Eco-Friendly Additive Manufacturing in Berlin: A Sustainable Future for 3D Printing

Table of Contents

1. Introduction: Why Eco-Friendly Additive Manufacturing Matters in Berlin’s Industrial Ecosystem

As one of Europe’s most innovative and environmentally conscious cities, Berlin is leading the charge toward a sustainable manufacturing future. With its strong focus on clean technologies, renewable energy, and circular economy principles, Berlin has become a hub for eco-friendly additive manufacturing (AM), especially in sectors like automotive, aerospace, and medical devices.

Additive manufacturing, also known as 3D printing, offers significant environmental benefits over traditional manufacturing, including:

- Reduced material waste through precise layer-by-layer deposition

- Lower transportation emissions via localized production

- Energy efficiency in production and post-processing

- Flexibility to design lightweight parts that reduce fuel consumption in end-use applications

Yet, the green potential of AM can only be fully realized when eco-friendly materials and sustainable production methods are used. That’s where innovators like Metal3DP come in—pioneering sustainable 3D printing with high-quality metal powders and advanced printing technologies.

Key Benefits of Eco-Friendly 3D Printing:

| Benefit | Description |

|---|---|

| Waste Reduction | Additive processes use only the material needed, eliminating scrap |

| Energy Efficiency | Lower energy consumption during both production and post-processing |

| Lightweight Components | Lighter parts reduce energy usage in transportation and machinery |

| Localized Manufacturing | Reduces transport emissions and supports regional economies |

| Recyclable Materials | Many metal powders can be reused or recycled without quality degradation |

Berlin’s industrial base, supported by government incentives and a skilled workforce, is perfectly positioned to adopt and scale sustainable AM, especially through international partnerships.

2. Market Trends: The Rise of Sustainable 3D Printing in Germany

Germany has long been a global manufacturing powerhouse, and in recent years, it has embraced additive manufacturing as a key driver of Industry 4.0 and environmental transformation. According to a 2023 report by AM Power, the German AM market is expected to grow at a CAGR of over 17% through 2027, with sustainability being a major growth catalyst.

Key Drivers Behind Eco-Friendly AM Growth in Berlin:

- Government Support: The German federal government offers funding for green innovation and energy-efficient manufacturing.

- Corporate Sustainability Mandates: Companies like Siemens, BMW, and Bosch are integrating AM to meet ESG goals.

- Urban Innovation: Berlin’s startup ecosystem fosters cross-industry collaborations in green tech and 3D printing.

- Academic R&D: Institutions like TU Berlin and Fraunhofer Institute are at the forefront of sustainable AM research.

Top Applications of Eco-Friendly Additive Manufacturing in Berlin

| Industry | Application Examples |

|---|---|

| Aerospace | Lightweight turbine parts, fuel-efficient components |

| Medical Devices | Biocompatible implants with minimal waste |

| Automotive | Custom tooling, lightweight brackets, EV components |

| Architecture | Sustainable housing components, design prototypes |

| Consumer Goods | Eco-friendly packaging molds, biodegradable prototypes |

Berlin’s green manufacturing momentum has led to increased demand for eco-friendly 3D printing materials, particularly metal powders that are recyclable, high-performing, and produced with low-emission processes.

3. Key Factors to Consider When Choosing Eco-Friendly Additive Manufacturing Suppliers

Selecting the right supplier is critical for businesses looking to adopt sustainable additive manufacturing. Whether you’re sourcing wholesale metal powders, industrial-grade 3D printers, or seeking a long-term partner for green production, the following criteria will help you identify a reliable and eco-conscious supplier.

✅ Key Selection Criteria for Sustainable AM Suppliers

- Material Quality & Certification

- Ensure the supplier offers high-purity metal powders with traceability and ISO certifications.

- Look for materials optimized for low waste and high yield during the build process.

- Green Manufacturing Processes

- Does the supplier use eco-friendly powder production methods such as gas atomization or PREP (Plasma Rotating Electrode Process)?

- Do they recycle unused powders and minimize energy consumption?

- Sustainability Commitment

- Is sustainability embedded in their operations, logistics, and R&D?

- Do they provide lifecycle analysis or carbon footprint data?

- Customization & Technical Support

- Can they tailor powder compositions or printing parameters to reduce waste?

- Are they willing to collaborate on green product development?

- Global Logistics & Scalability

- Can they handle bulk orders for wholesale 3D printing materials and ship internationally?

