Inconel 718 Powder: Price,Specifications

Table of Contents

Inconel 718 is a high-performance nickel-chromium-based superalloy exhibiting excellent strength and corrosion resistance at elevated temperatures up to 700°C. This guide provides a detailed overview of Inconel 718 powder covering its characteristics, applications, manufacturing process, specifications, pricing, pros and cons, and frequently asked questions.

Overview of Inconel 718 Powder

Inconel 718 powder contains nickel, chromium, niobium, molybdenum, titanium and aluminum as its major alloying elements. Key properties:

- High yield, tensile and creep rupture strength at temperatures up to 700°C

- Good fatigue and corrosion resistance

- Age hardenable microstructure

- Excellent cryogenic properties

- Higher strength compared to Inconel 625

Inconel 718 powder is used in aerospace components like gas turbine disks, rocket motor casings, cylinders, pumps and valves requiring high temperature capability.

Applications of Inconel 718 Powder

Inconel 718 powder finds usage in demanding applications across industries:

| Industry | Applications |

|---|---|

| Aerospace | Engine components, rocket motors, actuators, hovercraft parts |

| Oil and gas | Wellhead equipment, downhole tools, valves, pumps |

| Nuclear | Reactor vessels, transfer tube assemblies |

| Automotive | Turbocharger rotors, valves, exhaust manifolds |

| Chemical | Heat exchangers, pressure vessels, process piping |

Benefits offered by Inconel 718:

- High temperature strength for improved efficiency

- Corrosion resistance in harsh environments

- Excellent fatigue properties for rotating components

- Good cryogenic properties down to -253°C

- Oxidation resistance up to 700°C

Manufacturing Process for Inconel 718 Powder

Inconel 718 powder can be produced via processes like:

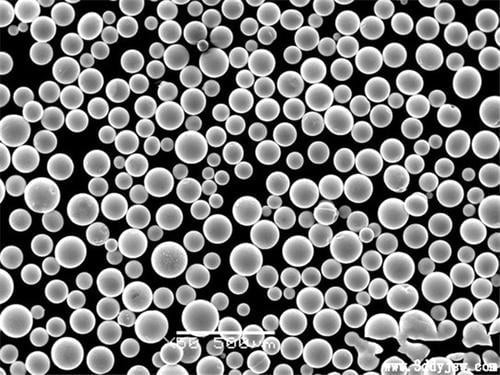

- Gas Atomization – Most common method where molten alloy is disintegrated by nitrogen/argon gas jets into fine droplets that solidify into powder particles. Provides spherical powder preferred for AM applications.

- Rotating Electrode Process – Electrode of alloy is spun at high speeds in an inert gas atmosphere and melted by an electric arc to generate fine droplets that solidify into powder.

- Plasma Rotating Electrode Process – Arc melting is done using ionized plasma jet instead of electric arc. It yields highly spherical powder ideal for AM.

- Vacuum Induction Melting – Alloy is induction melted under vacuum and the melt is then converted into powder using gas or water atomization process.

Gas atomization and PREP methods allow close control over powder characteristics like particle size distribution, morphology, oxide levels and microstructure.

Specifications of Inconel 718 Powder

Inconel 718 powder is available with the following specifications:

| Parameter | Specification |

|---|---|

| Alloy chemistry | 50-55% Ni, 17-21% Cr, 4.75-5.5% Nb+Ta, 2.8-3.3% Mo |

| Particle size | 10 to 150 microns |

| Particle shape | Spherical, irregular |

| Size distribution | Customizable based on application |

| Purity | Up to 99.9% |

| Oxygen level | <300 ppm |

| Apparent density | 2 – 4.5 g/cc |

| Flow rate | Up to 25 s/50g |

The specifications can be customized as per requirements for composition, particle characteristics, purity levels, density, and flow properties.

