Metal Powder for Motorsport

Table of Contents

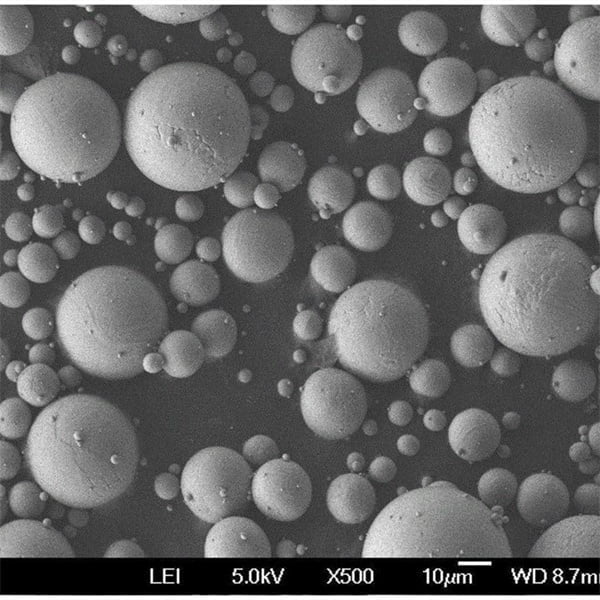

When it comes to motorsport, every component and material is meticulously chosen to ensure top performance. One of the most critical elements in the development and optimization of high-performance motorsport parts is the use of metal powders. These fine metallic particles play a crucial role in creating components that are lightweight yet strong, durable yet flexible, and efficient under extreme conditions. In this comprehensive guide, we will explore the various aspects of metal powders used in motorsport, including specific models, their compositions, properties, applications, and much more. Let’s dive into the fascinating world of metal powders and see how they rev up the motorsport industry.

Overview of Metal Powders in Motorsport

Metal powders are extensively used in motorsport for manufacturing high-performance components. These powders, derived from metals and metal alloys, are processed into fine particles that can be used in various manufacturing techniques such as additive manufacturing, powder metallurgy, and more. The main advantages of using metal powders in motorsport include:

- Weight Reduction: Achieving the optimal balance between strength and weight.

- Improved Performance: Enhancing engine components, suspension systems, and other critical parts.

- Customization: Allowing for the creation of bespoke parts tailored to specific needs.

- Durability: Ensuring parts can withstand the rigors of high-speed racing and harsh conditions.

Key Benefits of Metal Powders

| Benefits | Description |

|---|---|

| Weight Reduction | Lighter components mean faster acceleration and better handling. |

| Strength and Durability | Metal powders can be used to create parts that are both strong and durable, essential for high-stress environments like motorsport. |

| Precision | The fine nature of metal powders allows for the creation of highly detailed and precise components. |

| Versatility | Metal powders can be used in various manufacturing processes, including 3D printing, which is revolutionizing the creation of complex parts. |

Types of Metal Powders for Motorsport

1. Titanium Powder

Composition: Primarily titanium (Ti) with small amounts of oxygen, nitrogen, carbon, and hydrogen.

Properties: High strength-to-weight ratio, excellent corrosion resistance, and high melting point.

Applications: Engine components, exhaust systems, and structural parts.

2. Aluminum Powder

Composition: Mainly aluminum (Al) with traces of silicon, magnesium, and other elements.

Properties: Lightweight, good thermal conductivity, and excellent corrosion resistance.

Applications: Suspension components, brake calipers, and wheel rims.

3. Stainless Steel Powder

Composition: Iron (Fe), chromium (Cr), nickel (Ni), and molybdenum (Mo).

Properties: High strength, excellent corrosion resistance, and good weldability.

Applications: Fasteners, fuel system components, and structural supports.

4. Inconel Powder

Composition: Nickel (Ni), chromium (Cr), and molybdenum (Mo).

Properties: High strength, oxidation resistance, and retains mechanical properties at high temperatures.

Applications: Turbocharger components, exhaust manifolds, and high-temperature fasteners.

5. Copper Powder

Composition: Mainly copper (Cu) with traces of other elements such as silver (Ag).

Properties: Excellent electrical and thermal conductivity, good corrosion resistance.

