High-Resolution Metal 3D Printing in Seoul: A Complete Guide for B2B Buyers, Distributors & Manufacturers

Table of Contents

1. Introduction: The Rise of High-Resolution Metal 3D Printing in Seoul

The industrial landscape in South Korea is undergoing a transformative shift. From aerospace and medical devices to electronics and automotive, manufacturers in Seoul and beyond are embracing high-resolution metal 3D printing to stay competitive in a rapidly digitizing global market. For B2B buyers, distributors, and OEMs in Seoul, this shift presents a unique opportunity to optimize production, reduce lead times, and innovate faster.

Why Metal 3D Printing Is Booming in Seoul

Seoul, as the innovation hub of South Korea, has always been at the forefront of adopting emerging technologies. With the increasing demand for complex, lightweight, and durable components, traditional manufacturing methods are often too slow or costly. High-resolution metal 3D printing fills this gap by offering:

- Unprecedented Design Freedom: Create complex geometries and internal channels impossible through casting or milling.

- Rapid Prototyping to Production: Move seamlessly from design to functional parts in days, not weeks.

- Reduced Waste: Additive manufacturing uses only the material needed, reducing scrap and cost.

- Localized Production: Manufacture parts closer to end users, minimizing logistics.

Key B2B Use Cases in Seoul

| Industry Sector | Applications of Metal 3D Printing |

|---|---|

| Aerospace | Lightweight engine parts, turbine blades, heat exchangers |

| Medical | Custom implants, dental prosthetics, orthopedic tools |

| Automotive | High-performance components, functional prototypes |

| Electronics | Heat sinks, EMI shielding, microstructure housings |

| Tooling & Molds | Injection molds, conformal cooling channels |

What “High-Resolution” Really Means in Metal AM

High-resolution 3D printing refers to the ability to produce parts with:

- Fine Feature Detail (typically <50 microns)

- High Dimensional Accuracy (±0.05 mm or better)

- Smooth Surface Finish (Ra ≤ 10μm before post-processing)

This level of precision is critical for industries like aerospace and medical, where tolerances are tight and performance is non-negotiable.

2. Market Trends & Growth Potential of Metal 3D Printing in South Korea

The South Korean additive manufacturing (AM) market—especially in Seoul—is growing at an impressive pace, driven by government support, R&D, and increasing demand for advanced manufacturing capabilities.

📈 Key Market Insights

| Metric | Statistic / Trend |

|---|---|

| Compound Annual Growth Rate | 25% CAGR in metal AM (2023–2028) |

| Government Investment | $100M+ in AM innovation centers and smart factories |

| Domestic 3D Printer Adoption | 60% of large manufacturers in Seoul use or plan to use AM |

| Export Growth | 3D printed parts & powders exported to US, EU, Japan |

Drivers of Growth

- National Smart Factory Initiatives: Under Industry 4.0, South Korea aims to digitize 30,000 factories by 2030.

- Defense & Space Programs: Increasing reliance on lightweight, high-strength 3D printed metal parts.

- Medical Customization Demands: Surge in demand for patient-specific implants and surgical guides.

Increasing Need for High-Quality Metal Powders

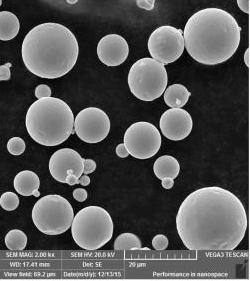

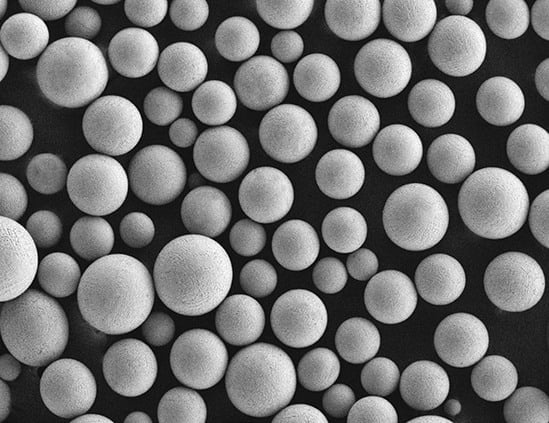

As high-resolution printing becomes mainstream, there’s a growing emphasis on the quality and consistency of metal powders used. Korean manufacturers are increasingly sourcing metal powders internationally due to:

- Limited local production of specialized alloys

- Better pricing and quality from global suppliers

- Demand for spherical powders with high flowability and purity

🔗 If you’re looking for advanced metal powders for high-resolution applications, check out Metal3DP’s product portfolio designed for aerospace, medical, and industrial-grade printing.

