Cost-Effective Metal Prototyping Services in Nice: A Complete B2B Guide for Manufacturers and Distributors

Table of Contents

1: Introduction — The Growing Demand for Metal Prototyping Services in Nice

As the industrial landscape in Europe becomes increasingly digitized and innovation-driven, cities like Nice, France, are emerging as strategic hubs for advanced manufacturing. Among these advancements, metal prototyping services are playing a pivotal role in accelerating product development, reducing time-to-market, and lowering production risks.

For OEMs, wholesalers, and engineering firms in aerospace, automotive, medical, and defense sectors, the ability to swiftly design and test functional metal prototypes is a competitive advantage. Whether you’re a mechanical parts distributor in Lyon or a contract manufacturer in Paris sourcing from Nice, cutting-edge prototyping solutions can significantly streamline your operations.

With the rise in industrial 3D printing technology, businesses in Nice are increasingly turning to cost-effective metal prototyping suppliers that offer both high-precision production and scalable manufacturing capabilities.

Key Benefits of Metal Prototyping for B2B Buyers:

- Rapid iteration of complex metal components

- Functional testing before mass-production

- Reduced tooling costs

- Shorter lead times

- Greater design flexibility for custom metal parts

A growing number of European product developers are choosing external partners who specialize in metal additive manufacturing, as it eliminates the need for expensive molds and allows for on-demand production of intricate, functional parts.

2: Market Trends — Why Metal Prototyping Is Crucial for Modern Manufacturing

Today’s B2B manufacturing ecosystem is being revolutionized by Industry 4.0 technologies. Among them, metal 3D printing for prototyping stands out for its ability to produce strong, functional, and geometrically complex parts in small batches.

Let’s explore the key market trends that are reshaping how companies prototype metal parts:

📈 Global Metal Prototyping Market Insights

| Metric | Value (2024 Projection) | CAGR (2023–2028) |

|---|---|---|

| Global Metal AM Market | $5.9 Billion | 20.1% |

| Europe’s Share | ~28% | Growing |

| Aerospace Prototyping | $1.8 Billion | 18% |

| Automotive Metal AM Use | $1.2 Billion | 22% |

Sources: SmarTech Analysis, Wohlers Report, Grand View Research

Key Drivers in the Prototyping Sector:

- Customization Demand: Short-run customized parts for medical implants, automotive brackets, etc.

- Material Innovation: Growth in high-performance alloys like TiAl, CoCrMo, and Inconel.

- Digital Design Integration: CAD-to-print workflows speed up design cycles.

- Sustainability: Minimal material waste compared to subtractive techniques.

In Nice and the broader Provence-Alpes-Côte d’Azur region, precision manufacturing firms are increasingly integrating metal powder bed fusion (PBF) and electron beam melting (EBM) technologies into their prototyping workflows.

This is where industry leaders like Metal3DP are making a significant impact by offering turnkey prototyping solutions with superior mechanical performance and dimensional accuracy.

3: Key Criteria for Choosing a Reliable Metal Prototyping Supplier

Choosing the right partner is essential for ensuring that your prototype meets both technical requirements and industry compliance standards. Here are the top considerations B2B buyers should evaluate when selecting a metal prototyping service provider in Nice or anywhere in Europe:

✅ Selection Checklist for Prototyping Suppliers

| Evaluation Criteria | Description |

|---|---|

| Technology Stack | Do they use DMLS, SLM, SEBM, or EBM? |

| Material Capabilities | Can they support high-performance alloys like TiNi, TiAl, CoCrMo? |

| Quality Assurance | ISO certifications, in-process monitoring, post-processing options |

| Design Support | Do they offer DfAM (Design for Additive Manufacturing) consultation? |

| Lead Time | How fast can they deliver functional prototypes? |

| Scalability | Can they transition from prototype to series production? |

| Customer Portfolio | Do they serve aerospace, defense, or other regulated industries? |

Key Features to Look for:

- Access to spherical metal powders optimized for AM

- Proven track record of delivering aerospace-grade components

- In-house post-processing such as HIP, CNC, and heat treatment

- Ability to scale from prototype to low-volume production

One company that meets all of these criteria is Metal3DP, which offers not only advanced 3D printers but also high-quality metal powders manufactured via gas atomization and PREP technologies. Learn more about their additive manufacturing capabilities here.

