Urządzenia VIGA z pojedynczym piecem

Spis treści

Witamy w najlepszym przewodniku po Jednopiecowy sprzęt VIGA (atomizacja gazu metodą próżniową indukcyjną). Jeśli zagłębiasz się w świat zaawansowanej metalurgii i produkcji proszków metalowych, jesteś we właściwym miejscu. Przedstawimy wszystko, co musisz wiedzieć o systemach VIGA z pojedynczym piecem, omawiając ich funkcjonalność, zalety, zastosowania i wiele więcej.

Przegląd Urządzenia VIGA z pojedynczym piecem

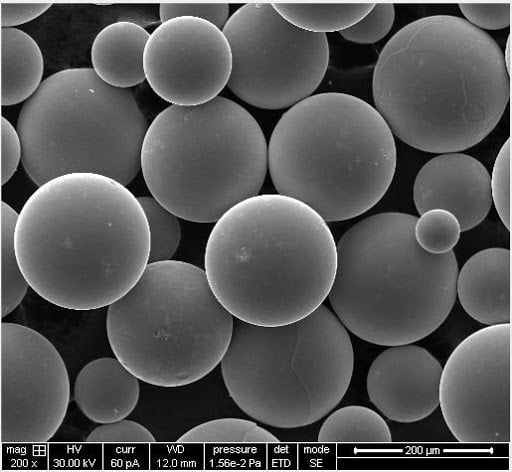

Sprzęt VIGA z pojedynczym piecem to najnowocześniejsza metoda produkcji wysokiej jakości proszków metalowych. Systemy te wykorzystują próżniowe topienie indukcyjne w połączeniu z atomizacją gazową w celu tworzenia drobnych, kulistych proszków o doskonałych właściwościach. Ta technika jest krytyczna dla branż wymagających precyzyjnych właściwości materiałów, takich jak sektory lotnictwa, motoryzacji i biomedycyny.

Rodzaje proszków metalowych produkowanych w piecu jednopiecowym VIGA

Zacznijmy od przyjrzenia się niektórym konkretnym modelom proszków metalowych produkowanych przez urządzenia VIGA z pojedynczym piecem. Oto szczegółowa lista, która pozwoli Ci się zapoznać:

| Model proszku metalowego | Skład | Kluczowe właściwości | Zastosowania |

|---|---|---|---|

| Stal nierdzewna 316L | Fe, Cr, Ni, Mo | Odporność na korozję, wysoka wytrzymałość | Implanty medyczne, sprzęt morski |

| Stal nierdzewna 17-4 PH | Fe, Cr, Ni, Cu, Nb | Wysoka wytrzymałość, odporność na korozję | Części lotnicze, obróbka chemiczna |

| Stop tytanu Ti-6Al-4V | Ti, Al, V | Wysoki stosunek wytrzymałości do wagi, biokompatybilność | Komponenty lotnicze, urządzenia medyczne |

| Inconel 718 | Ni, Cr, Fe, Nb, Mo | Odporność na ciepło, odporność na utlenianie | Części silników odrzutowych, reaktory jądrowe |

| Stop kobaltowo-chromowy | Współ, Cr, Mo, W | Odporność na zużycie, wysoka twardość | Implanty dentystyczne, urządzenia ortopedyczne |

| Stop aluminium AlSi10Mg | Al, Si, Mg | Lekka konstrukcja, dobre właściwości odlewnicze | Części samochodowe, konstrukcje lotnicze |

| Stal maraging | Fe, Ni, Co, Mo | Wysoka wytrzymałość, doskonała ciągliwość | Oprzyrządowanie, konstrukcje lotnicze i kosmiczne |

| Haynes 282 | Ni, Cr, Co, Mo, Ti | Wytrzymałość na pełzanie, stabilność termiczna | Turbiny gazowe, wymienniki ciepła |

| Stop miedzi C18150 | Cu, Cr, Zr | Wysoka przewodność elektryczna, dobra wytrzymałość | Komponenty elektryczne, elektrody spawalnicze |

| Nadstop niklu Nimonic 90 | Ni, Cr, Co, Ti, Al | Odporność na utlenianie, wytrzymałość na wysoką temperaturę | Łopatki turbiny, zawory wydechowe |

