SLM Technology

Redefining Metal Fabrication

Discovering the Potential of SLM Technology

Welcome to the realm of precision engineering: Metal3DP’s Selective Laser Melting (SLM) Technology. As pioneers in this field, we’re dedicated to harnessing the power of SLM to redefine the possibilities of metal component fabrication.

Selective Laser Melting (SLM) is an advanced additive manufacturing technique that transforms metal powder into intricate, fully functional components through a precise layer-by-layer fusion process.

Principle and Process

SLM operates on a fundamental principle – utilizing a high-energy laser to selectively melt and fuse metal powders layer by layer. This meticulous process achieves intricate, highly detailed designs with unprecedented accuracy.

Limitations and Considerations

While SLM boasts exceptional precision, it’s essential to acknowledge limitations such as build size constraints and surface finish considerations.

Advantages of SLM Technology

Advantages 01

Intricate Customization

SLM empowers the creation of complex, customized components that were once unattainable through traditional methods.

Advantages 02

Materials Mastery

SLM accommodates a diverse array of metals and alloys, allowing for the tailored manipulation of material properties.

Advantages 03

Precision Perfected

The layer-by-layer approach results in components of exceptional accuracy and quality.

Advantages 04

Waste Reduction

SLM’s near-net shape production minimizes material waste, setting it apart from traditional subtractive methods.

Advantages 05

Accelerated Prototyping

SLM expedites prototyping cycles, enabling rapid iterations and design optimization.

Application of SLM Technology

SLM Technology is a game-changer in additive manufacturing, opening doors to a multitude of industries seeking precision and complexity in metal components.

Aerospace

SLM reshapes aerospace with intricate engine components and lightweight structures, improving aircraft efficiency and performance.

Medical

From implants to surgical tools, SLM creates biocompatible, patient-specific medical solutions with unmatched precision.

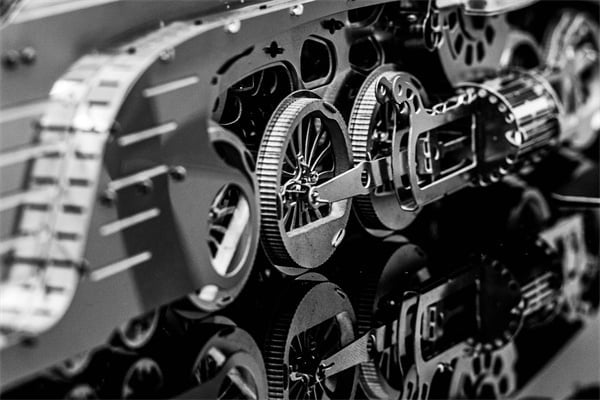

Automotive

SLM’s ability to produce intricate and lightweight components transforms automotive design, enhancing fuel efficiency and overall performance.

mechanical

SLM is a cornerstone in producing complex parts for machinery, tooling, and advanced mechanical systems.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731