Connecting Businesses with Metal Additive Manufacturing (AM) Experts: A Guide for B2B Buyers and Distributors

Table of Contents

1. Introduction: The Strategic Value of Partnering with Metal AM Experts

In today’s highly competitive industrial ecosystem, businesses are under constant pressure to deliver faster, cheaper, and more innovative solutions. Traditional manufacturing methods, while still foundational, often fall short in delivering the speed, customization, and cost-efficiency required in modern product development. That’s where metal additive manufacturing (AM)—commonly referred to as metal 3D printing—steps in as a transformative force.

But technology alone is not the game-changer—partnering with the right metal AM experts is what truly unlocks the potential of this digital revolution. Whether you’re in aerospace, medical devices, automotive, or tooling, establishing a B2B relationship with experienced suppliers and consultants in metal AM can lead to:

- Faster product development cycles

- Reduced prototyping costs

- Enhanced material performance

- Greater design freedom

- Scalable production options for complex parts

Why Metal Additive Manufacturing Matters for B2B Buyers

Metal AM is no longer a niche technology. It’s become an essential part of the Industry 4.0 toolkit, enabling manufacturers to create complex metal parts that are strong, lightweight, and customized—all without the need for expensive tooling or long lead times.

| Benefit | Traditional Manufacturing | Metal Additive Manufacturing |

|---|---|---|

| Tooling Costs | High | None or minimal |

| Lead Time | Weeks to months | Days to weeks |

| Design Flexibility | Limited | High |

| Material Efficiency | Wastage common | Near-net-shape, less waste |

| Customization | Costly | Easy and scalable |

This is precisely why wholesale buyers, industrial distributors, and OEMs are actively seeking partnerships with metal AM experts who can help them transition or scale up their operations with additive capabilities.

Strategic Advantages of Working with AM Experts

By engaging a seasoned expert or supplier in metal additive manufacturing, B2B buyers gain:

- Access to state-of-the-art 3D printing equipment

- Tailored consultation on material selection and design optimization

- Assurance of consistent, high-quality output

- Cost-effective scaling of both prototyping and production

- Support with certifications and regulatory compliance

In short, metal AM experts serve as a bridge between innovation and execution. Companies like Metal3DP, a leading provider of industrial AM printers and high-performance metal powders, are not just vendors—they are strategic partners in digital transformation.

👉 Learn more about Metal3DP’s capabilities and company values.

2. Exploring the Global Metal AM Market: Trends and B2B Growth Opportunities

The metal additive manufacturing industry has evolved rapidly over the last decade. Once relegated to research labs and prototyping centers, it’s now a full-fledged industrial solution adopted by some of the world’s largest OEMs. For B2B buyers and suppliers, the opportunities for growth, profit, and innovation are vast.

Global Market Overview

According to industry reports, the metal AM market was valued at USD 3.9 billion in 2023 and is projected to grow at a CAGR of 23% through 2030. This growth is driven by widespread adoption across industries:

| Industry | Share of Metal AM Usage | Key Applications |

|---|---|---|

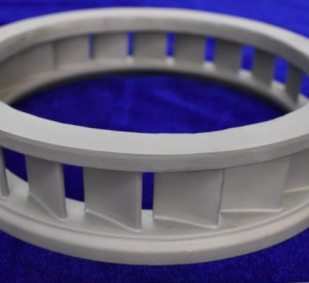

| Aerospace | 30% | Lightweight engine parts, fuel nozzles, brackets |

| Medical | 25% | Orthopedic implants, dental frameworks, surgical tools |

| Automotive | 20% | Engine components, heat exchangers, custom tooling |

| Industrial Tooling | 15% | Dies, molds, jigs, fixtures |

| Energy | 10% | Turbine blades, heat-resistant components |

Regional Trends

- North America leads in R&D and military applications.

- Europe is strong in automotive and aerospace innovations.

- Asia-Pacific, especially China, is emerging as a global production hub due to advancements in metal powder manufacturing and cost-effective 3D printers.

Trends Driving B2B Engagement in Metal AM

- Shortened Supply Chains: Localized production capabilities reduce logistical risks.

- On-Demand Manufacturing: No need for mass inventory—print parts as needed.

- Mass Customization: Perfect for B2B customers with small-batch, high-variety needs.

- Sustainability Goals: Less material waste and energy consumption align with ESG targets.

- Digital Warehousing: Store CAD files instead of physical parts for just-in-time production.

