Nickel Superalloys: types, prices, suppliers

Table of Contents

Imagine a material so strong it can withstand the scorching heat of a jet engine or the intense pressure of a gas turbine. Imagine this same material being shaped into intricate components with unparalleled precision. This isn’t science fiction; it’s the reality of nickel superalloys for 3D printing.

Nickel superalloys are a class of metallic materials renowned for their exceptional properties at high temperatures. Their unique blend of strength, oxidation resistance, and creep resistance makes them the go-to choice for demanding applications in aerospace, energy production, and other high-performance industries. But here’s the game-changer: 3D printing technology is unlocking the true potential of these remarkable materials, allowing for the creation of complex, lightweight components with unprecedented design freedom.

Unveiling the Power of Nickel Superalloys for 3D Printing

Nickel superalloys are not created equal. Each formulation boasts a specific mix of elements, resulting in a unique set of properties. To understand their capabilities in 3D printing, let’s delve into the specifics:

Composition and Properties of Nickel Superalloys for 3D Printing

| Element | Function | Impact on Properties |

|---|---|---|

| Nickel (Ni) | Base Metal | Provides the foundation for strength and ductility |

| Chromium (Cr) | Main Strengthening Element | Enhances oxidation resistance and high-temperature strength |

| Cobalt (Co) | Solid Solution Strengthening | Improves high-temperature performance and creep resistance |

| Aluminum (Al) | Lightening Agent | Reduces weight while maintaining strength |

| Titanium (Ti) | Grain Refiner | Controls microstructure for improved mechanical properties |

| Tantalum (Ta) | Carbide Former | Enhances high-temperature strength and oxidation resistance |

| Tungsten (W) | Carbide Former | Strengthens the material at high temperatures |

Applications of Nickel Superalloys in 3D Printing

| Industry | Application | Benefits of 3D Printing |

|---|---|---|

| Aerospace | Turbine blades, combustor liners, heat exchangers | Lightweight, complex designs for improved engine efficiency and performance |

| Energy Production | Gas turbine components, heat shields | Efficient power generation with weight reduction and design flexibility |

| Chemical Processing | Reactors, heat exchangers | Corrosion-resistant, custom-designed components for harsh environments |

| Medical Devices | Implants, surgical instruments | Biocompatible options for personalized medical solutions with intricate geometries |

Specifications, Sizes, Grades, and Standards of Nickel Superalloys for 3D Printing

Due to the diverse nature of applications, nickel superalloy powders come in a variety of specifications. Here’s a breakdown of key factors to consider:

- Particle Size Distribution: Affects flowability, printability, and final component properties. Common ranges include 15-45 microns and 45-90 microns.

- Powder Flowability: Impacts the ability of the powder to be spread evenly during the printing process. Good flowability ensures consistent layer formation.

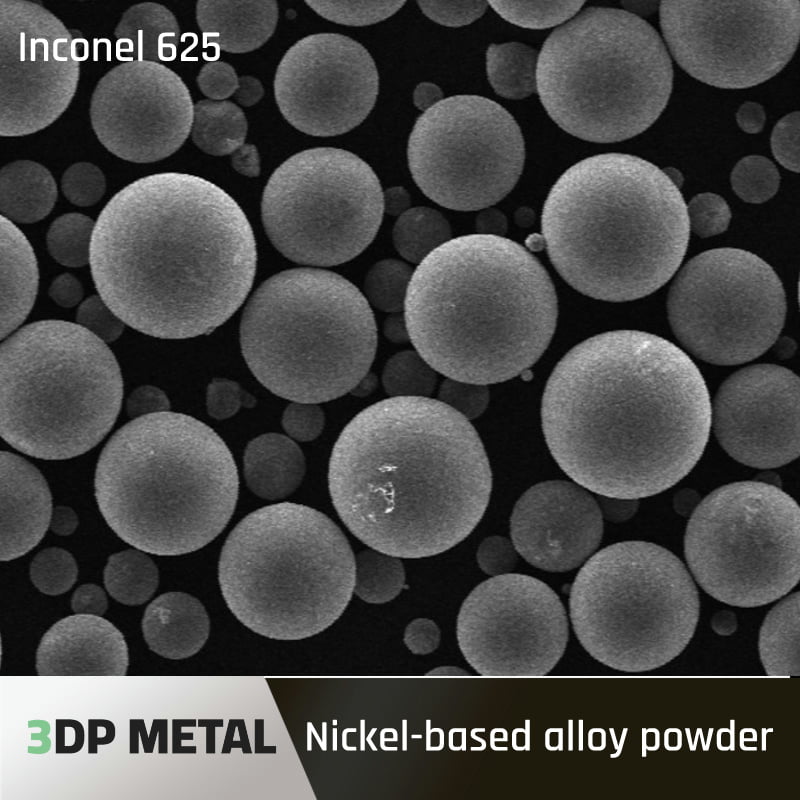

- Sphericity and Morphology: Powder shape influences packing density and laser absorption during printing. Spherical shapes are preferred for optimal results.

- Chemical Composition: Determines the final properties of the printed component. Specific standards like ASTM International (ASTM) or Aerospace Material Specifications (AMS) define acceptable compositions.

Popular Nickel Superalloy Powders for 3D Printing

- AM260S: Developed specifically for additive manufacturing, AM260S powder offers exceptional printability and high-temperature capabilities. Compared to IN718, AM260S boasts superior creep resistance and strength at elevated temperatures, making it a strong contender for demanding aerospace applications.