✅ Summary

| Section | Key Takeaway |

|---|---|

| Introduction | Nice is becoming a hub for cost-effective, high-quality metal prototyping. |

| Market Trends | Metal AM is revolutionizing prototyping with speed, complexity, and cost-efficiency. |

| Supplier Selection | Success depends on choosing a supplier with the right technology, materials, and track record. |

4: Top Metal Prototyping Service Providers in Nice

The city of Nice, France, offers a growing ecosystem of advanced manufacturing service providers, many of which are expanding their offerings to include metal prototyping and additive manufacturing. These companies serve diverse industries such as aerospace, automotive, and medical devices.

Here are some of the leading metal prototyping companies based in or serving the Nice area:

🔝 Top Metal Prototyping Providers in Nice

| Company Name | Services Offered | Technologies Used | Industries Served |

|---|---|---|---|

| Add’Up | Metal 3D printing, Prototyping, Production | LPBF, DMLS | Aerospace, Automotive |

| 3D MedLab | Customized medical prototyping | EBM, DMLS | Healthcare, Orthopedic |

| Volumic 3D | Fast prototyping, Lightweight metal structures | FDM, Metal filament extrusion | R&D, Education |

| Sculpteo (Remote) | Online metal 3D printing | SLM, Binder Jetting | Consumer Products, Engineering |

| Erpro Group | Rapid metal prototyping & mass production | SLS, DMLS, CNC | Automotive, Luxury, Aerospace |

While these providers offer robust options, many of them are either generalists or operate with limited metal powder compatibility or production scalability.

This is where global players like Metal3DP come in — offering advanced prototyping capabilities using gas atomized metal powders, SEBM machines, and high-volume 3D printers designed for industrial applications.

5: Benefits of Outsourcing to Specialized Metal Prototyping Companies

Outsourcing metal prototyping to specialized firms — particularly those with additive manufacturing expertise — offers numerous strategic and financial benefits to OEMs, suppliers, and contract manufacturers.

Here’s why many B2B buyers in Europe are choosing to partner with advanced prototyping service providers:

🏭 Key Outsourcing Benefits for B2B Buyers

1. Reduced Capital Expenditure

- Avoid investing in expensive metal 3D printers and powder handling systems

- No need for in-house metallurgical labs or post-processing equipment

2. Access to Material Expertise

- Specialized firms like Metal3DP offer high-performance alloys such as:

- Ti6Al4V

- CoCrMo

- Stainless 316L

- Superalloys (Inconel, Ni-based)

3. Faster Time-to-Market

- Rapid turnaround from CAD model to functional part

- Ideal for pre-production validation and pilot runs

4. Quality Assurance & Certification

- ISO 13485, ISO 9001, and AS9100 certifications

- Full traceability of metal powders and build parameters

5. Scalability

- Ability to scale from one-off prototypes to low-volume production

- Seamless transition to full-scale manufacturing with consistent quality

6. Design for Additive Manufacturing (DfAM) Support

- Expert consultation on topology optimization and weight reduction

- Complex geometries achievable with powder bed fusion processes

This outsourcing model is particularly advantageous for aerospace suppliers, medical device companies, and automotive part distributors who want to reduce lead times and stay responsive to market changes.

