Proszki metali dla półprzewodników

Spis treści

W ciągle ewoluującym świecie półprzewodników rola proszków metalowych jest kluczowa. Od tworzenia mikroprocesorów po rozwój zaawansowanej pamięci masowej, proszki metalowe są niedocenianymi bohaterami umożliwiającymi te cuda technologiczne. W tym artykule zagłębiamy się w zawiłości proszki metalowe do półprzewodników, ich rodzaje, składy, zastosowania, specyfikacje i wiele więcej. Przyjrzyjmy się szczegółowo temu fascynującemu tematowi.

Przegląd proszków metalowych do półprzewodników

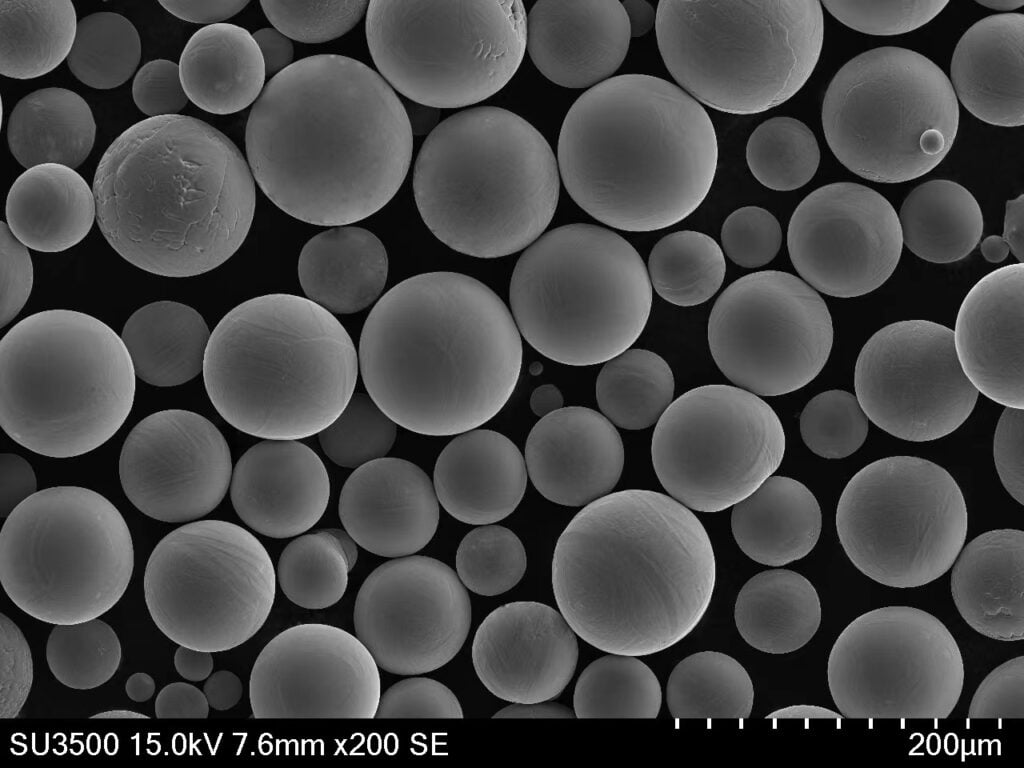

Proszki metalowe to drobno rozdrobnione cząsteczki metali, które są wykorzystywane w różnych zastosowaniach, w tym w przemyśle półprzewodnikowym. Ich znaczenie leży w ich unikalnych właściwościach, takich jak wysoka czystość, kontrolowany rozmiar cząstek i powierzchnia właściwa, co czyni je idealnymi do stosowania w produkcji urządzeń półprzewodnikowych.

Kluczowe punkty:

- Proszki metalowe odgrywają kluczową rolę w procesie produkcji półprzewodników.

- Oferują wysoką czystość i kontrolowaną wielkość cząstek.

- Stosowany w mikroprocesorach, pamięciach masowych i innych urządzeniach półprzewodnikowych.