Applications: Electrical connectors, heat exchangers, and brake pads.

6. Cobalt-Chrome Powder

Composition: Cobalt (Co), chromium (Cr), and molybdenum (Mo).

Properties: High strength, wear resistance, and biocompatibility.

Applications: Valve seats, camshafts, and wear-resistant coatings.

7. Magnesium Powder

Composition: Primarily magnesium (Mg) with small amounts of other elements like aluminum (Al).

Properties: Extremely lightweight, good machinability, and excellent strength-to-weight ratio.

Applications: Gearbox components, steering wheels, and chassis parts.

8. Nickel Powder

Composition: Mainly nickel (Ni) with traces of cobalt (Co) and iron (Fe).

Properties: High strength, corrosion resistance, and good thermal conductivity.

Applications: Battery electrodes, fuel cells, and high-strength fasteners.

9. Tungsten Powder

Composition: Tungsten (W) with small amounts of other elements.

Properties: High density, excellent thermal conductivity, and high melting point.

Applications: Ballast weights, vibration dampers, and heat shields.

10. Bronze Powder

Composition: Copper (Cu) and tin (Sn).

Properties: Good wear resistance, high strength, and excellent machinability.

Applications: Bearings, bushings, and gear components.

Characteristics of Metal Powders for Motorsport

The characteristics of metal powders used in motorsport are pivotal in determining their suitability for specific applications. Here’s a breakdown of some key characteristics:

| Metal Powder | Density (g/cm³) | Melting Point (°C) | Tensile Strength (MPa) | Hardness (HV) | Corrosion Resistance |

|---|---|---|---|---|---|

| Titanium Powder | 4.51 | 1668 | 900 | 349 | Excellent |

| Aluminum Powder | 2.70 | 660 | 310 | 100 | Good |

| Stainless Steel Powder | 7.80 | 1400 | 600 | 200 | Excellent |

| Inconel Powder | 8.44 | 1390 | 1000 | 300 | Excellent |

| Copper Powder | 8.96 | 1085 | 210 | 100 | Good |

| Cobalt-Chrome Powder | 8.50 | 1330 | 1200 | 400 | Excellent |

| Magnesium Powder | 1.74 | 650 | 220 | 50 | Moderate |

| Nickel Powder | 8.90 | 1455 | 620 | 150 | Excellent |

| Tungsten Powder | 19.30 | 3422 | 1510 | 400 | Good |

| Bronze Powder | 8.80 | 950 | 240 | 120 | Good |

Applications of Metal Powders in Motorsport

Metal powders find applications in a wide range of motorsport components, thanks to their unique properties and the versatility of the manufacturing processes they enable.

| Application | Metal Powder Used | Advantages |

|---|---|---|

| Engine Components | Titanium, Inconel | High strength, lightweight, and high-temperature resistance. |

| Exhaust Systems | Titanium, Inconel | Corrosion resistance and ability to withstand high temperatures. |

| Suspension Components | Aluminum, Magnesium | Lightweight and strong, improving handling and performance. |

| Brake Calipers | Aluminum, Bronze | Good thermal conductivity and wear resistance. |

| Turbocharger Components | Inconel, Stainless Steel | High-temperature strength and oxidation resistance. |

| Electrical Connectors | Copper, Nickel | Excellent electrical conductivity and corrosion resistance. |

| Bearings and Bushings | Bronze, Cobalt-Chrome | High wear resistance and strength. |

| Structural Supports | Stainless Steel, Titanium | High strength and corrosion resistance. |

| Gearbox Components | Magnesium, Bronze | Lightweight and good machinability. |

| Heat Exchangers | Copper, Aluminum | Excellent thermal conductivity and corrosion resistance. |

Grades and Standards of Metal Powders for Motorsport

Metal powders are available in various grades and must meet specific standards to ensure their suitability for motorsport applications. These standards ensure consistent quality and performance.