- Do they offer stable lead times and consistent quality?

Checklist: What to Ask Your Additive Manufacturing Supplier

| Question | Why It Matters |

|---|---|

| What powder production methods do you use? | Gas atomization and PREP are cleaner than chemical methods |

| Can your metal powders be reused? | Reusability reduces waste and cost |

| Do you provide environmental certifications? | Shows commitment to sustainability |

| How do you handle logistics and packaging? | Efficient packaging reduces carbon footprint |

| Do you offer technical support for green applications? | Expertise accelerates sustainable innovation |

One supplier that checks all the above boxes is Metal3DP, which manufactures high-quality metal powders using eco-friendly gas atomization and PREP technologies. Their powders are specifically engineered for low-waste, high-performance builds in industries like aerospace and medical.

4. Top 5 Eco-Friendly Additive Manufacturing Suppliers in Berlin

Berlin is home to a growing number of additive manufacturing companies that prioritize environmental sustainability, offering eco-friendly materials, energy-efficient equipment, and closed-loop production models. Below is a curated list of the top 5 eco-conscious AM suppliers in Berlin that are making waves in the European market.

🏆 Top 5 Sustainable 3D Printing Suppliers in Berlin

| Company Name | Key Strengths | Eco-Friendly Features | B2B Services |

|---|---|---|---|

| BigRep | Large-format 3D printing | Recyclable filaments, energy-efficient machines | Custom manufacturing, prototyping |

| Trinckle | Design automation | Software for material-efficient design | Integration with green design pipelines |

| 3YOURMIND | Workflow automation | Optimizes print jobs to minimize waste | Enterprise software for AM fleets |

| Formlabs Berlin | Resin-based printing | Low-emission resins, recycling initiatives | Equipment sales, training |

| Fraunhofer IKTS | R&D and ceramics | Green materials, closed-loop systems | Contract research, development services |

🔍 What Makes These Suppliers Stand Out?

- BigRep: Known for their XL 3D printers, BigRep uses recyclable thermoplastics and optimizes for minimal energy consumption.

- Trinckle: Offers software that helps industrial buyers design lightweight, material-saving parts.

- 3YOURMIND: Helps manufacturers reduce material waste through intelligent print job scheduling.

- Formlabs: Offers eco-friendly resins and initiatives for material reclamation.

- Fraunhofer IKTS: Provides sustainable material innovation for ceramics and metal AM.

However, while these Berlin-based companies are excellent for prototyping and small-batch runs, many industrial buyers are now looking globally for high-volume, cost-effective, and sustainable sourcing — especially for metal powders and equipment.

5. Why More Buyers Are Choosing Chinese Suppliers for Green 3D Printing Materials

As the demand for sustainable additive manufacturing solutions grows, many B2B buyers, OEMs, and distributors in Germany and across Europe are increasingly turning to Chinese suppliers for their eco-friendly 3D printing needs. China’s AM industry has matured rapidly in recent years, offering not only affordability but also technical excellence and green manufacturing innovation.

🌍 The Shift Toward Global Sourcing in Additive Manufacturing

| Reason | Impact for Buyers |

|---|---|

| Lower material costs | Competitive pricing for bulk orders |

| Advanced powder technology | High-performance powders like TiAl, CoCrMo, TiNbZr |

| Scalable production | Suitable for mass manufacturing |

| Green manufacturing processes | Gas atomization, powder recycling, energy optimization |

| Technical support in English | Global B2B collaboration is easier than ever |

🔋 Why Chinese Suppliers Excel in Sustainability

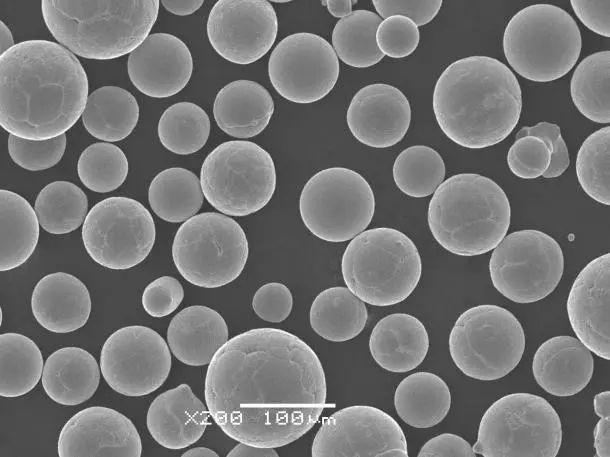

- Green Powder Production Methods: Many Chinese manufacturers now use gas atomization and PREP technologies, which are more energy-efficient and produce spherical powders with excellent flowability.

