużycie. Ten stop, składający się z żelaza (Fe), kobaltu (Co), niklu (Ni), chromu (Cr) i manganu (Mn) w proporcjach zbliżonych do ekwiatomowych, jest szeroko stosowany w przemyśle lotniczym, implantach medycznych, inżynierii morskiej,

Proszek FeCoNiCr: kompletny przewodnik na 2025 r.

Przegląd Proszek FeCoNiCr to stop o wysokiej entropii (HEA) znany ze swoich wyjątkowych właściwości mechanicznych, doskonałej odporności na korozję i znakomitej stabilności termicznej. Dzięki zrównoważonemu składowi żelaza (Fe), kobaltu (Co), niklu (Ni) i chromu (Cr) stop ten jest szeroko stosowany w przemyśle lotniczym, implantach medycznych, powłokach przemysłowych i wysokowydajnej produkcji addytywnej

Proszek CoCrFeNi: kompletny przewodnik na 2025 r.

Przegląd Proszek CoCrFeNi to stop o wysokiej entropii (HEA) znany ze swojej wyjątkowej wytrzymałości, odporności na korozję, odporności na zużycie i stabilności termicznej. Stop ten jest szeroko stosowany w przemyśle lotniczym, implantach medycznych, energetyce i w zastosowaniach związanych z produkcją addytywną o wysokiej wydajności ze względu na dobrze zbilansowany skład wieloelementowy, który obejmuje kobalt (Co), chrom (Cr), żelazo (Fe) i

Proszek AlCrFeCoNiCu: najlepszy przewodnik na 2025 r.

Przegląd Proszek AlCrFeCoNiCu to najnowocześniejszy stop o wysokiej entropii (HEA) znany ze swojej wyjątkowej wytrzymałości, odporności na korozję, odporności na zużycie i stabilności termicznej. Stop ten jest szeroko stosowany w przemyśle lotniczym, powłokach przemysłowych, energetyce i zastosowaniach w produkcji addytywnej o wysokiej wydajności ze względu na swój unikalny skład, który obejmuje aluminium (Al), chrom (Cr), żelazo (Fe), kobalt

Proszek AlCoCrFeNi: najlepszy przewodnik na 2025 r.

Przegląd Proszek AlCoCrFeNi to stop o wysokiej entropii (HEA), który łączy w sobie wyjątkową wytrzymałość mechaniczną, stabilność termiczną i odporność na korozję. Ze względu na swój unikalny, wieloelementowy skład, stop ten jest szeroko stosowany w przemyśle lotniczym, energetycznym, obronnym i wysoko wydajnych zastosowaniach przemysłowych. Skład ✔ Aluminium (Al): Zwiększa odporność na utlenianie i wytrzymałość ✔ Kobalt (Co): Poprawia zużycie

Proszek CoCrFeMnNi: najlepszy przewodnik na 2025 r.

Przegląd Proszek CoCrFeMnNi, powszechnie nazywany stopem o wysokiej entropii (HEA), to specjalistyczny proszek metalowy znany ze swojej wyjątkowej wytrzymałości mechanicznej, odporności na zużycie i korozję. Stop ten jest szeroko stosowany w przemyśle lotniczym, biomedycznym, energetycznym i wysokowydajnym ze względu na unikalną kombinację pięciu głównych pierwiastków — kobaltu (Co),

Proszek Ti-6-2-4-6: najlepszy przewodnik na 2025 rok

Przegląd Proszek Ti-6-2-4-6, znany również jako Ti-6Al-2Sn-4Zr-6Mo, to wysokowytrzymały, wysokotemperaturowy stop tytanu przeznaczony do zastosowań w lotnictwie, motoryzacji i przemyśle, wymagających wyjątkowej wytrzymałości, odporności na utlenianie i odporności na pełzanie w podwyższonych temperaturach. Ten stop jest szeroko stosowany w silnikach odrzutowych, elementach płatowca i wysokowydajnych elementach konstrukcyjnych. Ten stop składa się z:✔ 6%

Proszek Ti-6Al-2Sn-4Zr-6Mo: najlepszy przewodnik na rok 2025

Przegląd Proszek Ti-6Al-2Sn-4Zr-6Mo to wysokowytrzymały, wysokotemperaturowy stop tytanu znany ze swoich wyjątkowych właściwości mechanicznych, odporności na utlenianie i doskonałej odporności na pełzanie. Ten stop jest szeroko stosowany w przemyśle lotniczym, motoryzacyjnym i wysokowydajnym, szczególnie w silnikach odrzutowych, elementach płatowca i turbinach gazowych. Ten stop składa się z: ✔ 6% Aluminium (Al) –

Proszek Ti-5Al-2.5Sn: najlepszy przewodnik na rok 2025

Przegląd Proszek Ti-5Al-2.5Sn to stop tytanu bliski alfa, znany ze swojej wysokiej wytrzymałości, doskonałej odporności na utlenianie i doskonałej odporności na pełzanie w podwyższonych temperaturach. Stop ten jest szeroko stosowany w zastosowaniach lotniczych, morskich i konstrukcyjnych w wysokich temperaturach, szczególnie w konstrukcjach samolotów, silnikach odrzutowych i wysokowydajnych komponentach samochodowych. Stop ten składa się z:✔ 5%

Proszek Ti-8Al-1Mo-1V: najlepszy przewodnik na rok 2025

Przegląd Proszek Ti-8Al-1Mo-1V to bardzo wytrzymały, lekki stop tytanu znany ze swoich doskonałych właściwości w wysokiej temperaturze, odporności na utlenianie i doskonałych właściwości mechanicznych. Ten stop jest szeroko stosowany w przemyśle lotniczym, motoryzacyjnym i w zastosowaniach konstrukcyjnych w wysokiej temperaturze, szczególnie w silnikach odrzutowych, elementach płatowców i turbinach gazowych. Ten stop składa się z: ✔ 8% Aluminium (Al) –

Proszek FeCoNiCrMn: najlepszy przewodnik na rok 2025

Przegląd Proszek FeCoNiCrMn to stop o wysokiej entropii (HEA), który wykazuje wyjątkową wytrzymałość mechaniczną, wyjątkową odporność na korozję, doskonałą stabilność termiczną i doskonałą odporność na zużycie. Ten stop,

Proszek FeCoNiCr: kompletny przewodnik na 2025 r.