| Metal Powder | Grade | Standard | Description |

|---|---|---|---|

| Titanium Powder | Grade 1, Grade 2 | ASTM B348, ASTM F67 | Unalloyed titanium with different levels of oxygen, nitrogen, carbon, and hydrogen for specific properties. |

| Aluminum Powder | 6061, 7075 | ASTM B211, ASTM B221 | Aluminum alloys with different compositions for improved strength and machinability. |

| Stainless Steel Powder | 304L, 316L | ASTM A240, ASTM A276 | Austenitic stainless steels with excellent corrosion resistance and good formability. |

| Inconel Powder | Inconel 625, 718 | ASTM B443, ASTM B637 | Nickel-chromium alloys with high strength and oxidation resistance at high temperatures. |

| Copper Powder | C11000, C10100 | ASTM B170, ASTM B152 | Pure copper grades with high electrical and thermal conductivity. |

| Cobalt-Chrome Powder | ASTM F75, ASTM F1537 | ASTM F75, ASTM F1537 | Cobalt-chromium alloys with high strength and wear resistance, often used in medical implants as well. |

| Magnesium Powder | AZ31B, AZ91D | ASTM B107, ASTM B108 | Magnesium alloys with good strength-to-weight ratio and corrosion resistance. |

| Nickel Powder | Nickel 200, Nickel 201 | ASTM B160, ASTM B162 | Pure nickel grades with good mechanical properties and corrosion resistance. |

| Tungsten Powder | ASTM B777 | ASTM B777 | Pure tungsten with high density and melting point, used for heavy-duty applications. |

| Bronze Powder | C93200, C95400 | ASTM B505, ASTM B271 | Copper-tin alloys with good wear resistance and machinability. |

Suppliers and Pricing of Metal Powders for Motorsport

The cost and availability of metal powders can vary significantly based on the type, grade, and supplier. Here is a comparison of some suppliers and the typical pricing range for metal powders used in motorsport.

| Supplier | Metal Powder | Price Range (per kg) | Notes |

|---|---|---|---|

| Carpenter Technology | Titanium, Inconel | $150 – $500 | High-quality powders for aerospace and motorsport applications. |

| Höganäs | Aluminum, Stainless Steel | $20 – $100 | Wide range of metal powders with consistent quality. |

| Sandvik | Copper, Cobalt-Chrome | $50 – $200 | Specialized in high-performance metal powders. |

| Praxair Surface Technologies | Nickel, Tungsten | $100 – $400 | Advanced metal powders for high-stress applications. |

| EOS GmbH | Aluminum, Bronze | $30 – $150 | Leading provider of 3D printing materials. |

| AP&C | Titanium, Stainless Steel | $100 – $350 | Known for high-quality powders used in additive manufacturing. |

| GKN Powder Metallurgy | Magnesium, Nickel | $50 – $250 | Broad portfolio of metal powders for various industries. |

| LPW Technology | Inconel, Titanium | $200 – $600 | Premium metal powders for aerospace and motorsport. |

| Tekna | Copper, Tungsten | $80 – $300 | Specializes in high-purity metal powders. |

| H.C. Starck | Cobalt-Chrome, Magnesium | $70 – $220 | Produces a variety of metal powders with high consistency and quality. |

Comparing Metal Powders for Motorsport

Choosing the right metal powder for motorsport applications involves considering various factors such as weight, strength, corrosion resistance, and cost. Here’s a comparison to help you make an informed decision:

| Metal Powder | Advantages | Disadvantages |

|---|---|---|

| Titanium Powder | Lightweight, high strength, excellent corrosion resistance | Expensive, difficult to machine |

| Aluminum Powder | Lightweight, good thermal conductivity, cost-effective | Lower strength compared to some other metals |

| Stainless Steel Powder | High strength, excellent corrosion resistance | Heavier compared to titanium and aluminum |

| Inconel Powder | High-temperature strength, oxidation resistance | Very expensive, heavy |

| Copper Powder | Excellent electrical and thermal conductivity | Not as strong as other metal powders |

| Cobalt-Chrome Powder | High strength, wear resistance, biocompatibility | Expensive, heavy |

| Magnesium Powder | Extremely lightweight, good machinability | Moderate corrosion resistance, flammable |

| Nickel Powder | High strength, good thermal conductivity | Expensive, heavy |

| Tungsten Powder | High density, excellent thermal conductivity | Very heavy, difficult to machine |

| Bronze Powder | Good wear resistance, machinability | Heavier than aluminum, lower strength |

