Comprehensive Guide of ASTM F2924

Table of Contents

When it comes to the world of metallurgy and material science, ASTM F2924 stands as a pivotal standard. It’s particularly crucial in the realm of additive manufacturing, especially for titanium alloy parts produced via powder bed fusion. This article will provide an exhaustive exploration of ASTM F2924, delving into its composition, properties, applications, and much more. Let’s embark on this detailed journey to understand ASTM F2924 fully.

Overview of ASTM F2924

ASTM F2924 is a specification for the additive manufacturing of Ti-6Al-4V using powder bed fusion. This titanium alloy is highly valued for its superior strength-to-weight ratio, excellent corrosion resistance, and high biocompatibility, making it ideal for aerospace, medical, and industrial applications.

Key Details of ASTM F2924

- Material: Titanium Alloy (Ti-6Al-4V)

- Manufacturing Process: Additive Manufacturing (Powder Bed Fusion)

- Applications: Aerospace, Medical Implants, Automotive, Industrial Components

- Properties: High strength, Lightweight, Corrosion resistant, Biocompatible

Composition of ASTM F2924

Understanding the exact composition of ASTM F2924 is essential for appreciating its properties and performance in various applications. The primary elements include titanium, aluminum, and vanadium, among others.

| Element | Symbol | Typical Composition (%) |

|---|---|---|

| Titanium | Ti | Balance |

| Aluminum | Al | 5.5 – 6.75 |

| Vanadium | V | 3.5 – 4.5 |

| Iron | Fe | ≤ 0.3 |

| Oxygen | O | ≤ 0.2 |

| Carbon | C | ≤ 0.08 |

| Nitrogen | N | ≤ 0.05 |

| Hydrogen | H | ≤ 0.015 |

| Other Elements | Various | ≤ 0.4 |

Properties and Characteristics of ASTM F2924

The properties of ASTM F2924 make it a standout material for various demanding applications. Here’s a detailed look at its physical and mechanical properties.

Physical Properties

- Density: 4.43 g/cm³

- Melting Point: Approximately 1600°C

- Thermal Conductivity: 7.2 W/m·K

- Electrical Resistivity: 170 µΩ·cm

Mechanical Properties

- Tensile Strength: 895 MPa

- Yield Strength: 825 MPa

- Elongation at Break: 10%

- Modulus of Elasticity: 113.8 GPa

- Hardness: 350 HV

Characteristics

- Biocompatibility: Excellent

- Corrosion Resistance: High

- Fatigue Resistance: Good

- Machinability: Moderate

Applications of ASTM F2924

The versatility of ASTM F2924 makes it suitable for a wide array of applications across different industries. Here’s a closer look at where and how it’s used.

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Engine Components, Structural Parts | Lightweight, Strong, Corrosion Resistant |

| Medical | Implants, Surgical Instruments | Biocompatible, High Strength |

| Automotive | High-Performance Parts | Lightweight, Durable |

| Industrial | Tooling, Prototyping | Corrosion Resistant, Reliable |

| Consumer Goods | Sporting Goods, Jewelry | Lightweight, Attractive |

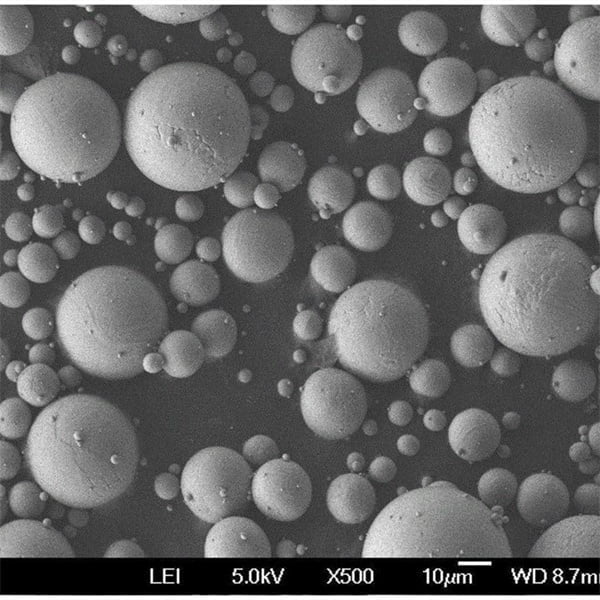

Specific Metal Powder Models for ASTM F2924

When dealing with ASTM F2924, it’s crucial to choose the right metal powder for additive manufacturing. Below are some specific metal powder models that are commonly used.