Rodzaje proszków metalowych do półprzewodników

Różne metale są używane w formie proszków do różnych zastosowań półprzewodnikowych. Każdy proszek metalowy ma odrębne właściwości, które czynią go odpowiednim do konkretnych zastosowań.

| Metalowy proszek | Skład | Właściwości | Charakterystyka |

|---|---|---|---|

| Miedź (Cu) | Czysta miedź | Wysoka przewodność | Odporność na korozję, plastyczność |

| Aluminium (Al) | Czyste aluminium | Lekkość, wysoka przewodność | Odblaskowość, podatność na odkształcanie |

| Srebro (Ag) | Czyste srebro | Najwyższa przewodność elektryczna | Odporność na matowienie, antybakteryjny |

| Złoto (Au) | Czyste złoto | Doskonała przewodność | Niereaktywny, ciągliwość |

| Nikiel (Ni) | Czysty nikiel | Odporność na korozję | Magnetyzm, wysoka temperatura topnienia |

| Tytan (Ti) | Czysty tytan | Wytrzymałość, lekkość | Odporność na korozję, biokompatybilność |

| Wolfram (W) | Czysty wolfram | Wysoka temperatura topnienia | Gęstość, twardość |

| Molibden (Mo) | Czysty molibden | Wysoka wytrzymałość | Wysoka przewodność cieplna, niska rozszerzalność cieplna |

| Pallad (Pd) | Czysty pallad | Odporność na korozję | Dobra przewodność, właściwości katalityczne |

| Kobalt (Co) | Czysty kobalt | Właściwości magnetyczne | Wysoka temperatura topnienia, wytrzymałość |

Zastosowania proszku metalowego w półprzewodnikach

Proszki metalowe są używane w różnych zastosowaniach w przemyśle półprzewodnikowym. Oto podział na to, gdzie i jak te proszki są wykorzystywane.

| Zastosowanie | Używane proszki metali | Opis |

|---|---|---|

| Mikroprocesory | Miedź, złoto, srebro | Ścieżki przewodzące i połączenia międzyprzewodowe |

| Pamięć masowa | Aluminium, Nikiel | Warstwy pamięci masowej i zapis magnetyczny |

| Czujniki | Pallad, Kobalt | Elementy czułe w czujnikach |

| Tranzystory | Wolfram, molibden | Materiały bramkowe i połączeniowe |

| Kondensatory | Tytan, nikiel | Materiały dielektryczne i elektrodowe |

| Diody LED | Aluminium, Złoto | Ścieżki przewodzące i radiatory |

| Urządzenia zasilające | Miedź, Srebro | Komponenty przewodzące duży prąd |

| Ogniwa słoneczne | Srebro, aluminium | Siatki i styki przewodzące |

Specyfikacje, rozmiary, gatunki i normy

Zrozumienie specyfikacji, rozmiarów, klas i norm proszków metali jest kluczowe dla ich efektywnego zastosowania w półprzewodnikach.

| Metalowy proszek | Rozmiary (µm) | Stopnie | Standardy |

|---|---|---|---|

| Miedź (Cu) | 0.1 – 10 | Wysoka czystość (99.99%) | ASTM B170-99 |

| Aluminium (Al) | 0.5 – 15 | Klasa elektroniczna | Certyfikat ISO 8000 |

| Srebro (Ag) | 0.2 – 5 | 99.999% Czysty | ASTM B779-99 |

| Złoto (Au) | 0.1 – 3 | Klasa półprzewodnikowa | Norma ISO 9208 |

| Nikiel (Ni) | 1 – 20 | 99.98% Czysty | ASTM B330-03 |

| Tytan (Ti) | 2 – 30 | Wysoka czystość (99,6%) | ASTM B348-19 |

| Wolfram (W) | 0.3 – 15 | Wysoka czystość | Norma ISO 2768-1 |

| Molibden (Mo) | 0.5 – 10 | 99.95% Czysty | ASTM B386-03 |

| Pallad (Pd) | 0.1 – 5 | 99,9% Czysty | ISO 6284 |

| Kobalt (Co) | 1 – 25 | 99,8% Czysty | ASTM B330-03 |

Dostawcy i szczegóły dotyczące cen

Wiedza o tym, gdzie kupować proszki metali i znajomość ich cen ma kluczowe znaczenie dla planowania i budżetowania produkcji półprzewodników.

| Dostawca | Dostępne proszki metali | Cena (za kg) |

|---|---|---|

| Elementy amerykańskie | Miedź, złoto, nikiel, srebro | $300 – $10,000 |

| NanoAmor | Aluminium, Wolfram, Tytan | $200 – $8,000 |

| Nanomateriały SkySpring | Pallad, Kobalt, Molibden | $500 – $12,000 |

| Tekna | Aluminium, miedź, nikiel | $250 – $9,000 |

| Dobry człowiek | Złoto, Srebro, Tytan | $400 – $15,000 |

Porównanie zalet i wad proszków metalowych

Każdy proszek metalowy ma swoje zalety i ograniczenia. Oto analiza porównawcza, która pomoże zrozumieć, który z nich może być lepiej dostosowany do konkretnych zastosowań.

