GH3536: High-Performance Metal Powder

Table of Contents

Overview

GH3536, also known as Hastelloy X, is a nickel-chromium-iron-molybdenum alloy known for its exceptional high-temperature strength and oxidation resistance. This material is widely used in extreme environments such as gas turbines, aircraft engines, and chemical processing. Understanding the nuances of GH3536 and its applications can help engineers and materials scientists choose the right metal powder for their specific needs.

In this guide, we’ll dive into the properties, composition, and various models of GH3536 metal powder. We’ll also explore its applications, specifications, suppliers, and compare its pros and cons with similar materials.

Composition of GH3536

GH3536 is a superalloy composed of several key elements. Here’s a breakdown of its typical composition:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 47-52 |

| Chromium (Cr) | 20.5-23 |

| Iron (Fe) | 17-20 |

| Molybdenum (Mo) | 8-10 |

| Tungsten (W) | 0.2-1 |

| Cobalt (Co) | 1-2.5 |

| Carbon (C) | 0.05-0.15 |

| Manganese (Mn) | 1 max |

| Silicon (Si) | 1 max |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

Characteristics of GH3536

GH3536 boasts several notable characteristics, making it a preferred choice for high-stress applications. Let’s break down these properties:

| Property | Description |

|---|---|

| High-Temperature Strength | Maintains mechanical strength at temperatures up to 1200°C. |

| Oxidation Resistance | Excellent resistance to oxidation at high temperatures. |

| Corrosion Resistance | Withstands various corrosive environments, particularly in oxidizing and reducing atmospheres. |

| Fabrication Ability | Easily fabricated using traditional techniques like welding, forming, and machining. |

| Creep Resistance | Low creep rate under high-stress conditions. |

| Ductility | High ductility, allowing it to withstand deformation without fracture. |

Applications of GH3536

GH3536 is versatile and finds use in numerous high-stress, high-temperature environments. Here are some key applications:

| Industry | Applications |

|---|---|

| Aerospace | Turbine blades, afterburner components, jet engines. |

| Chemical Processing | Heat exchangers, reactor vessels, piping systems. |

| Power Generation | Gas turbines, industrial furnace components. |

| Petrochemical | Catalytic systems, refinery components. |

| Automotive | High-performance exhaust systems. |

Specifications, Sizes, Grades, and Standards

When selecting GH3536 for a specific application, it’s essential to consider the various specifications and standards. Here’s a detailed table for your reference:

| Specification | Details |

|---|---|

| Standards | ASTM B435, ASTM B572, AMS 5536, AMS 5798 |

| Form | Plate, sheet, bar, wire, forging, powder |

| Size Range | Thickness: 0.01 – 100 mm, Width: 10 – 1000 mm, Length: up to 3000 mm |

| Grades | Standard GH3536, Modified GH3536 (for specific applications) |

| Tolerances | Precision-cut to meet specific design requirements |

| Surface Finish | Available in various finishes, including polished, matte, and coated |

| Heat Treatment | Solution treated at 1175°C (2147°F), air cooled or water quenched |

| Mechanical Properties | Tensile strength: 827 MPa, Yield strength: 310 MPa, Elongation: 50% |

| Thermal Conductivity | 11.2 W/m·K at 20°C |

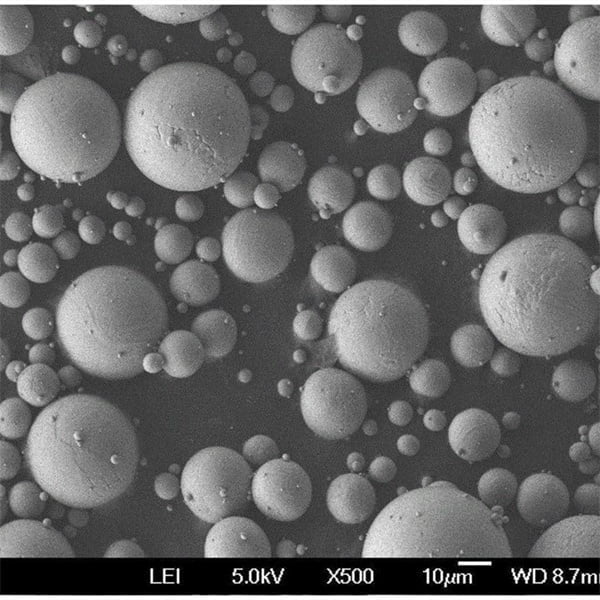

Metal Powder Models

When it comes to GH3536 metal powders, several models are available, each tailored for specific applications and processes. Here are ten notable ones:

1. GH3536-PM01

- Description: Fine powder, ideal for additive manufacturing and 3D printing.

- Particle Size: 15-45 microns.

- Application: Aerospace components, medical implants.

2. GH3536-PM02

- Description: Coarser powder suitable for powder metallurgy.

- Particle Size: 45-150 microns.

- Application: High-strength parts, automotive components.

3. GH3536-PM03

- Description: Spherical powder, optimized for laser cladding.

- Particle Size: 20-63 microns.

- Application: Surface coating, repair applications.

4. GH3536-PM04

- Description: Gas-atomized powder with excellent flowability.

- Particle Size: 10-50 microns.

- Application: Selective laser melting (SLM), electron beam melting (EBM).

