Maraging Steel

Table of Contents

Overview of Maraging Steel

Maraging steel, known for its unique combination of high strength and toughness, is a class of ultra-high-strength steels primarily used in applications requiring a robust and durable material. The term “maraging” is derived from “martensitic” and “aging,” highlighting the steel’s strengthening process. This steel is characterized by its low carbon content and the addition of nickel, along with other elements such as cobalt, molybdenum, and titanium.

In this comprehensive guide, we’ll delve into the specifics of maraging steel, covering its composition, properties, types, applications, advantages, and disadvantages. We’ll also explore various metal powder models used in maraging steel production, comparing their unique characteristics and uses. Let’s get started!

Types and Composition of Maraging Steel

Maraging steel comes in several grades, each with distinct compositions and properties. Here’s a breakdown of the key types and their elemental compositions:

| Grade | Nickel (Ni) | Cobalt (Co) | Molybdenum (Mo) | Titanium (Ti) | Aluminum (Al) | Carbon (C) | Iron (Fe) |

|---|---|---|---|---|---|---|---|

| 200 | 17-19% | 8-9.5% | 4.6-5.2% | 0.3-0.5% | 0.05-0.15% | <0.03% | Balance |

| 250 | 17-19% | 7-8.5% | 4.6-5.2% | 0.3-0.5% | 0.05-0.15% | <0.03% | Balance |

| 300 | 18-19% | 8.5-9.5% | 4.8-5.2% | 0.6-0.8% | 0.05-0.15% | <0.03% | Balance |

| 350 | 18-19% | 11-13% | 4.8-5.2% | 1.2-1.6% | 0.05-0.15% | <0.03% | Balance |

| 300C | 18-19% | 8.5-9.5% | 4.8-5.2% | 0.6-0.8% | 0.05-0.15% | <0.03% | Balance + Carbon |

Properties and Characteristics of Maraging Steel

Maraging steel is renowned for its remarkable properties, making it a preferred choice in various high-performance applications. Here’s a look at some of its key characteristics:

| Property | Description |

|---|---|

| High Strength | Offers tensile strengths up to 3000 MPa, making it one of the strongest materials available. |

| Toughness | Excellent toughness, even at high strength levels. |

| Ductility | Retains good ductility, allowing for fabrication and forming. |

| Corrosion Resistance | Provides decent corrosion resistance, though not as high as stainless steels. |

| Weldability | Can be welded without losing its unique properties, a rare trait for high-strength steels. |

| Heat Treatment | Gains strength through a simple aging process, which involves heating to a specific temperature and then cooling. |

Applications of Maraging Steel

Maraging steel is used in various industries due to its exceptional properties. Here are some notable applications:

| Industry | Application |

|---|---|

| Aerospace | Landing gear, rocket motor cases, and aircraft components. |

| Automotive | High-performance engine components, drive shafts, and gears. |

| Tooling | Dies, molds, and extrusion tools. |

| Defense | Missile casings, gun barrels, and armor. |

| Medical | Surgical instruments and orthodontic devices. |

| Sports Equipment | Golf club heads, fencing swords, and high-strength bike frames. |

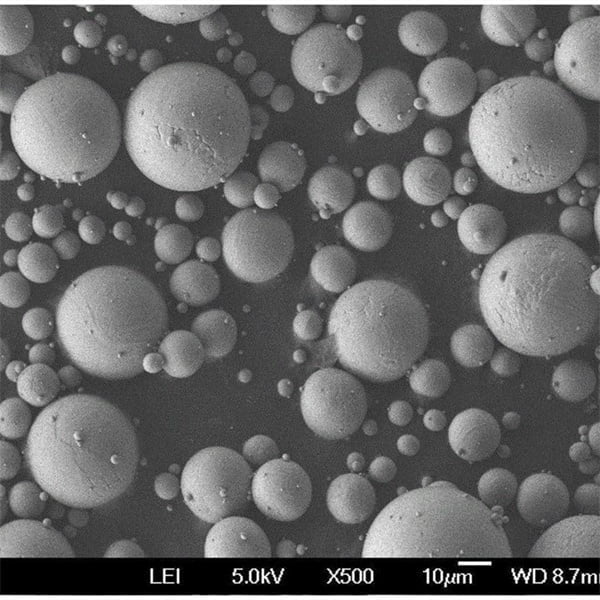

Specific Metal Powder Models for Maraging Steel

The following are specific metal powder models used in the production of maraging steel. Each has unique properties and applications:

