Reducing Waste with Additive Manufacturing in Busan

Table of Contents

1. Introduction: The Growing Need for Sustainable Manufacturing in Busan

Busan, South Korea’s second-largest city and a critical hub for maritime, automotive, and heavy manufacturing, is at a pivotal moment. As global regulations tighten and ESG (Environmental, Social, and Governance) standards become non-negotiable, manufacturers in Busan must rethink traditional production methods.

South Korea has committed to achieving net-zero carbon emissions by 2050. In line with this goal, Busan’s industrial sector is under pressure to modernize operations in ways that reduce energy consumption, limit waste, and improve material efficiency.

Why Waste Reduction is a Priority in Busan

- Industrial Density: Busan is home to major shipbuilding yards, automotive suppliers, and electronic component manufacturers — all of which generate significant industrial waste.

- Environmental Regulations: South Korea’s Ministry of Environment is increasing inspections, taxing carbon-heavy processes, and incentivizing green technologies.

- Global Supply Chain Demands: International partners and buyers are favoring suppliers with strong sustainability credentials.

Additive Manufacturing (AM) as a Game-Changer

Additive manufacturing, often referred to as 3D printing, is emerging as a powerful tool to reduce waste in manufacturing processes. Unlike traditional subtractive manufacturing — where material is cut away from a block — AM builds parts layer by layer, using only the material needed.

In Busan, adopting AM means:

- Less material waste

- Shorter supply chains

- Localized production

- Reduced carbon footprint

These sustainability benefits are not just theoretical. They’re already being realized by companies across aerospace, medical, and automotive sectors in Busan — particularly those using high-performance metal AM systems.

2. The Role of Additive Manufacturing in Reducing Industrial Waste

Traditional Manufacturing vs. Additive Manufacturing

| Feature | Traditional (Subtractive) | Additive Manufacturing (AM) |

|---|---|---|

| Material Usage | High waste (e.g., 60-80% of material removed) | Near-net-shape with minimal waste |

| Tooling | Requires expensive molds/tools | No tooling required |

| Inventory | Requires bulk stock and warehousing | On-demand production minimizes overstock |

| Energy Use | High (especially for machining metals) | Lower in many AM processes |

| Scrap Rate | High due to human error or defects | Low with optimized digital designs |

How AM Reduces Waste

- Near-Net-Shape Production: AM builds parts close to their final shape, reducing the need for trimming, machining, or post-processing.

- Digital-First Manufacturing: Components are created directly from CAD files, improving precision and eliminating guesswork.

- Localized Production: AM enables production near the point of use, reducing packaging and transport waste.

- On-Demand Fabrication: No need to overproduce or store large inventories, reducing obsolete stock and disposal.

Additive Manufacturing Technologies Supporting Sustainability

| AM Technology | Waste Reduction Benefits |

|---|---|

| Powder Bed Fusion (PBF) | Re-uses unused powder, minimal excess material |

| Directed Energy Deposition (DED) | Adds material only where needed for repair or build-up |

| Binder Jetting | Lower energy usage, minimal support structures |

Learn more about these methods on Metal3DP’s printing methods page.

3. Key Environmental and Economic Benefits for Businesses in Busan

Transitioning to additive manufacturing is not just good for the planet — it’s also a smart business decision. Companies in Busan that have integrated AM into their operations report savings across multiple fronts.

Environmental Benefits

- 🌍 Waste Reduction: Up to 90% less material waste compared to subtractive methods.

- 💨 Lower Carbon Emissions: Fewer transport needs, less energy-intensive processes.

- ♻️ Material Recyclability: Many AM systems allow for powder reuse with minimal degradation.

- 🌱 Compliance with Green Regulations: Helps meet Korean and international sustainability standards.

Economic Benefits

| Benefit | Description |

|---|---|

| Material Savings | Reduce cost of raw materials by up to 80% |

| Tooling Elimination | Save tens of thousands by avoiding mold fabrication |

| Faster Time-to-Market | AM shortens prototyping and production cycles |

| Lower Inventory Costs | Produce on-demand and reduce storage expenses |

| Increase in Part Performance | Lightweight, optimized parts reduce total cost of ownership |

Case Study: Busan-Based Aerospace Supplier

A Busan-based aerospace tier-2 supplier reduced titanium waste by 75% after switching to metal additive manufacturing. The company used spherical titanium alloy powders from Metal3DP to print complex brackets and housings used in aircraft cabins.