3. Key Factors to Consider When Choosing a Metal 3D Printing Supplier in Seoul

Choosing the right 3D printing service provider or equipment supplier in Seoul is crucial for B2B companies aiming for precision, repeatability, and scalability. Here are the top factors to evaluate:

✅ 1. Technical Capabilities

| Criteria | What to Look For |

|---|---|

| Printer Resolution | <50 microns; ability to print fine details |

| Layer Thickness Control | Adjustable for balance between speed and resolution |

| Powder Compatibility | Supports Ti, CoCr, Ni alloys, stainless steels, etc. |

| Post-Processing Options | Heat treatment, machining, polishing |

✅ 2. Material Quality & Availability

- Can the supplier produce or source high-purity spherical metal powders?

- Are they using gas atomization or PREP to ensure high flowability?

- Do they offer custom alloy development for specific use cases?

💡 Metal3DP is a global leader in producing high-quality metal powders using gas atomization and PREP technologies, enabling high-resolution, high-strength parts. Learn more about their metal 3D printing capabilities.

✅ 3. B2B Service Experience

- Does the supplier offer bulk pricing or wholesale supply agreements?

- Can they handle large-scale production or prototyping runs?

- Are they experienced in working with aerospace, medical, or automotive clients?

✅ 4. Support & Documentation

- Do they provide certificates of analysis (CoA) for material batches?

- Can they offer application support and training?

- Are they fluent in international shipping and compliance (RoHS, REACH, ISO)?

✅ 5. Location & Logistics

While a Seoul-based supplier offers local convenience, many B2B buyers also consider trusted overseas partners for better pricing and material diversity. That’s why partnerships with firms like Metal3DP in China are becoming increasingly popular.

🌐 Learn more about Metal3DP’s global presence and company mission to understand why they’re trusted by manufacturers worldwide.

Summary of This Section

| Evaluation Factor | Local Seoul Supplier | Global Supplier like Metal3DP |

|---|---|---|

| High-Res Printing Systems | ✔️ | ✔️ |

| Custom Metal Powders | ❌ Limited | ✔️ Advanced Alloys Available |

| Competitive Pricing | ❌ Higher | ✔️ Wholesale Discounts |

| Logistics Support | ✔️ | ✔️ International Shipping |

| Application Expertise | Varies | ✔️ Aerospace, Medical, Auto |

4. Top 5 High-Resolution Metal 3D Printing Suppliers in Seoul

Seoul is home to a growing number of advanced manufacturing companies offering metal 3D printing services. For B2B buyers, choosing a supplier with the right combination of technology, material capabilities, and industry specialization is key.

Here are five top-rated high-resolution metal 3D printing suppliers in Seoul for manufacturers, OEMs, and distributors:

🏆 1. Korea Institute of Industrial Technology (KITECH)

- Specialty: R&D-focused, materials development, precision manufacturing projects.

- Strengths:

- Government-backed research

- Expertise in powder metallurgy and electron beam melting

- Ideal for prototyping and pilot production

- Best For: Aerospace and medical device prototyping

🏆 2. InssTek Korea

- Specialty: Direct energy deposition (DED) metal 3D printers and services.

- Strengths:

- Proprietary DMT® (Directed Metal Tooling) technology

- High-resolution layering and metal deposition

- Custom material compatibility

- Best For: Tooling, molds, and repair applications

🏆 3. ProtoFab Korea

- Specialty: SLM and SLA-based 3D printing services for industrial clients.

- Strengths:

- Strong customer support

- High-precision metal parts production

- Batch production capabilities

- Best For: Automotive, electronic enclosures, and rapid prototyping

🏆 4. 3D Systems Korea

- Specialty: Global brand with local presence; wide range of metal and polymer printers.

- Strengths:

- Industrial-grade printers

- Verified material suppliers

- ISO-certified production workflows

- Best For: Enterprises needing repeatable, certified parts

🏆 5. KITECH Additive Manufacturing Center (Seongnam)

- Specialty: National R&D and prototyping hub.

