Multi Material Jetting (MMJ)

Table of Contents

Overview of Multi Material Jetting (MMJ)

Imagine a technology that allows you to print not just one type of material but multiple materials simultaneously. That’s what Multi Material Jetting (MMJ) offers. It’s like having a magical 3D printer that can combine different materials into a single print, giving you more flexibility, complexity, and functionality in your designs.

Multi Material Jetting, often abbreviated as MMJ, is a cutting-edge additive manufacturing process that leverages the power of multiple materials being deposited in a single build cycle. This technology stands out for its ability to create complex parts with varied mechanical properties, colors, and textures, all in one go. If you’re looking to dive deep into this revolutionary technology, you’re in the right place. Let’s explore everything there is to know about MMJ, from the basics to the intricate details.

Introduction to Multi Material Jetting (MMJ)

What is Multi Material Jetting?

Multi Material Jetting (MMJ) is a form of 3D printing where multiple materials are jetted layer by layer to build a part. Unlike traditional 3D printing that uses a single material, MMJ uses various materials, which can be deposited simultaneously or sequentially, to create a single, cohesive part. This method allows for parts with different mechanical properties, colors, and textures within the same build, making it ideal for complex, multi-functional components.

How Does MMJ Work?

MMJ works by using printheads to jet tiny droplets of material onto a build platform. These materials can be photopolymers, metals, or other composites that solidify when exposed to UV light or heat. The printheads can switch between different materials quickly, allowing for precise placement of various materials in the desired pattern. This process repeats layer by layer until the final part is complete.

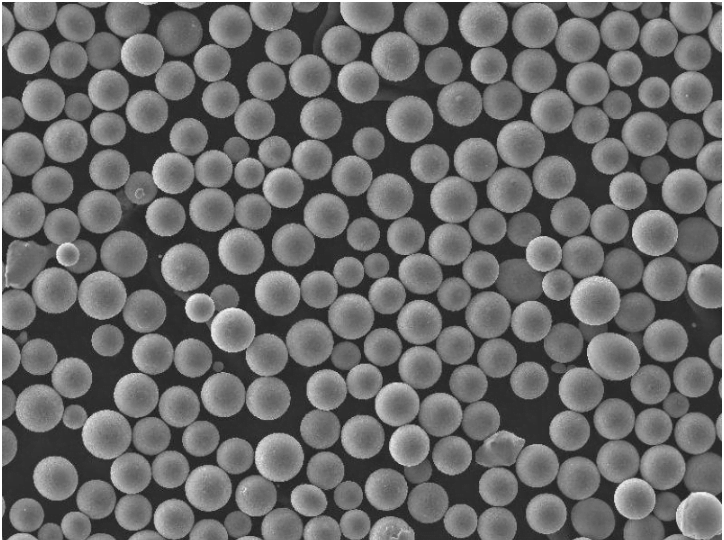

Types of Metal Powders Used in MMJ

Using metal powders in MMJ opens up a world of possibilities in terms of part strength, durability, and functionality. Here are ten specific metal powders commonly used in MMJ, each with unique properties and applications:

| Metal Powder Model | Composition | Properties | Characteristics |

|---|---|---|---|

| Stainless Steel 316L | Fe, Cr, Ni, Mo | High corrosion resistance, good mechanical properties | Ideal for harsh environments, medical devices |

| Titanium Ti6Al4V | Ti, Al, V | High strength-to-weight ratio, excellent corrosion resistance | Aerospace, medical implants |

| Aluminum AlSi10Mg | Al, Si, Mg | Lightweight, good thermal properties, high strength | Automotive, aerospace components |

| Nickel Alloy 625 | Ni, Cr, Mo, Nb | High strength, excellent resistance to oxidation and corrosion | Marine, chemical processing |

| Cobalt Chrome (CoCr) | Co, Cr, Mo | High wear resistance, biocompatible | Dental, orthopedic implants |

| Tool Steel H13 | Fe, Cr, Mo, V | High hardness, excellent wear resistance | Tooling, die-casting |

| Copper Cu | Cu | Excellent electrical and thermal conductivity | Electrical components, heat exchangers |

| Inconel 718 | Ni, Cr, Fe, Nb, Mo | High strength, good creep resistance at high temperatures | Aerospace, gas turbines |

| Maraging Steel | Fe, Ni, Co, Mo | High strength, good toughness, low carbon content | Tooling, aerospace |

| Bronze CuSn10 | Cu, Sn | Good wear resistance, corrosion resistance | Bearings, bushings |

