Corrosion-Resistant Metal Parts in Essen: A Comprehensive Guide for Wholesale Buyers and Manufacturers

Table of Contents

1. Introduction to Corrosion-Resistant Metal Parts

Corrosion-resistant metal parts are essential components in industries such as aerospace, automotive, medical, and construction. These parts are designed to withstand harsh environmental conditions, preventing oxidation, rust, and material degradation over time.

Key Benefits of Corrosion-Resistant Metal Parts:

- Extended Lifespan – Reduced maintenance costs and longer service life.

- High Mechanical Strength – Maintains durability in extreme temperatures and pressures.

- Superior Aesthetic Appeal – Prevents rusting and oxidation, maintaining a polished look.

- Enhanced Performance – Ensures reliability in critical applications like aerospace and medical implants.

Industries such as oil & gas, marine, and chemical processing rely heavily on these materials for safety and longevity. With Essen being a hub for industrial manufacturing, the demand for high-quality corrosion-resistant metals continues to grow.

2. Market Trends and Demand for Corrosion-Resistant Metals in Essen

Essen, Germany, is a significant center for industrial innovation and metal manufacturing. The demand for corrosion-resistant metal parts has surged due to:

Key Market Trends:

- Growing Adoption of Additive Manufacturing (3D Printing) – Industries are shifting to metal 3D printing to produce complex corrosion-resistant components with greater efficiency.

- Increased Use in Renewable Energy – Wind and solar power industries require high-durability metals for long-term performance.

- Stricter Environmental Regulations – Companies are investing in sustainable, corrosion-resistant materials to meet regulatory compliance.

- Advancements in Alloy Development – New materials such as TiAl (Titanium Aluminum) and CoCrMo (Cobalt Chromium Molybdenum) offer superior resistance to corrosion.

Market Growth Statistics:

| Market Segment | Growth Rate (CAGR) | Key Drivers |

|---|---|---|

| Aerospace | 7.2% | Lightweight and durable materials |

| Medical Implants | 8.5% | Biocompatibility and long-term corrosion resistance |

| Automotive | 6.1% | Demand for rust-proof, high-strength components |

| Industrial Machinery | 5.8% | Wear-resistant materials for long-term use |

With Essen’s emphasis on advanced manufacturing and sustainability, companies are looking for reliable suppliers to meet their corrosion-resistant metal demands.

3. Key Factors to Consider When Choosing a Supplier

Selecting the right supplier for corrosion-resistant metal parts is crucial for ensuring quality, reliability, and cost efficiency. Here are the essential factors to evaluate:

1. Material Quality & Certification

- Ensure the supplier offers high-purity metals with international certifications (ISO 9001, ASTM, DIN).

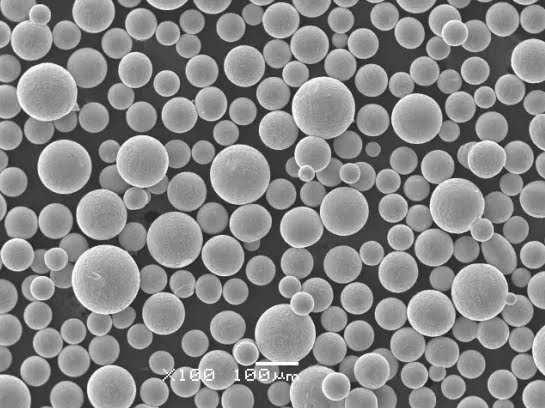

- Look for materials with high sphericity and flowability for 3D printing applications.

2. Manufacturing Processes

- Does the supplier use advanced powder-making systems such as Gas Atomization and PREP technology?

- Are the parts manufactured using Selective Electron Beam Melting (SEBM) or Powder Bed Fusion (PBF)?

3. Customization and Scalability

- Ability to customize compositions for specific applications.

- Scalable production for bulk orders and wholesale buyers.

4. Supply Chain & Delivery

- Fast and reliable shipping to Essen and other European regions.

- Strong logistics network to ensure timely delivery.

5. Pricing & Bulk Discounts

- Competitive pricing for wholesale corrosion-resistant metal parts.

- Volume discounts for large-scale industrial applications.

6. Technical Support & Expertise

- Does the supplier provide custom alloy development and engineering support?

- Availability of application development services for industries such as medical, aerospace, and automotive.

Comparison Table: What to Look for in a Supplier

| Factor | Importance | What to Look For |

|---|---|---|

| Material Quality | High | ISO-certified, high-purity metals |

| Manufacturing Technology | Critical | SEBM, Gas Atomization, PREP |

| Customization | Important | Tailor-made alloys for industry-specific needs |

| Delivery & Logistics | Essential | Fast, reliable shipping to Essen |

| Pricing & Discounts | Cost-Saving | Bulk pricing for wholesale buyers |

| Technical Support | Value-Added | Engineering and R&D assistance |

By carefully evaluating these factors, businesses can ensure they select the best supplier for their corrosion-resistant metal needs.