High-Intent B2B Keywords to Target

- Metal AM suppliers

- Wholesale metal 3D printing parts

- B2B additive manufacturing services

- Industrial metal powder distributors

- OEM metal printing solutions

These terms reflect real buying intent and are essential for manufacturers, purchasing managers, and procurement teams searching for reliable, scalable metal AM partners.

3. What B2B Buyers Should Look for in a Metal AM Supplier

When choosing a metal AM supplier, B2B buyers must go beyond price and consider technical capability, supply chain resilience, and service reliability. Below are key evaluation criteria to help industrial buyers, wholesalers, and distributors select the right partner.

1. Quality Control and Certification

- ISO 9001, AS9100, or medical certifications (ISO 13485)

- In-house quality assurance labs

- Material traceability and part validation

- Powder sphericity, purity, and flowability metrics

✅ Met3DP uses advanced gas atomization and PREP systems to produce highly spherical metal powders suitable for both laser and electron beam powder bed fusion processes.

2. Material Portfolio and Customization Options

A good supplier should offer a diverse catalog of metal powders, including:

- Titanium alloys (Ti6Al4V, TiNi, TiTa)

- Cobalt-chromium (CoCrMo)

- Superalloys (Inconel, Hastelloy)

- Stainless steels (316L, 17-4PH)

- Custom alloys for specific applications

Met3DP manufactures innovative alloys and offers custom powder blends for OEMs and research institutions. Explore Met3DP’s full product range here.

3. Equipment Capabilities

Reliable suppliers should also provide or support industrial-grade printers with:

- High build volume for large parts

- Multi-laser systems for faster throughput

- Ultra-fine resolution for precision components

- Compatibility with various materials

- Software support for slicing and process control

Met3DP’s printers are known for industry-leading accuracy, print volume, and reliability, making them ideal for mission-critical industries like aerospace and medical.

4. Technical Support and Consultation

A supplier must be more than a vendor—they should be a technology partner:

- Pre-project consultation

- Design for additive manufacturing (DfAM) support

- On-site installation and training

- After-sales technical support

- Long-term collaboration opportunities

5. Production Scalability

- Can the supplier handle both prototyping and mass production?

- Do they offer fast turnaround times?

- Are there minimum order quantities (MOQs)?

- Do they support international logistics?

Met3DP offers flexible production models, from small-batch R&D runs to large-scale industrial supply, making it a strategic partner for growing operations.

4. Top Metal AM Suppliers and Consultants in Asia, Europe, and North America

As the global demand for metal additive manufacturing (AM) grows, several regions have emerged as innovation hubs for AM technology and services. B2B buyers, OEMs, and industrial distributors seeking reliable partners often evaluate suppliers based on regional strengths, technological maturity, and cost-effectiveness.

Below is a regional breakdown of some of the top metal AM suppliers and consultants across Asia, Europe, and North America.

🌏 Asia: Fast-Growing Innovation and Cost-Effective Solutions

Asia—particularly China, Japan, and South Korea—has become a global powerhouse in metal AM manufacturing. China, in particular, leads in metal powder production and affordable, high-performance 3D printers.

Top Suppliers in Asia:

| Company | Country | Specialty | Strengths |

|---|---|---|---|

| Metal3DP | China | SEBM printers, spherical metal powders | High sphericity powders, precision printers, cost-effective B2B solutions |

| DMTC (Digital Manufacturing Tech Co.) | China | Metal AM systems | Integration of AI and AM for industrial use |

| JSR Corporation | Japan | AM resin and metal materials | R&D-backed innovation and material science |

| Korea Institute of Industrial Technology (KITECH) | South Korea | Metal AM R&D | Research and consulting in metal AM for manufacturers |

🟢 Why choose Asian suppliers?

- Lower manufacturing costs

- Rapid prototyping capabilities

- Shorter lead times in the APAC region

- Continuous innovation in powder metallurgy

👉 Learn more about Metal3DP’s metal additive manufacturing solutions

🇪🇺 Europe: Precision Engineering and Certification Leadership

Europe is a pioneer in AM technologies, especially in aerospace and medical industries. European suppliers are known for stringent quality control, material innovation, and regulatory certifications.