Applications of Multi Material Jetting (MMJ)

MMJ’s ability to combine different materials within a single part opens up numerous application possibilities across various industries. Let’s explore some key applications:

| Application | Industry | Benefits |

|---|---|---|

| Medical Devices | Healthcare | Custom implants, prosthetics with varied mechanical properties |

| Aerospace Components | Aerospace | Lightweight, high-strength parts with integrated functions |

| Automotive Parts | Automotive | Durable, lightweight components with complex geometries |

| Consumer Electronics | Electronics | Multi-material circuits, housings with embedded functionalities |

| Jewelry and Art | Fashion and Art | Complex, multi-material designs with high precision |

| Industrial Tools | Manufacturing | Custom tooling with enhanced wear resistance and strength |

| Dental Implants | Healthcare | Biocompatible implants with precise fit and varied properties |

| Heat Exchangers | Energy | Efficient, complex geometries for better heat transfer |

| Orthopedic Implants | Healthcare | Tailored mechanical properties for specific patient needs |

| Prototyping | Various | Rapid prototyping with functional material properties |

Specifications, Sizes, Grades, and Standards

When it comes to MMJ, understanding the specifications, sizes, grades, and standards is crucial for ensuring the right material choice and application. Here’s a detailed table summarizing these aspects:

| Material | Specifications | Sizes | Grades | Standards |

|---|---|---|---|---|

| Stainless Steel 316L | ASTM F138, F139 | Powder size: 15-45 μm | Medical Grade | ISO 5832-1 |

| Titanium Ti6Al4V | ASTM F136 | Powder size: 20-60 μm | Grade 5 | ISO 5832-3 |

| Aluminum AlSi10Mg | ASTM B209 | Powder size: 10-50 μm | – | EN 1706 |

| Nickel Alloy 625 | ASTM B443 | Powder size: 15-45 μm | – | AMS 5666 |

| Cobalt Chrome (CoCr) | ASTM F75 | Powder size: 10-50 μm | – | ISO 5832-4 |

| Tool Steel H13 | ASTM A681 | Powder size: 15-45 μm | Type H13 | DIN 1.2344 |

| Copper Cu | ASTM B216 | Powder size: 15-45 μm | – | ISO 1338 |

| Inconel 718 | ASTM B637 | Powder size: 15-45 μm | – | AMS 5662 |

| Maraging Steel | ASTM A579 | Powder size: 15-45 μm | Grade 300 | AMS 6514 |

| Bronze CuSn10 | ASTM B505 | Powder size: 10-50 μm | – | DIN 1705 |

Suppliers and Pricing Details

Navigating the market for MMJ materials involves understanding suppliers and pricing. Here’s a table with some key suppliers and their pricing details:

| Supplier | Material | Price per kg (USD) | Additional Notes |

|---|---|---|---|

| Höganäs | Stainless Steel 316L | $100 – $150 | Available globally |

| Carpenter Technology | Titanium Ti6Al4V | $200 – $300 | High purity |

| Eckart | Aluminum AlSi10Mg | $80 – $120 | High availability |

| Sandvik | Nickel Alloy 625 | $150 – $250 | Customizable sizes |

| HC Starck | Cobalt Chrome (CoCr) | $180 – $270 | Medical grade options |

| Uddeholm | Tool Steel H13 | $120 – $180 | High quality |

| GKN Powder Metallurgy | Copper Cu | $70 – $110 | High conductivity |

| Kennametal | Inconel 718 | $170 – $260 | Aerospace grade |

| Aubert & Duval | Maraging Steel | $150 – $220 | Consistent quality |

| Oerlikon Metco | Bronze CuSn10 | $90 – $130 | Custom blends available |

Comparing Pros and Cons of MMJ Materials

Understanding the pros and cons of different MMJ materials is key to making informed choices. Here’s a comparison of various materials used in MMJ:

| Material | Pros | Cons |

|---|---|---|

| Stainless Steel 316L | High corrosion resistance, biocompatible | Expensive |

| Titanium Ti6Al4V | High strength-to-weight ratio, biocompatible | High cost, difficult to process |

| Aluminum AlSi10Mg | Lightweight, good thermal properties | Lower strength compared to other metals |

| Nickel Alloy 625 | Excellent corrosion resistance, high strength | Expensive, difficult to machine |

| Cobalt Chrome (CoCr) | High wear resistance, biocompatible | Brittle, expensive |

| Tool Steel H13 | High hardness, excellent wear resistance | Prone to cracking under certain conditions |

| Copper Cu | Excellent electrical and thermal conductivity | Oxidizes easily |

| Inconel 718 | High strength, good creep resistance | Expensive, difficult to process |

| Maraging Steel | High strength, good toughness | Limited suppliers, expensive |

| Bronze CuSn10 | Good wear resistance, easy to cast | Lower mechanical strength |

Advantages of Multi Material Jetting (MMJ)

MMJ offers numerous advantages that make it a game-changer in the world of additive manufacturing:

1. Complexity and Design Freedom

MMJ allows for the creation of highly complex geometries that would be impossible with traditional manufacturing methods. The ability to jet multiple materials in a single build cycle means designers can integrate different properties and functionalities into a single part.

