High-End Additive Manufacturing in Europe: Top Suppliers, Trends, and Sourcing Insights for B2B Buyers

Table of Contents

1. Introduction: Why High-End Additive Manufacturing Is Transforming European Industries

High-end additive manufacturing (AM), particularly metal 3D printing, is redefining how European industries innovate, produce, and scale. With precision engineering, reduced lead times, and material efficiency, AM has become a strategic pillar for sectors such as:

- Aerospace

- Automotive

- Medical Device Manufacturing

- Energy & Power

- Industrial Tooling

Unlike traditional subtractive processes, additive manufacturing builds components layer by layer, enabling complex geometries and lightweight structures that were previously impossible or too costly to produce. The result? Enhanced product performance, reduced waste, and shorter supply chains—all of which are critical in today’s competitive and sustainability-driven landscape.

Why B2B Buyers Are Investing in Advanced AM

For B2B buyers, the shift to high-end AM offers:

- Customization at Scale: From aerospace brackets to orthopedic implants.

- Reduced Tooling Costs: Eliminate the need for expensive molds or dies.

- Accelerated Prototyping & Production: Cut design-to-manufacture cycles drastically.

- Improved Part Performance: Especially with the use of titanium alloys, nickel superalloys, and stainless steels.

European OEMs, Tier 1 suppliers, and industrial manufacturers are increasingly integrating metal AM systems into their production workflows to stay ahead of the curve.

🔍 High-Intent Keyword Focus: high-end additive manufacturing Europe, metal 3D printing, industrial additive manufacturing systems, B2B 3D printing procurement

2. European Additive Manufacturing Market Trends and Growth Potential

The European Union is one of the world’s most dynamic regions for additive manufacturing innovation. According to the 2023 Wohlers Report and regional industry data:

| Indicator | Value (2023) | Forecast (2027) |

|---|---|---|

| EU AM Market Size | €5.2 Billion | €9.8 Billion |

| CAGR (2023–2027) | 17.3% | |

| % of Global AM Installations | 29% | ~30% |

| Key Growth Sectors | Aerospace, Automotive, Medical |

Emerging Trends Driving the European AM Boom

- Public-Private Investment Initiatives: EU-funded programs like Horizon Europe and national R&D grants are accelerating AM adoption.

- Sustainability Regulations: Companies are turning to AM to meet carbon reduction goals by reducing material waste.

- Localizing Production: Especially in aerospace and defense, where IP security and supply chain resilience are key.

- Innovation Hubs: Germany, France, Italy, the Netherlands, and the Nordics are home to world-class AM research centers and OEMs.

Key European AM Use Cases:

- Airbus: Using AM for lightweight aircraft brackets and structural parts.

- BMW & Volkswagen: Implementing metal 3D printing for tooling and end-use parts.

- Siemens: Leveraging AM for gas turbine parts.

📈 As the European AM ecosystem matures, B2B buyers have increasing access to highly specialized service bureaus, material providers, and OEMs—but also face rising costs and long lead times due to regional constraints.

3. Key Factors B2B Buyers Should Consider When Choosing a European Additive Manufacturing Supplier

Selecting the right additive manufacturing supplier is a mission-critical decision for any business sourcing high-performance components or materials. For European B2B buyers, the following considerations are essential:

✅ 1. Technical Capabilities

| Capability | What to Look For |

|---|---|

| Machine Type | SEBM, SLM, EBM, DMLS systems |

| Build Volume | Large-format vs. small-batch systems |

| Tolerance & Resolution | Micron-level precision for aerospace/medical |

| Material Compatibility | Titanium, Inconel, Stainless Steel, CoCr, etc. |

✅ 2. Certifications & Compliance

- ISO 9001, AS9100 (Aerospace)

- ISO 13485 (Medical)

- CE Compliance for Parts

- ITAR/EAR for export control (if sourcing from outside EU)

✅ 3. Lead Time & Production Capacity

- Can the supplier meet your volume and delivery schedule?

- Do they offer rapid prototyping AND low-volume production?

