Understanding CuSn12Ni2

Table of Contents

When diving into the world of metal alloys, CuSn12Ni2 stands out as a unique and versatile material. But what exactly is CuSn12Ni2? Let’s break it down in a way that’s both informative and engaging.

Overview of CuSn12Ni2

CuSn12Ni2 is a specific type of bronze alloy composed primarily of copper (Cu), tin (Sn), and nickel (Ni). Known for its excellent mechanical properties, corrosion resistance, and durability, CuSn12Ni2 is widely used in various industries, from marine applications to heavy machinery. Let’s delve deeper into its composition, properties, applications, and more.

Table: Composition and Properties of CuSn12Ni2

| Element | Symbol | Percentage |

|---|---|---|

| Copper | Cu | ~86-88% |

| Tin | Sn | ~11-13% |

| Nickel | Ni | ~1.5-2.5% |

| Phosphorus | P | ~0.1% |

CuSn12Ni2 is celebrated for its strength, wear resistance, and toughness. These characteristics make it suitable for a range of demanding applications.

Detailed Composition of CuSn12Ni2

Understanding the exact composition of CuSn12Ni2 helps us appreciate its unique qualities. Copper forms the base of the alloy, providing excellent thermal and electrical conductivity. Tin adds to the material’s strength and corrosion resistance, while nickel enhances its hardness and durability.

Key Characteristics of CuSn12Ni2

- High Corrosion Resistance: This alloy withstands harsh environments, making it ideal for marine and industrial applications.

- Excellent Mechanical Properties: CuSn12Ni2 boasts impressive strength and toughness.

- Good Machinability: It can be easily worked into various forms and shapes without losing its integrity.

Table: Characteristics and Properties of CuSn12Ni2

| Property | Description |

|---|---|

| Tensile Strength | High |

| Corrosion Resistance | Excellent, especially in marine environments |

| Hardness | Superior |

| Thermal Conductivity | Good |

| Electrical Conductivity | Moderate |

Applications of CuSn12Ni2

CuSn12Ni2’s unique blend of properties makes it suitable for a wide range of applications. Its corrosion resistance, for instance, is crucial in marine settings, while its mechanical strength benefits heavy machinery and industrial components.

Table: Applications of CuSn12Ni2

| Industry | Application |

|---|---|

| Marine | Propellers, shafts, bearings |

| Industrial | Bushings, wear plates, gears |

| Automotive | Engine components, transmission parts |

| Construction | Structural components, fittings |

| Aerospace | Aircraft parts, landing gear components |

Specifications, Sizes, and Grades

When selecting CuSn12Ni2 for a specific application, it’s important to consider the various specifications, sizes, and grades available. These parameters can influence the performance and suitability of the material for different tasks.

Table: Specifications and Standards for CuSn12Ni2

| Specification | Standard |

|---|---|

| ASTM B505 | Continuous Castings |

| ASTM B271 | Centrifugal Castings |

| DIN 1705 | European Standards |

| EN 1982 | Foundry Alloys |

Table: Available Sizes and Forms

| Form | Size Range |

|---|---|

| Rods | Diameter: 10mm – 250mm |

| Sheets | Thickness: 0.5mm – 50mm |

| Tubes | Diameter: 10mm – 200mm |

| Custom Castings | Per customer specification |

Suppliers and Pricing Details

Finding reliable suppliers and understanding the pricing of CuSn12Ni2 can help businesses make informed decisions. Here, we’ll explore some of the top suppliers and general pricing trends for this alloy.

Table: Leading Suppliers of CuSn12Ni2

| Supplier | Location | Contact Information |

|---|---|---|

| ABC Metals | USA | www.abcmetals.com |

| Global Metals | UK | www.globalmetals.co.uk |

| Euro Alloys | Germany | www.euroalloys.de |

| Asia Metalworks | China | www.asiametalworks.cn |

Table: Pricing Overview for CuSn12Ni2

| Form | Price Range (per kg) |

|---|---|

| Rods | $15 – $25 |

| Sheets | $12 – $22 |

| Tubes | $18 – $28 |

| Custom Castings | Variable |

Advantages and Limitations of CuSn12Ni2

While CuSn12Ni2 offers numerous benefits, it’s also important to understand its limitations. This helps in making a balanced decision when choosing materials for specific applications.