4. Top Suppliers of Corrosion-Resistant Metal Parts in Essen

Essen is home to several leading suppliers of corrosion-resistant metal parts, serving industries such as aerospace, medical, and automotive manufacturing. Below is a list of the top suppliers recognized for their high-quality materials and advanced manufacturing processes.

Top Suppliers in Essen

| Supplier Name | Specialization | Key Strengths | Location |

|---|---|---|---|

| Thyssenkrupp AG | Stainless steel, titanium alloys | Large-scale production, high-strength materials | Essen, Germany |

| Deutsche Edelstahlwerke | Specialty steels, nickel-based alloys | High-purity corrosion-resistant metals | Witten (near Essen), Germany |

| Voestalpine High Performance Metals | Aerospace & medical-grade metals | Advanced R&D, custom alloy solutions | Düsseldorf, Germany |

| Metal3DP | Additive manufacturing metal powders & 3D printed parts | Advanced powder-making technologies, SEBM 3D printing | Qingdao, China (serving Essen & Europe) |

Each of these suppliers provides corrosion-resistant materials for various industrial applications. However, with the rise of additive manufacturing, more companies are turning to 3D-printed corrosion-resistant metal parts for enhanced performance and efficiency.

5. Why More Manufacturers Are Choosing 3D Printed Corrosion-Resistant Metals

The Shift to Additive Manufacturing (AM)

Traditional metalworking methods such as casting and CNC machining have been the industry standard for decades. However, 3D printing of corrosion-resistant metals is revolutionizing the way manufacturers design and produce parts.

Key Advantages of 3D Printed Corrosion-Resistant Metal Parts

- Enhanced Corrosion Resistance: 3D printing enables the use of high-performance alloys with superior resistance to oxidation and wear.

- Complex Geometries: Additive manufacturing allows for intricate designs that cannot be achieved with traditional machining.

- Material Efficiency: Reduces waste by only using the exact amount of material needed for production.

- Faster Production: Rapid prototyping and manufacturing enable quicker turnaround times compared to conventional methods.

- Lightweight & Strong: Ideal for aerospace, medical, and automotive applications where high strength-to-weight ratios are critical.

Comparison: Traditional vs. 3D Printed Corrosion-Resistant Metals

| Feature | Traditional Manufacturing | 3D Printing (Additive Manufacturing) |

|---|---|---|

| Material Waste | High (cutting, machining) | Minimal (layered deposition) |

| Complexity | Limited by machining tools | Highly customizable, intricate designs |

| Production Speed | Longer lead times | Rapid prototyping & production |

| Mechanical Strength | Strong, but limited in complex shapes | Stronger in customized, optimized geometries |

| Cost-Effectiveness | More expensive for small production runs | Cost-efficient for low and medium-volume production |

These advantages make 3D-printed corrosion-resistant metals an attractive option for manufacturers looking to optimize performance and cost efficiency.

6. Why Choose Metal3DP for Corrosion-Resistant Metal Parts

Metal3DP: A Leader in Additive Manufacturing Solutions

Metal3DP is a global provider of high-quality corrosion-resistant metal parts and advanced metal powders for 3D printing. With a strong focus on precision, reliability, and innovation, Metal3DP has become a trusted supplier for industries requiring high-performance materials.

Key Advantages of Metal3DP:

- Industry-Leading Print Volume & Accuracy – Our Selective Electron Beam Melting (SEBM) technology ensures high-density, corrosion-resistant metal parts with superior mechanical properties.

- Advanced Powder Making System – We utilize Gas Atomization and PREP (Plasma Rotating Electrode Process) to produce metal powders with high sphericity and excellent flowability.

- Comprehensive Materials Portfolio – Our corrosion-resistant materials include:

- Titanium alloys (TiAl, TiNbZr, TiTa)

- Cobalt-Chromium-Molybdenum (CoCrMo)

- Nickel-based superalloys

- Stainless steels for medical and industrial use

- Custom Alloy Development – We work with clients to engineer specialized alloys tailored to their applications.

- Global Supply & Logistics – We ship high-quality additive manufacturing powders and parts to Essen and other European markets.

Why Metal3DP Stands Out

| Feature | Metal3DP | Traditional Suppliers |

|---|---|---|

| Advanced 3D Printing | ✅ Yes | ❌ No |

| High-Purity Metal Powders | ✅ Yes | ✅ Yes |

| Custom Alloy Development | ✅ Yes | ❌ Limited |

| Bulk Wholesale Discounts | ✅ Yes | ✅ Yes |

| Industry Certifications | ✅ Yes (ISO, ASTM) | ✅ Yes |

| Application Development Support | ✅ Yes | ❌ No |

With cutting-edge additive manufacturing capabilities, Metal3DP is transforming how corrosion-resistant metals are produced and utilized in industries worldwide.

