Upload 3D Files and Print High-Quality Metal Parts in Berlin – A Complete Guide for Industrial Buyers & Engineers

Table of Contents

1. Introduction: Why Metal 3D Printing is Revolutionizing Manufacturing in Berlin

Berlin has long been known as a center of innovation, engineering, and advanced manufacturing in Europe. Today, the city’s industrial landscape is being transformed by a new force: metal additive manufacturing, also known as metal 3D printing. From automotive to aerospace, medical to precision tooling, companies across Berlin are leveraging on-demand 3D printing services to accelerate product development, reduce tooling costs, and produce complex, high-performance parts.

🔧 What Is Metal 3D Printing?

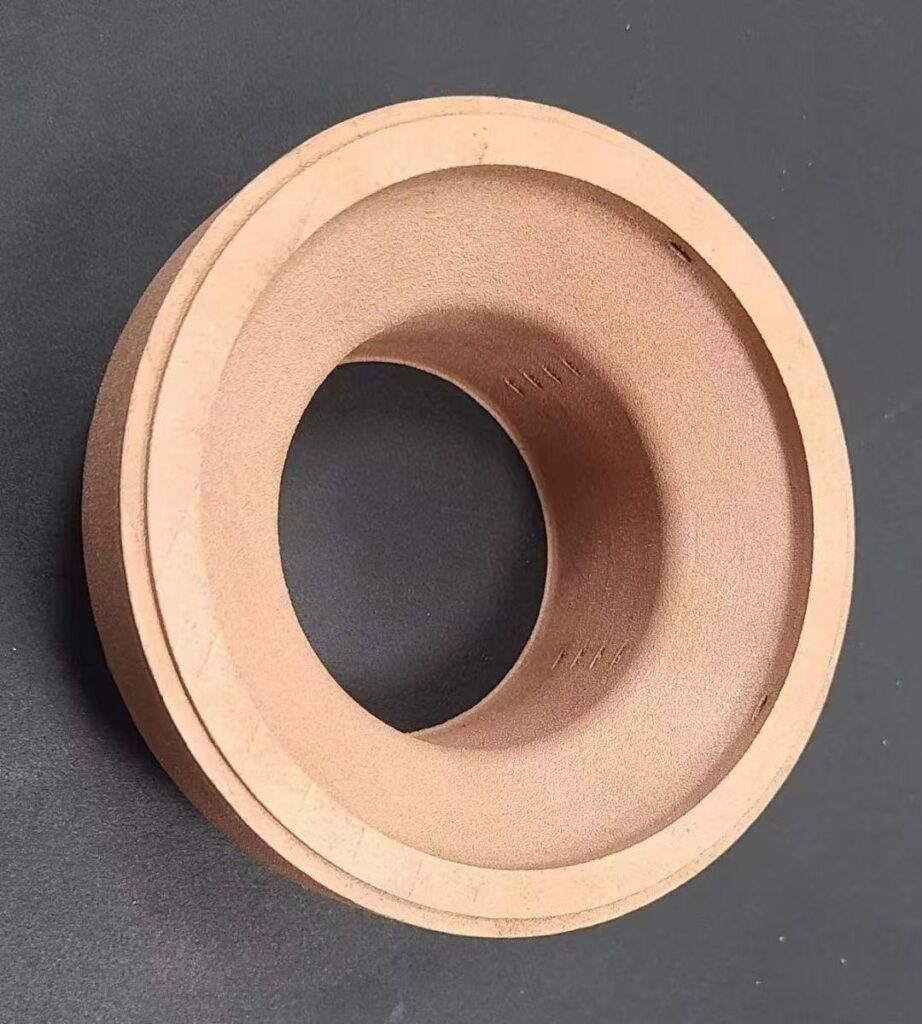

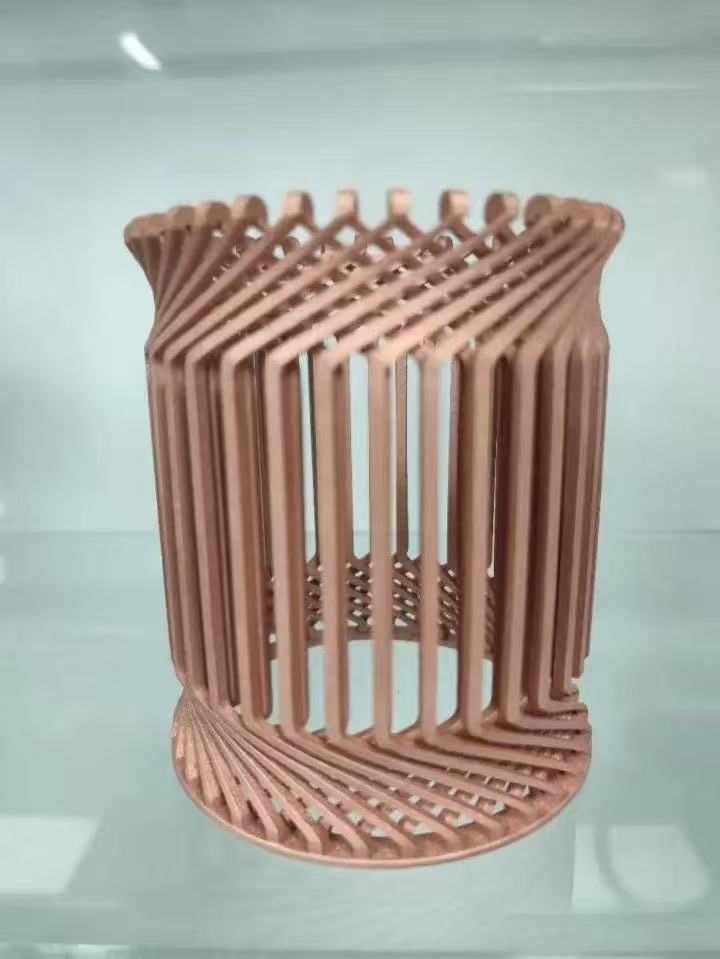

Metal 3D printing is a form of additive manufacturing that builds metal components layer by layer from a digital 3D model. Unlike traditional subtractive methods (e.g., milling, turning), this process eliminates material waste and allows for highly complex geometries.

🏭 Why It’s Ideal for Berlin’s Industrial Ecosystem

Berlin’s thriving ecosystem of startups, OEMs, and research institutions makes it a prime location for adopting cutting-edge manufacturing technologies. Here’s why:

- Proximity to key industries: automotive, aerospace, robotics

- Strong R&D infrastructure: universities and Fraunhofer institutes

- Fast lead times: local production enables rapid prototyping and delivery

- Sustainability: reduced material waste and energy usage compared to CNC

🌐 Upload and Print: A New Manufacturing Paradigm

Thanks to modern service providers, Berlin-based engineers and OEMs can now upload their 3D CAD files, choose from a variety of high-performance metal powders, and receive finished parts in just days — all without investing in expensive equipment.