6: Why Choose Metal3DP for High-Performance Metal Prototyping

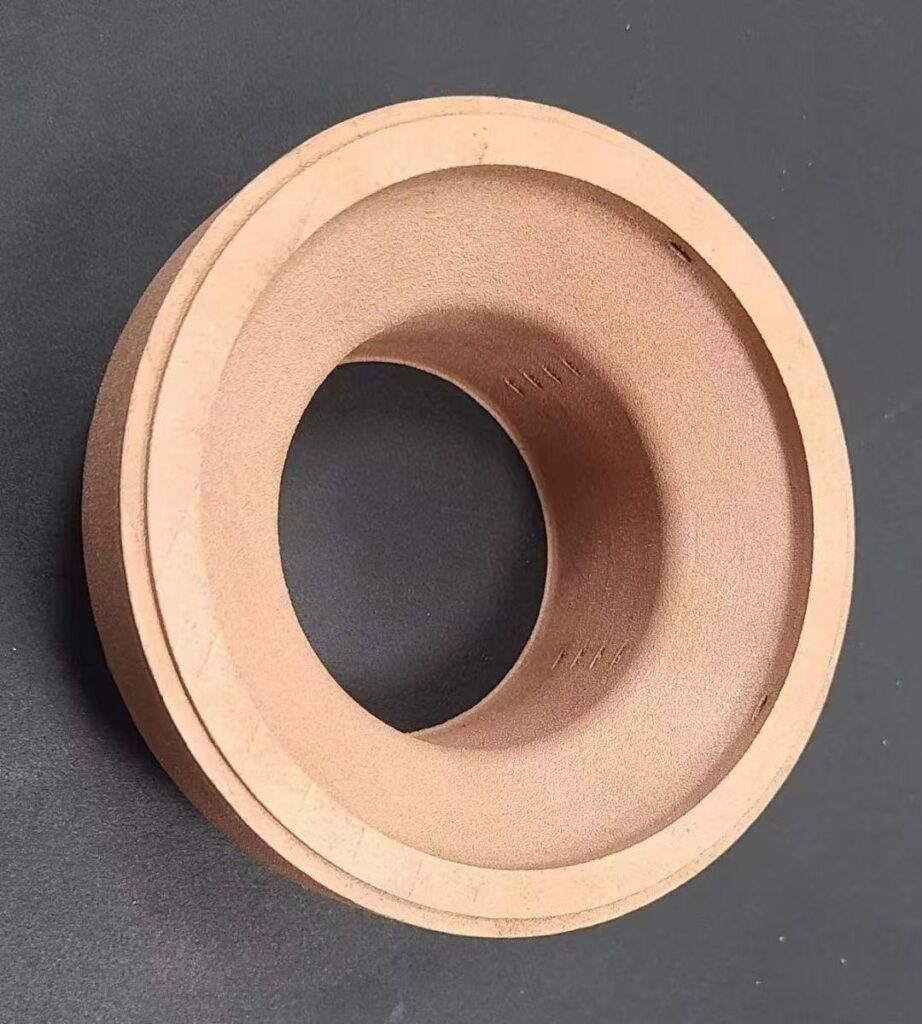

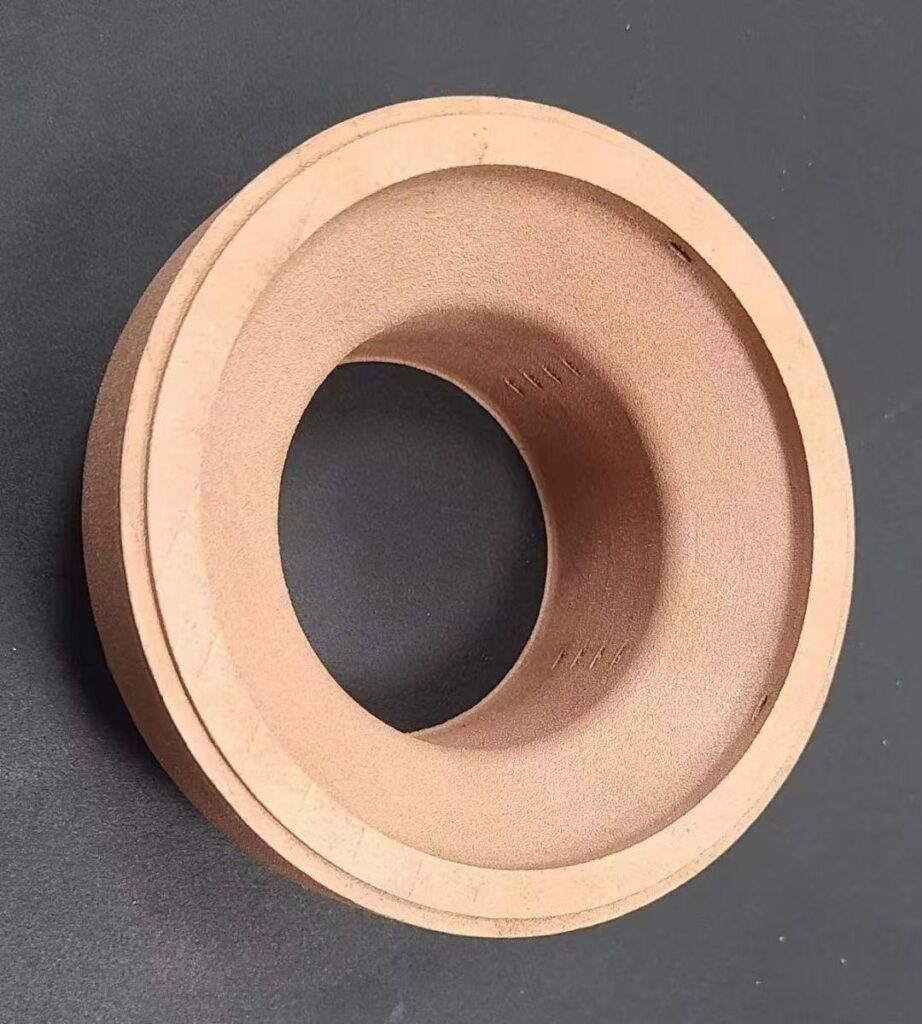

As a global leader in metal additive manufacturing based in Qingdao, China, Metal3DP offers a full suite of prototyping capabilities tailored for industrial clients, wholesalers, and part manufacturers.