- MarM247 LC: This advanced alloy powder is known for its exceptional creep resistance and oxidation resistance at extreme temperatures. MarM247 LC surpasses even Rene 41 in these aspects, making it ideal for next-generation turbine blades and hot-section components in jet engines.

- Nickel Alloy Haynes 282: Offering a unique combination of high-temperature strength and good weldability, Haynes 282 powder is a valuable choice for applications requiring both performance and ease of fabrication. This material finds use in heat exchangers, exhaust systems, and other high-temperature components.

- Met3DP Nickel Superalloy Powders: Met3DP, a leading manufacturer of metal powders for 3D printing, offers a range of high-quality nickel superalloy powders optimized for various applications. Their portfolio includes established options like IN718 and Inconel 625, alongside more innovative alloys tailored for specific performance needs.

Pricing and Suppliers of Nickel Superalloy Powders for 3D Printing

The cost of nickel superalloy powders varies depending on the specific alloy, particle size, and supplier. Generally, these powders are more expensive compared to conventional metal powders due to the complex manufacturing processes involved. Here’s a glimpse into the pricing landscape:

- Price Range: Expect a price range of $100-300 per kilogram for commonly used alloys like IN718 and Inconel 625. More advanced options like MarM247 LC can reach higher price points due to their specialized properties.

- Suppliers: Several reputable companies supply high-quality nickel superalloy powders for 3D printing. Some prominent names include EOS GmbH, Elementum 3D, SLM Solutions, and, as mentioned earlier, Met3DP.

Pros and Cons of Nickel Superalloys for 3D Printing

Advantages:

- Exceptional High-Temperature Performance: Nickel superalloys retain their strength and integrity at temperatures where other materials would fail, making them ideal for demanding applications.

- Design Freedom and Lightweighting: 3D printing unlocks the potential for complex geometries with reduced weight, leading to improved efficiency in aerospace and other weight-critical industries.

- Reduced Waste and Near-Net-Shape Manufacturing: Compared to traditional subtractive manufacturing techniques, 3D printing minimizes material waste and allows for near-net-shape production, reducing machining requirements.

- Improved Part Functionality: The ability to create intricate internal features with 3D printing enhances the functionality and performance of components made from nickel superalloys.

Disadvantages:

- Higher Material Cost: Nickel superalloy powders are generally more expensive than other metal powders used in additive manufacturing.

- Limited Material Availability: While the range of available nickel superalloy powders is expanding, it may not encompass all the specific alloy compositions needed for certain applications.

- Process Optimization Required: Successful 3D printing of nickel superalloys requires careful parameter optimization to ensure good printability and achieve desired material properties in the final component.

- Post-Processing Considerations: Some nickel superalloy components may require additional post-processing steps like heat treatment or hot isostatic pressing (HIP) to optimize their final properties.

FAQ on Nickel Superalloys for 3D Printing

Q: What are the benefits of using nickel superalloys in 3D printing?

A: Nickel superalloys offer exceptional high-temperature performance, design freedom for lightweighting, reduced waste with near-net-shape manufacturing, and the potential for improved part functionality through intricate internal features.

Q: What are some of the challenges associated with 3D printing nickel superalloys?

A: The main challenges include higher material cost, limited material availability compared to standard options, the need for process optimization for successful printing, and potential post-processing requirements.

Q: What are some typical applications of nickel superalloys printed using 3D printing?

A: Common applications include turbine blades, combustor liners, heat exchangers (aerospace), gas turbine components, heat shields (energy production), reactors, heat exchangers (chemical processing), and implants, surgical instruments (medical devices).

Q: Where can I buy nickel superalloy powders for 3D printing?

A: Several reputable suppliers offer nickel superalloy powders, including EOS GmbH, Elementum 3D, SLM Solutions, and Met3DP. Met3DP, specifically, manufactures a wide range of high-quality metal powders optimized for laser and electron beam powder bed fusion. Their portfolio includes innovative alloys like TiNi, TiTa, TiAl, TiNbZr, CoCrMo, stainless steels, superalloys, and more, making them a one-stop shop for various 3D printing needs.

The Future of Nickel Superalloys in 3D Printing

The future of nickel superalloys in 3D printing is ablaze with possibilities. As research and development efforts continue, we can expect to see:

- Development of New Alloys: Material scientists are constantly innovating new nickel superalloy formulations optimized for 3D printing. These alloys will push the boundaries of performance, offering even greater strength, oxidation resistance, and high-temperature capabilities.

- Advancements in 3D Printing Technology: Improvements in 3D printing technologies like higher laser power and tighter process control will enable the creation of even more complex and high-performance components from nickel superalloys.

- Reduced Cost and Wider Availability: As the technology matures and production volumes increase, the cost of nickel superalloy powders is expected to decrease. This will make them more accessible to a wider range of applications.

- Qualification for Critical Applications: Stringent qualification processes are underway to certify nickel superalloy 3D printed components for use in critical aerospace and energy applications. This will open doors for the widespread adoption of this technology in these demanding industries.

In conclusion, nickel superalloys are poised to play a transformative role in the future of 3D printing. Their unique combination of high-temperature performance, design freedom, and potential for lightweighting makes them ideal for a vast array of demanding applications. As technology advancements continue, nickel superalloys will undoubtedly become a cornerstone material for pushing the boundaries of what’s possible in 3D printing.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731