Suppliers and Pricing of Inconel 718 Powder

Some of the major suppliers and pricing for Inconel 718 powder include:

| Supplier | Location | Price Range |

|---|---|---|

| Sandvik | Germany | $90 – $220 per kg |

| Praxair | USA | $100 – $250 per kg |

| AP&C | Canada | $110 – $200 per kg |

| Met3DP | China | $70 – $150 per kg |

| Tekna | Canada | $140 – $280 per kg |

The price varies based on:

- Purity levels

- Particle size and distribution

- Sphericity and flowability

- Production method used

- Order quantity

- Additional analysis or treatment

Prices are higher for spherical and controlled particle size distribution powder.

Pros and Cons of Inconel 718 Powder

| Pros | Cons |

|---|---|

| High strength at elevated temperatures | Expensive compared to steel and titanium alloys |

| Excellent corrosion resistance | Lower thermal conductivity than copper alloys |

| Good fatigue strength and cryogenic toughness | Challenging to machine and grind |

| Age hardening capability | Subject to strain-age cracking |

| Oxidation resistance up to 700°C | Requires heat treatment for optimal properties |

| Non-magnetic property | Limited availability for larger sections |

Ideal for critical applications despite higher cost. Limitations include lower thermal conductivity, machinability issues, propensity for cracking during forming.

FAQs

Q: What is the typical composition range of Inconel 718 alloy?

A: Typical composition is 50-55% Ni, 17-21% Cr, 4.75-5.5% Nb, 2.8-3.3% Mo, 0.65-1% Ti, 0.2-0.8% Al and trace elements like Co, Cu, Mn, Si, P, S.

Q: What particle size is recommended for Inconel 718 powder for AM?

A: For powder bed fusion AM, Inconel 718 powder with particle size range of 15-45 microns is typically used. Finer powder below 100 microns improves density and properties.

Q: What affects the pricing of Inconel 718 powder?

A: Pricing is affected by purity levels, particle characteristics like size range and sphericity, production method, order volume, additional analysis or treatment, and supplier profit margins.

Q: What is the role of niobium in Inconel 718 alloy?

A: Niobium is the key strengthening element in Inconel 718. It causes precipitation of intermetallic phases gamma double prime and gamma prime for high temperature strength and corrosion resistance.

Q: What are the typical applications of Inconel 718 alloy?

A: Inconel 718 is widely used in aircraft engines, rockets, pumps, nuclear reactors, and cryogenic tankage due to its high strength at elevated temperatures and good corrosion resistance.

Q: What are the alternatives to Inconel 718 for high temperature applications?

A: Alternatives include stainless steels like 310 and 330, iron-nickel alloys, cobalt alloys MP159 and FSX-414, and titanium alloys Ti-6242 and IMI 834. However, Inconel 718 remains superior.

Q: How does Inconel 718 compare with Inconel 625 in terms of properties?

A: Inconel 718 has higher tensile and creep rupture strength compared to Inconel 625 but lower oxidation and corrosion resistance. Inconel 625 is easier to weld and fabricate.

Q: What are the latest developments in Inconel 718 alloy?

A: New variants like Allvac 718Plus offer higher strength through composition modification. Research is ongoing to improve processing methods and properties using powder metallurgy and additive manufacturing.

Q: What makes Inconel 718 suitable for 3D printing applications?

A: Fine Inconel 718 powder with controlled particle size enables printing complex shapes with high density and superior mechanical properties compared to cast alloy components.

Conclusion

Inconel 718 nickel-based superalloy powder provides an exceptional combination of high temperature strength, corrosion resistance, fatigue properties and cryogenic toughness for critical applications where performance requirements are paramount. This guide summarizes Inconel 718 powder characteristics, manufacturing methods, pricing, pros and cons, and FAQs to support engineers, designers and technical teams in adopting this advanced material. With its unique properties, Inconel 718 powder will continue seeing high demand across aerospace, gas turbines, chemical and nuclear sectors.

know more 3D printing processes

Additional FAQs about Inconel 718 Powder (5)

1) What powder specifications matter most for PBF/SLM quality?

