GH3625: A Comprehensive Guide to Composition, Characteristics, and Applications

Table of Contents

Welcome to our in-depth exploration of GH3625, a remarkable metal powder that has gained significant traction in various industries. In this article, we’ll delve into the nitty-gritty details of GH3625, covering everything from its composition and characteristics to its applications and advantages. Whether you’re a materials engineer, a researcher, or simply curious about advanced materials, this guide will provide you with all the information you need.

Overview of GH3625

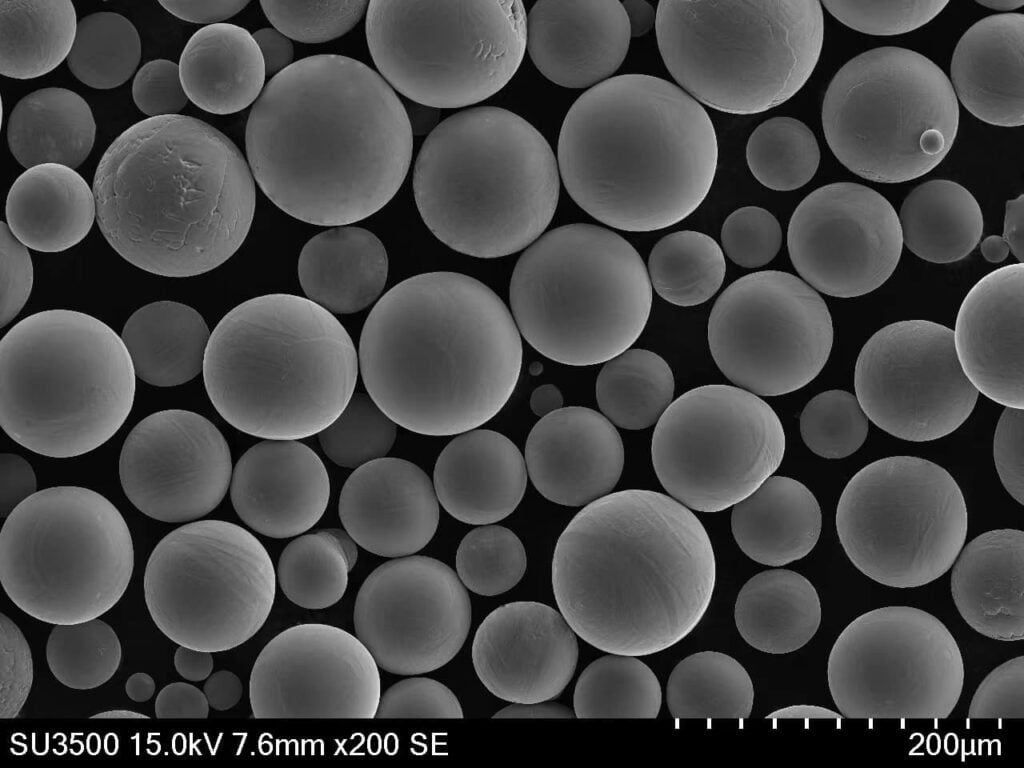

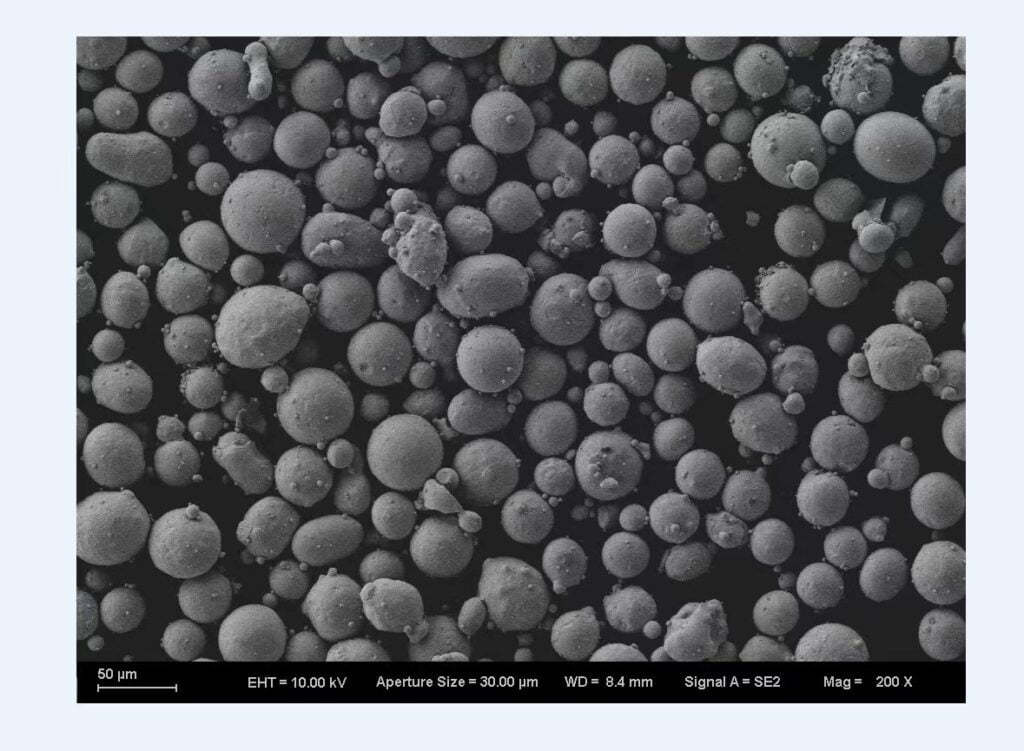

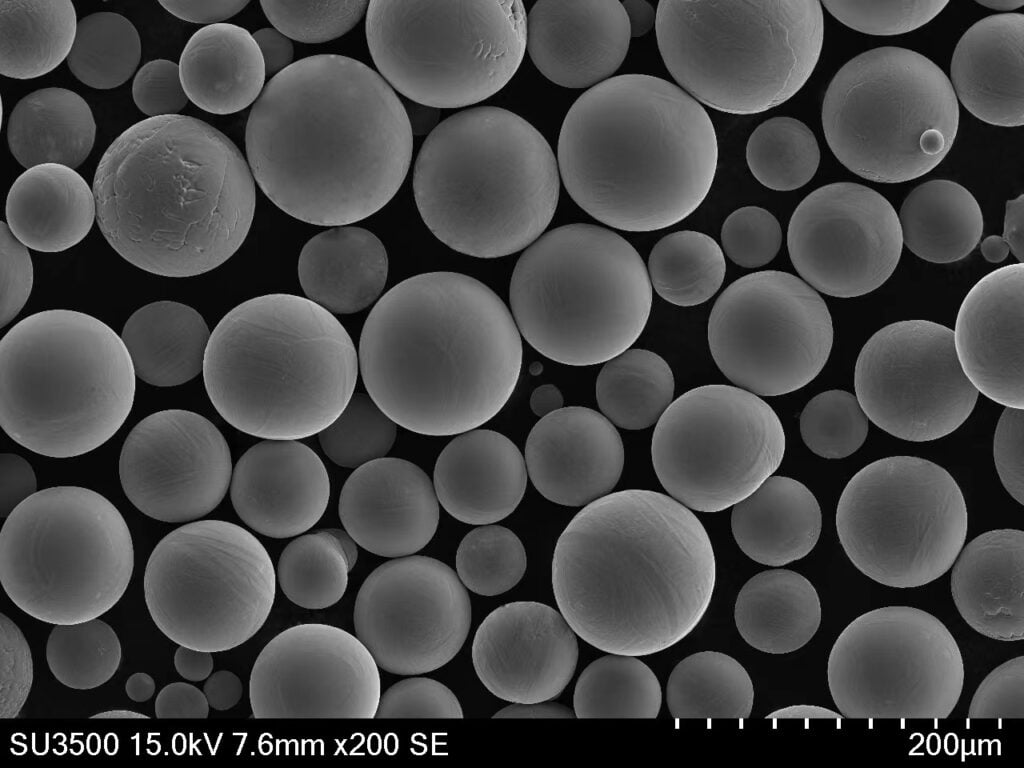

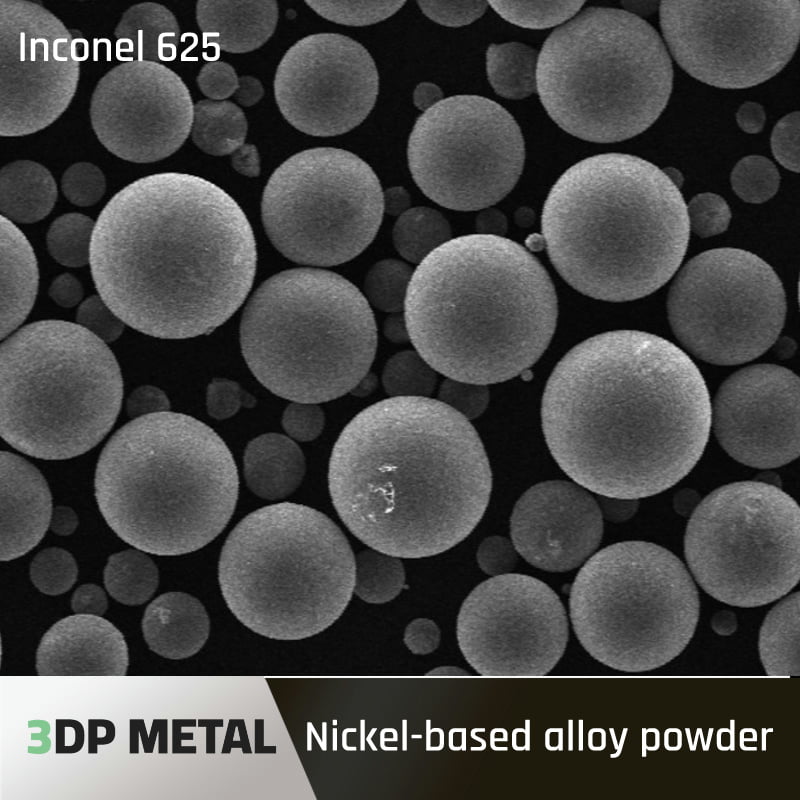

GH3625 is a high-performance nickel-chromium-based superalloy known for its exceptional resistance to oxidation and corrosion, high-temperature stability, and excellent mechanical properties. This alloy is often utilized in demanding environments, such as aerospace, power generation, and chemical processing industries.

Key Details:

- Composition: Nickel-chromium-based superalloy

- Properties: High-temperature stability, corrosion and oxidation resistance, excellent mechanical strength