“We used to machine parts from solid titanium billets, wasting over half the material. Now, we only use what we need — and the parts are even stronger.”

— CTO, Busan Aerospace Components Co.

4. Top Industries in Busan Benefiting from Additive Manufacturing

Busan is a powerhouse of industrial activity and holds strategic importance due to its port access, skilled manufacturing workforce, and close proximity to major Korean and global markets. Several industries in Busan are rapidly adopting additive manufacturing technologies to reduce waste and improve production efficiency.

Key Industries Embracing Additive Manufacturing in Busan

| Industry | AM Applications | Waste Reduction Benefits |

|---|---|---|

| Aerospace | Lightweight brackets, turbine blades, structural components | Reduces titanium and aluminum waste by up to 80% |

| Medical Devices | Custom implants, surgical tools, prosthetics | Eliminates tooling waste and enables patient-specific solutions |

| Automotive | Engine parts, heat exchangers, jigs & fixtures | Reduces scrap metal and streamlines prototyping |

| Marine Engineering | Propeller components, pump housings, corrosion-resistant parts | Optimized geometries reduce raw material usage |

| Tooling & Molds | Conformal cooling channels, die inserts | Extends tool life and reduces excess machining |

Aerospace Manufacturing in Busan

Busan is home to several aerospace component manufacturers supplying to global OEMs such as Boeing and Airbus. These companies are turning to metal additive manufacturing to optimize part geometries, reduce weight, and significantly cut down on high-value material waste such as titanium and Inconel.

- Example Application: Using Metal3DP’s high-performance Ti-6Al-4V powder, a Busan aerospace firm reduced titanium billet waste by 70% for bracket production.

Medical Sector: Precision with Less Waste

The region’s growing medical device sector benefits from AM’s ability to produce patient-specific implants and tools with minimal material loss. AM technologies like Electron Beam Melting (EBM) are ideal for printing biocompatible metal implants in CoCrMo and TiNbZr alloys.

- Example: Custom cranial implants made with Metal3DP’s biocompatible powders reduce hospital stock waste and improve surgical outcomes.

Interested in learning more about additive manufacturing in the medical and aerospace sectors? Visit Metal3DP’s metal 3D printing solutions page to explore real-world applications.

5. How Additive Manufacturing Reduces Material Waste vs Traditional Methods

One of the strongest arguments for additive manufacturing is its ability to significantly reduce raw material waste. Let’s break down how AM achieves this compared to traditional subtractive methods such as CNC machining, forging, and casting.

Subtractive Manufacturing: The Waste Problem

Subtractive manufacturing starts with a block of material and removes portions through cutting, drilling, or grinding. This produces large amounts of scrap — especially when working with expensive metals like titanium, cobalt-chrome, or nickel-based alloys.

- Material Yield: Often below 30% for complex parts

- Secondary Waste: Chips, coolant, and worn tooling

- Post-Processing: Adds further material removal and energy use

Additive Manufacturing: Efficient, Layer-by-Layer

Additive manufacturing builds parts from the ground up using only the material needed for that part’s geometry. Unused powder in powder bed fusion systems can be recycled and reused, further improving material efficiency.

| Criteria | Subtractive Manufacturing | Additive Manufacturing |

|---|---|---|

| Material Yield | 20–50% | 90–98% |

| Tooling Required | Yes | No |

| Scrap Waste | High | Minimal |

| Reusability | Low | High (especially with powders) |

| Energy Consumption | High (machining, forging) | Lower (localized fusion) |

Quantifying the Waste Reduction

| Process | Initial Material | Final Part Weight | Waste Generated |

|---|---|---|---|

| CNC Machining (Titanium) | 10 kg billet | 2 kg part | 8 kg waste |

| Powder Bed Fusion (AM) | 2.2 kg powder | 2 kg part | 0.2 kg unused (recyclable) |

This stark contrast demonstrates why AM is becoming the preferred method in industries where material costs and sustainability are key concerns.

6. Why Metal3DP Is a Trusted Additive Manufacturing Partner in Busan

When it comes to industrial-grade additive manufacturing, choosing the right supplier can make or break your production efficiency. Metal3DP, headquartered in Qingdao, China, is a trusted partner for manufacturers in Busan and across Asia seeking to reduce waste and improve part performance through metal AM.

What Sets Metal3DP Apart?

