Sustainable Production Using Recycled Metals in Paris: A Game-Changer for Wholesale Metal Buyers and Distributors

Table of Contents

1. Introduction: Why Sustainable Metal Production Is Transforming B2B Supply Chains

In today’s global industrial landscape, sustainability is no longer a trend—it’s a strategic imperative. For B2B buyers, OEMs, and metal distributors, the shift toward sustainable sourcing practices is being driven by regulatory demands, consumer expectations, and the pursuit of long-term cost efficiency. One of the most impactful changes in this sphere is the rise of recycled metals in manufacturing.

Paris, known for its commitment to green innovation, has become one of Europe’s leaders in sustainable industrial practices. With a strong focus on circular economy principles, the city is witnessing a surge in demand for recycled metals, particularly in high-performance sectors such as:

- Aerospace engineering

- Medical device manufacturing

- Automotive production

- Precision tooling and additive manufacturing

Sourcing recycled metals not only reduces environmental impact but also supports compliance with EU sustainability regulations like REACH and RoHS. For wholesale buyers, this presents an opportunity to gain a competitive edge by integrating eco-friendly materials into their supply chains.

Why B2B Buyers Should Prioritize Recycled Metals:

| Benefit | Description |

|---|---|

| 🌱 Environmental Compliance | Helps meet EU climate and material sustainability directives |

| 💰 Cost Efficiency | Recycled metals often come at a lower cost than virgin metals, without sacrificing quality |

| 🔄 Circular Economy Alignment | Supports closed-loop production systems |

| 🏭 Industrial Performance | High-quality recycled metals can meet or exceed the performance of primary raw materials |

| 📈 Market Advantage | Brands using sustainable materials are favored by both clients and regulators |

As companies increasingly seek to decarbonize their operations, sustainable metal production will be a cornerstone of future-ready manufacturing.

2. Market Trends: The Rise of Green Manufacturing and Recycled Metal Demand in France

The French metal industry is undergoing a profound transformation. The French government’s Green Industry Plan (France 2030) is channeling billions of euros into clean tech and sustainable manufacturing. This includes strong support for:

- Recycled raw materials

- Energy-efficient production

- Eco-certification frameworks

- Localized circular supply chains

Key Market Drivers in France:

- Regulatory Push: EU and French authorities are mandating stricter emissions and material traceability standards.

- Corporate ESG Mandates: Multinational companies are pressuring suppliers to comply with environmental, social, and governance (ESG) goals.

- Technological Advancements: Improved sorting, purification, and additive manufacturing technologies now enable high-quality output from recycled metals.

- Public Sentiment: Buyers and end-consumers are increasingly favoring eco-responsible brands.

Market Data Snapshot:

| Segment | 2023 Recycled Metal Usage in France | CAGR (2024–2030) |

|---|---|---|

| Aerospace | 18% of total alloys | 9.2% |

| Automotive | 37% of structural metal | 7.8% |

| Medical Devices | 12% of titanium used | 11.5% |

| General Manufacturing | 42% of steel and aluminum | 6.1% |

According to a 2023 report by the French National Institute of Industrial Ecology, the recycled metal market in France is projected to exceed €5.7 billion by 2030.

Paris: A Recycled Metal Innovation Hub

Paris is home to a growing ecosystem of eco-metal startups, research labs, and additive manufacturing suppliers. The city’s strategic location and access to European logistics networks make it a central hub for:

- Distribution of recycled ferrous and non-ferrous metals

- Supply of recycled powder materials for metal 3D printing

- Contract manufacturing using eco-certified metals

For global buyers and distributors, sourcing from Paris presents both logistical and environmental advantages.

3. Key Benefits of Using Recycled Metals for Wholesale Buyers and OEMs

Recycled metals are not just environmentally friendly—they’re also performance-optimized and cost-effective. For B2B buyers, especially those in high-tech or high-volume manufacturing, switching to recycled metals brings a range of operational and strategic benefits.

✅ Technical and Operational Benefits

| Feature | Benefit to OEMs & Distributors |

|---|---|

| High Purity Levels | Advanced recycling processes now deliver up to 99.8% purity |

| Alloy Customization | Recycled metals can be blended to meet specific industrial specs |

| Compatibility | Fully compatible with CNC, casting, and additive manufacturing |

| Mechanical Performance | Comparable tensile strength, fatigue resistance, and corrosion resistance |

| Reduced Lead Time | Local sourcing reduces shipping and customs delays |

✅ Financial Benefits for B2B Procurement

- Lower Raw Material Costs: Recycled metal suppliers often offer 10–30% savings compared to virgin material prices.