7. How to Order Wholesale Corrosion-Resistant Metal Parts from Metal3DP

For businesses in Essen and across Europe, sourcing high-quality corrosion-resistant metal parts from Metal3DP is a straightforward process. Our streamlined ordering system ensures fast delivery, competitive pricing, and expert technical support for bulk and wholesale buyers.

Step-by-Step Guide to Ordering from Metal3DP

Step 1: Choose Your Metal Powder or 3D Printed Part

Metal3DP offers a variety of corrosion-resistant materials tailored to different industries. Select from our wide range of high-performance metal powders or custom 3D-printed components.

| Product Type | Available Materials | Key Applications |

|---|---|---|

| Metal Powders | TiAl, TiNbZr, CoCrMo, Stainless Steel, Nickel Superalloys | Aerospace, Medical, Automotive, Industrial |

| 3D Printed Parts | Titanium Alloys, Cobalt-Chrome, Custom Alloys | Complex industrial components, implants, lightweight structures |

➡ Browse our full product catalog here.

Step 2: Request a Quote for Bulk Orders

- Contact our sales team with your specific material requirements and order volume.

- We offer custom alloy development and bulk pricing for large-scale buyers.

- Receive a detailed quotation with pricing, shipping timelines, and technical specifications.

➡ Get a custom quote today by visiting our contact page.

Step 3: Confirm Your Order & Production Start

- Once you approve the quote, our team will begin the production process.

- If ordering metal powders, we ensure high purity, excellent flowability, and consistent particle size.

- If ordering 3D printed parts, we utilize Selective Electron Beam Melting (SEBM) for high-density, corrosion-resistant components.

Step 4: Fast Shipping to Essen, Germany

- We provide global shipping with secure packaging to ensure your materials arrive in perfect condition.

- Our logistics team ensures timely delivery to Essen and other European regions.

Step 5: Post-Purchase Support & Reordering

- Our team offers technical support for material selection and application development.

- Need a reorder or custom material batch? We offer priority processing for returning customers.

By partnering with Metal3DP, businesses in Essen can access world-class corrosion-resistant metal solutions with ease.

8. FAQs: Common Questions About Buying Corrosion-Resistant Metals

1. What are the best corrosion-resistant metals for industrial use?

The best options include:

- Titanium Alloys (TiAl, TiNbZr) – Lightweight, high strength, and superior corrosion resistance.

- Cobalt-Chromium-Molybdenum (CoCrMo) – Excellent wear and corrosion resistance, ideal for medical and aerospace applications.

- Nickel-Based Superalloys – High-temperature resistance and extreme durability.

- Stainless Steels – Cost-effective and widely used in general industrial applications.

2. Why is 3D printing better for corrosion-resistant metal parts?

- Less Material Waste – Uses only the required material, making it more cost-effective.

- Complex Geometries – Enables intricate designs not possible with traditional machining.

- Stronger Performance – Optimized structures lead to better mechanical properties.

Learn more about metal 3D printing technologies here.

3. What industries benefit from corrosion-resistant metals?

- Aerospace – Jet engine components, structural parts.

- Medical – Implants, orthopedic devices.

- Automotive – Lightweight, durable car parts.

- Chemical Processing – Corrosion-resistant piping and tanks.

4. How do I determine the right material for my application?

Our team of experts can guide you in selecting the best material based on:

- Environmental conditions (exposure to moisture, chemicals, high temperatures).

- Mechanical properties (strength, hardness, flexibility).

- Regulatory compliance (medical, aerospace, industrial standards).

5. Can I order customized corrosion-resistant metal alloys?

Yes! We specialize in custom alloy development for unique industrial applications. Contact us to discuss your specific material needs.

9. Conclusion & Next Steps

The demand for corrosion-resistant metal parts is growing rapidly in Essen and across Europe, driven by advancements in additive manufacturing and high-performance alloys. With Metal3DP, businesses can take advantage of cutting-edge metal 3D printing technologies and high-purity metal powders to enhance their manufacturing capabilities.

Why Choose Metal3DP?

✅ Industry-Leading 3D Printing & Metal Powders

✅ Custom Alloy Development for Specialized Applications

✅ Bulk Wholesale Pricing & Reliable Global Shipping

✅ Technical Support & Application Development Services

Next Steps: Order High-Quality Corrosion-Resistant Metals for Your Business

🔹 Get a quote today – Contact Metal3DP

🔹 Explore our products – View our full product catalog

🔹 Learn more about metal 3D printing – Visit our technology page

By choosing Metal3DP, manufacturers in Essen can leverage advanced metal powders and additive manufacturing solutions to stay ahead in their industries.

Interested in Wholesale Corrosion-Resistant Metal Parts? Contact Us Now!

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731