East Asia’s Metal AM Revolution: A Comparative Guide to Japan, Korea, and China’s Additive Manufacturing Technologies

Table of Contents

1. Introduction: East Asia’s Growing Leadership in Metal Additive Manufacturing

In the past decade, East Asia has emerged as a global powerhouse in metal additive manufacturing (metal AM), with Japan, South Korea, and China playing pivotal roles in shaping the future of industrial 3D printing. These three nations are not only investing heavily in next-generation AM technologies but are also driving innovation across key sectors such as aerospace, medical, automotive, energy, and defense.

For B2B buyers, OEM manufacturers, industrial suppliers, and global distributors, sourcing metal 3D printing systems and powders from East Asia offers a powerful combination of cutting-edge technology, cost efficiency, and manufacturing scale. Whether you’re a wholesale buyer seeking high-performance metal powders or a distributor evaluating large-volume 3D printing equipment, understanding the regional strengths of Japan, Korea, and China is essential.

East Asia’s growing influence in metal AM can be attributed to:

- National policies promoting advanced manufacturing

- Strong R&D ecosystems and university-industry collaborations

- Export-focused manufacturing strategies

- High demand from domestic sectors such as automotive and electronics

This blog explores the latest trends, technologies, and suppliers in the region—helping B2B decision-makers make informed sourcing choices and unlock new supply chain opportunities.

2. Market Trends: Growth of Metal AM in Japan, Korea, and China

East Asia’s metal additive manufacturing market is expanding at an unprecedented pace. According to the 2023 Wohlers Report and regional market studies, the region accounts for a growing share of global metal AM system installations and powder production. Let’s examine the trends driving growth in each country.

🇯🇵 Japan: Precision Engineering Meets Additive Innovation

Japan is known for its excellence in precision manufacturing, which aligns well with the demands of high-accuracy metal 3D printing. The country’s metal AM market is driven by:

- Aerospace and defense investments from major players like Mitsubishi Heavy Industries

- Medical device innovation, especially in titanium orthopedic implants

- Automotive prototyping and tooling, led by OEMs like Toyota and Honda

- Government support via the Ministry of Economy, Trade and Industry (METI)

🇰🇷 South Korea: Smart Manufacturing and Industrial Scaling

Korea is rapidly scaling its AM capabilities as part of its “Manufacturing Innovation 3.0” initiative. Key drivers include:

- Electronics and semiconductors: Precision parts in copper and nickel alloys

- Automotive sector: Hyundai and Kia using AM for tooling and lightweighting

- Academic research: Korea Institute of Machinery and Materials (KIMM) leading AM R&D

- National funding for SMEs to adopt 3D printing

🇨🇳 China: Volume, Innovation, and Global Expansion

China is perhaps the most dynamic player in the metal AM sphere, with a strong emphasis on:

- Large-format additive systems for aerospace and energy sectors

- Domestic production of metal powders at competitive cost

- Export-oriented manufacturing for global OEMs

- National plans like “Made in China 2025” emphasizing AM as a key technology

| Country | Key Industries Driving AM | Government Support | Export Readiness | Powder Production Strength |

|---|---|---|---|---|

| Japan | Aerospace, Medical | High | Moderate | Moderate |

| Korea | Automotive, Electronics | High | Moderate | Moderate |

| China | Aerospace, Automotive | Very High | High | Very High |

💡 Tip for B2B buyers: China offers the most competitive pricing and powder sourcing options, while Japan and Korea offer precision and niche applications.

3. Key Considerations When Choosing a Metal AM Supplier in East Asia

When sourcing metal AM systems or powders from East Asia, B2B buyers must evaluate a range of technical and commercial criteria to ensure quality, reliability, and long-term support. Here are the most important factors to consider:

✅ 1. Technology Capabilities

- Does the supplier offer SEBM, SLM, or EBM technologies?

- What are the build volume limits and layer resolution of the printers?

- Are the systems compatible with multiple powder types?

✅ 2. Powder Consistency and Quality

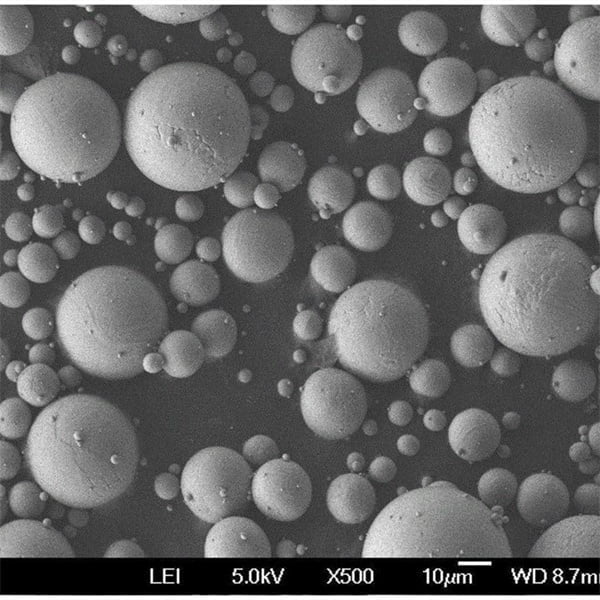

- Are powders produced using gas atomization or plasma methods?