Top Suppliers in Europe:

| Company | Country | Specialty | Strengths |

|---|---|---|---|

| EOS GmbH | Germany | DMLS printers, metal powders | Industry leader in metal AM, certified systems |

| Renishaw | UK | Metal 3D printing systems | Engineering-grade AM with strong R&D |

| SLM Solutions | Germany | Multi-laser LPBF systems | High-speed, scalable metal printing |

| AddUp | France | PBF and DED systems | Automotive and aerospace applications |

🟢 Why choose European suppliers?

- Aerospace and medical compliance

- Leading multi-laser systems

- Deep engineering expertise

- Strong B2B service infrastructure

🇺🇸 North America: Innovation, Software Integration, and Customization

North America—especially the U.S.—remains a hub for AM startups, research, and military applications. American companies excel in software integration, customized solutions, and end-to-end production services.

Top Suppliers in North America:

| Company | Country | Specialty | Strengths |

|---|---|---|---|

| 3D Systems | USA | Direct metal printing | Turnkey solutions, software + hardware integration |

| GE Additive | USA | EBM and DMLM systems | Aerospace-grade quality, in-house powder production |

| Desktop Metal | USA | Binder jetting for metal | Affordable systems for SMBs and mid-size OEMs |

| ExOne | USA | Metal binder jetting systems | Scalable production and design flexibility |

🟢 Why choose North American suppliers?

- High-end R&D and innovation

- Military and aerospace-grade systems

- Strong domestic support and training

- Advanced software integration

5. Why More Businesses Are Turning to High-Quality Metal AM Powders and Printers from China

While Europe and North America have traditionally dominated the AM landscape, China has rapidly emerged as a global leader in additive manufacturing—especially in metal AM powders and cost-effective printer systems. For B2B buyers, this shift presents new opportunities in affordability, scalability, and innovation.

Key Reasons for the Shift Toward Chinese Metal AM Suppliers

✅ 1. Cost-Effective Manufacturing

Chinese companies offer competitive pricing without compromising on quality. This is particularly beneficial for:

- Wholesale buyers

- E-commerce sellers

- OEMs in developing regions

- Research institutions with limited budgets

✅ 2. High-Quality Metal Powders

China has invested heavily in powder metallurgy, especially through gas atomization and PREP (Plasma Rotating Electrode Process). Companies like Metal3DP produce high-performance spherical powders that meet international standards.

| Powder Feature | Benefit for B2B Buyers |

|---|---|

| High Sphericity | Better flowability and packing density |

| Controlled PSD (Particle Size Distribution) | Consistency in printing |

| Low Oxygen Content | Improved mechanical properties |

| Custom Alloying | Tailored to specific applications |

✅ 3. Advanced 3D Printing Equipment

Chinese manufacturers now offer printer systems with industrial-grade volume, resolution, and reliability—comparable to European and American counterparts but at a fraction of the cost.

✅ 4. Faster Turnaround Times

With localized production and logistics hubs, Chinese suppliers often offer shorter lead times, making them attractive to APAC and global buyers.

✅ 5. B2B-Focused Services

Leading Chinese AM companies offer:

- OEM/ODM printer services

- Custom powder production

- Free consultations and trials

- International shipping and on-site installation

Spotlight: Metal3DP – A Trusted Metal AM Manufacturer from China

Metal3DP stands out as a full-solution provider for metal AM, offering:

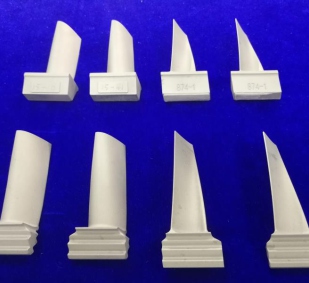

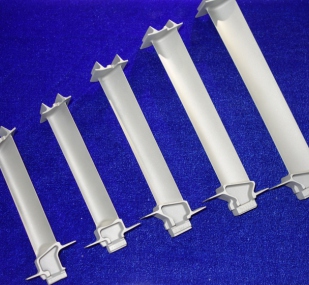

- Industrial-grade SEBM printers with high dimensional accuracy

- A wide portfolio of spherical metal powders including TiNi, TiTa, TiAl, CoCrMo, stainless steel, and custom superalloys

- Advanced powder production lines using both gas atomization and PREP

- End-to-end consultation, from powder selection to printer training

📌 Browse Metal3DP’s metal powder and printer offerings

6. Why Choose Met3DP as Your Trusted Metal AM Partner

When selecting a metal AM partner, businesses need a supplier who offers more than just products. They need a technology partner with deep expertise, scalable solutions, and a commitment to long-term success. That’s where Metal3DP delivers unmatched value.