- Tax Incentives: Many EU governments, including France, offer tax reductions or subsidies for businesses using recycled materials.

- Long-term Cost Predictability: Recycled metals are less vulnerable to global commodity price volatility.

✅ Strategic Procurement Advantages

- Green Branding: Clients increasingly prefer suppliers with sustainable procurement policies.

- Compliance Simplification: Easier certification for ISO 14001, LEED, and other environmental standards.

- Stronger Supplier Relations: Working with green-certified partners fosters long-term collaboration and shared innovation.

🌟 Case in Point: Why More OEMs Are Choosing Met3DP’s Sustainable Metal Powders

As a global leader in additive manufacturing, Met3DP provides a full portfolio of sustainable 3D printing solutions, including high-performance metal powders produced using advanced gas atomization and PREP technology. Their powders—featuring alloys like TiAl, CoCrMo, and Inconel—are optimized for both performance and eco-responsibility.

Met3DP works with industries that demand the highest quality materials, including:

- Aerospace and space exploration firms using titanium-based recycled powders

- Medical device companies needing biocompatible alloys like CoCrMo

- Automotive OEMs incorporating lightweight, recycled aluminum alloys

By integrating Met3DP’s metal 3D printing solutions into your supply chain, your organization can reduce its carbon footprint, meet ESG targets, and stay competitive in a rapidly evolving industrial landscape.

🔍 Summary Table: Benefits of Recycled Metals for B2B Buyers

| Category | Benefit |

|---|---|

| Environmental | Reduces CO₂ emissions by up to 80% compared to virgin metal |

| Financial | 10–30% cost savings on raw material sourcing |

| Technical | High purity and mechanical strength |

| Strategic | Aligns with global ESG and compliance frameworks |

4. Top Recycled Metal Suppliers and Distributors in Paris and Greater France

With the rising demand for environmentally responsible sourcing, France—particularly Paris—has seen a surge in companies specializing in recycled metals for B2B use. These suppliers cater to industries ranging from aerospace and automotive to medical and energy sectors.

🇫🇷 Leading Recycled Metal Suppliers in Paris:

| Company | Location | Specialty | B2B Services Offered |

|---|---|---|---|

| Paprec Métal | Paris, France | Recycled ferrous and non-ferrous metals | Bulk distribution, scrap metal recovery, sorting |

| Derichebourg Environnement | Paris HQ | Industrial metal recycling, circular logistics | Custom alloys, metal certification, logistics support |

| Recytech | Hauts-de-France (near Paris) | Zinc and non-ferrous metal recycling | B2B alloy transformation, green certifications |

| EcoTitanium | Clermont-Ferrand (serves Paris region) | Recycled titanium alloys | Aerospace-grade materials, powder production |

| Recylex SA | Île-de-France | Lead, zinc and specialty metals | Closed-loop recycling, B2B sourcing programs |

🔍 What B2B Buyers Should Look for in a Recycled Metal Supplier:

- ISO 14001 or equivalent environmental certifications

- Traceability of metal origin and purity

- Experience in your specific industry (e.g., medical, aerospace, automotive)

- Capability to blend and customize alloys

- Proximity to transport hubs (for bulk orders)

For European and international buyers, sourcing from Paris-based suppliers not only reduces carbon emissions due to logistics proximity but also ensures compliance with EU sustainability directives.

5. Why Recycled Metal Is Becoming the Preferred Choice for Aerospace, Automotive, and Medical Industries

The adoption of recycled metals is no longer limited to low-grade applications. Today, advanced recycling and powder production technologies enable the use of sustainable metals in the most demanding environments.