👉 This upload-to-print model is particularly attractive for:

- Small-batch production

- Rapid prototyping

- Spare parts for legacy equipment

- Complex geometries that cannot be CNC machined

2. Market Trends: Growth of Metal 3D Printing in Germany & Europe

Germany has emerged as a global leader in additive manufacturing, with Berlin playing a pivotal role in the metal 3D printing revolution. According to the 2023 Wohlers Report, Germany accounts for over 10% of global metal AM system installations, trailing only the U.S. and China.

📈 Industry Growth Drivers in Germany

| Driver | Description |

|---|---|

| Engineering Excellence | Germany’s deep engineering roots and precision manufacturing expertise make it a natural adopter of additive technologies. |

| Automotive Innovation | Brands like BMW, Mercedes-Benz, and Volkswagen are integrating 3D-printed metal parts into prototypes and production vehicles. |

| Aerospace Demands | Lightweight, high-strength components for aircraft and satellites are driving rapid adoption. |

| Medical Customization | Patient-specific implants, surgical tools, and dental devices are increasingly 3D printed for precision and speed. |

| Government Support | Federal and EU grants for Industry 4.0 and digital manufacturing initiatives fuel R&D and infrastructure. |

🌍 Europe-Wide Demand for On-Demand Metal Printing

Berlin is strategically positioned to serve not only Germany but also the broader European market. The ability to upload 3D files remotely and have parts printed and shipped across the EU makes Berlin an attractive hub for distributed additive manufacturing.