🔍 What Sets Met3DP Apart?

| Feature | Description | B2B Benefit |

|---|---|---|

| Advanced SEBM Printers | Superior electron beam melting systems | High accuracy and print reliability |

| Wide Powder Portfolio | Ti, CoCrMo, stainless steels, superalloys | Support for diverse applications |

| In-House Powder Production | Gas atomization + PREP | Consistent quality and faster delivery |

| Custom Alloy Development | R&D and prototyping support | Tailored material solutions |

| Global Logistics | International shipping & support | Reliable, scalable supply chain |

🧪 Metal3DP’s Technical Capabilities

- High sphericity powders with excellent flowability

- Low oxygen and nitrogen content for enhanced mechanical performance

- Particle size distribution (PSD) tailored to LPBF and SEBM systems

- Expertise in both laser and electron beam powder bed fusion

- In-house labs for powder characterization and batch testing

👉 Learn more about how Metal3DP supports global additive manufacturing transformations.

🤝 B2B Services and Partner Programs

Met3DP works with:

- OEMs in aerospace, automotive, and energy

- Distributors seeking high-margin metal AM products

- Universities and R&D centers for material development

- Manufacturing service bureaus for contract printing

Key partnership benefits:

- Volume-based pricing for wholesale buyers

- Dedicated account managers for B2B clients

- Technical training and support

- Private labeling and OEM printing systems

7. How to Order Metal Powders and 3D Printers for Industrial Applications

For B2B buyers—wholesalers, OEMs, procurement managers, or research institutions—placing an order for metal AM equipment or powders involves a series of critical steps. Selecting the right product, ensuring compatibility, and receiving the necessary technical support are vital for a successful transaction and long-term collaboration.

Whether you’re looking to scale additive production or begin exploring metal AM, Met3DP provides an efficient, consultative, and streamlined B2B ordering process tailored to industrial needs.

🛒 Step-by-Step: Ordering from Met3DP

Here’s how businesses can order metal powders and SEBM 3D printers from Met3DP:

| Step | Description | B2B Benefit |

|---|---|---|

| 1. Inquiry & Consultation | Contact Met3DP via website or sales rep | Ensures product fit and tailored advice |

| 2. Technical Discussion | Define material specs, equipment needs, and application goals | Custom recommendations based on use case |

| 3. Sample Request (Optional) | Request trial powder batches or demo prints | Evaluate quality before bulk order |

| 4. Quotation & Terms | Receive detailed pricing, MOQ, and delivery timelines | Transparent, no hidden costs |

| 5. Order Confirmation | Confirm specs and place PO | Secure reservation of stock or production slot |

| 6. Production & QA | Manufacturing and quality assurance procedures | Ensures consistent batch quality |

| 7. Shipping & Delivery | Air/sea freight with tracking and customs support | Global logistics support |

| 8. Installation & Training (for printers) | On-site installation and staff training | Smooth onboarding and usage |

| 9. After-Sales Support | Dedicated tech support and reordering system | Long-term partnership benefits |

👉 Visit Met3DP’s product center to browse available powders and printers

📦 Available Products for B2B Buyers

Met3DP’s Metal Powder Portfolio

Optimized for laser and electron beam powder bed fusion:

- Titanium Alloys: Ti6Al4V, TiNi, TiTa, TiAl

- Nickel-Based Superalloys: Inconel 718, Hastelloy

- Cobalt Alloys: CoCrMo

- Stainless Steels: 316L, 17-4PH

- Custom Alloys: Tailored for aerospace, medical, and energy

Met3DP’s Metal AM Equipment

High-precision SEBM printers designed for industrial-scale production:

- Large build volume

- High printing resolution

- Multi-material compatibility

- Integrated software for slicing and monitoring

- Smart calibration and process control

🔧 Customization and R&D Services

Met3DP offers custom alloy development, powder atomization for unique compositions, and application development support for enterprises looking to innovate or differentiate.

These services are ideal for:

- Aerospace tier-1 suppliers needing proprietary materials

- Medical OEMs requiring biocompatible powders

- Research institutions developing new AM applications

- Distributors looking to private-label AM materials

✅ Learn how Met3DP supports R&D and application development for industrial clients

8. Success Stories: How Businesses Transformed with Metal AM Solutions

Real-world case studies demonstrate the transformative power of metal additive manufacturing. Below are select success stories across key industries where businesses have collaborated with metal AM experts like Met3DP to achieve breakthrough results.