✅ 4. Material Quality & Traceability

- Are the metal powders certified and traceable?

- Do they meet ASTM/ISO standards?

✅ 5. Total Cost of Ownership

- Consider not just unit price, but tooling, post-processing, shipping, and opportunity cost.

✅ 6. Support & Application Expertise

- Does the supplier offer design-for-AM support?

- Can they co-develop or optimize parts for lightweighting, heat resistance, or strength?

💡 Pro Tip: European suppliers are often ideal for precision-critical applications but may come with higher costs and longer lead times. In such cases, expanding your supplier base to include trusted Asian partners like Metal3DP can offer both quality and cost advantages.

📌 Want to learn more about different metal printing technologies for industrial use? Visit Metal3DP’s Printing Methods Overview to compare SEBM, SLM, and other approaches.

🔄 Recap

| Section | Key Takeaways |

|---|---|

| Introduction | High-end AM enables innovation, speed, and complexity for B2B sectors |

| Market Trends | EU AM market is growing rapidly, driven by aerospace, medical, and auto |

| Supplier Considerations | Evaluate capabilities, certifications, lead times, and total cost carefully |

4. Top 5 High-End Additive Manufacturing Suppliers in Europe (2024)

Europe is home to some of the most advanced additive manufacturing companies globally. These suppliers serve high-demand B2B applications across aerospace, defense, medical implants, automotive tooling, and energy. Below are five of the most respected and innovative AM suppliers in Europe as of 2024:

🔝 Top 5 Additive Manufacturing Suppliers in Europe

| Company Name | Headquarters | Specialization | Industries Served |

|---|---|---|---|

| EOS GmbH | Germany | Industrial metal 3D printers (DMLS) | Aerospace, Medical, Tooling |

| SLM Solutions | Germany | Large-format SLM systems | Automotive, Aerospace |

| AddUp | France | Powder bed fusion and DED systems | Defense, Aerospace, Energy |

| Renishaw | UK | High-precision metal AM systems | Medical, Dental, Aerospace |

| Materialise | Belgium | Software + Production Services | Orthopedics, Automotive, R&D |

Key Differentiators:

- EOS GmbH: Pioneered Direct Metal Laser Sintering (DMLS) and offers a wide portfolio of systems and materials.

- SLM Solutions: Known for open architecture and multi-laser systems ideal for production scaling.

- AddUp: Joint venture between Michelin and Fives, offering robust industrial-scale systems.

- Renishaw: Specializes in precision, metrology, and high-reliability applications.

- Materialise: A leader in AM services and software, especially for medical and academic use.

Challenges with European Suppliers:

- Lead Time: 4–10 weeks for machine delivery or component fulfillment.

- Cost: High labor and operational costs in Western Europe.

- Availability: Limited capacity for large-volume metal powder production.

🛠️ For B2B buyers seeking faster lead times, competitive pricing, or specific alloy availability, it’s worth exploring trusted suppliers in Asia that meet European quality standards.

5. Why More European Buyers Are Turning to Asian Suppliers for Additive Manufacturing Materials

While Europe leads in additive manufacturing innovation, many European buyers are now partnering with Asian suppliers—especially for sourcing metal powders and AM equipment.

📦 Key Reasons B2B Buyers Are Sourcing from Asia:

- Cost Efficiency

- Asian suppliers like those in China and South Korea offer up to 40–60% lower costs on metal powders and 3D printers.

- High-Quality Manufacturing

- Top-tier Chinese AM companies now meet or exceed international standards (ISO, ASTM, CE).

- Scalability

- Asian suppliers often have higher production capacity and can fulfill bulk orders reliably.

- Shorter Lead Times for Bulk Materials

- Metal powders can be shipped in under 2–3 weeks depending on location.

- Wider Range of Materials

- Titanium alloys, superalloys, and custom blends are more readily available through Asian suppliers.