- Eco-Certified Supply Chains: Leading suppliers in China are obtaining ISO 14001 and other environmental certifications to meet EU regulatory standards.

- Innovation in Alloy Development: Chinese suppliers offer custom alloys specifically designed to reduce post-processing and energy use.

Among these suppliers, Metal3DP is a standout. Headquartered in Qingdao, China, Metal3DP provides eco-friendly metal powders and high-performance 3D printers that are already being used in aerospace, medical, and automotive sectors across Europe.

✅ “We are seeing a surge in inquiries from German OEMs and service bureaus who are not only looking for cost-effective solutions but also demand materials with minimal environmental impact,” says a spokesperson from Metal3DP.

6. Why Choose Metal3DP as Your Sustainable Additive Manufacturing Partner

If you’re a wholesale buyer, distributor, or industrial manufacturer in Berlin looking to implement sustainable 3D printing at scale, Metal3DP offers a comprehensive, reliable, and eco-conscious solution.

🔧 What Makes Metal3DP Unique?

| Feature | Benefit for B2B Buyers |

|---|---|

| Spherical metal powders | High flowability, low waste, consistent quality |

| Gas atomization & PREP technologies | Clean, sustainable production methods |

| Wide alloy portfolio | TiNi, TiTa, TiAl, CoCrMo, Stainless Steels, Superalloys |

| High-volume build capacity | Ideal for industrial manufacturing |

| Global logistics | Fast, scalable delivery to Europe and beyond |

🌱 Sustainability-Driven Manufacturing

Metal3DP’s commitment to sustainability is embedded in every aspect of its operations:

- Eco-Friendly Powder Making: The company uses a proprietary nozzle and gas flow design to minimize energy consumption and maximize yield during atomization.

- Material Reusability: Its powders are engineered for multiple reuse cycles without compromising mechanical properties.

- Design for Sustainability: Metal3DP collaborates with clients to reduce their carbon footprint through topology optimization and material efficiency.

🎯 Tailored B2B Services Offered by Metal3DP

- Bulk ordering of high-performance metal powders

- Custom alloy development for specific applications

- Turnkey SEBM printer solutions for industrial use

- Application development support for sustainable part design

- Global shipping and multilingual customer service

📌 Learn more about their products and capabilities for sustainable additive manufacturing.

🛠 Example: Sustainable Aerospace Component Production

A Tier 1 aerospace supplier in Europe collaborated with Metal3DP to 3D print lightweight, high-stress components using TiAl alloy. By switching to Metal3DP’s powders and SEBM system:

- Material waste was reduced by 38%

- Post-processing steps were reduced by 25%

- Component weight was reduced by 22%, improving fuel efficiency

This partnership helped the client meet both technical and ESG targets, proving that sustainability and performance can go hand-in-hand.

7. How to Order Eco-Friendly 3D Printing Powders and Equipment Wholesale

For industrial buyers in Berlin and the broader EU looking to scale their additive manufacturing operations with a focus on sustainability, sourcing the right materials and equipment wholesale is critical. Whether you need high-performance metal powders, SEBM 3D printers, or full production solutions, choosing a reliable supplier with a streamlined ordering process is essential to reduce procurement costs and ensure operational efficiency.

Here’s how to order eco-friendly 3D printing materials and equipment wholesale from trusted suppliers like Metal3DP.

✅ Step-by-Step Guide to Wholesale Ordering

| Step | Description |

|---|---|

| 1. Define Your Requirements | Identify the type of material (e.g., TiAl, CoCrMo), quantity (kg/ton), and equipment needs |

| 2. Evaluate Supplier Capabilities | Check certifications, production capacity, and environmental compliance |

| 3. Request a Quote or Sample | Ask for pricing tiers based on volume and request powder samples for testing |

| 4. Assess Technical Support | Ensure the supplier can offer custom R&D, alloy composition services, and print optimization |

| 5. Review Logistics & Timelines | Clarify lead times, shipping options, and customs documentation for EU import |

| 6. Place Bulk Order | Finalize purchase agreement and confirm payment terms (TT, LC, etc.) |

| 7. Post-Sales Support | Confirm warranty, training, and service agreements for equipment purchases |

📦 Bulk Ordering from Metal3DP: What You Can Expect

Metal3DP offers a full-service approach to wholesale 3D printing procurement:

- High-volume production of gas-atomized and PREP metal powders

- OEM support for selective electron beam melting (SEBM) printers

- Customized alloy development for application-specific performance

- Global shipping with EU-compliant documentation and REACH conformity

- Dedicated technical support and powder reusability consulting

💡 Learn about Metal3DP’s metal additive manufacturing solutions for aerospace, medical, and automotive use cases.