🛫 Aerospace: Reducing Weight and Improving Fuel Efficiency

Client: Aerospace component manufacturer

Challenge: Reduce the weight of structural components while maintaining strength

Solution:

- Used Met3DP’s Ti6Al4V powder for SEBM

- Replaced machined parts with topology-optimized printed structures

- Integrated lattice features to reduce weight

Results:

- 35% reduction in part weight

- Improved fuel efficiency of aircraft

- Reduced lead time from 12 weeks to 2 weeks

🏥 Medical: Custom Orthopedic Implants

Client: Orthopedic implant company

Challenge: Manufacture patient-specific implants quickly and cost-effectively

Solution:

- Utilized Met3DP’s CoCrMo and TiNi powders

- Printed customized implants using Met3DP’s SEBM printer

- Achieved high biocompatibility and mechanical strength

Results:

- 100% patient fit with fewer post-op corrections

- 60% faster production cycles

- Enhanced osseointegration properties

🚗 Automotive: Functional Prototypes for Engine Components

Client: Automotive OEM

Challenge: Rapidly prototype complex engine components with high thermal resistance

Solution:

- Printed Inconel 718 turbocharger components

- Used Met3DP’s gas-atomized superalloy powders

- Performed iterative testing and design refinements in-house

Results:

- Cut prototyping time by 80%

- Achieved performance gains through design enhancements

- Reduced tooling costs by 90%

🛠️ Tooling and Industrial Equipment

Client: Industrial tooling distributor

Challenge: Reduce wear and tear on high-frequency replacement parts

Solution:

- Shifted to AM production using 17-4PH stainless steel

- Partnered with Met3DP for powder supply and print file optimization

Results:

- Increased tool life by 3x

- Reduced inventory costs through on-demand manufacturing

- Enabled product customization for end clients

✅ Want similar results? Explore Met3DP’s industrial AM capabilities

9. FAQs: Working with Metal AM Experts and Suppliers

To help B2B buyers and industrial stakeholders make informed decisions, here are some frequently asked questions about sourcing metal AM powders and equipment.

❓ What is the minimum order quantity (MOQ) for powders from Met3DP?

Met3DP offers flexible MOQs depending on the material. For standard alloys like Ti6Al4V or 316L, MOQs are as low as 1–5kg. For custom alloys, MOQ may vary depending on R&D requirements.

❓ Are Met3DP powders compatible with other printers?

Yes. Met3DP powders are compatible with most PBF (LPBF & SEBM) systems from EOS, SLM Solutions, Renishaw, and others. The company can also tailor PSD ranges based on your printer’s requirements.

❓ Does Met3DP offer international shipping?

Absolutely. Met3DP ships globally with customs support, air/sea freight options, and real-time tracking. Logistics partners ensure safe delivery of both powders and equipment to North America, Europe, Asia-Pacific, and the Middle East.

❓ How do I know which powder is suitable for my application?

Met3DP provides free technical consultations to help you choose the right material. Based on your application (e.g., biomedical, aerospace, tooling), their experts recommend appropriate alloy types, PSD ranges, and oxygen content levels.

❓ Can I visit Met3DP’s facilities?

Yes. B2B clients and strategic partners are welcome to visit Met3DP’s headquarters in Qingdao, China. Facility tours include powder production lines, quality control labs, and SEBM printer demonstrations.

✅ Meet the team and explore Met3DP’s facilities

✅ Conclusion & Call to Action: Partner with Met3DP for Scalable Metal AM Success

The future of manufacturing lies in digital, scalable, and customized production—and metal additive manufacturing is at its core. But to fully leverage its potential, businesses must collaborate with trusted experts who offer not just products, but complete solutions.

Met3DP stands out as a global leader in metal powders, 3D printers, and industrial AM expertise—backed by cutting-edge technology, deep materials science, and global logistics.

🔑 Key Takeaways for B2B Buyers:

- Metal AM can reduce costs, lead times, and waste

- Choosing the right supplier is critical for success

- China is becoming a dominant force in affordable, high-quality AM solutions

- Met3DP offers a complete portfolio of powders, equipment, and services

- Long-term partnerships with Met3DP drive innovation and growth

📞 Ready to explore a partnership?

Reach out to Met3DP today for a personalized consultation.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731