- Applications: Aerospace, power generation, chemical processing, and more

Composition of GH3625

Understanding the composition of GH3625 is crucial for appreciating its unique properties. This alloy is meticulously engineered with specific elements to achieve its outstanding performance.

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 58.0 – 63.0 |

| Chromium (Cr) | 20.0 – 23.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Iron (Fe) | 5.0 – 7.0 |

| Niobium (Nb) | 3.15 – 4.15 |

| Titanium (Ti) | 0.65 – 1.15 |

| Aluminum (Al) | 0.2 – 0.8 |

| Cobalt (Co) | ≤ 1.0 |

| Manganese (Mn) | ≤ 0.35 |

| Silicon (Si) | ≤ 0.35 |

| Carbon (C) | ≤ 0.10 |

Characteristics of GH3625

GH3625 boasts a range of impressive characteristics that make it suitable for high-stress applications:

- High-Temperature Stability: Maintains strength and integrity at elevated temperatures.

- Oxidation and Corrosion Resistance: Withstands harsh chemical environments.

- Mechanical Strength: Offers excellent tensile strength and fatigue resistance.

- Versatility: Suitable for various manufacturing processes, including additive manufacturing and powder metallurgy.

Applications of GH3625

GH3625 is used across multiple industries, thanks to its robust properties. Here’s a look at some of the key applications:

| Industry | Application |

|---|---|

| Aerospace | Turbine blades, exhaust systems, combustion chambers |

| Power Generation | Gas turbines, heat exchangers |

| Chemical Processing | Reactors, piping systems, heat treatment equipment |

| Marine | Engine components, valves, pumps |

| Automotive | Turbocharger rotors, exhaust manifolds |

Specifications, Sizes, Grades, and Standards

When selecting GH3625 for specific applications, it’s essential to consider its specifications, sizes, grades, and standards.

| Parameter | Details |

|---|---|

| Standards | ASTM B443, B444, B446, AMS 5666, DIN 17751 |

| Grades | GH3625, Inconel 625 |

| Sizes | Available in powder form, bar, plate, and sheet |

| Specifications | Powder: D50 10-45 microns, Bars: 1-100 mm diameter |

Specific Metal Powder Models

When it comes to metal powders, having a variety of models allows for precise selection based on the intended application. Here are ten specific models of GH3625 metal powder, each with unique attributes:

- GH3625-P1: Ideal for additive manufacturing with a particle size of 15-45 microns.