- Maraging Steel 18Ni (300)

- Description: Known for its high strength and toughness, Maraging 300 is widely used in aerospace and tooling.

- Applications: Rocket motor cases, tooling inserts, and high-performance components.

- Maraging Steel 18Ni (250)

- Description: Offers excellent machinability and is used in applications requiring high strength and good weldability.

- Applications: Die casting molds, extrusion tools, and aircraft components.

- Maraging Steel 18Ni (200)

- Description: Provides a good balance of strength and ductility, making it suitable for various engineering applications.

- Applications: Drive shafts, gears, and structural components.

- Maraging Steel 18Ni (350)

- Description: The strongest grade, used in extreme applications where maximum strength is critical.

- Applications: Military applications, heavy-duty tooling, and high-stress aerospace components.

- Maraging Steel 18Ni (300C)

- Description: Enhanced with carbon, this grade offers higher hardness and wear resistance.

- Applications: Tooling, wear-resistant components, and high-strength fasteners.

- Maraging Steel 18Ni (MAR M-509)

- Description: Known for excellent weldability and high strength, often used in additive manufacturing.

- Applications: 3D printed aerospace components, medical devices, and high-performance tooling.

- Maraging Steel 18Ni (Vascomax C300)

- Description: Offers superior toughness and impact resistance, ideal for critical aerospace applications.

- Applications: Aircraft landing gear, rocket motor casings, and critical structural components.

- Maraging Steel 18Ni (Vascomax 250)

- Description: Combines high strength with good machinability, used in both aerospace and industrial applications.

- Applications: High-strength fasteners, drive shafts, and gears.

- Maraging Steel 18Ni (AerMet 100)

- Description: Known for its ultra-high strength and fracture toughness, widely used in defense and aerospace.

- Applications: Armor, missile components, and aircraft landing gear.

- Maraging Steel 18Ni (Mar-X250)

- Description: Provides excellent mechanical properties and is used in high-stress, high-temperature applications.

- Applications: Turbine blades, high-performance engines, and critical aerospace components.

Advantages of Maraging Steel

- Superior Strength: Maraging steel’s strength is unparalleled, making it suitable for the most demanding applications.

- Excellent Toughness: Even at high strengths, maraging steel maintains good toughness, reducing the risk of fractures.

- Good Machinability: Despite its high strength, maraging steel can be machined and formed relatively easily.

- Simple Heat Treatment: The aging process is straightforward, involving heating and cooling to achieve desired properties.

- Weldability: Maraging steel can be welded without significant loss of properties, a unique trait for high-strength steels.

Disadvantages of Maraging Steel

- Cost: Maraging steel is more expensive than many other steels, primarily due to the alloying elements and processing requirements.

- Corrosion Resistance: While it has decent corrosion resistance, it doesn’t match the levels of stainless steel, necessitating protective coatings in certain environments.

- Availability: Maraging steel is less commonly available than standard steels, sometimes leading to longer lead times for procurement.