Przegląd Proszek FeCoNiCr to stop o wysokiej entropii (HEA) znany ze swoich wyjątkowych właściwości mechanicznych, doskonałej odporności na korozję i wyjątkowej stabilności termicznej. Dzięki zrównoważonemu składowi

Proszek CoCrFeNi: kompletny przewodnik na 2025 r.

Przegląd Proszek CoCrFeNi to stop o wysokiej entropii (HEA) znany ze swojej wyjątkowej wytrzymałości, odporności na korozję, odporności na zużycie i stabilności termicznej. Stop ten jest szeroko stosowany

Proszek AlCrFeCoNiCu: najlepszy przewodnik na 2025 r.

Przegląd Proszek AlCrFeCoNiCu to najnowocześniejszy stop o wysokiej entropii (HEA) znany ze swojej wyjątkowej wytrzymałości, odporności na korozję, odporności na zużycie i stabilności termicznej. Stop ten jest szeroko stosowany

Proszek AlCoCrFeNi: najlepszy przewodnik na 2025 r.

Przegląd Proszek AlCoCrFeNi to stop o wysokiej entropii (HEA), który łączy wyjątkową wytrzymałość mechaniczną, stabilność termiczną i odporność na korozję. Ze względu na swój unikalny skład wieloelementowy, ten

Proszek CoCrFeMnNi: najlepszy przewodnik na 2025 r.

Przegląd Proszek CoCrFeMnNi, powszechnie nazywany stopem o wysokiej entropii (HEA), to specjalistyczny proszek metalowy znany ze swojej wyjątkowej wytrzymałości mechanicznej, odporności na zużycie i

Proszek Ti-6-2-4-6: najlepszy przewodnik na 2025 rok

Przegląd Proszek Ti-6-2-4-6, znany również jako Ti-6Al-2Sn-4Zr-6Mo, to wysokowytrzymały, wysokotemperaturowy stop tytanu przeznaczony do zastosowań w przemyśle lotniczym, motoryzacyjnym i przemysłowym, wymagających wyjątkowej wytrzymałości, odporności na utlenianie,

Proszek Ti-6Al-2Sn-4Zr-6Mo: najlepszy przewodnik na rok 2025

Przegląd Proszek Ti-6Al-2Sn-4Zr-6Mo to wysokowytrzymały, wysokotemperaturowy stop tytanu znany ze swoich wyjątkowych właściwości mechanicznych, odporności na utlenianie i doskonałej odporności na pełzanie. Stop ten jest szeroko

Proszek Ti-5Al-2.5Sn: najlepszy przewodnik na rok 2025

Przegląd Proszek Ti-5Al-2.5Sn to stop tytanu bliski alfa, znany ze swojej wysokiej wytrzymałości, doskonałej odporności na utlenianie i doskonałej odporności na pełzanie w podwyższonych temperaturach. Ten stop

Proszek Ti-8Al-1Mo-1V: najlepszy przewodnik na rok 2025

Przegląd Proszek Ti-8Al-1Mo-1V to wytrzymały, lekki stop tytanu znany ze swoich doskonałych właściwości w wysokiej temperaturze, odporności na utlenianie i doskonałych właściwości mechanicznych. Stop ten jest szeroko stosowany

Nasz produkt

PRODUKT GORĄCEJ SPRZEDAŻY

KONTAKT

Masz pytania? Wyślij nam wiadomość teraz! Po otrzymaniu wiadomości obsłużymy Twoją prośbę całym zespołem.

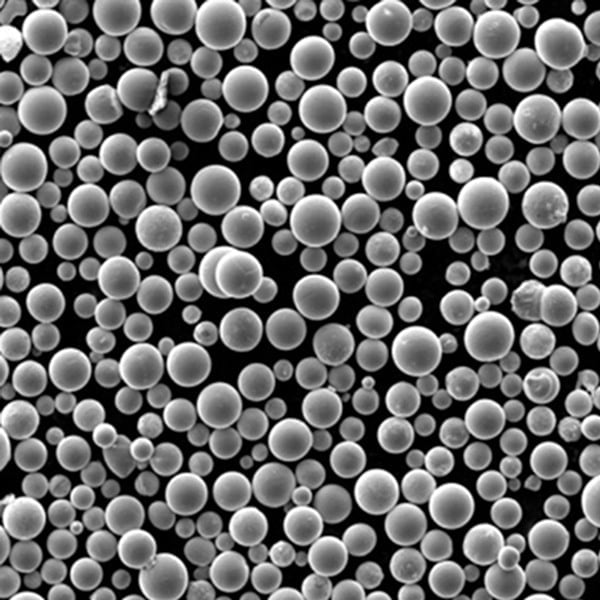

Proszki metali do druku 3D i produkcji addytywnej

PRODUKT

cONTACT INFO

- Miasto Qingdao, Shandong, Chiny

- [email protected]

- [email protected]

- +86 19116340731