📄 Required Documentation for Importing into the EU

| Document | Purpose |

|---|---|

| Material Safety Data Sheet (MSDS) | Details hazards and handling for metal powders |

| Certificate of Analysis (CoA) | Proof of material quality and composition |

| EU REACH Compliance | Confirms product meets European chemical safety standards |

| ISO 9001 / 13485 / 14001 | Quality and environmental certifications |

| Packing List & Commercial Invoice | Required for customs and freight forwarding |

By working with established suppliers like Metal3DP, B2B buyers in Berlin can simplify international sourcing while aligning with sustainability and performance goals.

8. Frequently Asked Questions About Sustainable Additive Manufacturing in Berlin

To help procurement professionals, engineers, and industrial buyers navigate the evolving landscape of sustainable 3D printing, we’ve compiled a list of answers to the most common questions about eco-friendly additive manufacturing in Berlin.

❓ What qualifies a 3D printing process as “eco-friendly”?

A 3D printing process is considered eco-friendly when it minimizes environmental impact through:

- Reduced material waste (as in powder bed fusion processes)

- Use of recyclable or reusable materials

- Energy-efficient equipment and workflows

- Green powder production methods like gas atomization

- Localized manufacturing to shorten supply chains

❓ Are metal powders recyclable?

Yes. High-quality metal powders, especially those from suppliers like Metal3DP, are designed for multiple reuse cycles in powder bed fusion systems such as SEBM and SLM. These powders maintain consistent flowability and mechanical properties when reused properly.

❓ Can I order custom alloys for specific applications?

Absolutely. Metal3DP offers custom alloy formulation services for clients who need specialized mechanical, thermal, or biomedical properties. Popular custom alloys include:

- TiNbZr (biocompatible orthopedic implants)

- TiAl (high-temperature aerospace parts)

- CoCrMo (wear-resistant medical devices)

❓ What’s the lead time for wholesale metal powder orders?

Typical lead times range from 2 to 6 weeks, depending on order volume and alloy type. For European customers, Metal3DP provides consolidated shipping options and customs clearance support.

❓ What industries benefit most from sustainable 3D printing?

The biggest adopters of eco-friendly additive manufacturing in Berlin and across Europe include:

- Aerospace: Lightweight, fuel-efficient components

- Medical: Biocompatible implants and surgical tools

- Automotive: EV parts, brackets, and tooling

- Architecture: Sustainable construction components

- Industrial Manufacturing: Custom jigs, molds, and spare parts

For more on Metal3DP’s industry applications, visit the About Us page.

9. Conclusion: Building a Greener Supply Chain with Additive Manufacturing

Sustainability is no longer a nice-to-have — it’s a business imperative. For manufacturers and procurement leaders in Berlin, embracing eco-friendly additive manufacturing offers a powerful way to meet ESG mandates, reduce operational waste, and drive innovation in product development.

While Berlin-based suppliers are advancing local capabilities, global players like Metal3DP are making it easier than ever to source sustainable materials and equipment at scale. With a robust portfolio of metal powders, next-gen SEBM printers, and green powder production methods, Metal3DP is uniquely positioned to support your transition to a more sustainable digital manufacturing model.

✅ Why Choose Metal3DP?

- Industry-leading gas atomization and PREP technologies

- High-performance, eco-friendly metal powders

- Proven expertise in aerospace, medical, and automotive applications

- Custom alloy services and wholesale B2B pricing

- End-to-end technical support and global logistics

📩 Ready to Start Your Sustainable 3D Printing Journey?

Visit the Metal3DP website to explore the full range of products and services, or contact their team for a customized quote on wholesale 3D printing powders and equipment. Whether you’re a Berlin-based OEM, a European distributor, or a global partner, Metal3DP is here to help you build greener, smarter, and more efficient manufacturing systems.

🔗 Internal Anchor Text Links Used in This Article:

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731