The Marvel of Metal Jet Machines

Table of Contents

Welcome to the future of manufacturing! Metal jet machines are at the forefront of revolutionizing how we create metal parts and components. If you’ve been hearing the buzz about these high-tech machines and are curious about how they work, their applications, and why they’re becoming so popular, you’ve come to the right place. We’re going to dive deep into the world of metal jet machines, exploring everything from the basics to the nitty-gritty details, all while keeping things conversational and easy to digest. So, grab a cup of coffee, and let’s get started!

Overview of Metal Jet Machines

What is a Metal Jet Machine?

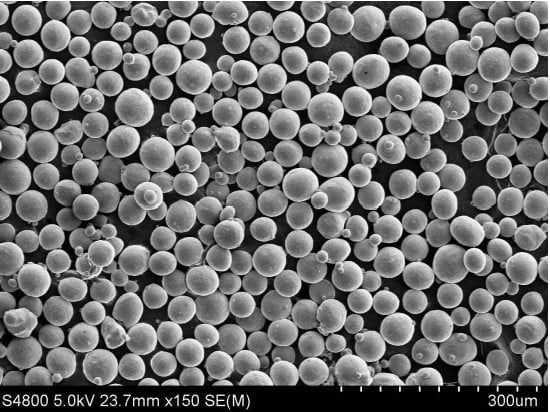

A metal jet machine, often referred to as a metal 3D printer, is an advanced piece of equipment that uses additive manufacturing technology to create intricate metal parts layer by layer. This process involves the deposition of metal powder, which is then fused together using a binding agent or through sintering with a laser or electron beam. The result? Highly precise and durable metal components that are difficult, if not impossible, to create using traditional manufacturing methods.

Why Are They Important?

Metal jet machines are significant because they enable the production of complex geometries and customized parts with remarkable precision. They reduce material waste, shorten production times, and allow for the creation of prototypes and end-use products on-demand. This technology is a game-changer for industries like aerospace, automotive, healthcare, and more.

Types of Metal Powders Used in Metal Jet Machines

When it comes to metal jet machines, the type of metal powder used is crucial. Different powders offer varying properties and are suited for different applications. Let’s look at some specific metal powder models.

1. Stainless Steel 316L

Description: Known for its excellent corrosion resistance and high strength, Stainless Steel 316L is a popular choice in metal jet printing. It is particularly suited for medical and marine applications due to its resistance to chlorides and acidic environments.

2. Inconel 718

Description: Inconel 718 is a nickel-chromium alloy that exhibits exceptional strength and resistance to heat and corrosion. It’s widely used in aerospace and high-temperature applications because it can withstand extreme environments.

3. Titanium Ti6Al4V

Description: Titanium Ti6Al4V is a high-strength, lightweight alloy with excellent biocompatibility, making it ideal for medical implants and aerospace components. It offers a superb balance of strength, corrosion resistance, and workability.

4. Aluminum AlSi10Mg

Description: This aluminum alloy is known for its excellent casting properties, making it ideal for producing lightweight, high-strength parts. It’s commonly used in the automotive and aerospace industries.

5. Cobalt-Chrome CoCr

Description: Cobalt-Chrome alloys are known for their high wear resistance and biocompatibility, making them perfect for medical implants and dental applications. They also offer excellent strength at high temperatures.

6. Maraging Steel 1.2709

Description: Maraging Steel 1.2709 is a high-strength steel known for its excellent mechanical properties and hardness. It’s used in tooling, aerospace, and high-stress applications.

7. Copper CuCr1Zr

Description: Copper CuCr1Zr is prized for its high thermal and electrical conductivity. It’s used in applications where efficient heat or electrical conduction is critical, such as in electrical components and heat exchangers.

8. Nickel Alloy 625

Description: Nickel Alloy 625 is a superalloy known for its high strength, excellent fatigue, and thermal resistance. It’s widely used in marine, chemical processing, and aerospace industries.