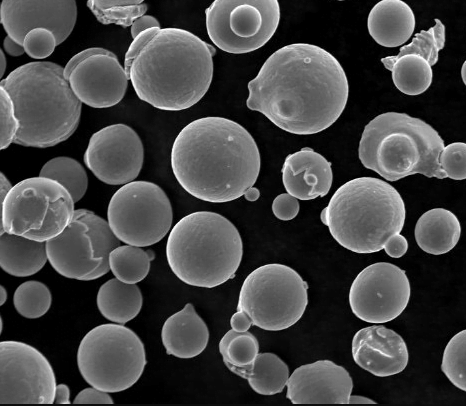

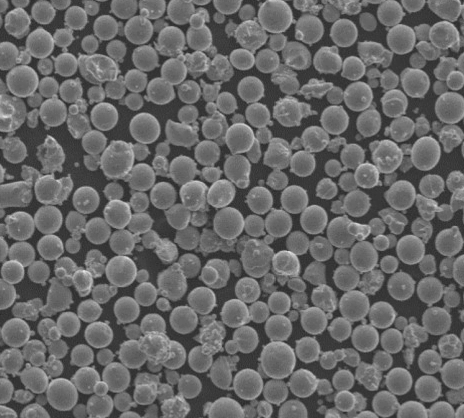

- Advanced Atomization Technologies

- Companies like Metal3DP use state-of-the-art gas atomization and PREP (plasma rotating electrode process) systems to produce high-quality spherical powders.

🌐 Asian suppliers are no longer just “low-cost alternatives”—they are now globally recognized players in high-end additive manufacturing.