| Metalowy proszek | Zalety | Wady |

|---|---|---|

| Miedź (Cu) | Wysoka przewodność, opłacalność | Podatność na utlenianie |

| Aluminium (Al) | Lekkość, dobra przewodność | Niższa temperatura topnienia |

| Srebro (Ag) | Najwyższa przewodność, odporność na matowienie | Drogie |

| Złoto (Au) | Niereaktywny, doskonała przewodność | Bardzo drogie |

| Nikiel (Ni) | Odporny na korozję, magnetyczny | Umiarkowana przewodność |

| Tytan (Ti) | Mocny, lekki, biokompatybilny | Drogi, reaktywny |

| Wolfram (W) | Wysoka temperatura topnienia, twarda | Bardzo gęsty, trudny w obróbce |

| Molibden (Mo) | Wysoka wytrzymałość, przewodność cieplna | Kruche, drogie |

| Pallad (Pd) | Dobra przewodność, odporność na korozję | Bardzo drogie |

| Kobalt (Co) | Właściwości magnetyczne, wysoka temperatura topnienia | Drogie, mogą być toksyczne |

Skład proszku metalowego dla półprzewodników

Skład proszków metalowych odgrywa kluczową rolę w ich skuteczności i zastosowaniu w urządzeniach półprzewodnikowych. Oto głębsze spojrzenie na składy i ich wpływ.

Proszek miedzi (Cu):

- Skład: Czysta miedź (99.99%)

- Uderzenie: Zapewnia doskonałą przewodność elektryczną, niezbędną do połączeń i ścieżek przewodzących w mikroprocesorach i urządzeniach pamięci.

Proszek aluminiowy (Al):

- Skład: Czysty aluminium (99.98%)

- Uderzenie: Lekki i odblaskowy, idealny do siatek przewodzących w ogniwach słonecznych i radiatorach LED.

Proszek srebrny (Ag):

- Skład: Czyste srebro (99.999%)

- Uderzenie: Najwyższa przewodność elektryczna, stosowana w urządzeniach o wysokiej częstotliwości i dużej mocy w celu uzyskania minimalnego oporu.

Proszek złota (Au):

- Skład: Czyste złoto (99.99%)

- Uderzenie: Nie reaguje i jest doskonałym przewodnikiem, używany w krytycznych zastosowaniach, w których niezawodność i trwałość mają priorytet.

Proszek niklu (Ni):

- Skład: Czysty nikiel (99.98%)

- Uderzenie: Odporne na korozję i magnetyczne, odpowiednie do przechowywania danych i czujników.

Proszek tytanu (Ti):

- Skład: Czysty tytan (99,6%)

- Uderzenie: Mocne i lekkie, stosowane w kondensatorach i zaawansowanych urządzeniach mocy.

Proszek wolframu (W):

- Skład: Czysty wolfram (99.95%)

- Uderzenie: Wysoka temperatura topnienia i gęstość, idealne do tranzystorów i zastosowań wymagających wysokiej temperatury.

Proszek molibdenu (Mo):

- Skład: Czysty molibden (99.95%)

- Uderzenie: Wysoka wytrzymałość i przewodność cieplna, stosowana w urządzeniach energetycznych i zarządzaniu ciepłem.

Proszek palladu (Pd):

- Skład: Czysty pallad (99,9%)

- Uderzenie: Doskonała przewodność i odporność na korozję, stosowane w czujnikach o wysokiej wydajności i zastosowaniach katalitycznych.

Proszek kobaltu (Co):

- Skład: Czysty kobalt (99,8%)

- Uderzenie: Właściwości magnetyczne i wysoka temperatura topnienia, wykorzystywane w magazynowaniu danych magnetycznych i zaawansowanych zastosowaniach czujnikowych.

Charakterystyka proszku metalowego do półprzewodników

Unikalne cechy każdego proszku metalowego sprawiają, że nadają się one do różnych zastosowań półprzewodnikowych. Oto podział tych cech.

