Advanced Metal AM Solutions in the USA and Canada: Top Suppliers, Market Trends, and How to Source High-Performance Metal Powders

Table of Contents

1. Introduction: Why Metal Additive Manufacturing Is Transforming North American Industries

Metal Additive Manufacturing (AM), also known as metal 3D printing, has become a transformative force across industries in the USA and Canada. From aerospace and automotive to healthcare and energy, metal AM is disrupting traditional supply chains and enabling design freedom, cost savings, and faster time to market.

What Is Metal Additive Manufacturing?

Metal AM refers to a family of technologies that build complex metal parts layer by layer from digital models. Unlike subtractive machining, which cuts away material, AM adds material only where needed, resulting in less waste and more design freedom.

The most common metal AM technologies include:

| Technology | Description | Common Applications |

|---|---|---|

| Laser Powder Bed Fusion (LPBF) | Uses a laser to melt metal powder layer-by-layer | Aerospace parts, medical implants |

| Electron Beam Melting (EBM) | Uses an electron beam in a vacuum chamber | Orthopedic implants, turbine blades |

| Directed Energy Deposition (DED) | Melts metal wire or powder using laser or electron beam | Repair & refurbishment, large parts |

| Binder Jetting | Uses binder to join powder particles, followed by sintering | Mass production, tooling |

Why the USA and Canada Are Embracing Metal AM

North America is a global leader in adopting advanced manufacturing technologies. Several factors are driving the rapid adoption of metal AM across the region:

- Supply Chain Resilience: Localized production reduces dependency on overseas suppliers and shortens delivery times.

- Innovation Incentives: Government grants and R&D tax credits in both the USA and Canada support AM innovation.

- Advanced Industries: The region’s strong aerospace, defense, and medical sectors demand high-performance, customized metal parts.

- Sustainability Goals: AM reduces waste and energy use, aligning with ESG goals.

As demand for lightweight and high-performance components grows, metal AM offers a competitive edge for North American manufacturers.

2. Market Trends & Growth Potential of Metal AM in the USA and Canada

The metal AM market in North America is experiencing exponential growth, fueled by technological advancements, industry demand, and global supply chain shifts. According to a report by SmarTech Analysis, the global metal AM market is expected to exceed $11 billion by 2027, with North America accounting for a major share.

Key Statistics

| Metric | USA | Canada |

|---|---|---|

| Estimated AM Market Size (2023) | $3.5B+ | $500M+ |

| Annual Growth Rate | 20–25% | 18–22% |

| Top Industries Using Metal AM | Aerospace, Medical, Defense, Automotive | Aerospace, Energy, Medical |

| Number of AM Companies | 1,000+ | 200+ |

Notable Trends in the USA & Canada

- Aerospace Drives Demand

Boeing, Lockheed Martin, and GE Aviation are leveraging AM for lightweight, mission-critical components. Canada’s aerospace hubs in Montreal and Toronto are also investing in AM. - Medical Implants and Devices

Both countries are using LPBF and EBM to produce orthopedic implants, dental prosthetics, and surgical tools with customized geometries. - Automotive Prototyping and Tooling

OEMs like Ford and GM are integrating AM into prototyping and low-volume production. Canadian automotive suppliers are adopting AM for tooling and jigs. - Defense and National Security

Metal AM reduces part lead times and enhances field readiness. The U.S. Department of Defense has funded numerous AM initiatives. - Workforce and Education Investments

Universities like MIT, Penn State, and the University of Waterloo are developing AM talent and R&D capabilities.

Emerging Opportunities

- Local Powder Production: There’s a growing need for regionally produced high-quality powders.

- AM for Energy Sector: Oil & gas and nuclear industries are exploring AM for corrosion-resistant parts.

- Post-processing Automation: More investment is going into finishing and inspection technologies.

North America is poised for a metal AM boom, but sourcing high-quality materials and equipment remains a key challenge — one that top suppliers and global partners can help solve.

3. Key Considerations When Choosing a Metal AM Supplier in North America

For buyers, OEMs, and contract manufacturers in the USA and Canada, selecting the right metal AM supplier is crucial for the success of any additive project. Whether you’re sourcing AM equipment, powders, or end-to-end solutions, here are the key factors to evaluate:

1. Technology Expertise

- Does the supplier offer LPBF, EBM, DED, or binder jetting?

- Do they understand your industry’s regulatory and performance requirements?

Look for suppliers who don’t just sell machines but help you optimize the entire AM process—from design to post-processing.