✈️ Aerospace: Precision and Performance with Recycled Titanium

Aerospace manufacturers are under immense pressure to improve fuel efficiency and reduce emissions. Lightweight, high-strength recycled titanium alloys are now widely used in:

- Turbine blades

- Structural frames

- Landing gear components

Benefits:

- Up to 30% reduction in raw material cost

- Lower carbon footprint

- Consistent mechanical properties in high-heat environments

🚘 Automotive: Lightweight, Recycled Alloys for EV and ICE Vehicles

Electric vehicle (EV) manufacturers are especially proactive in using recycled aluminum and steel alloys. These metals are used in:

- Battery enclosures

- Body panels

- Structural beams

Advantages:

- Reduced vehicle weight = higher energy efficiency

- Easier sourcing from local recyclers

- Meets EU End-of-Life Vehicle Directive (ELV)

🏥 Medical Devices: Biocompatibility and Clean Manufacturing

Medical device manufacturers are increasingly turning to bio-grade recycled metals like CoCrMo and Ti6Al4V. Applications include:

- Joint implants

- Surgical instruments

- Dental frameworks

Key Features:

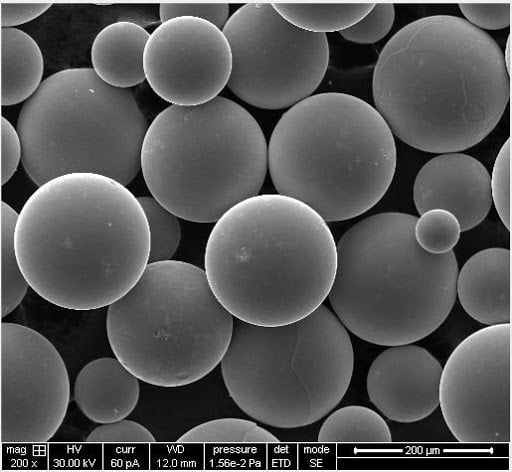

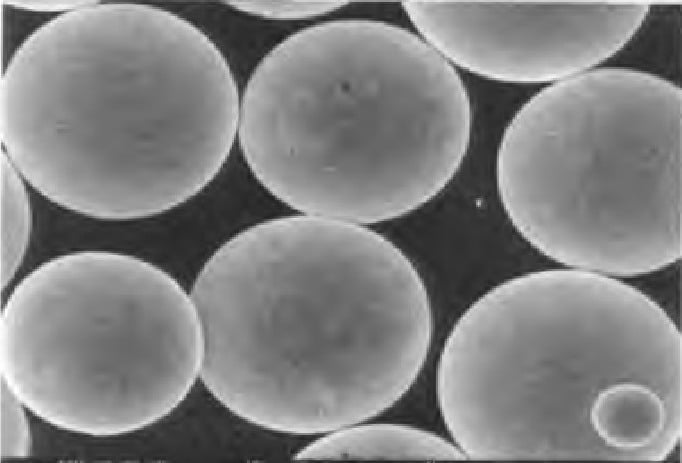

- High sphericity and flowability required for additive manufacturing

- Biocompatibility certified for regulatory approval

- Reduced material waste during production

🔬 The Role of Powder-Based Additive Manufacturing in These Industries

Additive manufacturing (AM) is the key enabler of sustainable metal usage in these sectors. Using recycled metal powders, engineers can create complex geometries with minimal waste.

Met3DP’s metal powder solutions are optimized for powder bed fusion (PBF), selective electron beam melting (SEBM), and direct energy deposition (DED)—ideal for mission-critical parts in aerospace, medical, and automotive fields.

6. Why Global Buyers Trust Met3DP for Sustainable Metal 3D Printing & Advanced Powders

As a global leader in metal additive manufacturing, Met3DP is redefining the standards for sustainable production. Headquartered in Qingdao, China, the company serves clients around the world—including buyers in Paris and across Europe—with cutting-edge 3D printing systems and eco-optimized metal powders.

🌱 Commitment to Sustainability

Met3DP integrates circular economy principles into every aspect of production:

- Advanced Powder Recycling: Uses gas atomization and PREP to remanufacture high-performance powders from recycled feedstock.

- Energy-Efficient Equipment: Designs 3D printers with low energy consumption and high print efficiency.

- Material Reusability: Offers powders with superior flowability and recyclability, reducing powder waste in AM processes.

