Al 3003 pulver

Al 3003-pulver är ett aluminiumlegeringspulver som huvudsakligen består av aluminium och mangan. Den tillhör 3xxx-serien av aluminiumlegeringar, som är kända för sin utmärkta bearbetbarhet och korrosionsbeständighet. Pulverformen möjliggör enkel hantering och bearbetning, vilket gör den lämplig för olika tillverkningstekniker.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt över Al 3003-pulver

Al 3003 eller 3A21 aluminium är en smideslegering som är känd för sin goda kallformbarhet, svetsbarhet och korrosionsbeständighet. Mangantillsatserna ökar hållfastheten genom solid lösningsförstärkning samtidigt som bearbetbarheten bibehålls.

Viktiga egenskaper hos Al 3003-pulver inkluderar:

- Måttlig hållfasthet med god duktilitet

- Utmärkt formbarhet och svetsbarhet

- God korrosionsbeständighet

- Hög termisk och elektrisk ledningsförmåga

- Låg densitet

- Finns i en rad olika pulverstorlekar och former

Al 3003 pulver används i stor utsträckning i kemiska tankar, rörledningar, bildelar, värmeväxlare, redskap och andra applikationer som behöver måttlig styrka, formbarhet och korrosionsbeständighet.

Kemisk sammansättning av Al 3003-pulver

Den typiska kemiska sammansättningen av Al 3003-pulver är:

| Element | Vikt % |

|---|---|

| Aluminium (Al) | Balans |

| Mangan (Mn) | 1.0-1.5% |

| Järn (Fe) | 0,7% max |

| Kisel (Si) | 0,6% max |

| Koppar (Cu) | 0.05-0.20% |

| Zink (Zn) | 0,10% max |

| Magnesium (Mg) | 0,10% max |

| Krom (Cr) | 0,10% max |

Mangan är det viktigaste legeringselementet i 3003 aluminium. Järn, kisel och koppar förekommer som orenheter. Sammansättningen kontrolleras för att säkerställa optimala egenskaper.

Egenskaper hos Al 3003-pulver

Al 3003 pulver har följande egenskaper:

| Fastighet | Värde |

|---|---|

| Täthet | 2,73 g/cm3 |

| Smältpunkt | 645-650°C |

| Termisk konduktivitet | 180 W/mK |

| Elektrisk konduktivitet | 43-44% IACS |

| Young's modul | 68-72 GPa |

| Poissonförhållande | 0.33 |

| Draghållfasthet | 145-185 MPa |

| Utbyteshållfasthet | 110-140 MPa |

| Töjning | 12-20% |

| Hårdhet | 35-55 Brinell |

Legeringen erbjuder måttlig hållfasthet med utmärkt duktilitet och formbarhet. Den har god motståndskraft mot atmosfärisk korrosion. Termisk och elektrisk ledningsförmåga är hög.

Produktionsmetod för Al 3003-pulver

Kommersiella produktionsprocesser som används för Al 3003-pulver inkluderar:

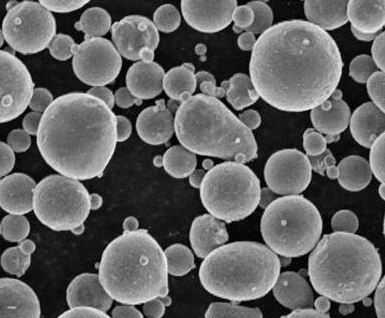

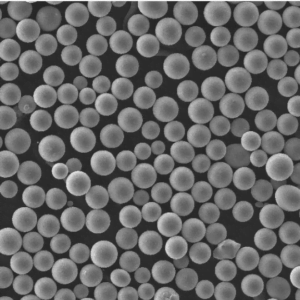

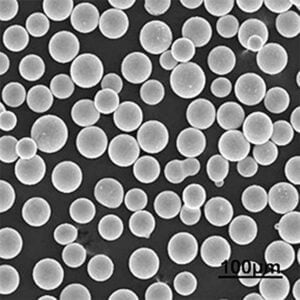

- Atomisering av gas - Smält legeringsström sönderdelas med högtrycksstrålar av inert gas till fina sfäriska pulver.

- Atomisering av vatten - Vattenstråle med hög hastighet träffar och sönderdelar smält metallström för att producera fina pulver.

- Mekanisk fräsning - Kulfräsning av aluminiumflingor/pulver för att uppnå finare partikelstorlekar och pulveregenskaper.

- Elektrolys - Aluminium som framställs genom elektrolysprocess och mals till fint pulver. Lägre renhet.

Gasatomisering ger den bästa kontrollen över partikelstorleksfördelning, morfologi och mikrostruktur hos pulvret.

Användningsområden för Al 3003-pulver

Al 3003 pulver används i följande huvudsakliga applikationer:

- Additiv tillverkning - Selektiv lasersmältning, binder jetting och andra 3D-printingprocesser för att tillverka komplexa komponenter.

- Pulvermetallurgi - Kompaktering och sintring för att skapa detaljer med goda mekaniska egenskaper och maskinbearbetbarhet.

- Formsprutning av metall - Att tillverka små komplicerade komponenter till fordons- och elektronikindustrin.

- Termisk sprutning - Trådbågesprutning för beläggning av Al 3003 med måttlig slitstyrka och korrosionsbeständighet.

- Fyllmedel för svetsning - Används som tillsatsmaterial vid bågsvetsning och reparation av aluminiumkomponenter.

- Pigment - Används i färger och ytbeläggningar för att ge lyster och korrosionsskydd.