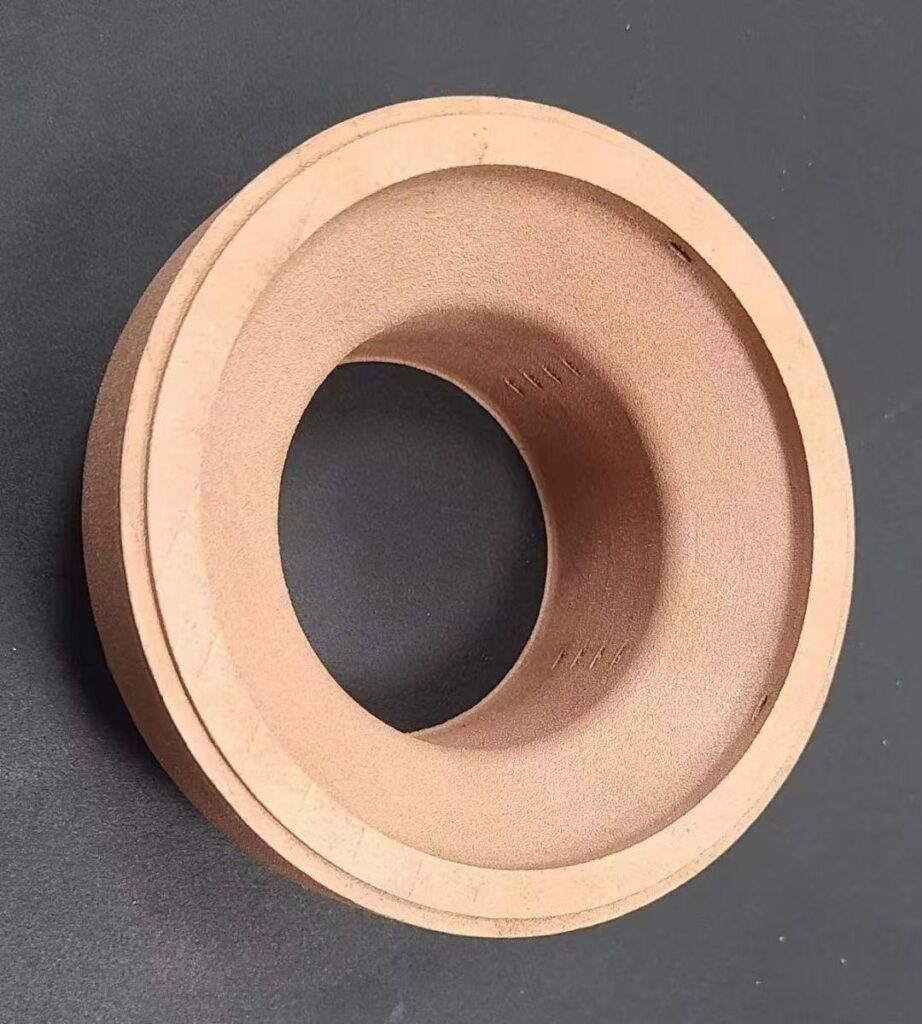

6. Why Choose Metal3DP as Your Additive Manufacturing Partner

Metal3DP is positioned as a top-tier partner for companies across Europe and worldwide looking for high-performance metal powders and additive manufacturing systems.

🏭 About Metal3DP

Metal3DP (Metal3DP Technology Co., Ltd.) is a China-based manufacturer specializing in:

- Industrial-grade metal 3D printers

- High-purity, spherical metal powders

- Additive manufacturing application development

With decades of collective expertise, the company supports clients in aerospace, medical, energy, and automotive sectors.

🔧 What Sets Metal3DP Apart?

| Feature | Description |

|---|---|

| Advanced Powder Making Systems | Gas atomization + PREP technologies for highly spherical, flowable powders |

| Broad Alloy Portfolio | TiNi, TiTa, TiAl, CoCrMo, Inconel, Stainless Steels, and more |

| Large-Volume 3D Printers | High-accuracy SEBM and PBF printers with large build envelopes |

| Global Quality Standards | ISO-compliant production, strict QC, and traceability |

| Application Engineering | Support for part design, optimization, and simulation |

📌 Use Case: Aerospace Titanium Component

A European aerospace firm recently partnered with Metal3DP to 3D print titanium brackets using Metal3DP’s SEBM printer and Ti6Al4V powder. Results included:

- 25% weight reduction

- 30% faster production time

- Full compliance with aerospace mechanical requirements

🌍 Why European Companies Trust Metal3DP

- Competitive Pricing: Up to 50% savings compared to EU-based powder suppliers.

- Fast Turnaround: 2–3 week delivery on bulk powder orders.

- Technical Collaboration: Co-development of prototypes and optimized part designs.

- Trusted Export Experience: Metal3DP regularly ships to Europe, North America, and Asia-Pacific.

📎 For more information on Metal3DP’s product lineup, visit the Metal3DP Products Page.

🔄 Recap of Part 2

| Section | Key Takeaways |

|---|---|

| Top 5 EU Suppliers | EOS, SLM, AddUp, Renishaw, Materialise lead in industrial AM |

| Rise of Asian Suppliers | Cost-effective, high-quality alternatives for powders and equipment |

| Why Choose Metal3DP | Advanced systems, global standards, and strong AM application engineering |

7. How to Procure High-Quality Metal Powders and AM Equipment from Metal3DP

For B2B buyers—OEMs, industrial distributors, materials managers, and procurement professionals—establishing a reliable supply chain for high-performance 3D printing materials and equipment is crucial. Metal3DP simplifies this process through a structured, transparent, and globally accessible procurement model.

📦 Metal3DP Procurement Overview

Whether you’re sourcing metal powders or looking to integrate additive manufacturing systems, Metal3DP provides end-to-end support across the entire industrial buying journey.

🔄 Ordering Process with Metal3DP

| Step | Action | Description |

|---|---|---|

| 1 | Consultation & Needs Assessment | Technical team reviews your industry needs, part complexity, and material requirements. |

| 2 | Material or Equipment Recommendation | Based on application (e.g., aerospace, medical), the optimal powder or printer is proposed. |

| 3 | Sample Testing (Optional) | Powder samples or part build trials can be arranged for performance validation. |

| 4 | Quotation & Terms | You receive a detailed quote including Incoterms, MOQ, shipping lead time, and payment options. |

| 5 | Order Confirmation & Production | Once confirmed, powders are atomized or equipment is prepared and tested. |

| 6 | Quality Inspection & Packaging | Full quality control with material certification and export-compliant packaging. |

| 7 | Global Shipping | Logistics coordination to Europe, North America, and APAC regions. |