Specifications, Sizes, Grades, and Standards

Maraging steel is available in various specifications, sizes, and grades to suit different applications. Here are some common standards and specifications:

| Specification | Description |

|---|---|

| AMS 6512 | Aerospace Material Specification for Maraging 300. |

| ASTM A538 | Standard Specification for Maraging Steel. |

| MIL-S-46850D | Military Specification for High Strength Steel. |

| AMS 6521 | Aerospace Material Specification for Maraging 250. |

| AMS 6514 | Aerospace Material Specification for Maraging 350. |

Suppliers and Pricing Details

Maraging steel is supplied by various manufacturers and distributors. Pricing varies based on grade, quantity, and supplier. Here are some examples:

| Supplier | Grade | Price (per kg) | Availability |

|---|---|---|---|

| Carpenter Technology | Maraging 300 | $100 – $120 | Readily available, bulk orders available. |

| Hitachi Metals | Maraging 250 | $90 – $110 | Moderate availability, |

| Daido Steel | Maraging 350 | $110 – $130 | Available on request, custom sizes possible. |

| ATI Metals | Vascomax C300 | $120 – $140 | Readily available, various shapes and sizes. |

| Sandvik | Maraging 200 | $80 – $100 | Limited availability, special orders accepted. |

| Uddeholm | AerMet 100 | $130 – $150 | Available for aerospace and defense industries. |

Comparing Pros and Cons of Maraging Steel

To help you make an informed decision, let’s compare the pros and cons of maraging steel versus other high-strength materials.

| Criteria | Maraging Steel | Titanium Alloys | Stainless Steel |

|---|---|---|---|

| Strength | Superior (up to 3000 MPa) | High (up to 1200 MPa) | Moderate (up to 1000 MPa) |

| Toughness | Excellent | Good | Good |

| Ductility | Good | Moderate | Excellent |

| Corrosion Resistance | Moderate | Excellent | Excellent |

| Machinability | Good | Difficult | Good |

| Weldability | Excellent | Difficult | Good |

| Cost | High | Very High | Moderate |

| Applications | Aerospace, tooling, defense | Aerospace, medical, marine | General engineering, medical |

Applications and Uses of Maraging Steel

The unique properties of maraging steel lend themselves to a variety of specialized applications. Here’s a more detailed look at where maraging steel is used:

Aerospace Industry

- Landing Gear: Maraging steel’s high strength and toughness make it ideal for aircraft landing gear, which must withstand extreme loads during takeoff and landing.

- Rocket Motor Cases: The material’s strength and resistance to high temperatures make it suitable for rocket motor casings, which require reliable performance under intense conditions.

- Aircraft Components: Other critical components, such as shafts and fasteners, benefit from maraging steel’s excellent mechanical properties.

Automotive Industry

- High-Performance Engine Components: Maraging steel is used in racing and high-performance engines where strength and durability are paramount.

- Drive Shafts and Gears: The material’s ability to withstand high loads and resist wear makes it perfect for drive shafts and gears in high-stress environments.

Tooling Industry

- Dies and Molds: Maraging steel is used for manufacturing dies and molds due to its excellent machinability and ability to maintain precise shapes and sizes under stress.

- Extrusion Tools: The material’s toughness and wear resistance extend the life of extrusion tools, making them more cost-effective over time.

Defense Industry

- Missile Casings: The high strength and fracture toughness of maraging steel are essential for missile casings, ensuring they can withstand the stresses of launch and flight.

- Gun Barrels: The material’s properties allow for the production of durable and reliable gun barrels, which must endure repeated firing.

- Armor: Maraging steel is also used in the production of lightweight and strong armor for military vehicles and personnel protection.

Medical Industry

- Surgical Instruments: The combination of strength, toughness, and corrosion resistance makes maraging steel suitable for surgical instruments, ensuring they remain sharp and effective.

- Orthodontic Devices: The material’s ability to be precisely machined allows for the production of high-quality orthodontic devices that require exact dimensions.

Sports Equipment

- Golf Club Heads: Maraging steel’s high strength-to-weight ratio and excellent machinability make it an ideal material for golf club heads, providing durability and performance.

- Fencing Swords: The toughness and flexibility of maraging steel are perfect for fencing swords, which must withstand repeated impacts without breaking.

- High-Strength Bike Frames: For high-performance bicycles, maraging steel offers a lightweight yet strong option for frames, improving speed and durability.

