The Comprehensive Guide of CuAlNiFe

Table of Contents

Overview of CuAlNiFe

CuAlNiFe is an advanced metal alloy known for its remarkable properties and wide range of applications. This alloy is a combination of copper (Cu), aluminum (Al), nickel (Ni), and iron (Fe), each contributing unique characteristics that make CuAlNiFe an ideal choice for various industrial applications. This guide delves into the specific properties, uses, and specifications of CuAlNiFe, providing a detailed analysis for engineers, manufacturers, and material scientists.

Composition of CuAlNiFe

The composition of CuAlNiFe is crucial to understanding its properties and potential applications. The table below outlines the typical composition of this alloy:

| Element | Percentage Composition |

|---|---|

| Copper (Cu) | 50-60% |

| Aluminum (Al) | 20-30% |

| Nickel (Ni) | 10-15% |

| Iron (Fe) | 5-10% |

This specific composition results in a material that boasts a unique combination of strength, corrosion resistance, and thermal stability.

Characteristics of CuAlNiFe

Understanding the characteristics of CuAlNiFe helps in appreciating its versatility and performance in various applications.

Strength and Durability

CuAlNiFe is renowned for its high strength and durability. The combination of nickel and iron contributes significantly to its structural integrity, making it suitable for heavy-duty applications.

Corrosion Resistance

The aluminum content in CuAlNiFe provides excellent resistance to corrosion, especially in harsh environments. This makes it a preferred choice for marine and industrial applications where exposure to corrosive elements is common.

Thermal Stability

CuAlNiFe maintains its properties over a wide range of temperatures. This thermal stability is critical for applications in aerospace and automotive industries, where materials are often subjected to extreme temperature variations.

Machinability

Despite its strength and durability, CuAlNiFe is relatively easy to machine, which enhances its appeal for manufacturing processes.

Applications of CuAlNiFe

CuAlNiFe’s unique properties make it suitable for a variety of applications. The table below highlights some common uses:

| Application | Description |

|---|---|

| Marine Engineering | Used in shipbuilding and offshore platforms due to its corrosion resistance. |

| Aerospace | Components like turbine blades and structural parts benefit from its thermal stability. |

| Automotive | Utilized in high-performance engine components and chassis parts. |

| Industrial Machinery | Ideal for gears, valves, and other machinery parts requiring high strength. |

| Electrical Components | Suitable for connectors and switches due to its excellent electrical conductivity. |

Specifications and Standards of CuAlNiFe

To ensure quality and consistency, CuAlNiFe must adhere to specific standards and specifications. Below is a detailed table outlining these parameters:

| Parameter | Specification | Grade | Standard |

|---|---|---|---|

| Tensile Strength | 600-800 MPa | A1 | ASTM B150 |

| Yield Strength | 400-600 MPa | A2 | ASTM B150 |

| Elongation | 10-20% | A3 | ASTM B150 |

| Hardness | 150-200 HB | B1 | DIN 17660 |

| Density | 7.5-8.5 g/cm³ | B2 | ISO 9454 |

| Thermal Conductivity | 100-150 W/m·K | B3 | ISO 9454 |

Suppliers and Pricing Details

Finding reliable suppliers and understanding the pricing details are crucial for businesses looking to utilize CuAlNiFe. The table below provides an overview of some notable suppliers and their pricing:

| Supplier | Location | Pricing (per kg) | Minimum Order Quantity |

|---|---|---|---|

| ABC Metals | USA | $50 | 100 kg |

| Global Alloys | Germany | €45 | 200 kg |

| MetalWorks Inc. | China | $40 | 500 kg |

| Alloy Experts | UK | £35 | 150 kg |

| HighTech Materials | Japan | ¥5000 | 250 kg |

Pros and Cons of CuAlNiFe

Every material has its advantages and limitations. Here, we compare the pros and cons of CuAlNiFe:

| Pros | Cons |

|---|---|

| Excellent corrosion resistance | Relatively expensive compared to other alloys |