2. Customization and Personalization

Because MMJ can handle multiple materials and colors, it’s perfect for producing customized and personalized products. Whether it’s a medical implant tailored to a patient’s anatomy or a unique piece of jewelry, MMJ offers unparalleled customization options.

3. Material Efficiency

Unlike subtractive manufacturing, which often results in significant material waste, MMJ is an additive process that uses only the material needed to build the part. This efficiency can lead to cost savings, especially when using expensive materials like titanium or nickel alloys.

4. Reduced Assembly Requirements

With MMJ, it’s possible to create parts that would traditionally require multiple components to be assembled. This not only reduces the need for assembly but also improves the overall strength and reliability of the part.

5. Rapid Prototyping and Production

MMJ is ideal for rapid prototyping because it can quickly produce parts with complex geometries and multiple materials. This speed translates into faster product development cycles and quicker time to market.

Disadvantages of Multi Material Jetting (MMJ)

Despite its many advantages, MMJ also has some limitations:

1. High Initial Costs

The equipment and materials for MMJ can be expensive, making it a significant investment for companies. The high initial costs can be a barrier for small businesses or startups.

2. Material Compatibility Issues

Not all materials are compatible with MMJ technology. Some materials may not adhere well to each other, leading to issues with part integrity. This limitation can restrict the types of parts that can be produced.

3. Post-Processing Requirements

Parts produced with MMJ often require post-processing to achieve the desired finish and mechanical properties. This additional step can add time and cost to the production process.

4. Limited Material Availability

While the range of materials available for MMJ is growing, it is still limited compared to traditional manufacturing methods. This limitation can be a drawback for industries that require specific material properties.

5. Technical Complexity

Operating and maintaining MMJ equipment requires specialized knowledge and skills. This technical complexity can be a challenge for companies without experienced personnel.

FAQ

| Question | Answer |

|---|---|

| What is Multi Material Jetting (MMJ)? | MMJ is an additive manufacturing process that jets multiple materials in a single build cycle to create complex parts with varied properties. |

| What materials can be used in MMJ? | Common materials include stainless steel, titanium, aluminum, nickel alloys, cobalt chrome, tool steel, copper, Inconel, maraging steel, and bronze. |

| What industries benefit from MMJ? | Industries such as healthcare, aerospace, automotive, electronics, fashion, and manufacturing benefit from MMJ. |

| What are the advantages of MMJ? | Advantages include design complexity, customization, material efficiency, reduced assembly requirements, and rapid prototyping. |

| What are the disadvantages of MMJ? | Disadvantages include high initial costs, material compatibility issues, post-processing requirements, limited material availability, and technical complexity. |

| How does MMJ compare to other 3D printing methods? | MMJ offers the unique ability to print multiple materials simultaneously, which sets it apart from other 3D printing methods that typically use a single material. |

| What is the cost of MMJ materials? | The cost varies by material, ranging from $70 per kg for copper to $300 per kg for titanium alloys. |

| Is MMJ suitable for mass production? | MMJ is more suited for customized, low-volume production due to its high costs and complexity. However, it excels in rapid prototyping and specialized applications. |

| What post-processing is required for MMJ parts? | Post-processing may include cleaning, curing, machining, and surface finishing to achieve the desired properties and aesthetics. |

| Can MMJ be used for producing functional parts? | Yes, MMJ can produce functional parts with varied mechanical properties and integrated functionalities, making it suitable for demanding applications. |

Conclusion

Multi Material Jetting (MMJ) represents a significant advancement in additive manufacturing technology. By enabling the simultaneous use of multiple materials, MMJ opens up new possibilities for creating complex, high-performance parts. Whether you’re in the aerospace, healthcare, automotive, or any other industry, understanding the capabilities and limitations of MMJ can help you make informed decisions about your manufacturing processes. Embrace the future of manufacturing with MMJ and unlock new levels of innovation and efficiency.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731