Technical Parameters of Metal Powders

When selecting metal powders for motorsport applications, it’s essential to consider various technical parameters that influence their performance.

| Parameter | Titanium | Aluminum | Stainless Steel | Inconel | Copper | Cobalt-Chrome | Magnesium | Nickel | Tungsten | Bronze |

|---|---|---|---|---|---|---|---|---|---|---|

| Particle Size (µm) | 15-45 | 20-60 | 10-50 | 15-53 | 10-50 | 15-45 | 10-100 | 10-50 | 1-50 | 20-60 |

| Apparent Density (g/cm³) | 2.5-3.5 | 1.2-1.6 | 2.5-4.5 | 4.5-5.5 | 2.0-3.5 | 4.5-5.5 | 0.6-1.2 | 4.5-5.5 | 10.0-15.0 | 2.5-4.0 |

| Tap Density (g/cm³) | 2.8-4.0 | 1.3-1.8 | 3.0-5.0 | 5.0-6.5 | 2.5-4.0 | 5.0-6.0 | 0.7-1.3 | 5.0-6.0 | 12.0-18.0 | 3.0-5.0 |

| Flow Rate (s/50g) | 20-30 | 15-25 | 30-40 | 25-35 | 25-35 | 25-35 | 15-30 | 25-35 | 40-60 | 30-40 |

| Oxygen Content (%) | <0.2 | <0.1 | <0.3 | <0.2 | <0.3 | <0.2 | <0.3 | <0.3 | <0.1 | <0.3 |

FAQ

What are metal powders used for in motorsport?

Metal powders are used to manufacture high-performance components in motorsport, such as engine parts, exhaust systems, suspension components, and more. They offer advantages like weight reduction, improved performance, and customization.

Why is titanium powder popular in motorsport?

Titanium powder is popular in motorsport due to its high strength-to-weight ratio, excellent corrosion resistance, and ability to withstand high temperatures. These properties make it ideal for critical components like engine parts and exhaust systems.

How does aluminum powder benefit motorsport applications?

Aluminum powder is lightweight and has good thermal conductivity and corrosion resistance. These properties make it suitable for components like suspension parts, brake calipers, and wheel rims, where reducing weight is crucial for performance.

What are the challenges of using metal powders in motorsport?

The main challenges include the high cost of certain metal powders like titanium and Inconel, the difficulty in machining some powders, and ensuring consistent quality and performance of the finished components.

Can metal powders be used in 3D printing for motorsport parts?

Yes, metal powders are extensively used in additive manufacturing (3D printing) to create complex and high-performance parts for motorsport. This technology allows for precise customization and rapid prototyping of components.

How do I choose the right metal powder for my motorsport application?

Choosing the right metal powder involves considering factors such as the required strength, weight, corrosion resistance, thermal conductivity, and cost. It’s also important to consult with suppliers and experts to ensure the selected powder meets the specific requirements of your application.

What is the role of standards in metal powder selection?

Standards ensure that metal powders meet specific quality and performance criteria, providing consistency and reliability. Adhering to recognized standards like ASTM helps in selecting powders that are suitable for high-performance and safety-critical applications in motorsport.

Are there any environmental concerns with using metal powders?

The production and handling of metal powders can have environmental impacts, including energy consumption and emissions. However, advancements in recycling and sustainable production methods are helping to mitigate these concerns.

What future trends are expected in the use of metal powders in motorsport?

Future trends include increased use of additive manufacturing, development of new alloy powders with enhanced properties, and improved cost-efficiency in powder production. These advancements will continue to drive innovation and performance in motorsport.

Where can I buy metal powders for motorsport?

Metal powders can be purchased from specialized suppliers such as Carpenter Technology, Höganäs, Sandvik, Praxair Surface Technologies, and others. It’s important to choose reputable suppliers to ensure high-quality powders for your applications.

By understanding the various types, characteristics, and applications of metal powders, motorsport enthusiasts and engineers can make informed decisions that enhance the performance, durability, and efficiency of their racing machines. Whether it’s the lightweight advantage of titanium or the high-temperature resilience of Inconel, the right metal powder can make all the difference on the track. So gear up and dive into the world of metal powders, where every particle counts in the race for excellence.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731