3. Key Considerations When Choosing a Metal 3D Printing Supplier in Berlin

Selecting the right metal 3D printing partner in Berlin is crucial for achieving the desired mechanical performance, lead time, and cost efficiency. Whether you’re a design engineer, procurement manager, or product developer, here are the key factors to evaluate:

✅ 1. Material Capabilities

Not all service providers offer the same range or quality of metal powders. Look for suppliers that cover a broad spectrum of industrial alloys, including:

- Titanium alloys (e.g., Ti6Al4V, TiAl, TiNi)

- Cobalt Chrome (CoCrMo)

- Nickel-based superalloys (e.g., Inconel 718, Hastelloy)

- Stainless steels (e.g., 316L, 17-4PH)

- Aluminum and copper alloys

🔗 Learn more about high-quality powders from Metal3DP’s product page

✅ 2. Printer Technology & Build Volume

Different printing technologies offer distinct benefits. In Berlin, look for suppliers using:

| Technology | Advantages |

|---|---|

| SEBM (Selective Electron Beam Melting) | High build rates, excellent for titanium and alloys |

| SLM/DMLS (Selective Laser Melting) | High precision and surface finish |

| EBM (Electron Beam Melting) | Ideal for aerospace-grade parts |

| Binder Jetting | Cost-effective for large batch production |

A supplier with industrial-scale metal printers will be able to handle larger parts and production volumes while maintaining tight tolerances.

✅ 3. Certification & Quality Control

Ensure that your supplier upholds international standards, particularly if you’re in regulated sectors like aerospace or medical. Look for:

- ISO 9001, ISO 13485 (medical)

- AS9100 (aerospace)

- In-house metallurgical analysis and CT scanning

✅ 4. Turnaround Time & Logistics

Berlin-based printing services can offer faster delivery compared to overseas providers. Ask about:

- Standard lead times for prototyping vs. production

- Express service availability

- Post-processing capabilities (e.g., heat treatment, CNC finishing, polishing)

✅ 5. Digital Workflow Integration

Top-tier suppliers allow you to upload 3D CAD files directly through online platforms, instantly select materials, and receive quotes — streamlining procurement and shortening development cycles.

🔗 Internal Link Highlight

If you’re looking for a supplier with world-class powder quality, advanced printer technology, and deep application expertise, Metal3DP’s About Us page is a great place to start. Based in Qingdao, China, but serving global markets including Germany and the EU, Metal3DP delivers:

- Advanced metal powders using PREP & gas atomization

- Industrial SEBM and SLM 3D printers

- Custom application development for aerospace, medical, and automotive sectors

4. Top Metal 3D Printing Service Providers in Berlin to Consider

Berlin is home to a growing ecosystem of 3D printing companies offering specialized metal additive manufacturing services. Whether you’re a design engineer, industrial buyer, or R&D manager, selecting the right provider depends on your specific project requirements — from material compatibility and precision tolerances to post-processing and certification.

Below is a comparative breakdown of some of the top service providers operating in Berlin:

| Company Name | Key Capabilities | Materials | Certifications | Target Industries |

|---|---|---|---|---|

| BigRep | Large-format 3D printing, including metal printing for tooling and prototypes | Stainless steel, aluminum | ISO 9001 | Automotive, Aerospace, Tooling |

| 3YOURMIND | Software + On-demand manufacturing platform with Berlin-based partners | Ti6Al4V, CoCrMo, Inconel | Variable (based on partners) | Medical, Industrial, R&D |

| Fabb-It GmbH | Metal and plastic 3D printing with DMLS and SLM technologies | Tool steels, stainless steel | ISO 9001 | Mechanical Engineering, Tool Making |

| Formicum 3D | Engineering consultancy with metal printing services | Titanium, stainless steel | N/A | Custom R&D, Functional Prototypes |

What Sets These Providers Apart:

- Local Expertise: Most providers are deeply embedded in Berlin’s engineering ecosystem and offer fast turnaround times.

- Customization: Many offer engineering support for optimizing parts for additive manufacturing.

- Flexible Quantities: Ranging from single prototypes to small-batch production.

However, most of these firms rely on third-party powder suppliers and may not always offer advanced alloys or the highest-quality powders — which is where global experts like Metal3DP come into play.

5. Why More Engineers & OEMs Are Choosing Outsourced 3D Metal Printing Over In-House Production

In recent years, there’s been a noticeable shift among Berlin-based OEMs, product design teams, and industrial engineers: they’re increasingly choosing to outsource metal additive manufacturing rather than investing in expensive, in-house systems. Here’s why:

💰 Cost Efficiency & Lower Capital Risk

Setting up an internal metal AM facility in Berlin can cost anywhere from €500,000 to over €2 million, including:

- Industrial metal 3D printer

- Powder handling and safety systems

- Post-processing equipment (e.g., HIP, CNC)

- Cleanroom and environmental controls

- Skilled labor and operator training

✅ Outsourcing eliminates this capital burden while still giving access to high-end materials and equipment.