| Metalowy proszek | Charakterystyka | Opis |

|---|---|---|

| Miedź (Cu) | Przewodność | Wysoka przewodność elektryczna, niezbędna dla mikroprocesorów. |

| Aluminium (Al) | Lekki | Zmniejsza całkowitą wagę urządzenia, co jest korzystne w przypadku elektroniki przenośnej. |

| Srebro (Ag) | Przewodność | Najwyższa przewodność elektryczna, optymalna dla urządzeń o wysokiej częstotliwości. |

| Złoto (Au) | Niereaktywny | Nie matowieje i nie koroduje, idealny do połączeń o kluczowym znaczeniu. |

| Nikiel (Ni) | Magnetyzm | Właściwości magnetyczne, przydatne do przechowywania danych. |

| Tytan (Ti) | Siła | Wysoki stosunek wytrzymałości do masy, stosowany w trwałych komponentach. |

| Wolfram (W) | Wysoka temperatura topnienia | Nadaje się do zastosowań w wysokich temperaturach, np. w tranzystorach. |

| Molibden (Mo) | Przewodność cieplna | Doskonale nadaje się do zarządzania ciepłem w urządzeniach energetycznych. |

| Pallad (Pd) | Odporność na korozję | Odporny na korozję, stosowany w czujnikach i urządzeniach o wysokiej wydajności. |

| Kobalt (Co) | Właściwości magnetyczne | Wysoka temperatura topnienia i magnetyzm, przydatne w zastosowaniach związanych z magazynowaniem. |

Gatunki proszków metalowych do półprzewodników

Gatunki proszków metalowych wskazują na ich czystość i przydatność do różnych zastosowań. Oto szczegółowy przegląd dostępnych gatunków różnych proszków metalowych.

| Metalowy proszek | Klasa | Czystość | Zastosowanie |

|---|---|---|---|

| Miedź (Cu) | Wysoka czystość | 99.99% | Połączenia, ścieżki przewodzące |

| Aluminium (Al) | Klasa elektroniczna | 99.98% | Ogniwa słoneczne, diody LED |

| Srebro (Ag) | 99.999% Czysty | 99.999% | Urządzenia o wysokiej częstotliwości |

| Złoto (Au) | Klasa półprzewodnikowa | 99.99% | Krytyczne połączenia |

| Nikiel (Ni) | 99.98% Czysty | 99.98% | Przechowywanie danych, czujniki |

| Tytan (Ti) | Wysoka czystość | 99.6% | Kondensatory, urządzenia mocy |

| Wolfram (W) | Wysoka czystość | 99.95% | Tranzystory, zastosowania wysokotemperaturowe |

| Molibden (Mo) | 99.95% Czysty | 99.95% | Zarządzanie ciepłem |

| Pallad (Pd) | 99,9% Czysty | 99.9% | Czujniki o wysokiej wydajności |

| Kobalt (Co) | 99,8% Czysty | 99.8% | Przechowywanie magnetyczne, czujniki |

Dostawcy i ceny proszków metalowych do półprzewodników

Zrozumienie, skąd pozyskiwać proszki metali i jakie są ich ceny, ma kluczowe znaczenie w przypadku produkcji półprzewodników.

| Dostawca | Dostępne proszki metali | Cena (za kg) |

|---|---|---|

| Elementy amerykańskie | Miedź, złoto, nikiel, srebro | $300 – $10,000 |

| NanoAmor | Aluminium, Wolfram, Tytan | $200 – $8,000 |

| Nanomateriały SkySpring | Pallad, Kobalt, Molibden | $500 – $12,000 |

| Tekna | Aluminium, miedź, nikiel | $250 – $9,000 |

| Dobry człowiek | Złoto, Srebro, Tytan | $400 – $15,000 |

Porównanie Proszki metali dla półprzewodników: Zalety i ograniczenia

Każdy proszek metalowy ma swój własny zestaw zalet i ograniczeń. Oto analiza porównawcza, która pomoże Ci zdecydować, który proszek metalowy najlepiej odpowiada Twoim potrzebom.

| Metalowy proszek | Zalety | Wady |

|---|---|---|

| Miedź (Cu) | Wysoka przewodność, opłacalność | Podatność na utlenianie |

| Aluminium (Al) | Lekkość, dobra przewodność | Niższa temperatura topnienia |

| Srebro (Ag) | Najwyższa przewodność, odporność na matowienie | Drogie |

| Złoto (Au) | Niereaktywny, doskonała przewodność | Bardzo drogie |

| Nikiel (Ni) | Odporny na korozję, magnetyczny | Umiarkowana przewodność |

| Tytan (Ti) | Mocny, lekki, biokompatybilny | Drogi, reaktywny |

| Wolfram (W) | Wysoka temperatura topnienia, twarda | Bardzo gęsty, trudny w obróbce |

| Molibden (Mo) | Wysoka wytrzymałość, przewodność cieplna | Kruche, drogie |

| Pallad (Pd) | Dobra przewodność, odporność na korozję | Bardzo drogie |

| Kobalt (Co) | Właściwości magnetyczne, wysoka temperatura topnienia | Drogie, mogą być toksyczne |

Najczęściej zadawane pytania

P1: Jakie proszki metali są najczęściej stosowane w produkcji półprzewodników?