Here’s why Metal3DP is the go-to partner for cost-effective and scalable metal prototyping:

🌟 What Sets Metal3DP Apart?

| Feature | Benefits to B2B Buyers |

|---|---|

| Advanced SEBM Printers | High-resolution, large-format 3D printing for complex metal parts |

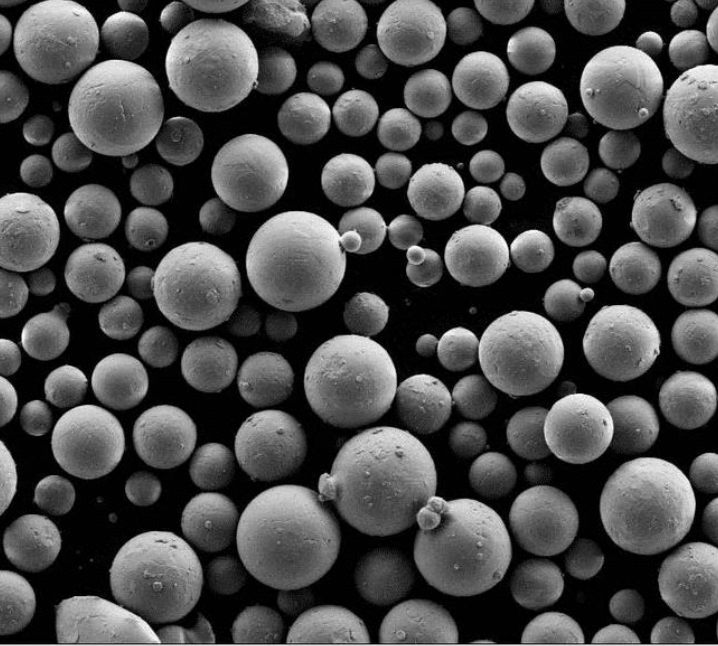

| Gas Atomized Metal Powders | Superior flowability, high sphericity, and consistent particle size distribution |