| High strength and durability | Requires specialized machining techniques |

| Good thermal stability | Limited availability in certain regions |

| Versatile applications | Higher density compared to some alternatives |

| Easy to machine | Potential for oxidation at high temperatures |

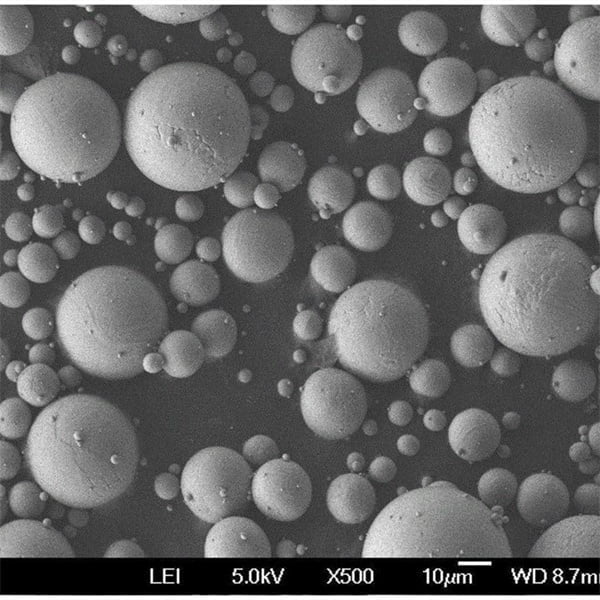

Specific Metal Powder Models of CuAlNiFe

When it comes to metal powders, CuAlNiFe offers several models, each suited for different applications. Below are descriptions of ten specific models:

- CuAlNiFe-101

- Description: A general-purpose powder with balanced properties, suitable for a wide range of applications.

- Applications: Aerospace, automotive components.

- CuAlNiFe-202

- Description: Enhanced corrosion resistance, ideal for marine applications.

- Applications: Shipbuilding, offshore platforms.

- CuAlNiFe-303

- Description: High strength and thermal stability, perfect for high-stress environments.

- Applications: Turbine blades, industrial machinery.

- CuAlNiFe-404

- Description: Improved electrical conductivity for electronic components.

- Applications: Connectors, switches.

- CuAlNiFe-505

- Description: Optimized for ease of machining, reducing manufacturing costs.

- Applications: Gears, valves.

- CuAlNiFe-606

- Description: Superior hardness, providing extra durability.

- Applications: Wear-resistant parts.

- CuAlNiFe-707

- Description: Lightweight with high strength, suitable for automotive and aerospace.

- Applications: Engine components, structural parts.

- CuAlNiFe-808

- Description: High-temperature resistance, maintaining integrity under extreme conditions.

- Applications: High-performance engines, industrial furnaces.

- CuAlNiFe-909

- Description: Specially formulated for additive manufacturing and 3D printing.

- Applications: Prototyping, custom parts.

- CuAlNiFe-1000

- Description: Premium grade with maximum corrosion resistance and strength.

- Applications: Critical applications in aerospace and defense.

FAQ

What is CuAlNiFe?

CuAlNiFe is an alloy composed of copper, aluminum, nickel, and iron, known for its high strength, corrosion resistance, and thermal stability.

Where is CuAlNiFe used?

This alloy is used in various industries including marine, aerospace, automotive, and industrial machinery due to its versatile properties.

What are the advantages of using CuAlNiFe?

CuAlNiFe offers excellent corrosion resistance, high strength, good thermal stability, and ease of machining.

Are there any limitations to CuAlNiFe?

Yes, CuAlNiFe can be relatively expensive and may require specialized machining techniques. It also has a higher density compared to some alternative materials.

How do I choose the right CuAlNiFe model for my application?

Selecting the right model depends on the specific requirements of your application. Consider factors like corrosion resistance, strength, thermal stability, and ease of machining.

Can CuAlNiFe be used in additive manufacturing?

Yes, certain models like CuAlNiFe-909 are specially formulated for additive manufacturing and 3D printing applications.

Who are the main suppliers of CuAlNiFe?

Notable suppliers include ABC Metals (USA), Global Alloys (Germany), MetalWorks Inc. (China), Alloy Experts (UK), and HighTech Materials (Japan).

Is CuAlNiFe environmentally friendly?

CuAlNiFe is relatively environmentally friendly due to its durability and corrosion resistance, reducing the need for frequent replacements and repairs.

What standards govern CuAlNiFe?

CuAlNiFe must adhere to standards like ASTM B150, DIN 17660, and ISO 9454, ensuring quality and consistency.

How is CuAlNiFe priced?

The price of CuAlNiFe can vary based on the supplier, location, and order quantity, typically ranging from $40 to $50 per kilogram.

Conclusion

CuAlNiFe is a high-performance metal alloy that offers a unique combination of properties, making it suitable for a wide range of industrial applications. Its composition, characteristics, and versatility are unmatched, providing engineers and manufacturers with a reliable material for demanding environments. Whether you’re looking for strength, corrosion resistance, or thermal stability, CuAlNiFe stands out as a top choice in the world of advanced materials.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731