⚙️ Access to Advanced Materials & Technologies

Most in-house operations are limited to a few standard alloys. Outsourcing gives engineers access to:

- Titanium aluminides (TiAl) for aerospace

- Shape memory alloys like TiNi

- Cobalt-chrome for medical implants

- Nickel superalloys like Inconel 625/718

These materials often require specialized powder production methods such as PREP and gas atomization, which only a few global suppliers — like Metal3DP — can provide.

🕒 Faster Turnaround from Concept to Part

By uploading 3D files to a qualified provider, parts can be manufactured and delivered within 3–7 business days, depending on complexity. This is especially valuable for:

- Rapid prototyping

- Short-run functional parts

- Emergency repairs or legacy parts

📉 Reduced Operational Complexity

Outsourcing also eliminates the headaches of:

- Powder storage compliance

- Operator training

- Maintenance and downtime

- Quality assurance and ISO certification

6. Why Choose Metal3DP for Your Berlin-Based Metal Printing Needs

While Berlin offers many capable service providers, few can match the depth of expertise, material innovation, and advanced manufacturing capabilities offered by Metal3DP.

🏢 About Metal3DP

Metal3DP is a leading metal additive manufacturing company based in Qingdao, China, serving global markets including Europe and Germany. With a strong focus on high-quality metal powders, electron beam and laser printing technologies, and application development, Metal3DP is the ideal partner for Berlin-based engineers and OEMs.

🔬 What Makes Metal3DP Different?

| Feature | Metal3DP Offering |

|---|---|

| Advanced Powder Production | Gas Atomization + PREP systems for ultra-spherical, flowable metallic powders |

| Material Portfolio | Ti6Al4V, TiAl, TiNi, TiTa, CoCrMo, Inconel, Stainless steels, and more |

| Printing Technologies | SEBM, SLM, EBM, Binder Jetting |

| Print Volume & Accuracy | Large build volumes with micron-level accuracy |

| Application Expertise | Aerospace, medical implants, automotive, energy, tooling |

| Quality Control | In-house metallurgy lab, SEM analysis, standardized QA protocols |

📎 Seamless Integration with Berlin’s Supply Chain

Metal3DP supports fast, international shipping and file-based manufacturing. German customers can:

- Upload 3D CAD models in formats like .STL or .STEP

- Select from a broad range of certified metal powders

- Receive instant DFM feedback and quotes

- Get parts delivered directly to Berlin in days

🔗 Internal Link Highlight

Explore Metal3DP’s full list of metal 3D printing capabilities and how they support global OEMs across various industries.

📦 Whether you’re a Berlin-based engineering firm looking to prototype a lightweight aerospace bracket or a medical device company sourcing titanium implants, Metal3DP offers the materials, technology, and reliability to scale your additive manufacturing goals.

7. How to Upload 3D Files and Get Instant Quotes for Metal Printing in Berlin

One of the biggest advantages of modern metal additive manufacturing is the convenience of digital file-based production. Engineers, designers, and purchasing teams in Berlin can now upload 3D models directly to a manufacturing portal and receive instant quotes for metal parts — no phone calls, no guesswork, and no delays.

Here’s a step-by-step guide to how the process works with a qualified AM supplier like Metal3DP:

🔄 Step-by-Step Metal 3D Printing Workflow

| Step | Action | Details |

|---|---|---|

| 1. Upload Your 3D Model | Acceptable formats: .STL, .STEP, .IGES, .3MF | Make sure your file is watertight and error-free |

| 2. Select Material | Choose from a list of certified metal powders | Options include Ti6Al4V, Inconel, CoCrMo, Stainless Steel, etc. |

| 3. Choose Technology | SEBM, SLM, or EBM based on project requirements | Metal3DP provides guidance based on tolerances and part geometry |

| 4. Review DFM Feedback | Automated checks for overhangs, thin walls, etc. | Receive design recommendations to improve printability |

| 5. Get Instant Quote | Pricing based on volume, material, and lead time | Transparent breakdown of production and post-processing costs |

| 6. Place Order & Pay | Secure online payment and invoice generation | PO-based billing available for B2B clients |

| 7. Production & QA | Parts are printed, inspected, and post-processed | Optional services: heat treatment, CNC finishing, polishing |

| 8. Shipping to Berlin | Express or standard international shipping | Delivered directly to your facility or production line |

💡 Pro Tip:

Before uploading, always verify the wall thickness, print orientation, and support strategy. If unsure, consult the supplier’s pre-print checklist or contact the engineering team.

