Bästa 17-4PH rostfritt stålpulver för 3D-utskrift

17-4PH-pulver, även känt som 17-4 Precipitation Hardening rostfritt stålpulver, är ett höghållfast, korrosionsbeständigt material som används i olika industrier. Det tillhör den martensitiska rostfria stålfamiljen och erbjuder en utmärkt kombination av mekaniska egenskaper och korrosionsbeständighet. Beteckningen "17-4PH" hänvisar till legeringens sammansättning, som består av cirka 17% krom, 4% nickel, 4% koppar och en liten mängd andra element.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt över 17-4PH rostfritt stålpulver för 3D-utskrift

17-4PH är ett utfällningshärdande rostfritt stålpulver som ofta används för additiv tillverkning av höghållfasta, korrosionsbeständiga komponenter inom flyg-, medicin-, fordons- och allmän ingenjörstillämpning.

Den här artikeln ger en detaljerad guide till 17-4PH-pulver för 3D-utskrift. Den täcker sammansättning, egenskaper, utskriftsparametrar, applikationer, specifikationer, leverantörer, hantering, inspektion, jämförelser, för- och nackdelar och vanliga frågor. Nyckelinformation presenteras i tabeller som är lätta att referera.

Sammansättning av 17-4PH pulver

17-4PH är ett krom-kopparutfällningshärdande rostfritt stål med en sammansättning av:

| Element | Vikt % | Syfte |

|---|---|---|

| Järn | Balans | Huvudmatriselement |

| Krom | 15 – 17.5 | Oxideringsbeständighet |

| Koppar | 3 – 5 | Härdning genom utfällning |

| Nickel | 3 – 5 | Stabilisator av austenit |

| Niob | 0.15 – 0.45 | Hårdmetallformare |

| Mangan | 1 max | Desoxidationsmedel |

| Kisel | 1 max | Desoxidationsmedel |

| Kol | 0,07 max | Förstärkare och hårdmetallformare |

Koppar ger utfällningshärdning medan krom ger korrosionsbeständighet.

Egenskaper för 17-4PH pulver

17-4PH har en mångsidig kombination av egenskaper:

| Fastighet | Beskrivning |

|---|---|

| Hög hållfasthet | Draghållfasthet upp till 1310 MPa i åldrat skick |

| Hårdhet | Upp till 40 HRC i åldern |

| Korrosionsbeständighet | Jämförbar med 316L rostfritt i många miljöer |

| Tålighet | Överlägsen martensitiska rostfria stål |

| Slitstyrka | Bättre än rostfritt stål i 300-serien |

| Stabilitet vid hög temperatur | Hållfastheten bibehålls upp till 300°C |

Egenskaperna gör den lämplig för olika applikationer, från plastformverktyg till flyg- och rymdkomponenter.

3D-utskriftsparametrar för 17-4PH pulver

Typiska parametrar för utskrift av 17-4PH inkluderar:

| Parameter | Typiskt värde | Syfte |

|---|---|---|

| Höjd på lager | 20-100 μm | Balans mellan hastighet och upplösning |

| Laserkraft | 150-400 W | Tillräcklig smältning utan avdunstning |

| Skanningshastighet | 400-1000 mm/s | Produktivitet vs densitet |

| Avstånd mellan luckor | 100-200 μm | Densitet och egenskaper |

| Stödstruktur | Minimal | Enkel borttagning |

| Varm isostatisk pressning | 1120°C, 100 MPa, 3 timmar | Eliminerar porositet |

Parametrar är optimerade för egenskaper, tid och efterbearbetningskrav.

Tillämpningar av 3D-tryckta 17-4PH delar

Additivt tillverkade 17-4PH-komponenter används i:

| Industri | Tillämpningar |

|---|---|

| Flyg- och rymdindustrin | Strukturella fästen, fixturer, manöverdon |

| Medicinsk | Tandimplantat, kirurgiska instrument |

| Fordon | Höghållfasta fästelement, kugghjul |

| Konsument | Klockfodral, sportutrustning |

| Industriell | Metallverktyg för slutanvändning, jiggar, fixturer |

Fördelarna med AM inkluderar komplexa geometrier, anpassning, minskad ledtid och bearbetning.

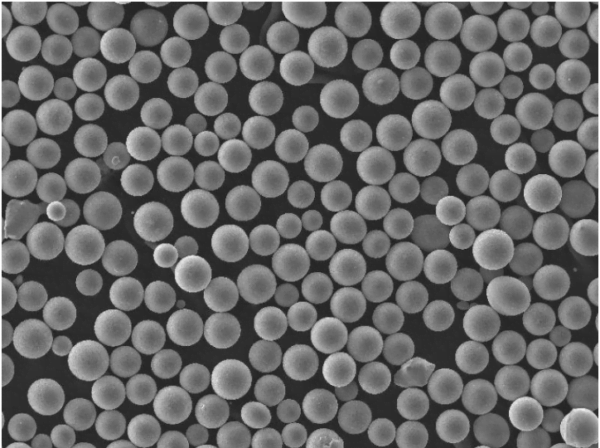

Specifikationer för 17-4PH-pulver för 3D-utskrift

17-4PH pulver måste uppfylla strikta specifikationer:

| Parameter | Specifikation |

|---|---|

| Partikelstorleksintervall | 15-45 μm typiskt |

| Partikelns form | Sfärisk morfologi |

| Skenbar densitet | > 4 g/cc |

| Tappdensitet | > 6 g/cc |

| Hall flödeshastighet | > 23 sekunder för 50 g |

| Renhet | >99,9% |

| Syrehalt | <100 ppm |

Anpassade storleksfördelningar och kontrollerade fuktnivåer tillgängliga.