| Powder Model | Description |

|---|---|

| AP&C Ti-6Al-4V | Produced by Advanced Powders & Coatings, known for high sphericity and excellent flowability. |

| Carpenter Additive Ti-6Al-4V | Offers consistent quality with tight particle size distribution for reliable printing. |

| Tekna Ti-6Al-4V | Known for low oxygen content and excellent purity, suitable for demanding applications. |

| GKN Hoeganaes Ti-6Al-4V | Provides high packing density and uniform particle size for optimal printing results. |

| Arcam EBM Ti-6Al-4V | Designed specifically for electron beam melting processes, offering high strength. |

| Sandvik Osprey Ti-6Al-4V | Offers excellent mechanical properties and good weldability. |

| Praxair TruForm Ti-6Al-4V | Known for its superior flow characteristics and consistent performance. |

| EOS Ti64 | High-quality powder tailored for EOS additive manufacturing systems. |

| Renishaw Ti-6Al-4V | Ensures high purity and is optimized for Renishaw AM systems. |

| LPW Technology Ti-6Al-4V | Known for tight control over particle size distribution and chemistry. |

Specifications, Sizes, and Standards

For those considering the use of ASTM F2924, understanding the specifications, sizes, and standards is essential. Here’s a detailed look.

| Specification | Details |

|---|---|

| Standard | ASTM F2924-14 |

| Particle Size | Typically 15-45 µm |

| Forms | Powder, Wire |

| Packing Density | 50-60% |

| Flow Rate | 15-18 s/50g (ASTM B213) |

| Purity | >99.5% |

| Shelf Life | Typically 1 year, depending on storage conditions |

Suppliers and Pricing Details

Finding the right supplier is crucial for ensuring the quality and consistency of ASTM F2924 powders. Here’s a breakdown of some suppliers and their pricing details.

| Supplier | Product | Price (per kg) | Location | Contact Information |

|---|---|---|---|---|

| AP&C | Ti-6Al-4V Powder | $350 – $400 | Canada | [email protected] |

| Carpenter Additive | Ti-6Al-4V Powder | $340 – $390 | USA | [email protected] |

| Tekna | Ti-6Al-4V Powder | $360 – $410 | Canada | [email protected] |

| GKN Hoeganaes | Ti-6Al-4V Powder | $330 – $380 | USA | [email protected] |

| Arcam EBM | Ti-6Al-4V Powder | $370 – $420 | Sweden | [email protected] |

| Sandvik Osprey | Ti-6Al-4V Powder | $350 – $400 | Sweden | [email protected] |

| Praxair | TruForm Ti-6Al-4V | $340 – $390 | USA | [email protected] |

| EOS | Ti64 Powder | $360 – $410 | Germany | [email protected] |

| Renishaw | Ti-6Al-4V Powder | $350 – $400 | UK | [email protected] |

| LPW Technology | Ti-6Al-4V Powder | $340 – $390 | UK | [email protected] |

Pros and Cons of ASTM F2924

No material is without its advantages and disadvantages. Here’s a comparison to help understand the strengths and limitations of ASTM F2924.

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Strength | High tensile and yield strength | May require post-processing for optimal properties |

| Weight | Lightweight | Higher cost compared to some other metals |

| Corrosion Resistance | Excellent resistance to corrosion | Limited machinability |

| Biocompatibility | Highly biocompatible | Requires strict control over production conditions |

| Fatigue Resistance | Good fatigue resistance | Can be brittle if not processed correctly |

| Applications | Versatile across various industries | Initial setup and material costs can be high |

FAQs

Let’s address some common questions about ASTM F2924 to clarify any uncertainties.

| Question | Answer |

|---|---|

| What is ASTM F2924? | ASTM F2924 is a standard specification for Ti-6Al-4V alloy used in additive manufacturing. |

| Why is Ti-6Al-4V alloy popular? | It’s popular due to its high strength-to-weight ratio, corrosion resistance, and biocompatibility. |

| What industries use ASTM F2924? | Mainly aerospace, medical, automotive, and industrial sectors. |

| How is ASTM F2924 manufactured? | Primarily through powder bed fusion additive manufacturing. |

| What are the key properties of ASTM F2924? | High tensile strength, lightweight, corrosion resistant, and biocompatible. |

| Who supplies ASTM F2924 powders? | Suppliers include AP&C, Carpenter Additive, Tekna, GKN Hoeganaes, and others. |

| What are the typical costs? | Prices range from $330 to $420 per kilogram, depending on the supplier and specifications. |

| Is ASTM F2924 suitable for medical implants? | Yes, due to its biocompatibility and high strength. |

| Can ASTM F2924 be used in 3D printing? | Absolutely, it is specifically designed for additive manufacturing processes like 3D printing. |

| What are the challenges with ASTM F2924? | Challenges include higher costs and the need for precise manufacturing controls. |

Conclusion

ASTM F2924 is a cornerstone in the field of additive manufacturing, particularly for high-performance titanium alloys like Ti-6Al-4V. Its unique combination of strength, weight, corrosion resistance, and biocompatibility makes it invaluable across various demanding industries. By understanding its composition, properties, applications, and the nuances of its manufacturing process, we can appreciate why ASTM F2924 is so highly regarded.

Whether you’re in aerospace, healthcare, or industrial manufacturing, this material offers robust solutions, though it comes with its own set of challenges and costs. Choosing the right supplier and understanding the material’s specifications are crucial steps towards leveraging its full potential.

For anyone diving into the world of additive manufacturing with titanium alloys, ASTM F2924 is undoubtedly a key standard to master.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731