9. Tool Steel H13

Description: Tool Steel H13 is known for its high toughness and ability to withstand high temperatures. It’s commonly used in hot work tooling applications, including die-casting and extrusion processes.

10. Hastelloy X

Description: Hastelloy X is a nickel-based superalloy known for its outstanding resistance to oxidation and high-temperature strength. It’s used in gas turbine engines and other high-temperature environments.

Types, Composition, Properties, and Characteristics of Metal Powders

| Metal Powder | Composition | Properties | Characteristics |

|---|---|---|---|

| Stainless Steel 316L | Fe, Cr, Ni, Mo | Corrosion resistance, high strength | Suitable for medical and marine uses |

| Inconel 718 | Ni, Cr, Fe, Nb, Mo, Ti, Al | High strength, heat, and corrosion resistance | Used in aerospace and high-temp applications |

| Titanium Ti6Al4V | Ti, Al, V | High strength, lightweight, biocompatibility | Ideal for medical implants and aerospace |

| Aluminum AlSi10Mg | Al, Si, Mg | Lightweight, high strength, good casting properties | Used in automotive and aerospace |

| Cobalt-Chrome CoCr | Co, Cr, Mo | Wear resistance, biocompatibility | Suitable for medical implants and dental |

| Maraging Steel 1.2709 | Fe, Ni, Co, Mo, Ti | High strength, excellent mechanical properties | Used in tooling and aerospace |

| Copper CuCr1Zr | Cu, Cr, Zr | High thermal and electrical conductivity | Used in electrical components and heat exchangers |

| Nickel Alloy 625 | Ni, Cr, Mo, Nb | High strength, excellent fatigue and thermal resistance | Used in marine, chemical processing, aerospace |

| Tool Steel H13 | Fe, Cr, Mo, V | High toughness, withstands high temperatures | Used in hot work tooling |

| Hastelloy X | Ni, Cr, Fe, Mo, W | Oxidation resistance, high-temperature strength | Used in gas turbine engines |

Applications of Metal Jet Machines

Metal jet machines are versatile and find applications across various industries due to their ability to produce complex and precise metal parts. Here’s a look at some key applications.

Aerospace Industry

Metal jet machines are a boon for the aerospace industry, allowing the production of lightweight and durable components. From engine parts to structural components, these machines help in reducing weight and improving fuel efficiency.

Automotive Industry

In the automotive industry, metal jet machines are used to create high-performance parts with complex geometries. This technology enables the production of lighter, stronger, and more efficient components, contributing to better vehicle performance and fuel economy.

Medical and Dental Applications

Metal jet machines are revolutionizing the medical and dental fields by enabling the creation of customized implants, prosthetics, and dental restorations. The biocompatibility of metals like titanium and cobalt-chrome makes them ideal for these applications.

Industrial Tooling

For industrial tooling, metal jet machines offer the ability to produce durable and precise tools. Maraging steel and tool steel are commonly used materials for creating molds, dies, and other tooling components.

Electronics and Electrical Engineering

Copper and other conductive materials are used in metal jet machines to produce components with high electrical and thermal conductivity. This is crucial for applications in electronics and electrical engineering, where efficient conduction is essential.

Table: Applications or Uses

| Industry | Applications | Benefits |

|---|---|---|

| Aerospace | Engine parts, structural components | Lightweight, durable, fuel-efficient |

| Automotive | High-performance parts, complex geometries | Lighter, stronger, more efficient components |

| Medical and Dental | Implants, prosthetics, dental restorations | Customized, biocompatible |

| Industrial Tooling | Molds, dies, tooling components | Durable, precise |

| Electronics and Electrical | Conductive components, heat exchangers | High electrical and thermal conductivity |

Specifications, Sizes, Grades, Standards

Understanding the specifications, sizes, grades, and standards of metal powders and parts produced by metal jet machines is crucial for selecting the right material for the job.