✅ Industry-Leading Metal 3D Printers

- High precision and large build volumes

- Optimized for aerospace, automotive, and medical applications

- Stable printing performance for mission-critical components

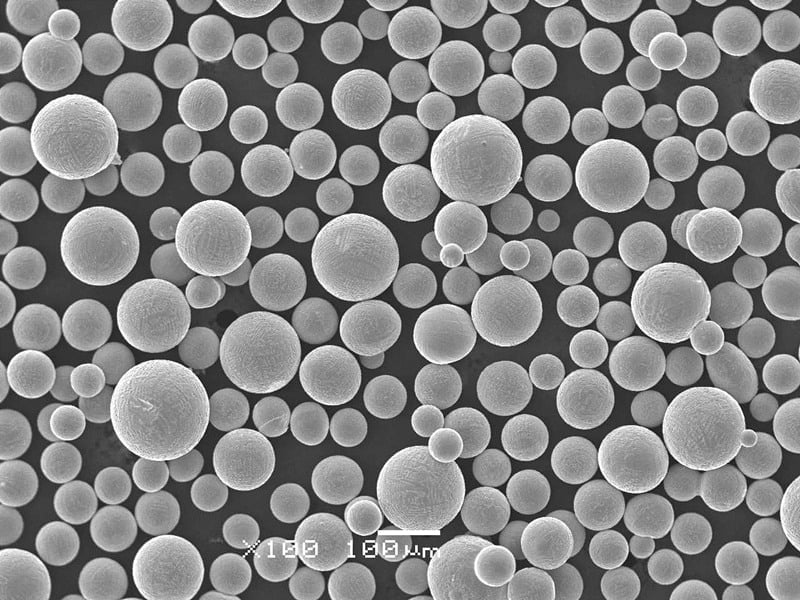

✅ Advanced Powder Production Capabilities

Metal3DP uses state-of-the-art gas atomization and PREP (Plasma Rotating Electrode Process) systems to produce high-quality spherical metal powders.

- High sphericity and low oxygen content

- Excellent flowability and packing density

- Tailored for both laser and EBM systems

✅ Extensive Powder Portfolio

| Alloy | Application | Benefits |

|---|---|---|

| Ti-6Al-4V | Aerospace, Medical | Lightweight, biocompatible, corrosion-resistant |

| CoCrMo | Orthopedics, Dentistry | High strength, wear resistance, biocompatibility |

| Inconel 718 | Turbo machinery | High-temp resistance, fatigue performance |

| Stainless Steel 316L | General engineering | Affordable, corrosion-resistant |

Explore our full product range on the Metal3DP product page.

✅ Turnkey Additive Manufacturing Solutions

- Equipment + Powder + Application Support

- Technical consulting on AM design and implementation

- Post-processing and material testing services

✅ Trusted by B2B Clients Across Asia

From Busan to Bangkok, Metal3DP supports manufacturers across the Asia-Pacific region with reliable supply chains, expert consultation, and high-performance materials.

Learn more about our mission and global reach on our About Us page.

7. How to Source High-Quality Metal Powders for AM in Korea

The quality of your additive manufacturing output is directly tied to the quality of your metal powders. For businesses in Busan and across Korea, sourcing reliable, consistent, and high-performance powders is not just a material decision — it’s a strategic one.

Why Powder Quality Matters

- Flowability: Affects layer consistency in powder bed fusion systems

- Particle Size Distribution: Impacts packing density and print resolution

- Sphericity: Reduces powder clumping and improves spreadability

- Purity: Low oxygen and nitrogen levels are essential for mechanical integrity

Key Considerations for B2B Buyers

| Factor | Importance | What to Look For |

|---|---|---|

| Certification | Ensures material traceability and standards compliance | ISO 13485, ASTM, AMS, GB standards |

| Batch Consistency | Critical for repeatable part quality | Uniform PSD, chemical composition |

| Technical Support | Accelerates implementation and troubleshooting | Access to metallurgists and AM engineers |

| Delivery Logistics | Important for minimizing production downtime | Local warehousing or fast shipping options |

Metal3DP’s Powder Manufacturing Advantage

Metal3DP produces a wide range of high-performance metal powders optimized for laser and electron beam powder bed fusion technologies. Using gas atomization and PREP systems, our powders offer:

- High sphericity (>95%)

- Excellent flowability

- Low oxygen and nitrogen content

- Batch-to-batch consistency

We supply to leading AM users in aerospace, medical, and automotive sectors across Korea, including Busan-based manufacturers.