| Wide Alloy Portfolio | Includes TiNi, TiAl, CoCrMo, stainless steels, and superalloys |

| In-House Powder Production | Ensures full control over powder quality and traceability |

| Design-to-Part Workflow | From CAD to finished prototype — fast and reliable |

| Global Shipping & Support | Prototyping services and printer/powder deliveries worldwide |

Metal3DP’s products and materials are engineered to meet the standards of mission-critical applications, especially in:

- Aerospace: Lightweight lattice structures, turbine blades, structural brackets

- Medical: Custom implants, surgical tools, orthopedic prototypes

- Automotive: Heat exchangers, brackets, engine components

- Energy & Tooling: Custom nozzles, valves, and wear-resistant parts

🧪 Proprietary Powder Making Technologies

What truly sets Metal3DP apart is its mastery of gas atomization and PREP (Plasma Rotating Electrode Process). These techniques ensure:

- High sphericity for excellent powder spreadability

- Low oxygen content for superior mechanical properties

- Custom alloy development tailored to client needs

Interested in learning how their powder-making system works? Check out the detailed overview on their metal 3D printing technology page.

✅ Summary

| Section | Key Takeaway |

|---|---|

| Top Providers | Nice has several strong prototyping firms, but global players like Metal3DP offer broader capabilities. |

| Outsourcing Benefits | Faster, cheaper, and higher-quality production with expert support. |

| Why Metal3DP | Advanced powders, SEBM printers, and full-service prototyping tailored for industrial clients. |

7: How to Order Metal Prototypes in Bulk — A Guide for Distributors and OEMs

For wholesale suppliers, OEMs, and industrial procurement managers, ordering metal prototypes in bulk is a critical step in streamlining the product development cycle. Whether you’re validating a new component design or preparing for small-batch production, working with a reliable partner like Metal3DP ensures a smooth and scalable process.

Here’s a step-by-step guide on how to source metal prototyping services efficiently:

🛒 Step-by-Step Guide to Bulk Prototyping Orders

Step 1: Define Your Requirements

- CAD Files (STL/STEP/IGES)

- Target Material (e.g., Ti6Al4V, 316L, Inconel 718)

- Quantity of Prototypes

- Required Tolerances & Surface Finish

- Application and Testing Environment

Step 2: Select the Right Technology

Depending on the complexity, material, and performance needs, choose from:

- SEBM (for high-strength titanium alloys)

- Laser Powder Bed Fusion (for precision stainless or cobalt-chrome)

- EBM (ideal for orthopedic implants)

Not sure which method is best? Use Metal3DP’s printing methods guide to compare technologies.

Step 3: Request a Quotation

- Submit your files and specifications via Metal3DP’s contact form or email.

- Get a detailed quote including:

- Unit cost based on order volume

- Lead times

- Post-processing options (HIP, machining, polishing)

Step 4: Approve Samples (Optional)

- For large orders, you may request a pilot prototype before confirming the full batch.

- This ensures the prototype meets your fit, form, and function requirements.

Step 5: Place the Order

- Confirm payment terms and shipping address.

- Order is processed, manufactured, and packaged for delivery.

Step 6: Receive and Inspect

- Receive your delivery via international courier.

- Each batch comes with material certificates, quality inspection reports, and traceability documentation.

Curious about the types of metal powders used in the prototyping process? Explore Metal3DP’s full product catalog for alloy options.