Stainless Steel 316L

- Specifications: ASTM A240, ASTM A276

- Sizes: Available in various particle sizes

- Grades: 316L

- Standards: ISO 9001, ISO 13485

Inconel 718

- Specifications: ASTM B637

- Sizes: 15-45 microns, 45-105 microns

- Grades: 718

- Standards: ASME, ASTM

Titanium Ti6Al4V

- Specifications: ASTM F136, ASTM B348

- Sizes: 15-45 microns

- Grades: Grade 5

- Standards: ISO 5832-3

Aluminum AlSi10Mg

- Specifications: EN AC-43400, ISO 3522

- Sizes: 20-63 microns

- Grades: AlSi10Mg

- Standards: DIN EN 1706

Cobalt-Chrome CoCr

- Specifications: ASTM F75, ISO 5832-4

- Sizes: 10-45 microns

- Grades: CoCr

- Standards: ISO 5832-4

Maraging Steel 1.2709

- Specifications: AMS 6514, ASTM A538

- Sizes: 15-45 microns

- Grades: 1.2709

- Standards: ISO 9001

Copper CuCr1Zr

- Specifications: ASTM B224

- Sizes: 20-50 microns

- Grades: CuCr1Zr

- Standards: ISO 9001

Nickel Alloy 625

- Specifications: ASTM B446, ASTM B564

- Sizes: 15-45 microns

- Grades: 625

- Standards: ASME, ISO

Tool Steel H13

- Specifications: ASTM A681

- Sizes: 15-45 microns

- Grades: H13

- Standards: ISO 9001

Hastelloy X

- Specifications: ASTM B435, ASTM B619

- Sizes: 15-45 microns

- Grades: X

- Standards: ISO 9001

Specifications, Sizes, Grades, Standards

| Metal Powder | Specifications | Sizes | Grades | Standards |

|---|---|---|---|---|

| Stainless Steel 316L | ASTM A240, ASTM A276 | Various particle sizes | 316L | ISO 9001, ISO 13485 |

| Inconel 718 | ASTM B637 | 15-45 µm, 45-105 µm | 718 | ASME, ASTM |

| Titanium Ti6Al4V | ASTM F136, ASTM B348 | 15-45 µm | Grade 5 | ISO 5832-3 |

| Aluminum AlSi10Mg | EN AC-43400, ISO 3522 | 20-63 µm | AlSi10Mg | DIN EN 1706 |

| Cobalt-Chrome CoCr | ASTM F75, ISO 5832-4 | 10-45 µm | CoCr | ISO 5832-4 |

| Maraging Steel 1.2709 | AMS 6514, ASTM A538 | 15-45 µm | 1.2709 | ISO 9001 |

| Copper CuCr1Zr | ASTM B224 | 20-50 µm | CuCr1Zr | ISO 9001 |

| Nickel Alloy 625 | ASTM B446, ASTM B564 | 15-45 µm | 625 | ASME, ISO |

| Tool Steel H13 | ASTM A681 | 15-45 µm | H13 | ISO 9001 |

| Hastelloy X | ASTM B435, ASTM B619 | 15-45 µm | X | ISO 9001 |

Suppliers and Pricing Details

Finding the right supplier and understanding the cost implications is essential when working with metal jet machines. Here, we’ll look at some leading suppliers and their pricing details.

Leading Suppliers

- Höganäs AB

- Description: A global leader in metal powders, offering a wide range of materials suitable for metal jet machines.

- Products: Stainless Steel 316L, Inconel 718, Titanium Ti6Al4V, Aluminum AlSi10Mg, Cobalt-Chrome CoCr

- GKN Additive

- Description: A renowned supplier specializing in high-performance metal powders for additive manufacturing.

- Products: Maraging Steel 1.2709, Copper CuCr1Zr, Nickel Alloy 625, Tool Steel H13

- Sandvik

- Description: Offers a comprehensive portfolio of metal powders tailored for additive manufacturing applications.

- Products: Stainless Steel 316L, Inconel 718, Titanium Ti6Al4V, Hastelloy X

- Carpenter Technology

- Description: Known for high-quality metal powders and advanced materials for industrial applications.