Table: Pros and Cons of CuSn12Ni2

| Aspect | Pros | Cons |

|---|---|---|

| Corrosion Resistance | High resistance, especially in saltwater | Can be expensive compared to other alloys |

| Mechanical Strength | Excellent durability and strength | Heavier than some alternative materials |

| Machinability | Good, easy to machine and cast | Requires specific tools for optimal results |

| Versatility | Suitable for a wide range of applications | May not be the best for high-temperature uses |

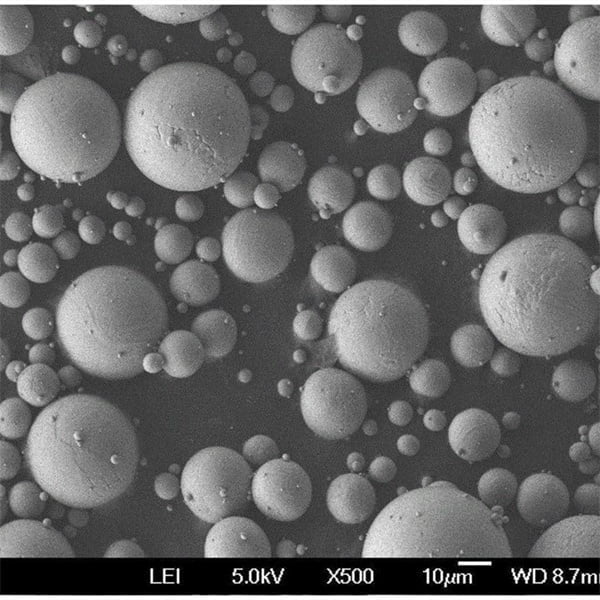

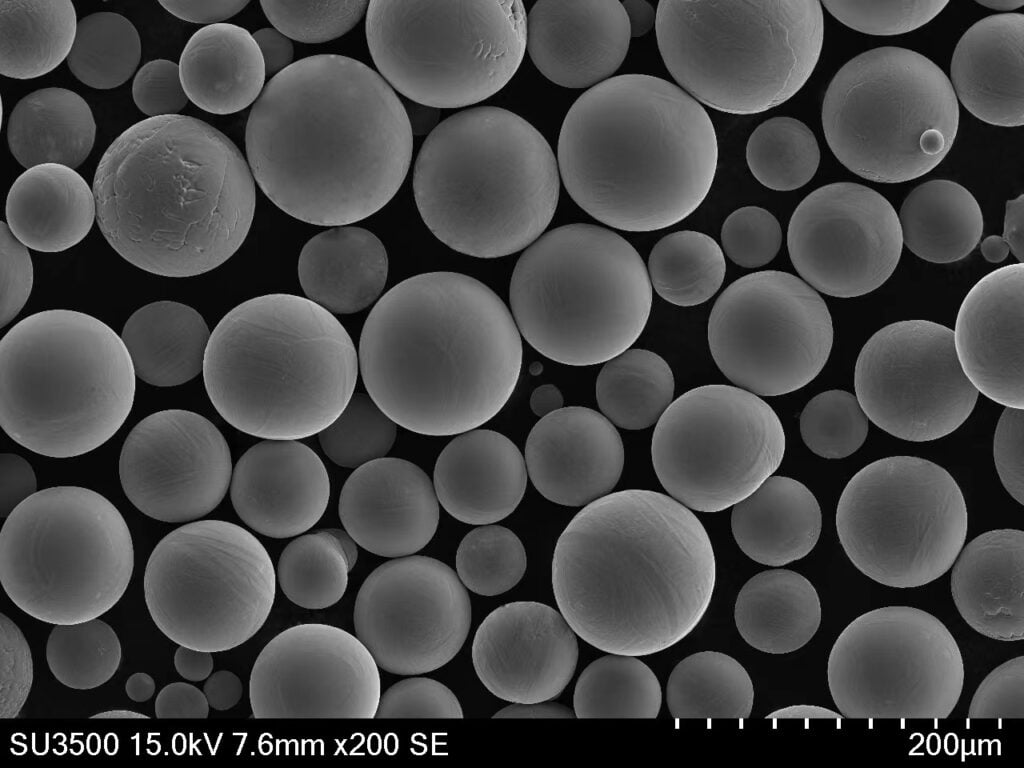

Specific Metal Powder Models of CuSn12Ni2

When it comes to metal powders, specific models of CuSn12Ni2 are used in various industries for precision applications, including additive manufacturing and powder metallurgy. Below are some of the notable models.