5. GH3536-PM05

- Description: Plasma-atomized powder for high-performance applications.

- Particle Size: 15-53 microns.

- Application: Turbine blades, high-temperature furnace parts.

6. GH3536-PM06

- Description: Customized particle size distribution for specific applications.

- Particle Size: 10-100 microns.

- Application: Diverse industrial uses, including chemical processing.

7. GH3536-PM07

- Description: Pre-alloyed powder ensuring uniform composition.

- Particle Size: 20-80 microns.

- Application: Metal injection molding (MIM), HIP processes.

8. GH3536-PM08

- Description: Vacuum-atomized powder with minimal impurities.

- Particle Size: 15-45 microns.

- Application: Critical aerospace and defense components.

9. GH3536-PM09

- Description: Fine powder for precision engineering.

- Particle Size: 5-25 microns.

- Application: Micro-fabrication, high-precision parts.

10. GH3536-PM10

- Description: Water-atomized powder with high bulk density.

- Particle Size: 25-100 microns.

- Application: Wear-resistant coatings, bulk parts manufacturing.

Suppliers and Pricing Details

Finding the right supplier for GH3536 is crucial for obtaining high-quality material. Here’s a list of reputable suppliers and approximate pricing details:

| Supplier | Location | Product Range | Approximate Price (USD/kg) |

|---|---|---|---|

| Hastelloy Inc. | USA | Sheets, plates, powders | 100-150 |

| Special Metals | UK | Bars, wires, forgings | 120-160 |

| Alloy Wire Intl. | USA, UK | Wires, coils | 110-140 |

| VDM Metals | Germany | Sheets, rods, powders | 130-170 |

| ATI Metals | USA | Sheets, bars, billets | 105-145 |

| Haynes Intl. | USA | Sheets, bars, wires | 115-155 |

| Sandvik Materials | Sweden | Tubes, wires, strips | 125-165 |

| Carpenter Tech. | USA | Powders, bars, rods | 120-160 |

| ThyssenKrupp | Germany | Plates, sheets, bars | 130-170 |

| Daido Steel | Japan | Bars, sheets, powders | 110-150 |

Pros and Cons of GH3536

When considering GH3536, it’s essential to weigh its advantages and disadvantages compared to other materials. Here’s a comprehensive comparison:

| Aspect | GH3536 | Alternative Alloys |

|---|---|---|

| High-Temperature Strength | Better: Superior strength at temperatures up to 1200°C. | Compared to: Inconel 718, which is limited to ~700°C. |

| Oxidation Resistance | Better: Excellent oxidation resistance at high temperatures. | Compared to: Stainless steel, which oxidizes faster. |

| Corrosion Resistance | Better: Withstands harsh environments. | Compared to: Alloy 600, less effective in reducing atmospheres. |

| Fabrication Ability | Comparable: Easily fabricated using traditional methods. | Compared to: Cobalt alloys, which are harder to machine. |

| Cost | More Expensive: Higher cost due to complex composition and processing. | Compared to:Stainless steels, which are generally cheaper. |

| Availability | Limited: Availability may be restricted compared to more common alloys. | Compared to: Widely available materials like stainless steel. |

| Applications | Versatile: Suitable for aerospace, chemical processing, and power generation. | Compared to: Limited use in specific industries. |

FAQ

What is GH3536 used for?

GH3536 is used in high-temperature and high-stress applications such as turbine blades, chemical processing equipment, and gas turbine components due to its excellent strength and oxidation resistance.

How does GH3536 compare to Inconel 718?

GH3536 offers superior high-temperature strength and oxidation resistance compared to Inconel 718, which is more limited in these aspects but generally cheaper and more available.

Can GH3536 be welded?

Yes, GH3536 can be welded using conventional welding techniques, including gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW).

What are the key benefits of using GH3536?

The key benefits include high-temperature strength, excellent oxidation and corrosion resistance, good fabricability, and versatility in various industrial applications.

Where can I buy GH3536?

GH3536 can be purchased from specialized suppliers such as Hastelloy Inc., Special Metals, VDM Metals, and others listed in the supplier section above.

Is GH3536 suitable for additive manufacturing?

Yes, GH3536 is suitable for additive manufacturing processes, particularly when using fine powders like GH3536-PM01, optimized for 3D printing and selective laser melting.

What are the common forms of GH3536?

Common forms include sheets, plates, bars, wires, forgings, and powders, available in various sizes and finishes to meet specific application requirements.

How does GH3536 perform in corrosive environments?

GH3536 performs exceptionally well in both oxidizing and reducing environments, making it ideal for use in chemical processing and petrochemical industries.

What standards apply to GH3536?

GH3536 conforms to standards such as ASTM B435, ASTM B572, AMS 5536, and AMS 5798, ensuring quality and consistency across different forms and applications.

What are the mechanical properties of GH3536?

GH3536 exhibits a tensile strength of 827 MPa, yield strength of 310 MPa, and an elongation of 50%, making it highly robust and ductile for demanding applications.

Conclusion

GH3536, or Hastelloy X, stands out as a premier choice for high-temperature and high-stress applications due to its remarkable mechanical properties, corrosion resistance, and fabricability. Whether you’re in aerospace, chemical processing, or power generation, understanding the specifics of GH3536 can guide you in making informed decisions for your projects. With various suppliers and models available, tailored solutions are within reach to meet your unique needs.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731