Zastosowania Urządzenia VIGA z pojedynczym piecem

Wszechstronność urządzeń VIGA z pojedynczym piecem jest widoczna w szerokim zakresie zastosowań. Oto kilka konkretnych zastosowań:

| Przemysł | Zastosowanie | Korzyści |

|---|---|---|

| Lotnictwo i kosmonautyka | Łopatki turbin, elementy konstrukcyjne | Wysoki stosunek wytrzymałości do masy, odporność na wysokie temperatury |

| Motoryzacja | Części silnika, lekkie konstrukcje | Poprawiona wydajność paliwowa, trwałość |

| Biomedyczne | Implanty, narzędzia chirurgiczne | Biokompatybilność, precyzja |

| Energia | Elementy reaktora jądrowego, wymienniki ciepła | Odporność na korozję i wysokie temperatury |

| Oprzyrządowanie | Formy, matryce | Odporność na zużycie, trwałość |

| Elektronika | Komponenty przewodzące | Wysoka przewodność elektryczna, niezawodność |

Szczegółowe specyfikacje, rozmiary i standardy

Zrozumienie specyfikacji i standardów proszków metalowych produkowanych przez urządzenia VIGA jest kluczowe dla wyboru odpowiedniego materiału do Twoich potrzeb. Oto zestawienie:

| Model proszku metalowego | Zakres wielkości cząstek | Standardy | Typowe zastosowania |

|---|---|---|---|

| Stal nierdzewna 316L | 15-45 µm | ASTM F138, ISO 5832-1 | Medyczne, morskie |

| Stal nierdzewna 17-4 PH | 20-63 µm | AMS 5643, ASTM A693 | Przemysł lotniczy i chemiczny |

| Stop tytanu Ti-6Al-4V | 15-45 µm | ASTM F1472, ISO 5832-3 | Lotnictwo i kosmonautyka, medycyna |

| Inconel 718 | 20-53 µm | AMS 5662, ASTM B637 | Silniki odrzutowe, jądrowe |

| Stop kobaltowo-chromowy | 10-50 µm | Normy ISO 5832-12 | Stomatologia, ortopedia |

| Stop aluminium AlSi10Mg | 20-60 µm | ISO 3522, ASTM B85 | Motoryzacja, lotnictwo i kosmonautyka |

| Stal maraging | 10-45 µm | AMS 6514, ASTM A538 | Oprzyrządowanie, lotnictwo i kosmonautyka |

| Haynes 282 | 20-53 µm | Normy AMS 5918 i ASTM B637 | Turbiny gazowe, wymienniki ciepła |

| Stop miedzi C18150 | 15-45 µm | ASTM B820, AMS 4596 | Elektryczne, spawalnicze |

| Nadstop niklu Nimonic 90 | 20-53 µm | Normy AMS 5829 i ASTM B637 | Łopatki turbiny, zawory wydechowe |

Dostawcy i szczegóły dotyczące cen

Jeśli chodzi o zakup proszków metalowych produkowanych za pośrednictwem urządzenia VIGA jednopiecowe, znajomość dostawców i cen jest kluczowa. Oto lista niektórych wybitnych dostawców i ich przybliżone ceny:

| Dostawca | Modele proszkowe | Cena (za kg) | Usługi dodatkowe |

|---|---|---|---|

| Höganäs | 316L, Ti-6Al-4V, Inconel 718 | $50-$200 | Niestandardowe rozmiary, wsparcie techniczne |

| Technologia Carpenter | 17-4 PH, stal maraging | $60-$250 | Doradztwo metalurgiczne, stopy niestandardowe |

| Sandvik | Kobalt-Chrom, Haynes 282 | $80-$300 | Testowanie jakości, wsparcie badawczo-rozwojowe |

| Technologia LPW | AlSi10Mg, stop miedzi C18150 | $40-$150 | Zarządzanie cyklem życia proszku, identyfikowalność |

| AP&C (GE Additive) | 316L, Ti-6Al-4V, Inconel 718 | $55-$220 | Zaawansowana charakterystyka, usługi recyklingu |

| Praxair Surface Technologies | Inconel 718, Nimonic 90 | $70-$280 | Inżynieria aplikacji, rozwiązania powłokowe |