🛠 Product Portfolio Tailored for B2B Clients

| Product Line | Description | Sustainability Highlight |

|---|---|---|

| SEBM Printers | Selective Electron Beam Melting systems for high-precision parts | High material utilization rate |

| Gas-Atomized Powders | Ultra-fine spherical powders for laser/electron beam PBF | Made from recycled metals |

| PREP Powders | Plasma rotating electrode process powders for advanced alloys | Ultra-clean, high-purity recycled alloy production |

| Custom Alloys | Tailored blends for specific industry applications | Circular sourcing from reclaimed materials |

📌 Learn more about Met3DP’s product solutions here

🌍 Global Reach, Local Service

While Met3DP operates globally, it works closely with regional partners and distributors to serve clients in Europe, including:

- Bulk powder shipments to Paris-based additive manufacturing labs

- Collaboration with aerospace and medical OEMs in France

- Support for EU compliance and certification processes

✅ Why B2B Buyers Choose Met3DP Over Competitors

| Feature | Met3DP | Other Suppliers |

|---|---|---|

| Gas Atomization & PREP | ✅ Yes | ❌ Limited |

| Recycled Powder Options | ✅ Yes | ❌ Rare |

| Industry-Specific Alloys | ✅ Full range | ⚠️ Limited catalog |

| Global Logistics Support | ✅ Yes | ⚠️ Regional only |

| End-to-End Service | ✅ Design to powder delivery | ❌ Not integrated |

📎 Explore how Met3DP supports sustainable metal 3D printing across industries.

🧪 Case Study: Met3DP Powers Circular Manufacturing with CoCrMo Recycled Powders

A French orthopedic implant manufacturer partnered with Met3DP to transition from virgin CoCrMo to recycled-grade powders. The result:

- 23% reduction in material cost

- 18% shorter production cycles due to better powder flowability

- Full ISO 13485 and ASTM F75 compliance

This transformation showcases Met3DP’s role as not just a material supplier—but a partner in innovation and sustainability.

7. How to Source High-Quality Recycled Metal Powders for 3D Printing Applications

For B2B buyers, especially those in the additive manufacturing (AM) industry, sourcing high-performance recycled metal powders is both a strategic and technical process. From powder morphology to flowability and purity, every parameter matters when you’re producing mission-critical components.

🧾 Key Considerations for B2B Buyers When Sourcing Recycled Metal Powders:

| Criteria | Why It Matters |

|---|---|

| Particle Size Distribution (PSD) | Determines laser/e-beam absorption and print resolution |

| Flowability | Affects powder spreading and part accuracy |

| Sphericity | Impacts powder recyclability and density of printed parts |

| Chemical Composition | Must match application-specific alloy standards (e.g., ASTM, ISO) |

| Source Traceability | Required for regulated industries (aerospace, medical) |

| Recyclability | Important for long-term cost savings and sustainability goals |

📦 Recommended Procurement Steps:

- Define Performance Specs: Establish required mechanical properties and applicable standards (e.g., Ti6Al4V Grade 23 for medical implants).

- Request Material Data Sheets (MDS): Ensure suppliers can provide full traceability and testing data (e.g., ICP-OES, SEM analysis).

- Evaluate Sample Batches: Test powder flow, printability, and post-processing characteristics with your AM system.

- Check Certification: Look for ISO 9001, ISO 13485, or AS9100 depending on your industry.

- Negotiate Bulk Supply Contracts: Secure volume discounts and consistent quality through long-term agreements.

📌 Met3DP’s Metal Powder Offering for Recycled AM Use

Met3DP manufactures a wide range of high-quality recycled and custom metal powders optimized for:

- Laser Powder Bed Fusion (LPBF)

- Electron Beam Melting (EBM)

- Directed Energy Deposition (DED)

- Binder Jetting & Hybrid AM-CNC manufacturing

Their advanced powder-making systems use gas atomization and PREP to achieve:

- ✅ High sphericity (≥ 95%)

- ✅ Narrow PSD control (15–45 μm for LPBF)

- ✅ Excellent flowability (Hall Flow ≤ 15 sec/50g)

- ✅ Low oxygen content (≤ 0.02% for titanium alloys)

🔩 Available Recycled Metal Powders from Met3DP:

| Alloy | Application | Available Forms | Sustainability Focus |

|---|---|---|---|

| Ti6Al4V (Grade 5 & 23) | Aerospace, Medical | Gas Atomized, PREP | Recycled titanium feedstock |

| CoCrMo | Implants, Dental | PREP | Biocompatible, circular supply |

| Inconel 718 | Turbines, Heat exchangers | Atomized | High-temperature recycled alloy |

| Stainless Steel 316L | General AM | Atomized | Recycled steel input |

| TiNbZr | Orthopedic | PREP | Custom bioalloy from reclaimed metals |

Met3DP’s powders are certified and validated by OEMs across aerospace and healthcare sectors—making them a top choice for sustainability-focused additive manufacturing buyers.