- Strengths:

- Advanced research in metal powders

- Collaborative projects with global AM leaders

- Pilot-scale production

- Best For: Early-stage validation, material testing, innovation partnerships

Supplier Comparison Table

| Supplier Name | Technology Focus | Industries Served | Key Strength |

|---|---|---|---|

| KITECH | EBM, SLM | Aerospace, Medical | R&D and materials innovation |

| InssTek Korea | DED (DMT®) | Tooling, Automotive | High-resolution deposition control |

| ProtoFab Korea | SLM, SLA | Automotive, Electronics | Prototyping and batch runs |

| 3D Systems Korea | SLS, DMP | Aerospace, Medical | ISO-certified industrial printing |

| KITECH Seongnam | EBM, SLM | R&D, Industrial | Government-backed innovation center |

5. Why More B2B Buyers Are Turning to Overseas Metal Powder Suppliers

While Seoul-based suppliers offer convenience, many B2B buyers in South Korea are increasingly sourcing metal powders and equipment from reliable overseas manufacturers. This trend is driven by a few key factors:

🌍 The Globalization of Additive Manufacturing

- Global sourcing allows access to a broader range of alloys, including titanium aluminide, TiNbZr, and CoCrMo.

- International suppliers often offer better pricing and volume discounts for wholesale purchases.

- Overseas partners like Metal3DP provide advanced manufacturing capabilities that may not yet be available locally.

💡 Advantages of Sourcing Metal Powders from China

China has emerged as a major hub for high-quality metal powder production, especially for additive manufacturing. Companies like Metal3DP are leading the way by combining:

- State-of-the-art powder atomization systems

- Proprietary gas flow designs for spherical powders

- Consistent batch quality for high-resolution printing

Explore how Metal3DP’s powder making system leverages both gas atomization and PREP (Plasma Rotating Electrode Process) for unmatched powder quality.

📦 Wholesale Buyers Benefit from:

- Better Material Pricing: Save up to 30% compared to local sourcing

- High Flowability Powders: Ideal for laser and electron beam PBF

- Custom Alloy Development: Tailored solutions for aerospace, medical, and industrial clients

- International Logistics Support: Smooth customs clearance and documentation

🌐 Commonly Sourced Metal Powders:

| Alloy Type | Application Area | Metal3DP Availability |

|---|---|---|

| Ti6Al4V | Aerospace, Medical Implants | ✅ Yes |

| CoCrMo | Dental, Surgical Instruments | ✅ Yes |

| TiNbZr | Orthopedic Applications | ✅ Yes |

| Inconel 718 | High-Temp Aerospace Parts | ✅ Yes |

| Stainless 316L | General Engineering, Tools | ✅ Yes |

6. Why Choose Metal3DP as Your Trusted Metal 3D Printing Partner

Metal3DP is a global leader in additive manufacturing, offering a full suite of solutions for B2B buyers, including 3D printing equipment, high-performance metal powders, and application development.

🏭 Company Overview

- Headquarters: Qingdao, China

- Specialization: 3D printers and spherical metal powders

- Industries Served: Aerospace, Medical, Automotive, Tooling

Learn more about Metal3DP’s mission and global footprint.

💡 What Sets Metal3DP Apart

| Feature | Benefit to B2B Clients |

|---|---|

| Industry-Leading Print Volume | Print larger parts without compromising accuracy |

| Gas Atomization & PREP Powder | High sphericity and flowability for dense parts |

| Broad Alloy Portfolio | Includes TiNi, TiTa, CoCrMo, Inconel, and more |

| Application Development Support | Engineering help from prototype to production |

| Global Logistics Network | Fast delivery and export documentation assistance |

🎯 Ideal for B2B Buyers Who:

- Want to scale additive manufacturing with reliable materials and machines

- Need custom alloy development for mission-critical parts

- Seek a trusted and experienced partner for long-term supply chain collaboration

🔗 Looking to source high-performance printers or powders? View the full product catalog from Metal3DP.

📌 Client Success Snapshot

| Client Type | Region | Solution Provided | Outcome |

|---|---|---|---|

| Aerospace OEM | South Korea | Ti6Al4V Powder + SEBM Printer | Reduced part weight by 25% |

| Medical Supplier | Japan | CoCrMo Powder + Application Support | 3X faster implant prototyping |

| Automotive R&D | Germany | Custom Alloy Blend | Improved engine part durability |

7. How to Order High-Performance Metal Powders and Printing Equipment from China to Seoul

For B2B buyers in Seoul looking to upgrade their additive manufacturing capabilities, sourcing directly from an experienced international supplier like Metal3DP offers a strategic advantage. Whether you’re ordering large volumes of metal powders or investing in a new high-resolution printer, the process is straightforward, efficient, and cost-effective.