Leverantörer av 17-4PH pulver

Ansedda leverantörer inkluderar:

| Leverantör | Plats |

|---|---|

| LPW-teknik | STORBRITANNIEN |

| Sandvik Osprey | STORBRITANNIEN |

| Snickare Tillsats | USA |

| Praxair | USA |

| Erasteel | Sverige |

| AMETEK | USA |

Priserna varierar från $50/kg till $120/kg baserat på renhet, storlek och beställningskvantitet.

Hantering och förvaring av 17-4PH-pulver

Som ett reaktivt material kräver 17-4PH-pulver kontrollerad hantering:

- Förvaras i svala, torra, inerta miljöer borta från fukt

- Förhindra oxidation och kontaminering under hantering

- Använd ledande behållare som är jordade för att förhindra statisk elektricitet

- Undvik ansamling av damm för att minimera explosionsrisken

- Lokal avgasventilation rekommenderas

- Bär personlig skyddsutrustning och undvik inandning

Noggrann förvaring och hantering säkerställer optimalt pulvertillstånd.

Inspektion och testning av 17-4PH-pulver

Metoder för kvalitetstestning inkluderar:

| Metod | Parametrar kontrollerade |

|---|---|

| Analys av siktar | Fördelning av partikelstorlek |

| SEM-avbildning | Partikelns morfologi |

| EDX | Kemi och sammansättning |

| XRD | Befintliga faser |

| Pyknometri | Täthet |

| Hall flödeshastighet | Flödbarhet för pulver |

Testning enligt ASTM-standarder verifierar pulverkvalitet och batchkonsistens.

Jämför 17-4PH med alternativa pulver

17-4PH jämförs med andra legeringar som:

| Legering | Styrka | Motståndskraft mot korrosion | Kostnad | Svetsbarhet |

|---|---|---|---|---|

| 17-4PH | Utmärkt | Bra | Medium | Rättvist |

| 316L | Medium | Utmärkt | Medium | Utmärkt |

| IN718 | Bra | Bra | Hög | Rättvist |

| CoCr | Medium | Rättvist | Medium | Utmärkt |

Med balanserade egenskaper ger 17-4PH den bästa kombinationen av styrka, korrosionsbeständighet och kostnad för många applikationer.

För- och nackdelar med 17-4PH-pulver för 3D-utskrift

| Proffs | Nackdelar |

|---|---|

| Högt förhållande mellan styrka och vikt | Lägre oxidationsbeständighet än austenitiska rostfria stål |

| Bra kombination av styrka och korrosionsbeständighet | Nödvändig efterbearbetning som HIP och värmebehandling |

| Lägre kostnad än exotiska legeringar | Förvaring i kontrollerad atmosfär krävs |

| Etablerade referenser inom AM | Svårt att svetsa och bearbeta |

| Jämförbara egenskaper med smidesmaterial | Känslig för grop- och spaltkorrosion |

17-4PH möjliggör högpresterande tryckta delar i alla branscher, men inte lämpade för extrema miljöer.

Vanliga frågor om 17-4PH Powder för 3D-utskrift

F: Vilket partikelstorleksintervall fungerar bäst för att trycka 17-4PH-legering?

S: Ett intervall på 15-45 mikron ger optimalt pulverflöde samtidigt som det möjliggör hög upplösning och densitet i de utskrivna delarna.

F: Vilken efterbearbetning krävs efter utskrift med 17-4PH?

S: Varm isostatisk pressning och värmebehandling är vanligtvis nödvändiga för att eliminera inre hålrum, lindra påfrestningar och uppnå optimala egenskaper.

F: Vilket material är 17-4PH mest jämförbart med för AM-applikationer?

S: Den är närmast 316L i korrosionsbeständighet men mycket starkare. 17-4PH ger den bästa övergripande kombinationen för många höghållfasta applikationer över 300-serien rostfritt.

F: Kräver 17-4PH stöd vid 3D-utskrift?

S: Minimala stöd rekommenderas på överhäng och komplexa inre kanaler för att förhindra deformation under utskrift och möjliggöra enkel borttagning.

F: Vilka industrier använder additivt tillverkade 17-4PH-komponenter?

S: Flyg-, medicin-, fordons-, industriverktyg och konsumentprodukter är de viktigaste applikationsområdena som drar nytta av 3D-utskrivna 17-4PH-delar.

F: Vilken noggrannhet och finish kan uppnås med 17-4PH AM-delar?

S: Efter efterbearbetning kan 17-4PH tryckta komponenter uppnå dimensionstoleranser och ytfinish jämförbar med CNC-bearbetade delar.

F: Vilken densitet kan förväntas med optimerade 17-4PH utskrifter?

S: Densiteter som överstiger 99% uppnås rutinmässigt med 17-4PH med hjälp av idealiska parametrar skräddarsydda för legeringen, matchande bearbetade egenskaper.

F: Är 17-4PH kompatibel med pulverbäddsfusionsprocesser?

S: Ja, det kan bearbetas med selektiv lasersmältning (SLM), direkt metalllasersintring (DMLS) och elektronstrålesmältning (EBM).

F: Vilka defekter kan uppstå vid utskrift av 17-4PH-komponenter?

S: Potentiella defekter är sprickbildning, förvrängning, porositet, ofullständig smältning och ytjämnhet. De kan minimeras genom optimerade utskriftsparametrar.

F: Kan stödstrukturer enkelt tas bort från 17-4PH tryckta delar?

S: Korrekt utformade minimala stöd är lätta att ta loss med tanke på legeringens utmärkta mekaniska egenskaper i åldrat tillstånd.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731