- Check for particle size distribution, sphericity, and flowability

- Ensure availability of certified alloys like Ti6Al4V, Inconel 718, and CoCrMo

For example, Metal3DP utilizes advanced gas atomization and PREP technology to manufacture highly spherical metal powders with excellent flow characteristics—ideal for both laser and electron beam printing.

✅ 3. Certifications and Compliance

- Look for ISO 9001, ISO 13485 (for medical), or AS9100 (for aerospace)

- Ensure RoHS and REACH compliance for European markets

- Request third-party material certification and batch traceability

✅ 4. After-Sale Support and Service

- Is there local technical support or a global service network?

- Does the seller offer training, spare parts, or remote diagnostics?

- Are software upgrades and firmware updates included?

✅ 5. Logistics and Export Experience

- Can the supplier handle international shipping, customs, and documentation?

- Do they have experience serving OEMs and resellers in your region?

- Consider lead times, MOQ (Minimum Order Quantities), and warranty terms

Supplier Evaluation Checklist (B2B Buyers)

| Criteria | Importance | Notes |

|---|---|---|

| Printer Build Volume | High | Suitable for industrial parts |

| Powder Particle Size Control | High | Affects print quality |

| Export Certifications | High | For aerospace/medical use |

| Customer Support Infrastructure | Medium | Remote and on-site options |

| Global Shipping Capabilities | High | Ensures smooth procurement |

Choosing the right supplier is a strategic decision for any industrial buyer. Leading companies like Metal3DP stand out due to their integrated offering of equipment, powders, and application support.

🔗 Visit About Metal3DP to learn more about their capabilities, certifications, and global partnerships.

4. Top 5 Metal AM Equipment and Powder Suppliers in China, Korea, and Japan

As additive manufacturing matures in East Asia, several companies have emerged as leading B2B suppliers of metal 3D printing systems and powders. These firms offer a diverse portfolio of technologies including SLM, EBM, and SEBM, along with proprietary metal powders optimized for performance, flowability, and print consistency.

Below is a curated list of top suppliers for industrial buyers and OEMs seeking reliable East Asian AM partners:

🇨🇳 China

1. Metal3DP Technology Co., LTD (Qingdao)

- Specialties: SEBM 3D printers, gas atomized and PREP powders

- Industries: Aerospace, medical, automotive

- Strengths: High-volume systems, advanced powder production, international export support

- Suitable For: OEMs, distributors, and R&D institutes

- Website: Metal3DP Product Catalogue

🔍 Why it stands out: Metal3DP offers an integrated solution for both additive equipment and consumables, making it ideal for B2B buyers seeking one-stop sourcing.

2. Farsoon Technologies

- Specialties: Open-platform SLM machines

- Industries: Automotive, tooling, prototyping

- Global Reach: Strong presence in Europe and North America

🇯🇵 Japan

3. DMG Mori / Sodick

- Specialties: Hybrid CNC + Laser AM machines

- Industries: Aerospace, precision tooling

- Strengths: High-precision, hybrid machining capabilities

- Suitable For: High-end aerospace and automotive applications

🇰🇷 South Korea

4. InssTek Inc.

- Specialties: DED (Directed Energy Deposition) systems

- Industries: Oil & gas, aerospace repair

- Strengths: Large-format, high-speed deposition

- Export Readiness: Strong B2B support for APAC and EU regions

5. KITECH (Korea Institute of Industrial Technology)

- Specialties: R&D and pilot line manufacturing

- Industries: Research, medical implants, electronics

- Strengths: Innovation, material development

- Suitable For: Collaborative development with OEMs and universities

| Company | Country | Technology Focus | Export Friendly | Powder Production | Ideal For |

|---|---|---|---|---|---|

| Metal3DP | China | SEBM, Laser PBF | ✅ Yes | ✅ Yes | OEMs, Distributors |

| Farsoon | China | SLM (Open Platform) | ✅ Yes | ❌ No | Prototyping, Tooling |

| DMG Mori/Sodick | Japan | Hybrid CNC + Laser | ✅ Yes | ❌ No | Aerospace, Precision |

| InssTek | Korea | DED | ✅ Yes | ❌ No | Large Parts, Repairs |

| KITECH | Korea | R&D, Custom AM | ⚠️ Limited | ❌ No | Research, Custom Projects |

When evaluating suppliers, it’s important to match their technology capabilities with your product needs. For example, if you’re sourcing high-purity metal powders for powder bed fusion, a supplier like Metal3DP is an ideal partner due to its proprietary powder-making systems and SEBM technology.