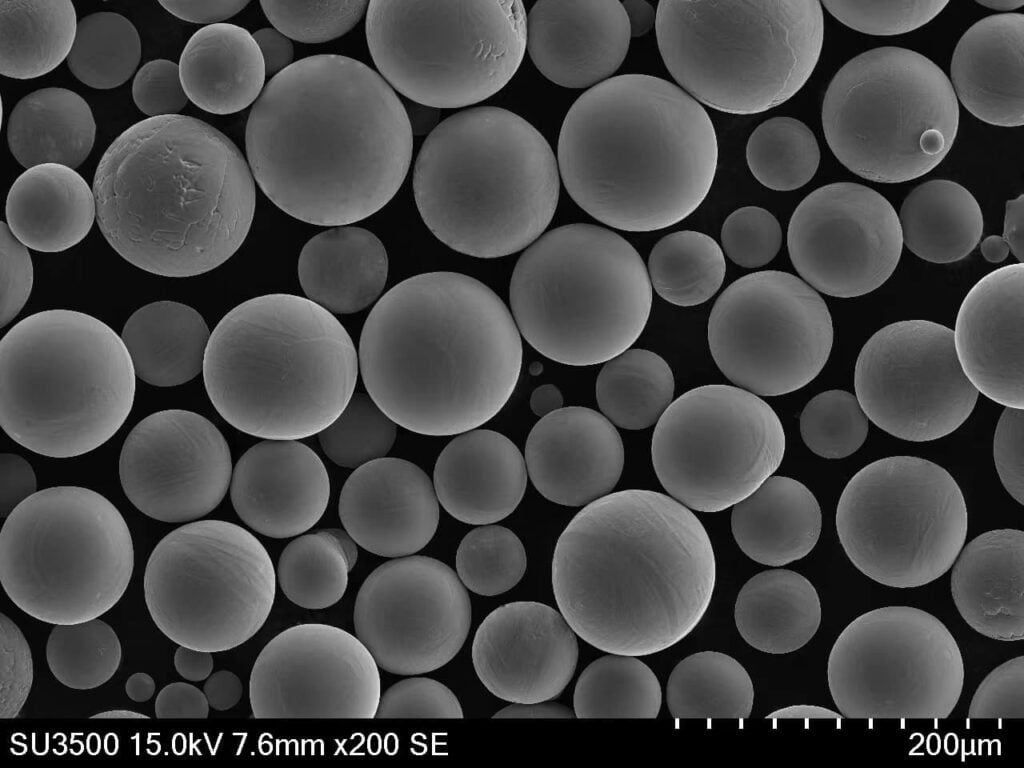

2. Powder Quality & Availability

Metal powders are the lifeblood of AM. Key powder characteristics include:

| Parameter | Importance |

|---|---|

| Particle Size Distribution | Impacts layer thickness and build quality |

| Sphericity | Affects flowability and packing density |

| Purity | Reduces porosity and ensures mechanical properties |

| Trace Elements | Should meet aerospace/medical standards |

Choose suppliers with in-house powder production capabilities and rigorous quality control.

✅ Example: Metal3DP produces high-performance spherical metal powders using advanced gas atomization and PREP systems.

3. Equipment Capabilities

Evaluate the following:

- Build volume and resolution

- Multi-laser systems for higher productivity

- Compatible materials and software

- Maintenance, training, and support services

Suppliers that offer scalable platforms and modular systems can support your growth.

4. Logistics & Lead Times

For North American buyers, fast delivery and local warehousing can be a competitive advantage. Ask:

- Do they ship from domestic or international hubs?

- What are typical lead times for powders and spare parts?

- Are customs and import procedures streamlined?

5. Certifications and Compliance

Especially for aerospace and medical applications, it’s vital that your supplier has:

- ISO 13485 or 9100 certifications

- Powder traceability and documentation

- Material property data sheets

6. Application Support

Look for partners that provide:

- Design for Additive Manufacturing (DfAM) consulting

- Simulation and build strategy services

- Post-processing and surface treatment guidance

7. B2B Services & Pricing Models

For wholesale buyers and OEMs, your supplier should offer:

- Bulk powder discounts

- Annual supply contracts

- Flexible payment terms

- Dedicated account managers

4. Top 5 Metal Additive Manufacturing Solution Providers in the USA and Canada

As metal additive manufacturing continues to grow across North America, many companies have emerged as leaders in supplying cutting-edge equipment, materials, and end-to-end solutions. Below is a curated list of some of the most reputable metal AM companies in the USA and Canada, trusted by OEMs, research institutions, and manufacturers alike.

