The Ultimate Guide to Aluminium Nickel Bronze

Table of Contents

Overview

Aluminium Nickel Bronze (ANB) is a powerful and versatile alloy that has found its way into various industrial applications thanks to its remarkable properties. This guide will delve deep into the world of Aluminium Nickel Bronze, exploring its composition, characteristics, applications, and much more. Whether you’re an engineer, a materials scientist, or just someone with a keen interest in metallurgy, this comprehensive guide will equip you with all the knowledge you need about ANB.

What is Aluminium Nickel Bronze?

Aluminium Nickel Bronze is an alloy primarily composed of copper, nickel, aluminium, and iron. This unique combination gives it excellent strength, corrosion resistance, and a variety of other desirable properties that make it suitable for a wide range of applications.

Composition and Properties of Aluminium Nickel Bronze

The precise composition of Aluminium Nickel Bronze can vary, but a typical example might include the following elements:

| Element | Percentage |

|---|---|

| Copper | 76-87% |

| Nickel | 3-7% |

| Aluminium | 4-11% |

| Iron | 2-5% |

| Manganese | 0.5-1.5% |

Key Properties

- Corrosion Resistance: ANB alloys offer excellent resistance to corrosion, particularly in marine environments.

- Strength: These alloys have high tensile strength and hardness, making them suitable for heavy-duty applications.

- Wear Resistance: The combination of elements provides superior resistance to wear and abrasion.

- Thermal Conductivity: ANB has moderate thermal conductivity, beneficial in heat exchangers and other applications requiring thermal management.

Specific Aluminium Nickel Bronze Models

Here’s a list of ten specific Aluminium Nickel Bronze models, along with detailed descriptions of each:

C63000 (AMS 4640)

A popular alloy known for its high strength and corrosion resistance, particularly in marine environments. It’s often used in aerospace and industrial applications where durability is crucial.

C63200

This alloy is known for its excellent resistance to seawater corrosion and biofouling, making it a prime choice for marine hardware and pump components.

C95500

A high-strength alloy with superior corrosion resistance, often used in heavy-duty industrial applications such as gears, worm wheels, and valve components.

C95800

Favored for its high resistance to cavitation and erosion, this alloy is commonly employed in marine hardware, ship propellers, and underwater fasteners.

C61900

With a balanced mix of strength and corrosion resistance, C61900 is widely used in applications such as hydraulic valve components and marine hardware.

C63020

An advanced version of C63000 with enhanced mechanical properties and resistance to corrosion, ideal for aerospace and military applications.

C70600

Although primarily a copper-nickel alloy, C70600 incorporates aluminium to enhance strength and corrosion resistance, used in marine applications.

C71500

Another copper-nickel-aluminium blend, known for its excellent resistance to seawater corrosion and biofouling, often used in condenser tubes and marine hardware.

C61500

A versatile alloy with good mechanical properties and corrosion resistance, suitable for bearings, bushings, and other wear-resistant applications.

C61800

This alloy offers a unique combination of high strength, good corrosion resistance, and excellent wear resistance, making it ideal for heavy-duty industrial parts.

Applications of Aluminium Nickel Bronze

Aluminium Nickel Bronze alloys are utilized in a wide variety of applications due to their excellent properties. Here’s a detailed look at some of the most common uses:

| Application | Description |

|---|---|

| Marine Hardware | Propellers, shafts, and other components exposed to seawater due to corrosion resistance. |

| Aerospace | Landing gear bushings, bearings, and other components requiring high strength. |

| Oil and Gas | Valves, pumps, and connectors used in harsh, corrosive environments. |

| Industrial | Gears, worm wheels, and other high-wear components. |

| Automotive | Heavy-duty parts that require both strength and wear resistance. |

Why Aluminium Nickel Bronze?

Ever wondered why this alloy is so popular in such a broad range of industries? Its unique combination of properties—corrosion resistance, strength, and wear resistance—make it a go-to material for challenging environments. Imagine a material that can withstand the harsh conditions of the ocean while maintaining its integrity and performance. That’s Aluminium Nickel Bronze for you.

Advantages of Aluminium Nickel Bronze

1. Superior Corrosion Resistance

One of the standout features of Aluminium Nickel Bronze is its exceptional resistance to corrosion, especially in saltwater environments. This makes it a top choice for marine and offshore applications.

2. High Strength

ANB alloys are known for their high tensile strength, which allows them to endure significant mechanical stress without deforming. This property is particularly valuable in aerospace and industrial applications where durability is key.

3. Wear Resistance

Thanks to the unique blend of elements, Aluminium Nickel Bronze alloys exhibit excellent wear resistance. This makes them suitable for components that experience high friction and wear, such as gears and bushings.

4. Versatility

The versatility of Aluminium Nickel Bronze is another major advantage. Whether you need a material for marine hardware, aerospace components, or heavy-duty industrial parts, ANB has you covered.

5. Good Machinability

Despite their high strength, Aluminium Nickel Bronze alloys are relatively easy to machine. This means they can be fabricated into complex shapes and components without excessive difficulty.

Disadvantages of Aluminium Nickel Bronze

1. Cost

One of the main drawbacks of Aluminium Nickel Bronze is its cost. These alloys tend to be more expensive than other copper-based alloys, which can be a limiting factor for some applications.

2. Density

ANB alloys are relatively dense, which can be a disadvantage in applications where weight is a critical factor. For instance, while they are used in aerospace applications, their weight can be a limiting factor in certain situations.