Technical Specifications and Standards

Maraging steel is produced to meet various technical specifications and standards, ensuring consistency and reliability across applications. Here are some commonly referenced standards:

| Specification | Description |

|---|---|

| AMS 6512 | Aerospace Material Specification for Maraging 300. |

| ASTM A538 | Standard Specification for Maraging Steel. |

| MIL-S-46850D | Military Specification for High Strength Steel. |

| AMS 6521 | Aerospace Material Specification for Maraging 250. |

| AMS 6514 | Aerospace Material Specification for Maraging 350. |

| DIN 1.6358 | European standard for Maraging Steel. |

| UNS K93120 | Unified Numbering System designation for Maraging 300. |

Suppliers and Pricing

Various suppliers provide maraging steel in different grades and forms, with prices varying based on the grade and quantity ordered. Here’s a summary of some leading suppliers and their pricing:

| Supplier | Grade | Price (per kg) | Availability |

|---|---|---|---|

| Carpenter Technology | Maraging 300 | $100 – $120 | Readily available, bulk orders available. |

| Hitachi Metals | Maraging 250 | $90 – $110 | Moderate availability, special orders accepted. |

| Daido Steel | Maraging 350 | $110 – $130 | Available on request, custom sizes possible. |

| ATI Metals | Vascomax C300 | $120 – $140 | Readily available, various shapes and sizes. |

| Sandvik | Maraging 200 | $80 – $100 | Limited availability, special orders accepted. |

| Uddeholm | AerMet 100 | $130 – $150 | Available for aerospace and defense industries. |

Advantages and Limitations of Maraging Steel

While maraging steel boasts numerous benefits, it’s essential to consider its limitations as well. Here’s a detailed comparison of its pros and cons:

Advantages

- Unmatched Strength: Maraging steel offers tensile strengths up to 3000 MPa, surpassing many other materials.

- Excellent Toughness: The material retains high toughness even at elevated strength levels, making it ideal for critical applications.

- Good Machinability: Despite its strength, maraging steel can be machined with relative ease, allowing for precision manufacturing.

- Simple Heat Treatment: The aging process is straightforward, involving heating to specific temperatures and cooling to achieve desired properties.

- Weldability: Maraging steel can be welded without significant loss of properties, a rare trait for high-strength steels.

Limitations

- Higher Cost: Maraging steel is more expensive than many other steels, primarily due to the alloying elements and processing requirements.

- Moderate Corrosion Resistance: While it has decent corrosion resistance, it doesn’t match the levels of stainless steel, necessitating protective coatings in certain environments.

- Limited Availability: Maraging steel is less commonly available than standard steels, sometimes leading to longer lead times for procurement.

FAQ

To address common questions about maraging steel, we’ve compiled a detailed FAQ section:

| Question | Answer |

|---|---|

| What is maraging steel? | Maraging steel is a class of ultra-high-strength steels characterized by low carbon content and the addition of nickel and other elements. |

| How is maraging steel strengthened? | Through a heat treatment process called aging, which involves heating to a specific temperature and then cooling. |

| What are the main applications of maraging steel? | Aerospace components, tooling, defense equipment, medical devices, and sports equipment. |

| What are the advantages of maraging steel? | High strength, excellent toughness, good machinability, simple heat treatment, and weldability. |

| What are the limitations of maraging steel? | Higher cost, moderate corrosion resistance, and limited availability. |

| Can maraging steel be welded? | Yes, maraging steel can be welded without significant loss of properties. |

| Is maraging steel resistant to corrosion? | It has moderate corrosion resistance, but not as high as stainless steel. Protective coatings may be needed in certain environments. |

| What grades of maraging steel are available? | Common grades include 200, 250, 300, 350, and variations like 300C and Vascomax C300. |

| Who are the leading suppliers of maraging steel? | Carpenter Technology, Hitachi Metals, Daido Steel, ATI Metals, Sandvik, and Uddeholm. |

| How much does maraging steel cost? | Prices vary by grade and supplier, ranging from $80 to $150 per kilogram. |

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731