🔝 Top Metal AM Solution Providers in North America

| Company Name | Location | Key Offerings | Industries Served |

|---|---|---|---|

| 3D Systems | Rock Hill, SC, USA | DMP metal printers, software, materials | Aerospace, medical, automotive |

| GE Additive | Cincinnati, OH, USA | Concept Laser & Arcam EBM printers, powders | Aerospace, energy, healthcare |

| Velo3D | Campbell, CA, USA | Sapphire printers with support-free printing | Aerospace, industrial, space |

| EOS North America | Novi, MI, USA | EOS M series metal printers, training & service | Aerospace, tooling, dental |

| Burloak Technologies | Oakville, ON, Canada | Full-service AM provider, including design & post-processing | Defense, energy, transportation |

What Makes These Suppliers Stand Out?

- Innovation Leadership: Companies like Velo3D and GE Additive are investing heavily in R&D to push the limits of metal AM.

- Material Ecosystems: EOS and 3D Systems offer optimized materials and open platforms.

- Full-Service Capabilities: Burloak and GE Additive provide design, simulation, and certification support.

Limitations for Wholesale Buyers and Distributors

While these companies are market leaders, they often focus on enterprise clients and large-scale contracts. For wholesale buyers, e-commerce sellers, and regional distributors, challenges include:

- High minimum order quantities (MOQs)

- Limited customization for powders

- Long lead times for equipment delivery

- Steep pricing for small to mid-sized businesses

This has led many B2B buyers in North America to explore global sourcing options — especially from Asia.

5. Why More North American Buyers Are Turning to Global Suppliers for Metal 3D Printing Powders

As the demand for high-performance metal powders grows, many North American companies are importing materials and equipment from global suppliers to optimize costs, expand alloy options, and improve supply chain flexibility.

Key Drivers for Exploring Global AM Suppliers

| Factor | Benefit for North American Buyers |

|---|---|

| Cost Efficiency | Lower price per kg for metal powders, especially titanium and superalloys |

| Material Diversity | Access to innovative alloys not yet available locally |

| Production Scale | High-volume output for large orders and consistent supply |

| Technical Expertise | Specialized knowledge in powder metallurgy and equipment design |

| Custom Formulations | Ability to create custom alloy blends for niche applications |

Why China Has Emerged as a Key Supplier Region

China is rapidly becoming a global hub for metal powder production and additive manufacturing equipment. The country has:

- Advanced gas atomization and PREP systems

- Competitive pricing on titanium, nickel, and cobalt-chromium alloys

- Shorter lead times due to large production capacity

- Increasing number of ISO-certified manufacturers

🌐 One standout example is Metal3DP, a Qingdao-based company known for its high-quality AM powders and industrial 3D printers.

6. Why Choose Metal3DP as Your Trusted Supplier for Metal AM Solutions

Metal3DP is a leading Chinese provider of industrial metal AM solutions, trusted by companies across North America, Europe, and Asia. The company offers a full ecosystem of products and services — from high-performance powders to advanced SEBM printing systems.

🔧 Complete Metal AM Solutions from a Single Source

| Category | Offering | Details |

|---|---|---|

| 3D Printers | SEBM, L-PBF systems | High build volume, multi-material support |

| Metal Powders | TiNi, TiAl, CoCrMo, stainless steel, superalloys | Spherical, high-purity powders optimized for AM |

| Powder Production | Gas Atomization & PREP | In-house systems ensure consistency and quality |

| Application Support | DfAM, post-processing, prototyping | End-to-end engineering assistance |

🎯 Why North American Buyers Trust Metal3DP

- High Sphericity Powders: Metal3DP uses proprietary gas atomization nozzles to produce powders with excellent flowability.

- Custom Alloy Development: Ideal for aerospace and medical customers requiring unique compositions.

- Advanced Equipment: SEBM (Selective Electron Beam Melting) printers offer high precision and reliability.

- Global Shipping: Metal3DP ships to the USA and Canada with efficient logistics and documentation.

🔗 Learn more about their additive manufacturing ecosystem on the Metal3DP Metal 3D Printing Page

📈 Case Study: Aerospace Supplier in Texas Reduces Costs by 35%

A Texas-based aerospace component manufacturer switched to Metal3DP for sourcing Ti6Al4V powder and SEBM printer components. Results:

- 35% cost savings per kg of powder

- No compromise on powder consistency or mechanical properties

- Improved uptime with Metal3DP’s responsive remote support

📌 Key Benefits for B2B Buyers

- Competitive pricing for bulk powder orders

- Flexible supply contracts

- Dedicated account managers for North American clients

- Technical documentation for certifications and audits

🔗 Discover Metal3DP’s full Product Portfolio including powder specs and printer models.