📝 Step-by-Step Ordering Guide

Here’s how B2B manufacturers, OEMs, and distributors in South Korea can order from Metal3DP:

| Step | Description |

|---|---|

| 1. Inquiry | Contact Metal3DP via the official website to request a quote. |

| 2. Specification Match | Provide your material or equipment requirements (e.g., Ti6Al4V powder, SEBM printer). |

| 3. Sample or Pilot Order | For powders: order a sample batch for qualification testing. <br> For printers: request a demo part or case study. |

| 4. Quotation & Lead Time | Receive FOB/CIF pricing, delivery estimates, and documentation. |

| 5. Payment & Shipping | Choose payment method (T/T, LC), and confirm international logistics details. |

| 6. Delivery & Support | Receive your order with COA, MSDS, and technical support. |

💼 Wholesale Options for B2B Buyers

Metal3DP offers flexible ordering options to accommodate businesses of all sizes:

- Bulk Powder Orders: From 10kg to metric ton scale

- OEM Partnerships: Custom powder blends and IP protection

- Equipment Sales: SEBM, SLM systems with installation support

- Annual Supply Agreements: Better pricing and delivery priority

📦 Ready to place an order? Visit Metal3DP’s metal 3D printing solutions page to explore your options.

🌏 Shipping & Compliance for South Korean Clients

- Lead Time: 5–14 days depending on material and quantity

- Documentation Provided:

- Commercial Invoice

- Certificate of Analysis (CoA)

- Material Safety Data Sheet (MSDS)

- Customs Declaration Forms

- HS Codes & Tariffs: Managed by Metal3DP’s experienced export team

- Shipping Methods:

- Air Freight (DHL/FedEx)

- Sea Freight (FOB Qingdao or CIF Incheon)

8. Frequently Asked Questions: Buying High-Resolution Metal 3D Printing Services in South Korea

Here are the most common questions B2B buyers ask about sourcing metal powders, printers, and services:

Q1: What industries benefit the most from high-resolution metal 3D printing?

A: Industries with strict performance and dimensional requirements benefit greatly, such as:

- Aerospace (e.g., turbine blades, brackets)

- Medical (e.g., orthopedic implants, dental crowns)

- Automotive (e.g., engine components, lightweight brackets)

- Tool & Die (e.g., conformal cooling molds)

Q2: What resolution and accuracy can I expect from Metal3DP printers?

A: Metal3DP printers deliver:

- Layer thickness: as low as 20–50 microns

- Dimensional accuracy: ±0.05 mm

- Surface finish: Ra ≤ 10μm (pre-finish)

This makes them ideal for mission-critical, fine-featured components.

Q3: Can Metal3DP support custom alloy powder development?

A: Yes. Metal3DP offers custom alloy formulation using advanced gas atomization and PREP technologies. You can collaborate on R&D-level alloy development for specialized applications.

🔗 Learn more about Metal3DP’s printing methods and powder technologies.

Q4: What are the minimum order quantities (MOQs) for powders?

A: MOQs typically start at:

- 5–10 kg for standard alloys

- 20–50 kg for custom alloys

Volume discounts are available for orders over 100 kg.

Q5: Do you provide post-processing services or equipment?

A: While Metal3DP focuses on powder production and printing systems, they can recommend or partner with post-processing vendors. Their SEBM and SLM machines also come with optional powder recovery and finishing modules.

9. Conclusion & Call to Action: Start Your B2B Metal Printing Journey with Expert Support

High-resolution metal 3D printing is no longer a futuristic concept—it’s a mission-critical manufacturing solution, especially in a tech-forward city like Seoul. Whether you’re a medical device supplier, aerospace OEM, or automotive innovator, additive manufacturing can give you a competitive edge in speed, precision, and scalability.

Why Metal3DP Is Your Ideal Partner

- ✅ Trusted by aerospace and medical clients worldwide

- ✅ Advanced metal powder technology using gas atomization and PREP

- ✅ Industry-leading printer resolution and reliability

- ✅ Seamless B2B order process with logistics support

- ✅ Custom alloy development and technical consulting

🌐 Ready to explore your options? Visit the Metal3DP homepage to speak with an expert or request a sample.

🧭 Final Checklist for B2B Buyers in Seoul

| Task | Status |

|---|---|

| Identify application requirements | ☐ |

| Evaluate local vs global suppliers | ☐ |

| Request technical specifications | ☐ |

| Order sample powders or demo parts | ☐ |

| Confirm logistics and documentation | ☐ |

| Partner with Metal3DP for next-gen AM | ☐ ✅ |

Thank you for reading our complete B2B guide on high-resolution metal 3D printing in Seoul. For tailored support, consultation, or to place an order, get in touch with Metal3DP today.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

Metal 3D Printing for U.S. Automotive Lightweight Structural Brackets and Suspension Components

Read More »About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.