A1: Do najczęściej stosowanych proszków metalicznych w produkcji półprzewodników należą miedź (Cu), aluminium (Al), srebro (Ag), złoto (Au), nikiel (Ni), tytan (Ti), wolfram (W), molibden (Mo), pallad (Pd) i kobalt (Co).

P2: Dlaczego czystość jest ważna w proszki metalowe do półprzewodników?

A2: Czystość jest kluczowa, ponieważ zanieczyszczenia mogą wpływać na właściwości elektryczne, wydajność i niezawodność urządzeń półprzewodnikowych. Proszki metali o wysokiej czystości zapewniają optymalną przewodność i minimalizują defekty.

P3: W jaki sposób proszki metali są wykorzystywane w mikroprocesorach?

A3: Proszki metali, na przykład miedź i złoto, służą do tworzenia ścieżek przewodzących i połączeń wewnątrz mikroprocesorów, zapewniając wydajne połączenia elektryczne między różnymi komponentami.

P4: Jakie są zalety stosowania proszku złota w półprzewodnikach?

A4: Proszek złota zapewnia doskonałą przewodność, nie wchodzi w reakcje, nie matowieje i nie koroduje, dzięki czemu idealnie nadaje się do połączeń o kluczowym znaczeniu, gdzie niezawodność i trwałość są najważniejsze.

P5: Czy możesz wyjaśnić rolę proszku wolframu w urządzeniach półprzewodnikowych?

A5: Proszek wolframu jest stosowany w urządzeniach półprzewodnikowych ze względu na wysoką temperaturę topnienia i gęstość, co czyni go odpowiednim do zastosowań wymagających wysokiej temperatury, takich jak tranzystory i urządzenia mocy.

P6: Jakie czynniki wpływają na wybór proszku metalowego do konkretnego zastosowania półprzewodnikowego?

A6: Czynniki te obejmują wymaganą przewodność elektryczną i cieplną, temperaturę topnienia, wytrzymałość, odporność na korozję oraz wymagania konkretnego zastosowania, takie jak waga i właściwości magnetyczne.

P7: Czy stosowanie proszków metalowych w półprzewodnikach wiąże się z jakimiś obawami dotyczącymi środowiska?

A7: Tak, produkcja i utylizacja proszków metalowych może mieć wpływ na środowisko. Aby zminimalizować te skutki, konieczne jest przestrzeganie zrównoważonych praktyk i środków recyklingu.

P8: W jaki sposób wielkość cząstek proszków metalowych wpływa na ich zastosowanie w półprzewodnikach?

A8: Wielkość cząstek wpływa na powierzchnię, gęstość upakowania i właściwości elektryczne proszków metalowych, co ma wpływ na ich wydajność w zastosowaniach półprzewodnikowych.

P9: Jakie wyzwania wiążą się z przetwarzaniem proszków metalowych na półprzewodniki?

A9: Wyzwania obejmują osiągnięcie jednorodnego rozkładu wielkości cząstek, utrzymanie wysokiej czystości, zapobieganie utlenianiu i zapewnienie spójnej jakości w trakcie produkcji i przetwarzania.

P10: Gdzie mogę kupić wysokiej jakości proszki metalowe do zastosowań w półprzewodnikach?

A10: Wysokiej jakości proszki metalowe można nabyć od dostawców, takich jak American Elements, NanoAmor, SkySpring Nanomaterials, Tekna i Goodfellow.

Udostępnij

MET3DP Technology Co., LTD jest wiodącym dostawcą rozwiązań w zakresie produkcji addytywnej z siedzibą w Qingdao w Chinach. Nasza firma specjalizuje się w sprzęcie do druku 3D i wysokowydajnych proszkach metali do zastosowań przemysłowych.

Zapytaj o najlepszą cenę i spersonalizowane rozwiązanie dla Twojej firmy!

Powiązane artykuły

Wysokowydajne segmenty łopatek dysz: Rewolucja w wydajności turbin dzięki drukowi 3D w metalu

Czytaj więcej "

Drukowane w 3D mocowania dla samochodowych czujników radarowych: Precyzja i wydajność

Czytaj więcej "Informacje o Met3DP

Ostatnia aktualizacja

Nasz produkt

KONTAKT

Masz pytania? Wyślij nam wiadomość teraz! Po otrzymaniu wiadomości obsłużymy Twoją prośbę całym zespołem.

Proszki metali do druku 3D i produkcji addytywnej

PRODUKT

cONTACT INFO

- Miasto Qingdao, Shandong, Chiny

- [email protected]

- [email protected]

- +86 19116340731