8. How Met3DP Supports Circular Manufacturing with Advanced Metal Powder Technology

Circular manufacturing is about designing waste out of the system. Met3DP is not just a supplier of powders—they are an enabler of closed-loop production across the entire additive manufacturing value chain.

🔄 Met3DP’s Circular Economy Strategy:

| Step | Description |

|---|---|

| ♻️ Metal Reclamation | Source recycled metal stock from industrial waste and machining scraps |

| 🔬 Powder Regeneration | Use proprietary PREP and gas atomization to convert scraps into high-grade powder |

| 🧪 Quality Testing | Perform particle analysis, flow testing, and chemical validation |

| 🖨 Printer Optimization | Match powder specs to AM machines for maximum material reuse |

| 📦 Logistics & Recycling | Offer powder reuse programs and support for returned powder batches |

🏭 Real-World Impact of Circular Manufacturing with Met3DP

Case Study: Aerospace Tier-1 Supplier in France

- Challenge: Reduce material waste from titanium machining by 40%

- Solution: Met3DP collected, recycled, and reprocessed titanium scraps into fresh Ti6Al4V powder

- Result:

- 38% less raw titanium purchased

- 22% decrease in CO₂ emissions

- €180K annual savings on materials

📎 Learn more about Met3DP’s sustainable manufacturing platform and how it supports OEMs and metal fabricators worldwide.

🔧 Why Circular Manufacturing Matters for B2B Buyers:

- Avoid landfill and reduce compliance risk (especially under EU Green Deal)

- Improve ESG performance for corporate reporting

- Reduce virgin material dependency and supply chain risk

- Lower total cost of ownership for AM systems

Met3DP’s approach empowers you to integrate sustainability into your operations without compromising on quality or throughput.

9. FAQs: Common Questions About Buying Recycled Metals in Bulk from Paris-Based Suppliers

❓ What’s the difference between recycled and virgin metal powders?

Recycled powders are produced from post-industrial or post-consumer metal waste, whereas virgin powders come from newly mined ores. With proper processing (like gas atomization), recycled powders can match or exceed virgin metal quality in AM applications.

❓ Are recycled metal powders safe for use in medical or aerospace components?

Yes—provided they are processed and certified correctly. Met3DP’s recycled powders meet ASTM, ISO 13485, and AS9100 standards depending on the alloy and application.

❓ Can I request custom alloy blends using recycled feedstock?

Absolutely. Met3DP offers bespoke alloy development using high-purity recycled metals for specific industry needs, including orthopedic, dental, and aerospace-grade materials.

❓ How do I ensure consistent quality across batch orders?

Look for powder providers like Met3DP who offer full MTRs (Material Test Reports), batch traceability, and standardized production protocols. Met3DP also supports repeatability testing and QA audits for long-term clients.

❓ Is it cheaper to buy in bulk from overseas suppliers like Met3DP?

Yes. When ordering large volumes, Met3DP offers competitive pricing even with international logistics costs. Their logistics team also helps manage customs, documentation, and delivery timelines to Europe, including France.

📣 Conclusion: Sustainability Meets High Performance with Met3DP’s Recycled Metal Solutions

As the global manufacturing industry pivots toward greener practices, choosing the right recycled metal supplier is critical for B2B success. Whether you’re sourcing for aerospace, automotive, medical, or general manufacturing, recycled metals offer:

- ♻️ Lower environmental footprint

- 💰 Cost savings on raw materials

- ⚙️ High-performance technical advantages

- 📈 Strategic alignment with ESG and circular economy goals

Met3DP stands at the forefront of this movement, providing cutting-edge metal powders and 3D printing systems that turn sustainability into a competitive advantage.

Ready to Source Sustainable Metal Powders?

Contact Met3DP today to request technical data sheets, sample batches, or a custom quote. Explore how advanced metal 3D printing and recycled powder technology can future-proof your supply chain.

Visit Met3DP’s official website to get started.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

Metal 3D Printing for U.S. Automotive Lightweight Structural Brackets and Suspension Components

Read More »About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.