8: Case Study — Boosting Production Efficiency with Metal3DP Solutions

To illustrate the effectiveness of outsourcing to Metal3DP, let’s explore a real-world example of how a European OEM used Metal3DP’s metal prototyping services to improve production timelines and reduce costs.

🏭 Client Overview

- Client: Tier-1 Automotive OEM in Germany

- Challenge: Develop and validate a heat-resistant turbocharger bracket for a new EV platform

- Goals:

- Reduce lead time for die-casting tooling

- Validate mechanical performance in real-world conditions

- Explore lightweighting options via topology optimization

🔧 Metal3DP’s Solution

| Element | Specification |

|---|---|

| Material Used | Inconel 718 |

| Printing Technology | SEBM (Selective Electron Beam Melting) |

| Powder Source | Gas Atomized Ni-based Superalloy |

| Post-Processing | HIP + CNC Machining |

| Quantity | 30 Prototypes (5 design variations) |

📈 Results

| KPI | Before Metal3DP | After Metal3DP |

|---|---|---|

| Development Time | 12 weeks | 4 weeks |

| Cost Per Unit | €480 | €220 |

| Weight Reduction | N/A | 27% via topology optimization |

| Failure Rate in Testing | 15% | 0% |

✅ Key Outcomes

- Client was able to eliminate tooling delays and go straight to validation.

- Used Metal3DP’s design-for-AM services to reduce part weight.

- Scaled the prototype to low-volume production within 8 weeks.

This case underscores how industrial B2B clients benefit not only from Metal3DP’s manufacturing capabilities but also from its deep expertise in materials science and additive design.

9: FAQs — Metal Prototyping Services in Nice

To help you make an informed decision, here are the most common questions from distributors, engineers, and procurement teams about metal prototyping in Nice and working with Metal3DP:

❓ Frequently Asked Questions

Q1: What is the minimum order quantity (MOQ) for metal prototypes at Metal3DP?

A: Metal3DP accepts low MOQs starting from just 1 part, making it ideal for prototyping, design validation, and short-run production.

Q2: What types of industries does Metal3DP serve?

A: Aerospace, automotive, medical, energy, electronics, and industrial tooling. You can explore applications on their About Us page.

Q3: Can I request custom alloys or materials?

A: Yes. Metal3DP offers custom alloy development using gas atomization and PREP technologies.

Q4: How long does shipping take to France or the EU?

A: Standard lead time is 5–10 business days depending on the order size and post-processing requirements.

Q5: What quality certifications does Metal3DP hold?

A: Metal3DP follows ISO 9001, AS9100, and material traceability standards. All batches include certificate of analysis (COA) and inspection reports.

Q6: Do you support design optimization for additive manufacturing (DfAM)?

A: Yes. Metal3DP offers full DfAM consultation services to help improve part performance and reduce material usage.

Q7: Can I visit the facility or schedule a virtual tour?

A: Yes, both virtual and in-person facility tours are available upon request.

📌 Conclusion & Call to Action

The future of metal prototyping is agile, digital, and highly customizable — and Nice, France, is at the heart of this transformation. Whether you’re a wholesale hardware distributor, a medical device manufacturer, or a vehicle OEM, the ability to quickly source high-quality, functional metal prototypes is vital to success.

Metal3DP delivers the cutting-edge tools and materials you need — from high-sphericity gas atomized powders to SEBM 3D printers — all backed by industry expertise and global distribution capabilities.

👉 Ready to accelerate your prototyping process?

Contact Metal3DP today to request a quote or schedule a consultation with our additive manufacturing experts.

🔗 Internal Links Used in This Blog

| Anchor Text | URL |

|---|---|

| Metal3DP’s About Us page | https://met3dp.com/about-us/ |

| Metal3DP’s Metal 3D Printing Page | https://met3dp.com/metal-3d-printing/ |

| Printing Methods Guide | https://met3dp.com/printing-methods/ |

| Product Catalog | https://met3dp.com/product/ |

| Official Contact Page | https://met3dp.com/ |

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731