- Tight particle size distribution (typically 15–45 µm), high sphericity (>0.9), low satellites, Hall/Carney flowability within spec, and low interstitials (O ≤0.10–0.15 wt%, N ≤0.02 wt%, H ≤0.005 wt%). PSD and oxygen drive density, surface finish, and fatigue.

2) How many reuse cycles are safe for Inconel 718 powder in AM?

- With sieving and SPC, 5–15 cycles are common. Top up 20–50% virgin powder per cycle and track O/N/H, PSD, and flow. Requalify if oxygen approaches alloy or process limits (check AMS/ASTM specs) or if density/fatigue drifts.

3) What post-processing is typical for AM 718 parts to reach spec properties?

- Stress relief, HIP (e.g., 1180–1200°C, 100–150 MPa, 2–4 h), and aging per AMS 5662/5664 equivalents (two-step age). Finish machining and surface treatments as required. HIP markedly improves fatigue and closes lack-of-fusion porosity.

4) How do gas atomization parameters affect powder quality?

- Inert gas purity and pressure, melt superheat, and nozzle design influence sphericity, oxide films, and satellite content. Argon vs nitrogen selection and low oxygen melt handling reduce oxide/nitride inclusions that harm fatigue.

5) Is Inconel 718 powder suitable for Binder Jetting as well as PBF?

- Yes. BJ requires tailored PSD (often 5–25 µm or 15–38 µm), flow modifiers, and debind/sinter/HIP recipes. Final density and elongation may lag PBF unless HIP is applied; still attractive for cost-sensitive, high-throughput geometries.

2025 Industry Trends for Inconel 718 Powder

- Tighter interstitial controls: Powder buyers specify lower oxygen (≤0.08–0.12 wt%) for fatigue-critical aerospace builds; vendors offer enhanced de-oxidation routes.

- Multi-laser PBF drives demand: 8–12 laser systems increase powder consumption rates; closed-loop sieving and automated conveying become standard.

- Traceability and sustainability: Digital MTRs link heats to build IDs; suppliers publish EPD-style data for Scope 3 reporting, including powder recycle rates.

- AM allowables expansion: More design allowables for AM 718 published under aerospace programs, aligning with ASTM F3301 process control plans.

- Price stabilization: Nickel volatility moderates vs 2024; lead times ease with added atomization capacity in NA/EU/Asia.

2025 snapshot: Inconel 718 Powder metrics

| Metric | 2023 | 2024 | 2025 YTD | Notes/Sources |

|---|---|---|---|---|

| Typical AM-grade PSD (µm) | 15–53 | 15–45 | 15–45 | PBF focus; BJ often finer |

| Oxygen spec (wt%, AM grade) | ≤0.15 | ≤0.12–0.15 | ≤0.08–0.12 | Buyer specs; aerospace lots |

| As-built PBF density (%) | 99.5–99.9 | 99.6–99.95 | 99.7–99.95 | Parameter/machine dependent |

| UTS after HIP + age (MPa) | 1250–1400 | 1300–1450 | 1320–1460 | Vendor/OEM datasets |

| Powder price (USD/kg, AM grade) | 110–240 | 120–260 | 115–240 | PSD/sphericity/volume affect |

| Avg powder reuse cycles (count) | 6–10 | 8–12 | 10–15 | With SPC and top-ups |

References:

- ASTM Committee F42 and ISO/ASTM 52907 (metal powder requirements): https://www.astm.org, https://www.iso.org

- SAE/AMS for IN718 (AMS 5662/5663/5664) and AM materials (AMS 7000-series): https://www.sae.org

- OEM technical notes (EOS, GE Additive, 3D Systems) and NIST AM resources: https://www.nist.gov

Latest Research Cases

Case Study 1: Multi‑Laser PBF of Inconel 718 with Low‑Oxygen Powder for Fatigue‑Critical Brackets (2025)

Background: An aerospace Tier‑1 needed improved HCF performance on flight brackets produced on an 8‑laser PBF line.

