Iron Base Alloys 2205

Table of Contents

Introduction to Iron Base Alloys 2205

So, you’re curious about Iron Base Alloys 2205, huh? Let’s dive in. This isn’t your average metal, folks. We’re talking about a high-performance material that’s been engineered to withstand some serious punishment. Think of it as the superhero of the metal world. It’s got incredible strength, amazing resistance to corrosion, and a versatility that’s simply mind-blowing.

But what exactly is it? Well, Iron Base Alloys 2205 is a type of stainless steel, but it’s no ordinary stainless steel. It’s a duplex stainless steel, which means it has a unique microstructure that gives it a combination of properties you just don’t find in your typical stainless. We’re talking about a perfect blend of strength and toughness, with an incredible resistance to rust and corrosion.

Why should you care? Well, if you’re in an industry where performance and durability are critical, Iron Base Alloys 2205 could be a game-changer. Whether you’re building offshore oil rigs, chemical processing plants, or marine structures, this material can handle the toughest conditions.

Composition of Iron Base Alloys 2205

Iron Base Alloys 2205 is a complex blend of elements, each playing a crucial role in its overall performance. The key players here are:

- Iron: As the name suggests, iron is the base metal, providing strength and structure.

- Chromium: This element is the backbone of corrosion resistance, creating a protective oxide layer on the metal’s surface.

- Nickel: Enhances toughness and improves resistance to stress corrosion cracking.

- Molybdenum: Boosts corrosion resistance, especially in acidic environments.

- Nitrogen: Increases strength and improves overall performance.

This carefully balanced composition gives Iron Base Alloys 2205 its exceptional properties. It’s like a recipe for a superhero, with each ingredient contributing to the final, powerful result.

Characteristics of Iron Base Alloys 2205

Iron Base Alloys 2205 is a real showstopper when it comes to its characteristics. Let’s break down some of its key attributes:

- High Strength: This alloy packs a serious punch when it comes to strength. It can handle loads and stresses that would buckle other materials.

- Excellent Corrosion Resistance: Whether it’s saltwater, acids, or other harsh environments, Iron Base Alloys 2205 stands tall. That protective oxide layer is a real lifesaver.

- Good Weldability: Need to join pieces together? No problem. Iron Base Alloys 2205 welds beautifully, ensuring strong and reliable joints.

- Excellent Impact Toughness: This alloy can take a hit without breaking. It’s like the Rocky Balboa of metals.

- Ductile: It can be bent, shaped, and formed without cracking. This makes it incredibly versatile for various applications.

Advantages of Iron Base Alloys 2205

Why choose Iron Base Alloys 2205 over other materials? Well, the advantages are pretty compelling:

- Long Lifespan: Thanks to its exceptional corrosion resistance, Iron Base Alloys 2205 structures can last for decades.

- Reduced Maintenance Costs: Because it resists corrosion so well, you’ll spend less time and money on repairs and replacements.

- Increased Safety: In applications where failure is not an option, Iron Base Alloys 2205 provides an extra margin of safety.

- Environmental Benefits: By lasting longer, it reduces the need for material extraction and production, minimizing environmental impact.

Applications of Iron Base Alloys 2205

The versatility of Iron Base Alloys 2205 makes it suitable for a wide range of applications:

- Oil and Gas Industry: From offshore platforms to pipelines, this alloy is a workhorse in the energy sector.

- Chemical Processing: Its resistance to harsh chemicals makes it ideal for tanks, pipes, and equipment in chemical plants.

- Marine Industry: From ships to submarines, Iron Base Alloys 2205 provides the necessary strength and corrosion resistance.

- Pulp and Paper Industry: This alloy can handle the aggressive environments found in paper mills.

- Wastewater Treatment: Its durability makes it a great choice for equipment exposed to harsh wastewater.