🔗 For a complete overview of the supported 3D printing methods, refer to Metal3DP’s printing technologies page.

8. Best Metal Alloys for 3D Printing Industrial Parts in Berlin

Material selection is a critical factor that determines the mechanical performance, surface finish, and application suitability of the final metal part. Whether you’re designing for aerospace, tooling, or biomedical applications, choosing the right alloy can significantly influence success.

Below is a guide to the most in-demand 3D printing metal powders used by industrial customers in Berlin:

🔩 Most Popular Metal Powders for Additive Manufacturing

| Alloy | Description | Common Applications |

|---|---|---|

| Ti6Al4V | Titanium alloy with excellent strength-to-weight ratio | Aerospace brackets, implants, racing parts |

| TiNi (Nitinol) | Shape-memory alloy with superelasticity | Biomedical stents, actuators |

| CoCrMo | High corrosion resistance and biocompatibility | Dental implants, hip joints |

| Inconel 718 | Nickel-based superalloy with high-temperature strength | Aerospace turbine blades, jet engine parts |

| 316L Stainless Steel | Corrosion-resistant, easy to print | Industrial equipment, tools, food-grade parts |

| Tool Steel (H13, M300) | High hardness and wear resistance | Injection molds, cutting tools |

🧪 Why Quality of Powder Matters

Not all powders are created equal. Metal3DP uses advanced gas atomization and PREP systems to manufacture spherical, flowable powders with:

- High purity

- Low oxygen content

- Tight particle size distribution

- Excellent flowability and packing density

🔗 To view Metal3DP’s full material catalog and specifications, visit the metal powder product page

9. FAQs: Common Questions About Uploading 3D Models and Metal 3D Printing in Berlin

To assist engineers, product managers, and industrial buyers in Berlin, here are answers to the most frequently asked questions about file submission, production, and logistics:

📌 General File & Design Questions

Q1: What file formats do you accept?

A: We accept .STL, .STEP, .IGES, and .3MF. For best results, use .STEP for parametric data and .STL for mesh-based models.

Q2: Can I print assemblies or moving parts?

A: Yes, but they must be designed with clearances suitable for metal AM. Speak with our application engineers for guidance.

Q3: What is the minimum wall thickness?

A: Recommended minimum is 0.5 mm for structural parts and 1.0 mm for load-bearing features.

📌 Production & Logistics

Q4: How long does it take to receive parts in Berlin?

A: Typical lead time is 5–10 business days depending on complexity. Expedited services are available.

Q5: Are post-processing services included?

A: Yes, basic support removal is included. Optional services like heat treatment, HIP, CNC machining can be added.

Q6: Can I get a certificate of material composition or mechanical test results?

A: Absolutely. We provide material traceability, composition certificates, and tensile test reports on request.

📌 Cost & Quoting

Q7: How is pricing calculated?

A: Based on material volume, print time, complexity, and post-processing. We offer volume discounts for batch orders.

Q8: Do you support B2B payments and tax invoices for German companies?

A: Yes, we support PO-based invoicing and provide EU-compliant tax documentation.

🔗 For more information about Metal3DP’s company profile, quality standards, and capabilities, visit our official homepage

✅ Conclusion: Start Printing Metal Parts in Berlin from Your Desktop

Metal 3D printing is no longer just an R&D curiosity — it’s a scalable, on-demand manufacturing solution for industries across Berlin. Whether you’re in automotive prototyping, aerospace part production, or surgical implant manufacturing, you can upload a file today and receive a precision-engineered metal part in just a few days.

With its advanced material science, global production capabilities, and commitment to quality, Metal3DP is the ideal partner for your additive manufacturing needs in Berlin and beyond.

🔁 Internal Links Summary (5 Anchor Texts with URLs)

| Anchor Text | URL |

|---|---|

| Metal3DP’s About Us page | https://met3dp.com/about-us/ |

| metal 3D printing capabilities | https://met3dp.com/metal-3d-printing/ |

| supported 3D printing methods | https://met3dp.com/printing-methods/ |

| metal powder product page | https://met3dp.com/product/ |

| homepage | https://met3dp.com/ |

🎯 Ready to Manufacture Your Next Metal Part in Berlin?

📩 Contact Metal3DP today to upload your CAD files, get a quote, and explore how we can help you reduce lead times, improve part performance, and lower production costs through advanced metal additive manufacturing.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731