Solution: Switched to low‑O (≤0.10 wt%) AM‑grade powder with automated closed-loop sieving; implemented in‑situ monitoring and standardized HIP + AMS‑aligned aging. SPC tracked O/N/H and PSD across 12 reuse cycles.

Results: 99.92% density as-built; UTS 1380–1440 MPa post‑HIP/age; HCF life +18% vs prior lot; powder O remained ≤0.11 wt% through 10 cycles; cost/part −9% via reduced scrap.

Case Study 2: Binder‑Jetted IN718 Turbine Seals with Sinter + HIP Consolidation (2024)

Background: Industrial gas turbine supplier sought cost reduction on complex seals.

Solution: Deployed BJ‑optimized IN718 powder (15–38 µm) and reducing-atmosphere debind/sinter, followed by HIP and aging. Distortion simulation guided setters and scaling.

Results: Final density 99.5%; dimensional Cp/Cpk ≥1.33; part count consolidated from 3 to 1; cost −22% at 10k units/year; mechanicals met house spec comparable to cast + HIP baseline.

Expert Opinions

- Dr. Hamish L. Fraser, Professor, The Ohio State University

Key viewpoint: “Powder cleanliness—especially oxygen and inclusions—directly correlates with fatigue in AM Inconel 718. HIP heals pores, but you can’t ‘HIP away’ nonmetallic inclusions.”

Source: Academic publications/talks on Ni-base superalloys: https://mse.osu.edu - Dr. Laura Ely, SVP Technology, 3D Systems

Key viewpoint: “Consistent properties in AM 718 come from disciplined powder lifecycle management: documented reuse, sieving, and interstitial tracking tied to build genealogy.”

Source: OEM technical notes: https://www.3dsystems.com - Michael Pepi, Senior Metallurgist, ATI Specialty Materials

Key viewpoint: “Dual-melt routes (VAR + ESR) for precursor feedstock reduce inclusion populations and improve downstream atomized powder quality for critical aerospace builds.”

Source: Producer datasheets/briefs: https://www.atimaterials.com

Practical Tools and Resources

- Standards and specifications:

- ASTM B637 (wrought 718), AMS 5662/5663/5664 (heat treatment), AMS 7000-series (AM), ISO/ASTM 52907 (powder): https://www.astm.org, https://www.sae.org, https://www.iso.org

- Process control and qualification:

- ASTM F3301 (PBF process control), CT standards (ASTM E1441), ISO 52930 (qualification): standards portals above

- Materials data and guides:

- Special Metals Alloy 718 datasheet: https://www.specialmetals.com

- NIST AM materials resources: https://www.nist.gov

- Powder suppliers and datasheets:

- Sandvik Osprey, Carpenter Additive, AP&C, Tekna: supplier websites with PSD/chemistry specs

- Simulation and QA:

- Ansys Additive/Workbench for distortion/HIP simulation: https://www.ansys.com

- CT and metallography service labs; leak testing references for internal channels

Notes on reliability and sourcing: Request full MTRs including interstitials and inclusion ratings; verify PSD via laser diffraction and morphology via SEM. Implement SPC on powder O/N/H and flow, maintain lot/build traceability, and requalify after any significant powder/process change. For critical parts, include HIP, CT, and statistically based coupon testing.

Last updated: 2025-10-15

Changelog: Added 5 focused FAQs, 2025 trend snapshot with data table and sources, two case studies, expert viewpoints with attributions, and a curated tools/resources list specific to Inconel 718 powder specification, pricing, and AM use

Next review date & triggers: 2026-02-15 or earlier if AMS/ASTM specs are revised, nickel market shifts >10%, or major OEMs publish new AM 718 powder cleanliness/fatigue datasets

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

Metal 3D Printing for U.S. Automotive Lightweight Structural Brackets and Suspension Components

Read More »About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.