- GH3625-P2: High purity powder designed for critical aerospace components.

- GH3625-P3: Optimized for high-temperature applications with enhanced oxidation resistance.

- GH3625-P4: Fine powder (10-30 microns) for precision parts and intricate designs.

- GH3625-P5: Medium-sized particles (20-50 microns) suitable for general-purpose use.

- GH3625-P6: High flowability powder for efficient powder bed fusion processes.

- GH3625-P7: Enhanced for chemical processing applications with superior corrosion resistance.

- GH3625-P8: Specifically tailored for marine environments with increased saltwater resistance.

- GH3625-P9: Designed for automotive components, providing excellent thermal stability.

- GH3625-P10: Multi-purpose powder with balanced properties for various industrial uses.

Suppliers and Pricing Details

Choosing the right supplier is critical to ensure the quality and reliability of GH3625. Here are some prominent suppliers along with indicative pricing details:

| Supplier | Location | Price (per kg) | Contact |

|---|---|---|---|

| Metalloy Corp | USA | $80 | www.metalloycorp.com |

| Advanced Alloys | Germany | $85 | www.advancedalloys.de |

| NickelTech | UK | $90 | www.nickeltech.co.uk |

| Superalloy Metals | China | $75 | www.superalloymetals.cn |

| TechMet | Japan | $95 | www.techmet.jp |

Comparing GH3625 with Other Alloys

When considering GH3625, it’s helpful to compare it with other similar alloys to understand its advantages and limitations.

| Property | GH3625 | Inconel 718 | Hastelloy X |

|---|---|---|---|

| Temperature Stability | Excellent | Very Good | Good |

| Corrosion Resistance | High | High | Moderate |

| Oxidation Resistance | High | Moderate | High |

| Mechanical Strength | Excellent | Very Good | Good |

| Cost | Moderate | High | Moderate |

| Applications | Aerospace, Power | Aerospace, Marine | Chemical Processing |

Advantages and Disadvantages of GH3625

Advantages:

- High-Temperature Performance: GH3625 excels in maintaining mechanical properties at elevated temperatures, making it ideal for aerospace and power generation applications.

- Corrosion and Oxidation Resistance: Its robust resistance to corrosive and oxidative environments ensures long-lasting performance, particularly in chemical processing and marine applications.

- Versatility: The alloy’s adaptability to various manufacturing processes, including additive manufacturing, broadens its application scope.

Disadvantages:

- Cost: While moderately priced, GH3625 can be more expensive compared to some other alloys, potentially impacting budget-conscious projects.

- Availability: Depending on the supplier and region, availability can vary, sometimes leading to longer lead times.

FAQ

To wrap up, let’s address some frequently asked questions about GH3625:

| Question | Answer |

|---|---|

| What is GH3625 primarily used for? | GH3625 is primarily used in aerospace, power generation, chemical processing, marine, and automotive applications. |

| How does GH3625 compare to Inconel 718? | GH3625 offers better oxidation resistance and high-temperature stability compared to Inconel 718 but may be more expensive. |

| Can GH3625 be used in additive manufacturing? | Yes, GH3625 is suitable for additive manufacturing, especially when using fine powder models like GH3625-P1 and GH3625-P4. |

| What are the key elements in GH3625’s composition? | Key elements include Nickel, Chromium, Molybdenum, Niobium, and Titanium. |

| Is GH3625 resistant to corrosion? | Yes, GH3625 has excellent corrosion resistance, making it ideal for harsh chemical environments. |

| What standards does GH3625 conform to? | GH3625 conforms to standards such as ASTM B443, B444, B446, AMS 5666, and DIN 17751. |

Conclusion

GH3625 is a powerhouse alloy, combining high-temperature stability, corrosion resistance, and mechanical strength, making it an indispensable material in high-stress applications. By understanding its composition, characteristics, and diverse applications, industries can harness its full potential to drive innovation and efficiency. Whether you’re in aerospace, power generation, or chemical processing, GH3625 offers a reliable solution for your material needs.

This comprehensive guide aims to provide you with all the essential information about GH3625. If you have any more questions or need further details, feel free to reach out to the suppliers listed or consult additional resources.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731