7. How to Source Advanced Metal Powders and AM Equipment from Metal3DP

For North American manufacturers, contract fabricators, and AM service providers, sourcing high-quality materials and equipment from overseas can seem complex. Fortunately, Metal3DP offers a streamlined process tailored for international B2B buyers.

🌍 Step-by-Step: How to Order from Metal3DP

| Step | Description | Notes |

|---|---|---|

| 1. Inquiry & Consultation | Contact Metal3DP via website or email to discuss your needs | Dedicated B2B sales team available |

| 2. Technical Evaluation | Share part/application requirements — Metal3DP recommends powders/printers | DfAM and application guidance available |

| 3. Quotation & Lead Time | Receive detailed quotation with shipping, delivery timelines, and MOQ | Bulk discounts for recurring orders |

| 4. Contract & Payment | Flexible payment terms available for qualified B2B clients | Includes material certification and MSDS |

| 5. Production & QA | Order enters production; QA and testing conducted before shipment | Powder specs aligned with ASTM/ISO |

| 6. Shipping & Delivery | Air or ocean freight with customs documentation | Global shipping partners ensure timely delivery |

| 7. After-Sales Support | Remote technical support, training materials, spare parts available | Time-zone-aligned support for USA/Canada |

🧭 Visit the About Us page to learn more about Metal3DP’s global operations and expertise.

📦 What Can You Order?

✅ Metal Spherical Powders (MOQ: 20–50 kg per alloy)

- Titanium Alloys: Ti6Al4V, TiNi, TiAl

- Nickel Superalloys: Inconel 625/718

- Cobalt Alloys: CoCrMo

- Stainless Steels: 316L, 17-4PH

- Custom Alloys: Available on request

✅ SEBM and L-PBF Printers

- Build volumes up to 500mm

- Multi-material and high-density printing

- Compatible with Metal3DP powders

🔗 Explore available Printing Methods and technologies supported by Metal3DP.

🛡️ Quality and Documentation

Metal3DP ensures all shipments include:

- Powder Datasheets (PSD, morphology, flowability)

- Material Safety Data Sheets (MSDS)

- Certificates of Analysis (CoA)

- Quality certifications (ISO, ASTM compliance)

8. FAQs: Common Concerns About Buying Metal AM Supplies Across Borders

If you’re considering importing AM supplies from China to the USA or Canada, you’re not alone — and you’re smart to ask the right questions. Here are some of the most common concerns and how Metal3DP addresses them:

❓ Is it reliable to import metal powders from China?

Absolutely. Metal3DP is a trusted supplier with customers in aerospace, medical, and industrial sectors worldwide. Their powders meet strict international standards.

❓ How long does shipping typically take?

- Air Freight: 5–10 business days

- Ocean Freight: 20–30 business days

Metal3DP provides full tracking and customs documentation.

❓ Are there import duties or taxes?

Yes, depending on your country’s HS codes and trade classification. Metal3DP helps customers classify shipments correctly and can recommend logistics partners.

❓ Can I get technical support in my time zone?

Yes. Metal3DP offers remote technical support and will coordinate meeting times to align with your business hours in the USA or Canada.

❓ What certifications do the powders have?

Metal3DP powders come with:

- ISO 9001:2015 Quality Management

- ASTM F2924, F3001 (for titanium alloys)

- Full chemical and mechanical analysis

📘 Need more answers? Visit the Metal3DP Metal 3D Printing Page for technology details.

9. Conclusion: Future-Proof Your Manufacturing with the Right Metal AM Partner

The metal additive manufacturing landscape in the USA and Canada is advancing rapidly — but staying competitive requires more than just technology. It takes trusted partners, reliable materials, and scalable solutions.

Whether you’re a contract manufacturer, OEM, or distributor, sourcing from a global leader like Metal3DP gives you:

✔️ Access to innovative, high-performance metal powders

✔️ Scalable AM printer platforms with proven reliability

✔️ Competitive B2B pricing and logistics tailored for North America

✔️ End-to-end support, from application development to post-processing

⏩ Ready to upgrade your AM capabilities? Contact Metal3DP today and discover how we can power your digital manufacturing transformation.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731