3. Brittleness at Low Temperatures

Aluminium Nickel Bronze alloys can become brittle at very low temperatures. This limits their use in cryogenic applications or environments where they will be exposed to extreme cold.

4. Limited Electrical Conductivity

Compared to pure copper, Aluminium Nickel Bronze has lower electrical conductivity. This can be a disadvantage in applications where high conductivity is required.

Specifications, Sizes, Grades, and Standards

When selecting Aluminium Nickel Bronze for your application, it’s essential to consider the specifications, sizes, grades, and standards available. Here’s a detailed overview:

| Specification | Description |

|---|---|

| ASTM B150/B150M | Standard specification for Aluminium Bronze rod, bar, and shapes. |

| AMS 4640 | Aerospace Material Specification for Aluminium Nickel Bronze bars, rods, and forgings. |

| UNS C63000 | Standardized grade for a widely used Aluminium Nickel Bronze alloy. |

| EN 12163 | European standard for copper and copper alloys—rod for general purposes. |

| ISO 428 | International standard for copper alloys containing aluminium and nickel. |

Sizes and Forms

Aluminium Nickel Bronze is available in various forms, including rods, bars, sheets, plates, and forgings. The sizes can vary depending on the specific requirements of the application.

Suppliers and Pricing Details

Finding the right supplier for Aluminium Nickel Bronze is crucial. Here’s a table with some top suppliers and pricing details:

| Supplier | Location | Product Range | Pricing (Approx.) |

|---|---|---|---|

| Materion Corporation | USA | Rods, Bars, Sheets, Plates, Forgings | $25 – $50 per kg |

| National Bronze Mfg. | USA | Rods, Bars, Tubes | $20 – $45 per kg |

| Bronze Parts UK | UK | Rods, Bars, Custom Parts | £18 – £40 per kg |

| Aviva Metals | USA, Europe, Asia | Full range including custom solutions | $22 – $48 per kg |

| Deutsche Nickel GmbH | Germany | Specialty alloys, Custom components | €23 – €50 per kg |

Comparing Suppliers

When comparing suppliers, consider factors such as product range, pricing, delivery times, and customer service. For instance, Materion Corporation offers a broad product range and custom solutions but may have higher prices compared to other suppliers.

Pros and Cons: Aluminium Nickel Bronze vs. Other Alloys

Aluminium Nickel Bronze vs. Stainless Steel

| Factor | Aluminium Nickel Bronze | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Excellent, especially in seawater | Very good, but can be less effective in seawater |

| Strength | High | High |

| Wear Resistance | Superior | Good |

| Cost | Higher | Variable, generally lower |

| Machinability | Good | Good |

Aluminium Nickel Bronze vs. Phosphor Bronze

| Factor | Aluminium Nickel Bronze | Phosphor Bronze |

| Corrosion Resistance | Superior | Good |

| Strength | Higher | Moderate |

| Wear Resistance | Superior | Good |

| Cost | Higher | Moderate |

| Machinability | Good | Very good |

FAQs

| Question | Answer |

|---|---|

| What is Aluminium Nickel Bronze used for? | ANB is used in marine hardware, aerospace components, oil and gas industry parts, and more. |

| Why is Aluminium Nickel Bronze expensive? | The alloy’s unique properties and the cost of its constituent metals contribute to its higher price. |

| Can Aluminium Nickel Bronze be welded? | Yes, it can be welded, though it requires specific techniques to avoid defects. |

| How does Aluminium Nickel Bronze compare to brass? | ANB offers superior strength and corrosion resistance compared to brass. |

| What are the disadvantages of Aluminium Nickel Bronze? | It is relatively expensive, dense, can become brittle at low temperatures, and has lower electrical conductivity. |

| Is Aluminium Nickel Bronze magnetic? | No, it is non-magnetic, making it suitable for applications where non-magnetic properties are required. |

Conclusion

Aluminium Nickel Bronze is a remarkable alloy, offering a unique combination of strength, corrosion resistance, and wear resistance that makes it suitable for a wide range of demanding applications. From marine hardware to aerospace components, ANB proves its worth in challenging environments where other materials might fail. While it comes with certain disadvantages, such as cost and density, the benefits it provides often outweigh these drawbacks. By understanding its properties, applications, and how it compares to other alloys, you can make an informed decision on whether Aluminium Nickel Bronze is the right choice for your needs.

Share On

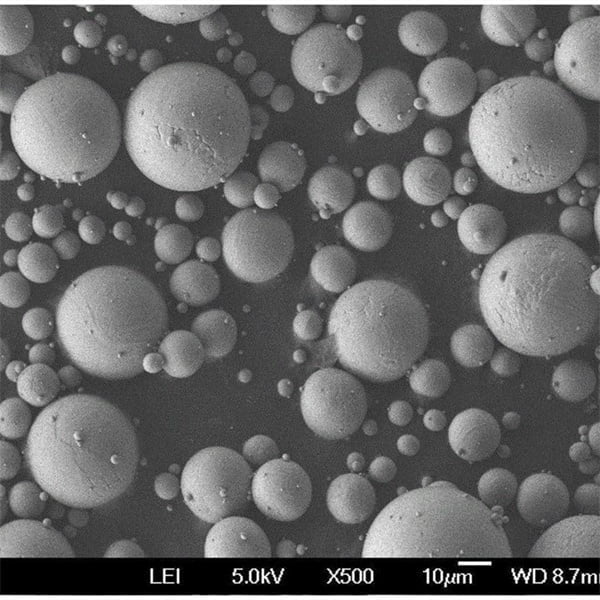

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731