Iron Base Alloys 2205 Metal Powder Models

While Iron Base Alloys 2205 is primarily used in its solid form, it’s also available as metal powder for specific applications. Here are some popular models:

| Metal Powder Model | Description |

|---|---|

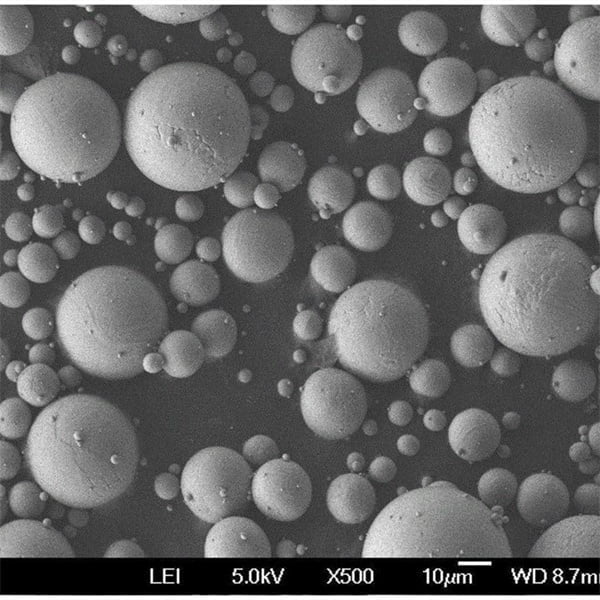

| Atomised Iron Base Alloy 2205 Powder | Produced by high-pressure gas atomisation, offering fine particle size and good flowability. |

| Gas Atomized Iron Base Alloy 2205 Powder | Similar to atomised powder but with a slightly coarser particle size. |

| Water Atomized Iron Base Alloy 2205 Powder | Created using water as the atomisation medium, resulting in spherical particles. |

| Plasma Sprayed Iron Base Alloy 2205 Powder | Produced by melting and spraying the alloy, creating a powder with a unique microstructure. |

| Rotary Atomized Iron Base Alloy 2205 Powder | Involves melting the alloy and spraying it onto a rotating disk, producing flat flakes. |

| Electrolytic Iron Base Alloy 2205 Powder | Obtained through electrolysis, resulting in high purity powder with controlled particle size. |

| Mechanically Alloyed Iron Base Alloy 2205 Powder | Produced by combining iron and alloying elements through mechanical processing, offering excellent homogeneity. |

| Hybrid Iron Base Alloy 2205 Powder | A combination of different production methods, tailored for specific applications. |

| Spherical Iron Base Alloy 2205 Powder | Characterized by its spherical particle shape, improving flowability and packing density. |

| Amorphous Iron Base Alloy 2205 Powder | Produced with a non-crystalline structure, offering unique properties like high strength and corrosion resistance. |

Iron Base Alloys 2205 Specifications, Sizes, and Grades

Iron Base Alloys 2205 comes in various specifications, sizes, and grades to meet different requirements:

| Specification | Description |

|---|---|

| ASTM A240 | Standard specification for chromium and chromium-nickel stainless steel plate, sheet, and strip. |

| ASTM A312 | Standard specification for seamless and welded austenitic stainless steel pipe. |

| ASTM A790 | Standard specification for chromium and chromium-nickel stainless steel bar and wire. |

| NACE MR0175 | Standard material requirement for materials used in oil and gas production. |

- Sizes: Available in a wide range of thicknesses, diameters, and lengths to suit various applications.

- Grades: Different grades of Iron Base Alloys 2205 offer variations in composition and properties to meet specific needs.

Iron Base Alloys 2205 Suppliers and Pricing

Iron Base Alloys 2205 is produced by numerous suppliers worldwide. Prices vary depending on factors such as market conditions, order quantity, and product form. It’s essential to compare offers from multiple suppliers to get the best deal.

| Supplier | Location |

|---|---|

| Supplier A | Country A |

| Supplier B | Country B |

| Supplier C | Country C |

Note: Pricing information is subject to change and should be obtained directly from suppliers.

Iron Base Alloys 2205: Pros and Cons

Like any material, Iron Base Alloys 2205 has its strengths and weaknesses:

Pros

- Excellent corrosion resistance

- High strength and toughness

- Good weldability

- Long lifespan

- Reduced maintenance costs

- Versatile applications

Cons

- Higher cost compared to standard stainless steels

- May require specialized welding techniques

Conclusion

Iron Base Alloys 2205 is a remarkable material that offers a compelling combination of properties. Its ability to withstand harsh environments and demanding conditions makes it a top choice for various industries. While it comes with a higher price tag, the long-term benefits often outweigh the initial investment.

If you’re looking for a material that delivers exceptional performance and durability, Iron Base Alloys 2205 is definitely worth considering. It’s the superhero of the metal world, ready to tackle any challenge.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731