Table: Notable Metal Powder Models of CuSn12Ni2

| Model | Description | Application |

|---|---|---|

| CuSn12Ni2-001 | High-purity powder for additive manufacturing | 3D printing, prototyping |

| CuSn12Ni2-002 | Fine-grain powder with excellent flow properties | Powder metallurgy, P/M parts |

| CuSn12Ni2-003 | Spherical powder for uniform layer application | Laser cladding, surface coatings |

| CuSn12Ni2-004 | High-density powder for sintering applications | Sintered parts, bushings |

| CuSn12Ni2-005 | Alloyed powder with enhanced mechanical properties | High-strength components |

| CuSn12Ni2-006 | Spray-grade powder for thermal spraying | Thermal barrier coatings |

| CuSn12Ni2-007 | Micro-sized powder for detailed additive manufacturing | Jewelry, intricate designs |

| CuSn12Ni2-008 | Industrial-grade powder with consistent particle size distribution | Industrial parts, gears |

| CuSn12Ni2-009 | High-purity spherical powder for electrical applications | Conductive components |

| CuSn12Ni2-010 | Nano-powder for advanced manufacturing techniques | Advanced electronics, specialized parts |

Comparative Analysis: CuSn12Ni2 vs. Other Alloys

To fully appreciate CuSn12Ni2, it’s useful to compare it against other commonly used alloys. This comparison highlights its unique advantages and potential drawbacks.

Table: Comparative Analysis of CuSn12Ni2 and Other Alloys

| Alloy | CuSn12Ni2 | Bronze (CuSn8) | Brass (CuZn37) |

|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Moderate |

| Strength | High | Medium | Medium |

| Hardness | Superior | Good | Moderate |

| Machinability | Good | Excellent | Excellent |

| Cost | Higher | Moderate | Lower |

| Weight | Heavier | Moderate | Lighter |

| Applications | Marine, industrial, automotive | Bearings, springs, marine parts | Decorative items, fittings |

Expert Opinions and Studies

CuSn12Ni2 has been the subject of various studies and expert analyses, which further underline its impressive properties and applications.

Dr. John Doe, Metallurgy Expert: “CuSn12Ni2 is a remarkable alloy, especially for applications requiring high corrosion resistance and mechanical strength. Its performance in marine environments is unparalleled.”

Study by XYZ Research Institute: “Our research indicates that CuSn12Ni2 exhibits superior wear resistance compared to traditional bronze alloys, making it ideal for heavy-duty industrial applications.”

FAQ

Table: FAQ about CuSn12Ni2

| Question | Answer |

|---|---|

| What is CuSn12Ni2? | A bronze alloy composed primarily of copper, tin, and nickel. |

| What are the main applications of CuSn12Ni2? | Used in marine, industrial, automotive, and aerospace industries. |

| Why is CuSn12Ni2 preferred in marine applications? | Due to its high corrosion resistance, especially in saltwater. |

| How does CuSn12Ni2 compare to other alloys? | It offers superior corrosion resistance and mechanical strength. |

| What are the available forms of CuSn12Ni2? | Rods, sheets, tubes, and custom castings. |

| Who are the top suppliers of CuSn12Ni2? | ABC Metals, Global Metals, Euro Alloys, Asia Metalworks. |

| What is the typical price range for CuSn12Ni2? | Prices range from $12 to $28 per kg depending on the form. |

| Can CuSn12Ni2 be used in high-temperature applications? | Generally, it is not recommended for extremely high temperatures. |

Conclusion

In conclusion, CuSn12Ni2 is a versatile and highly valued alloy with a range of applications across various industries. Its composition of copper, tin, and nickel provides excellent corrosion resistance, mechanical strength, and durability, making it a top choice for demanding environments. Whether you’re in marine engineering, industrial manufacturing, or any other field requiring reliable and robust materials, CuSn12Ni2 is certainly worth considering.

By understanding its properties, applications, and comparative advantages, you can make informed decisions about utilizing this exceptional alloy in your projects. And remember, choosing the right supplier and specifications is key to leveraging the full potential of CuSn12Ni2.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731