- Products: Stainless Steel 316L, Inconel 718, Titanium Ti6Al4V, Aluminum AlSi10Mg

Pricing Details

| Metal Powder | Price (per kg) | Supplier |

|---|---|---|

| Stainless Steel 316L | $50 – $70 | Höganäs, Sandvik |

| Inconel 718 | $100 – $150 | Höganäs, Carpenter |

| Titanium Ti6Al4V | $200 – $300 | Höganäs, Sandvik |

| Aluminum AlSi10Mg | $80 – $100 | Höganäs, Carpenter |

| Cobalt-Chrome CoCr | $150 – $200 | Höganäs |

| Maraging Steel 1.2709 | $120 – $180 | GKN Additive |

| Copper CuCr1Zr | $60 – $90 | GKN Additive |

| Nickel Alloy 625 | $110 – $160 | GKN Additive |

| Tool Steel H13 | $70 – $90 | GKN Additive |

| Hastelloy X | $200 – $250 | Sandvik |

Suppliers and Pricing Details

| Metal Powder | Price (per kg) | Supplier |

|---|---|---|

| Stainless Steel 316L | $50 – $70 | Höganäs, Sandvik |

| Inconel 718 | $100 – $150 | Höganäs, Carpenter |

| Titanium Ti6Al4V | $200 – $300 | Höganäs, Sandvik |

| Aluminum AlSi10Mg | $80 – $100 | Höganäs, Carpenter |

| Cobalt-Chrome CoCr | $150 – $200 | Höganäs |

| Maraging Steel 1.2709 | $120 – $180 | GKN Additive |

| Copper CuCr1Zr | $60 – $90 | GKN Additive |

| Nickel Alloy 625 | $110 – $160 | GKN Additive |

| Tool Steel H13 | $70 – $90 | GKN Additive |

| Hastelloy X | $200 – $250 | Sandvik |

Comparing Pros and Cons of Metal Jet Machines

Every technology comes with its set of advantages and limitations. Here’s a detailed comparison to help you understand the pros and cons of using metal jet machines.

Advantages of Metal Jet Machines

- Precision and Accuracy: Metal jet machines can produce highly precise and accurate components, making them ideal for complex geometries.

- Material Efficiency: These machines use only the material needed, significantly reducing waste compared to traditional manufacturing methods.

- Speed: Metal jet machines can produce parts faster than many conventional manufacturing processes, especially for complex or customized items.

- Customization: Ideal for producing customized and one-off parts, which is particularly beneficial in medical and aerospace industries.

- Versatility: Capable of working with a wide range of metal powders, from stainless steel to superalloys.

Disadvantages of Metal Jet Machines

- Cost: The initial investment for metal jet machines and metal powders can be high, making it a significant barrier for small and medium-sized enterprises.

- Complexity: Operating and maintaining these machines requires specialized knowledge and training.

- Material Limitations: While many metals can be used, not all materials are suitable for metal jet printing.

- Post-Processing: Parts often require post-processing, such as heat treatment or machining, to achieve the desired properties and surface finish.

Advantages and Limitations

| Aspect | Advantages | Limitations |

|---|---|---|

| Precision and Accuracy | Highly precise and accurate components | Requires specialized knowledge |

| Material Efficiency | Reduced waste compared to traditional methods | High initial investment |

| Speed | Faster production of complex or customized parts | Parts often require post-processing |

| Customization | Ideal for one-off and customized parts | Not all materials are suitable |

| Versatility | Wide range of metal powders available |

FAQs

What is the primary benefit of using metal jet machines?

The primary benefit of using metal jet machines is their ability to produce highly precise and complex metal parts with minimal waste. They also offer significant speed advantages and customization options.

Can all metals be used in metal jet machines?

No, not all metals can be used. However, a wide range of metal powders, including stainless steel, titanium, and superalloys, are suitable for metal jet machines.

What industries benefit most from metal jet machines?

Industries like aerospace, automotive, medical, and dental benefit the most due to the need for precise, complex, and customized components.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731