🌐 Metal3DP International Shipping Capabilities

- Shipping Mode: Air freight (DHL, FedEx, UPS) or sea freight based on volume

- Delivery Time to Europe: Typically 10–21 days depending on product type and volume

- Documentation: MSDS, Certificate of Analysis, Packing List, Commercial Invoice, and Export License (if required)

✅ How to Start Your Procurement Journey

B2B buyers can begin the process by filling out a contact form or request-for-quote (RFQ) on the official website. Visit the Metal Additive Manufacturing Solutions page to explore options and submit your inquiry.

8. FAQs: Common Questions About Buying Additive Manufacturing Products from Europe and Asia

To help procurement teams and technical buyers make informed decisions, here are some frequently asked questions about sourcing AM equipment and powders from both European and Asian suppliers:

❓ FAQ Table

| Question | Answer |

|---|---|

| Are Chinese AM powders as reliable as European ones? | Yes. Suppliers like Metal3DP use advanced atomization (gas + PREP) to meet ASTM/ISO specs. |

| What certifications should I look for when importing metal powders? | ISO 9001, CE, ASTM standards, and a Certificate of Analysis per batch. |

| Can I order small quantities (e.g., <100kg) of metal powders from Asia? | Yes, Metal3DP accommodates both small-batch prototyping and bulk orders. |

| Do Asian suppliers provide support for application engineering? | Trusted suppliers like Metal3DP offer DfAM (design for additive manufacturing) services. |

| What if I need custom alloy compositions? | Metal3DP offers custom alloy development based on buyer specifications. |

| How do shipping costs compare between Europe and Asia? | While shipping from Asia may add 5–10% to cost, the unit price savings often outweigh it. |

| Can I integrate Metal3DP machines with my existing workflow? | Yes. Metal3DP printers are compatible with most industrial CAD/CAM and workflow tools. |

📍 Want to learn more about Metal3DP’s technology, certifications, and powder portfolio? Check out the About Metal3DP page for technical specifications and company background.

9. Conclusion: Choosing the Right Additive Manufacturing Partner for Long-Term Success

Additive manufacturing is no longer just a prototyping tool—it has become a mission-critical production process for Europe’s most advanced industries. As the AM landscape continues to evolve, B2B buyers are faced with key decisions that impact:

- Product performance

- Supply chain resilience

- Cost control

- Time-to-market

🔍 Key Takeaways for B2B Buyers

- Europe remains a global leader in innovation, offering cutting-edge AM capabilities and certifications.

- Asian suppliers, especially companies like Metal3DP, now offer industrial-grade powders and printers at significantly more competitive prices without sacrificing quality.

- Strategic sourcing from both regions can provide redundancy, flexibility, and cost optimization.

🛠️ Why Metal3DP Is Your Ideal Partner

Metal3DP combines:

- Advanced powder manufacturing (gas atomization, PREP)

- Industry-leading SEBM and PBF printers

- A diverse alloy range covering titanium, nickel, cobalt-chrome, and stainless steels

- Global shipping, traceability, and technical support

Whether you’re an aerospace OEM, a medical device manufacturer, or a distributor seeking a reliable supplier for your network, Metal3DP delivers the quality, performance, and scalability your business needs.

📩 Ready to Transform Your Manufacturing Workflow?

👉 Contact Metal3DP Today to request a quote, schedule a technical consultation, or order your first batch of premium metal powders or industrial printers.

🔗 Embedded Internal Links Summary

| Anchor Text | URL |

|---|---|

| Metal3DP’s Printing Methods Overview | https://met3dp.com/printing-methods/ |

| Metal3DP Products Page | https://met3dp.com/product/ |

| Metal Additive Manufacturing Solutions page | https://met3dp.com/metal-3d-printing/ |

| About Metal3DP | https://met3dp.com/about-us/ |

| Contact Metal3DP Today | https://met3dp.com/ |

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731