5. Why Global Buyers Are Turning to Chinese Additive Manufacturing Suppliers

Over the past five years, China has rapidly become the go-to destination for businesses looking to source industrial metal AM solutions. From small-scale R&D labs to multinational OEMs, B2B buyers are increasingly favoring Chinese suppliers for their combination of innovation, affordability, and scalability.

🔧 Key Reasons Buyers Prefer Chinese AM Suppliers

✅ Cost-Effective Equipment and Consumables

- Competitive pricing on 3D printers and powders

- Lower total cost of ownership (TCO)

- Spare parts and maintenance at reduced costs

✅ Scalable Manufacturing Capacity

- Ability to quickly fulfill large-volume orders

- Fast production ramp-up for new projects

- Nationwide network of OEM and ODM facilities

✅ Rapid Technological Innovation

- Adoption of advanced AM technologies like SEBM

- In-house powder atomization and alloy development

- Integration of AI and IoT in AM machines

✅ Export Orientation and Global Support

- Bilingual engineering teams

- Export documentation and customs expertise

- Global logistics partners (DHL, FedEx, etc.)

For example, Metal3DP offers international buyers full-cycle support from machine installation to powder resupply, helping customers reduce downtime and optimize print output.

Real-World B2B Use Case: Aerospace Tier 1 Supplier

A European aerospace parts manufacturer switched from a German supplier to a Chinese provider due to:

- 25% lower machine acquisition costs

- 40% faster lead time on powder delivery

- 3x faster replacement part shipping

| Benefits for B2B Buyers | Outcome |

|---|---|

| Cost Savings | 15–30% reduction in procurement |

| Faster Time-to-Market | Reduced lead times by 2–4 weeks |

| Quality and Reliability | Maintained ISO/AS9100 standards |

📌 Explore Metal3DP’s metal AM printing services to discover how your business can benefit from Chinese innovation and efficiency.

6. Partnering with Metal3DP: A Trusted Source for High-Performance Metal AM Solutions

As one of China’s most advanced providers of metal additive manufacturing solutions, Metal3DP offers a full ecosystem of industrial-grade printers, specialized metal powders, and application engineering services for global customers.

🏭 What Makes Metal3DP a Preferred B2B Partner?

1. Full-Spectrum Additive Manufacturing Capabilities

- SEBM Printers with large build volumes and micron-level precision

- Laser and electron beam printers for aerospace, automotive, and medical sectors

- Multi-material compatibility and closed-loop powder management systems

2. Advanced Powder Manufacturing

- In-house gas atomization and PREP systems

- Alloy portfolio includes:

- Titanium alloys (Ti6Al4V, TiAl, TiNbZr)

- Superalloys (Inconel 718, CoCrMo)

- Stainless steels and custom formulations

- Spherical particles with excellent flowability and purity

3. Global B2B Support Infrastructure

- Turnkey installation and training services

- Remote diagnostics, software upgrades, and spare parts

- English-speaking engineering and sales teams

- Proven export experience across Europe, APAC, and North America

🔗 Visit Metal3DP Products to browse their full lineup of AM systems and powders for industrial buyers.

🛠 Key Benefits for OEMs, Distributors, and Resellers

- Flexible pricing for bulk orders and long-term contracts

- Custom alloy development for niche applications

- Co-development partnerships for R&D and prototyping

- Short lead times and competitive shipping rates

| Feature | Metal3DP Offering |

|---|---|

| Printer Build Size | Up to 500mm × 500mm × 500mm |

| Powder Particle Size Range | 15–53 μm (standard), custom sizes available |

| Export Certifications | ISO 9001, CE, RoHS, customized documentation |

| After-Sales Support | Global remote and on-site support |

| MOQ for Wholesale Orders | Flexible, starting from 10kg for powders |

📞 Contact Metal3DP to discuss your B2B sourcing needs and request a custom quotation.

7. How to Source and Import Metal AM Equipment and Powders from East Asia

For B2B buyers, sourcing metal additive manufacturing equipment and consumables from East Asia—especially China, Korea, and Japan—can unlock significant advantages in price, performance, and product variety. However, it’s important to follow a structured procurement process to ensure quality, compliance, and smooth logistics.