Zalety i wady Urządzenia VIGA z pojedynczym piecem

Przyjrzyjmy się bliżej zaletom i wadom stosowania systemów VIGA z pojedynczym piecem do produkcji proszków metalowych:

| Zalety | Wady |

|---|---|

| Wysoka czystość:Środowisko próżniowe minimalizuje zanieczyszczenie. | Koszt:Wysokie początkowe koszty inwestycyjne i operacyjne. |

| Jednolity rozmiar cząstek: Stała jakość proszku. | Złożoność: Wymaga wykwalifikowanych operatorów i konserwacji. |

| Wszechstronność:Nadaje się do szerokiej gamy stopów metali. | Zużycie energii:Znaczne zużycie energii. |

| Ulepszone właściwości materiału:Poprawione właściwości mechaniczne proszków. | Ograniczona pojemność:Pojedynczy piec ogranicza wielkość produkcji w porównaniu do konfiguracji z wieloma piecami. |

Najczęściej zadawane pytania

| Pytanie | Odpowiedź |

|---|---|

| Do czego służy sprzęt jednopiecowy VIGA? | Stosowany jest do produkcji wysokiej jakości proszków metalowych dla różnych gałęzi przemysłu, m.in. lotniczego, motoryzacyjnego i biomedycznego. |

| Jak działa urządzenie VIGA jednopiecowe? | Technologia ta wykorzystuje technologię indukcyjnego topienia w próżni w połączeniu z atomizacją gazową w celu uzyskania drobnych, kulistych proszków metalowych. |

| Jakie są korzyści ze stosowania maszyn VIGA do produkcji proszków metalowych? | Do zalet należą wysoka czystość, jednolity rozmiar cząstek i ulepszone właściwości materiału. |

| Jakie metale można obrabiać przy użyciu urządzeń VIGA? | Szeroka gama produktów obejmująca stale nierdzewne, stopy tytanu, superstopy niklu i wiele innych. |

| Czy istnieją jakieś ograniczenia w stosowaniu urządzeń VIGA z pojedynczym piecem? | Tak, ale wiąże się to z wysokimi kosztami, złożonością i ograniczoną zdolnością produkcyjną. |

| Które branże czerpią największe korzyści ze stosowania proszków VIGA? | Przemysł lotniczy i kosmiczny, motoryzacyjny, biomedyczny, energetyczny, narzędziowy i elektroniczny. |

| Jakie są typowe rozmiary cząstek proszków produkowanych przez firmę VIGA? | Rozmiary cząstek wahają się zazwyczaj od 10 do 63 mikronów, w zależności od stopu i konkretnych wymagań. |

| Jak VIGA wypada w porównaniu z innymi metodami produkcji prochu? | Metoda VIGA zapewnia wyższą czystość i lepszą kontrolę nad wielkością cząstek, ale może być droższa i bardziej złożona niż inne metody, takie jak atomizacja wody. |

Wnioski

Jednopiecowy sprzęt VIGA to przełom w dziedzinie produkcji proszków metalowych, oferujący niezrównaną czystość, spójność i wszechstronność. Niezależnie od tego, czy pracujesz w przemyśle lotniczym, motoryzacyjnym czy biomedycznym, zrozumienie zawiłości technologii VIGA może pomóc Ci podejmować świadome decyzje i korzystać z zalet wysokiej jakości proszków metalowych.

Jeśli masz więcej pytań lub potrzebujesz szczegółowych informacji, skontaktuj się z nami. Zanurz się w świecie zaawansowanej metalurgii dzięki jednopiecowemu sprzętowi VIGA i podnieś swoje możliwości materiałowe na nowe wyżyny!

Udostępnij

MET3DP Technology Co., LTD jest wiodącym dostawcą rozwiązań w zakresie produkcji addytywnej z siedzibą w Qingdao w Chinach. Nasza firma specjalizuje się w sprzęcie do druku 3D i wysokowydajnych proszkach metali do zastosowań przemysłowych.

Zapytaj o najlepszą cenę i spersonalizowane rozwiązanie dla Twojej firmy!

Powiązane artykuły

Wysokowydajne segmenty łopatek dysz: Rewolucja w wydajności turbin dzięki drukowi 3D w metalu

Czytaj więcej "

Drukowane w 3D mocowania dla samochodowych czujników radarowych: Precyzja i wydajność

Czytaj więcej "Informacje o Met3DP

Ostatnia aktualizacja

Nasz produkt

KONTAKT

Masz pytania? Wyślij nam wiadomość teraz! Po otrzymaniu wiadomości obsłużymy Twoją prośbę całym zespołem.

Proszki metali do druku 3D i produkcji addytywnej

PRODUKT

cONTACT INFO

- Miasto Qingdao, Shandong, Chiny

- [email protected]

- [email protected]

- +86 19116340731