Discover our powder technology and full alloy portfolio on the Metal3DP product page.

Popular Powders for Busan-Based Industries

| Alloy | Industry | Features |

|---|---|---|

| Ti-6Al-4V | Aerospace, Medical | Lightweight, corrosion-resistant |

| CoCrMo | Orthopedics | Biocompatible, wear-resistant |

| Inconel 625/718 | Energy, Marine | High-temperature, oxidation-resistant |

| 316L Stainless Steel | General Industrial | Cost-effective, corrosion-resistant |

We offer both standard and customized powders tailored to your application needs.

8. Step-by-Step Guide to Implementing Additive Manufacturing in Your Factory

Successful implementation of additive manufacturing in a traditional factory setting requires a strategic, phased approach. Whether you’re a medium-sized parts supplier or a large OEM in Busan, following a structured roadmap ensures smooth integration and ROI.

Step 1: Assess Your Application Suitability

✅ Identify high-cost, high-waste parts

✅ Look for design complexity or customization needs

✅ Evaluate current scrap rates and tooling costs

Tip: Start with low-volume, high-value components such as aerospace brackets or surgical tools.

Step 2: Partner with an AM Expert

✅ Choose a supplier that provides both materials and equipment

✅ Ensure technical support and training are available

✅ Evaluate their track record and application expertise

Metal3DP provides complete AM solutions — from SEBM printers to spherical metal powders and post-processing consulting.

Learn how our integrated solutions can accelerate your AM journey on our Metal 3D Printing Solutions page.

Step 3: Select the Right AM Technology

| Technology | Best For | Advantages |

|---|---|---|

| Laser Powder Bed Fusion (LPBF) | High-resolution, small parts | Excellent surface finish, precise |

| Electron Beam Melting (EBM) | Large, dense parts | Faster build rate, low residual stress |

| Directed Energy Deposition (DED) | Part repair or large builds | Applicable to hybrid manufacturing |

Step 4: Set Up Infrastructure

✅ Ensure power, ventilation, and inert gas systems are in place

✅ Establish powder handling and storage protocols

✅ Train your engineering and quality control teams

Step 5: Pilot, Monitor, Scale

✅ Run pilot production on a few parts

✅ Monitor quality metrics and material utilization

✅ Scale gradually to replace wasteful subtractive operations

9. FAQs: Additive Manufacturing for Waste Reduction in Busan

We’ve compiled the most frequently asked questions from manufacturers, suppliers, and engineers in Busan considering the shift to additive manufacturing.

❓ What is the typical waste reduction when switching to AM?

Most manufacturers experience a 70–90% reduction in material waste compared to subtractive machining, especially when using high-value metals like titanium or Inconel.

❓ Is additive manufacturing cost-effective for small batch production?

Absolutely. AM eliminates tooling, reduces setup time, and enables on-demand manufacturing — making it ideal for small-volume, high-mix production environments.

❓ Can AM help us meet Korea’s environmental regulations?

Yes. Additive manufacturing supports green manufacturing goals by reducing energy consumption, lowering material waste, and enabling localized production.

❓ How do I ensure powder recyclability?

Use spherical powders with high purity and controlled PSD. Metal3DP’s powders are engineered for high recyclability in both laser and electron beam systems.

❓ How do I get started with Metal3DP?

You can contact us directly for a consultation or visit our company homepage to explore our full range of products and services.

🔚 Conclusion: Building a Waste-Free Future with Additive Manufacturing in Busan

As Busan continues to evolve into a smart industrial hub, manufacturers must embrace technologies that align with sustainability, efficiency, and innovation. Additive manufacturing — particularly metal AM — presents an unparalleled opportunity to reduce waste, simplify supply chains, and unlock new design possibilities.

Whether you’re in aerospace, healthcare, automotive, or marine engineering, now is the time to explore how 3D printing can transform your business.

👉 Partner with Metal3DP to source high-quality powders, reliable printing systems, and expert support for your additive manufacturing journey.

Start your transformation today — visit our About Us page or contact us to learn more.

🔗 Summary of Internal Links Used (5 Total)

| Anchor Text | Linked Page |

|---|---|

| printing methods page | https://met3dp.com/printing-methods/ |

| metal 3D printing solutions page | https://met3dp.com/metal-3d-printing/ |

| Metal3DP product page | https://met3dp.com/product/ |

| About Us page | https://met3dp.com/about-us/ |

| company homepage | https://met3dp.com/ |

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731