Whether you’re an OEM, distributor, or research lab, the following step-by-step guide will help you navigate the sourcing process effectively.

📦 Step-by-Step Guide: Sourcing Metal AM from East Asia

🔍 Step 1: Define Your Technical Requirements

- Printer type: SEBM, SLM, EBM, or DED

- Build volume, resolution, and print speed

- Supported materials and software compatibility

- Powder particle size distribution and alloy composition

💼 Step 2: Identify and Vet Suppliers

- Research suppliers via exhibitions (e.g., TCT Asia, Formnext) or directories

- Evaluate certifications (ISO, CE, AS9100)

- Request brochures, white papers, and sample prints

- Read customer reviews and case studies

✅ Pro Tip: Metal3DP’s website offers detailed product specs, powder descriptions, and downloadable technical datasheets.

📋 Step 3: Request a Quotation and Confirm Terms

- Ask for CIF/FOB pricing for equipment and powders

- Confirm lead time, warranty, installation, and training provisions

- Understand payment terms (e.g., LC, TT deposit)

- Clarify MOQ (Minimum Order Quantity) for powders

🚚 Step 4: Handle Shipping and Logistics

- Choose between air freight (faster) or sea freight (cost-effective)

- Ensure supplier provides export documentation (Invoice, Packing List, CoO, MSDS)

- Work with freight forwarders experienced in AM equipment

🧪 Step 5: Quality Control and Compliance

- Conduct factory audits or virtual inspections

- Request third-party testing for powders (PSD, sphericity, oxygen levels)

- Align with local standards (FDA, CE, ASTM F2924, etc.)

🔄 Common B2B Use Cases for East Asian AM Equipment

| Industry | Common Applications | Preferred Tech | Example Alloy |

|---|---|---|---|

| Aerospace | Turbine blades, engine brackets | SEBM / EBM | Ti6Al4V, Inconel 718 |

| Medical | Orthopedic implants, surgical tools | SEBM / Laser PBF | TiAl, CoCrMo |

| Automotive | Lightweight parts, prototyping | Laser PBF | Stainless Steel, AlSi10Mg |

| Energy | Heat exchangers, impellers | DED / Laser PBF | Inconel 625, Hastelloy |

🔗 Discover which printing methods are best suited for your industry and application.

8. FAQs: Common Questions About Metal 3D Printing in East Asia

❓ Q1: What’s the difference between SEBM and SLM technologies?

A:

- SEBM (Selective Electron Beam Melting) uses an electron beam in a vacuum, providing faster build speeds and better fusion for dense parts—ideal for aerospace and medical.

- SLM (Selective Laser Melting) uses a laser and is more widely available, suitable for high-precision parts and a wider range of metals.

❓ Q2: Can I buy powders and equipment from the same supplier?

A:

Yes! In fact, buying both from the same supplier ensures compatibility and technical support. For example, Metal3DP provides both SEBM machines and proprietary gas-atomized powders that are optimized for their printers.

❓ Q3: What international certifications should I look for?

A:

- ISO 9001 – Quality management

- ISO 13485 – Medical device manufacturing

- AS9100 – Aerospace industry

- CE / RoHS / REACH – For EU compliance

❓ Q4: What are typical lead times for equipment and powders?

A:

- Equipment: 6–10 weeks depending on customization

- Powders: 1–3 weeks for in-stock alloys; 4–6 weeks for custom formulations

❓ Q5: Can I request sample prints or powder before placing a bulk order?

A:

Yes—many reputable suppliers offer sample prints or 1–5kg powder samples for evaluation. This is highly recommended before large-scale procurement.

❓ Q6: Do suppliers offer training and after-sales support?

A:

Yes. Leading suppliers like Metal3DP provide remote support, on-site training, and long-term service contracts to ensure smooth operation of equipment.

9. Conclusion & CTA: Exploring AM Partnerships with Asia’s Leading Suppliers

The rise of metal additive manufacturing in East Asia—driven by innovation in China, precision in Japan, and smart scaling in Korea—presents a golden opportunity for B2B buyers worldwide. Whether you are an OEM looking to integrate AM into your production line, or a distributor sourcing high-performance powders, East Asia offers a compelling balance of quality, cost, and capability.

Among the standout players, Metal3DP distinguishes itself with:

- Industry-leading SEBM systems

- Advanced gas atomization and PREP powder production

- Global export support and technical services

- A wide catalog of alloys for aerospace, medical, and industrial use

🔗 Ready to take your additive manufacturing capabilities to the next level? Contact Metal3DP for a free consultation or to request a custom quotation for your specific application.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

Metal 3D Printing for U.S. Automotive Lightweight Structural Brackets and Suspension Components

Read More »About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.