- Pyroteknik - Tillsatt i pyrotekniska kompositioner som bränsle på grund av aluminiumets brandfarlighet.

Specifikationer för Al 3003 pulver

Al 3003-pulver finns i olika storleksintervall, former och renhetsgrader:

- Partikelstorlek: Från 10-150 mikrometer för AM-metoder, upp till 300 mikrometer för termisk sprutning.

- Morfologi: Sfäriska, granulerade, flingor och oregelbundna partikelformer. Slätt pulver flyter bättre.

- Renhet: Från kommersiella till högrena (99,8%) kvaliteter skräddarsydda för olika tillämpningar.

- Flytbarhet: Pulver kundanpassat för flöden över 25 s/50 g.

- Betyg: Överensstämmer med ASTM B209, EN 573-3, ISO 209:2007 etc. Anpassade kvaliteter erbjuds.

Globala leverantörer av Al 3003-pulver

Några av de största leverantörerna av Al 3003-pulver globalt är:

- Valimet Inc, USA

- Makin Metal Powders, Storbritannien

- Metal Powder Company, USA

- Shanghai Chaowei Nanotechnology, Kina

- AMETEK Reading Alloys, USA

- CNPC Powder Group, Kina

- SCM Metal Products, USA

Dessa företag tillverkar Al 3003-pulver som lämpar sig för additiv tillverkning, termisk sprutning, svetsning, pulvermetallurgi och andra användningsområden.

Al 3003 Pulver Prissättning

Prissättningen av Al 3003 pulver beror på faktorer som:

- Renhetsnivåer

- Fördelning av partikelstorlek

- Pulvrets egenskaper

- Orderkvantitet

- Ytterligare bearbetning

- Leverantör och plats

| Betyg | Prisintervall |

|---|---|

| Kommersiell | $3-8 per kg |

| Hög renhet | $8-15 per kg |

| Ultrafin | $15-30 per kg |

| Särskild klass | $30-60 per kg |

Ultrafina, sfäriska och gasatomiserade pulver betingar mycket högre priser än vanliga kommersiella kvaliteter.

Förvaring och hantering av Al 3003-pulver

Al 3003-pulver ska förvaras och hanteras på rätt sätt för att förhindra:

- Oxidation och reaktion med fukt

- Dammexplosioner från antändning av pulver

- Inandning av fint pulver orsakar hälsoproblem

- Säkerhetsrutiner som rekommenderas av leverantören ska följas

Förvaring av inert gas, tillräcklig ventilation, jordning och personlig skyddsutrustning rekommenderas vid hantering av pulvret.

Test- och karakteriseringsmetoder

Viktiga testmetoder som används för Al 3003-pulver inkluderar:

- Kemisk analys med hjälp av OES eller XRF för sammansättning

- Partikelstorleksfördelning enligt ASTM B822-standarden

- Morfologisk analys genom SEM-bildtagning

- Mätning av flödeshastighet med Hall-flödestratt

- Densitetsbestämning med heliumpyknometri

- Test av föroreningar med ICP-MS

- Mikrostrukturundersökning med röntgendiffraktion

Dessa testmetoder säkerställer tillförlitlig och konsekvent kvalitet på aluminiumlegeringspulvret.

Jämförelse mellan Al 3003- och Al 6061-pulver

Al 3003 och Al 6061 är två aluminiumlegeringspulver som jämförs:

| Parameter | Al 3003 | Al 6061 |

|---|---|---|

| Legeringstyp | Ej värmebehandlingsbar | Värmebehandlingsbar |

| Mn-innehåll | 1.0-1.5% | 0,15% max |

| Mg-innehåll | 0,1% max | 0.8-1.2% |

| Styrka | Måttlig | Högre |

| Korrosionsbeständighet | Bra | Utmärkt |

| Svetsbarhet | Utmärkt | Bra |

| Kostnad | Lägre | Högre |

| Tillämpningar | Kemikalietankar, redskap | Flyg- och rymdindustrin, bildelar |

Al 6061 ger högre hållfasthet medan Al 3003 ger bättre svetsbarhet och formbarhet till en lägre kostnad.

Vanliga frågor om Al 3003-pulver

F: Hur produceras Al 3003-pulver?

S: Al 3003-pulver tillverkas kommersiellt med hjälp av gasatomisering, vattenatomisering, mekanisk fräsning och elektrolysprocesser. Gasatomisering ger den bästa kontrollen över partikelegenskaperna.

F: Vilka är de viktigaste användningsområdena för Al 3003-pulver?

S: Viktiga användningsområden är additiv tillverkning, termisk sprutning, pulvermetallurgi, formsprutning av metall, svetsfyllnadsmedel, pigment och pyrotekniska kompositioner.

F: Vilken är den typiska pulverstorleken för Al 3003 som används för lasersintring?

A: För selektiv lasersintringsprocess är det vanliga Al 3003-pulverstorleksintervallet 20-53 mikron med sfärisk morfologi för optimal pulverbäddens densitet.

F: Kräver Al 3003-pulver några särskilda försiktighetsåtgärder vid hantering?

S: Ja, aluminiumpulver kan vara brandfarligt och utgöra en explosionsrisk. Det rekommenderas att hantera dem försiktigt under inert atmosfär med korrekt jordning, ventilation och personlig skyddsutrustning.

F: Var kan jag köpa Al 3003-pulver som är lämpligt för beläggningar med termisk sprutning?

A: Företag som Valimet, Makin Metal Powders och AMETEK erbjuder Al 3003-kvaliteter som är lämpliga för trådbågssprutning och flamsprutningsbeläggningar som kräver måttlig slitstyrka och korrosionsbeständighet.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731