High-End Platinum Alloy 3D Printing in Dubai: A Comprehensive Guide for B2B Buyers

Table of Contents

1. Introduction to High-End Platinum Alloy 3D Printing

Platinum alloy 3D printing is revolutionizing industries such as jewelry, aerospace, medical implants, and electronics. As a rare and highly durable metal, platinum offers excellent properties, including corrosion resistance, high melting points, and biocompatibility, making it an ideal material for high-end applications.

Dubai, known for its luxury industry and advanced manufacturing sector, has become a hub for platinum alloy 3D printing. Businesses in the region are increasingly turning to additive manufacturing to produce intricate, high-performance parts with minimal waste.

Advantages of Platinum Alloy 3D Printing

- Precision & Complexity: Enables intricate designs that traditional methods cannot achieve.

- Material Efficiency: Reduces material waste compared to traditional fabrication.

- Customization: Allows for tailored solutions in jewelry, medical, and industrial applications.

- Speed & Scalability: Faster production cycles for rapid prototyping and full-scale manufacturing.

By leveraging advanced 3D printing technologies, businesses can improve product quality while reducing costs and lead times.

2. Market Trends and Growth Potential in Dubai

The demand for platinum alloy 3D printing in Dubai is growing rapidly due to advancements in additive manufacturing and increasing applications across various industries. Here are some key market trends:

Key Market Trends

| Trend | Description |

|---|---|

| Luxury Jewelry Manufacturing | Dubai is a global jewelry hub, and high-end brands are adopting 3D printing to create intricate platinum designs. |

| Medical & Dental Applications | The biocompatibility of platinum alloys makes them ideal for implants and medical equipment. |

| Aerospace Industry Growth | Lightweight, heat-resistant parts are crucial for aerospace applications, boosting demand for 3D-printed platinum components. |

| Sustainable Manufacturing | 3D printing reduces waste and environmental impact, aligning with Dubai’s sustainability goals. |

Growth Potential

- Projected Market Growth: The global metal 3D printing market is expected to reach $6.36 billion by 2028, with Dubai playing a significant role in this expansion.

- Government Support: Dubai’s 3D Printing Strategy 2030 aims to position the city as a leader in additive manufacturing.

- Increased Investment: Companies are investing in high-quality metal 3D printing due to its cost-effectiveness and design flexibility.

As more industries recognize the benefits of platinum alloy 3D printing, the market is set for steady growth in Dubai.

3. Key Factors to Consider When Choosing a 3D Printing Supplier

Selecting the right platinum alloy 3D printing supplier is crucial for ensuring high-quality products and reliable service. Here are the key factors to consider:

1. Material Quality & Selection

- Ensure the supplier offers high-quality platinum alloys with excellent mechanical properties.

- Look for suppliers that use advanced gas atomization or PREP technology for metal powder production.

2. Printing Technology & Equipment

- Check if the supplier uses Selective Electron Beam Melting (SEBM) or Laser Powder Bed Fusion (LPBF) for precision printing.

- The print volume and accuracy should meet industry standards for your applications.

3. Industry Expertise & Certifications

- Choose a supplier with experience in aerospace, jewelry, medical, or industrial applications.

- Ensure they have relevant certifications such as ISO 9001 for quality management.

4. Customization & Prototyping Capabilities

- The ability to produce custom designs is critical for jewelry and medical applications.

- Suppliers should offer rapid prototyping services for testing before full-scale production.

5. Pricing & Lead Times

- Compare pricing models to ensure competitive rates for wholesale platinum 3D printing.

- Fast lead times are crucial, especially for industries with tight production schedules.

6. Customer Support & After-Sales Service

- A responsive support team ensures smooth collaboration and problem resolution.

- Check for after-sales services such as post-processing and finishing options.

By considering these factors, businesses can select a reliable and high-quality platinum 3D printing supplier in Dubai.

4. Top 5 Suppliers of Platinum Alloy 3D Printing in Dubai

Dubai is home to several high-end 3D printing service providers, specializing in platinum alloy additive manufacturing. Below are the top five suppliers offering cutting-edge solutions for industries like jewelry, aerospace, and medical devices.

1. Metal3DP (Recommended Supplier)

Overview:

Metal3DP is a leading provider of metal 3D printing solutions, specializing in high-performance metal powders and precision additive manufacturing. The company offers industry-leading platinum alloy 3D printing services for luxury goods, aerospace, and medical applications.

Why Choose Metal3DP?

- Advanced SEBM and LPBF Printing Technology for superior accuracy

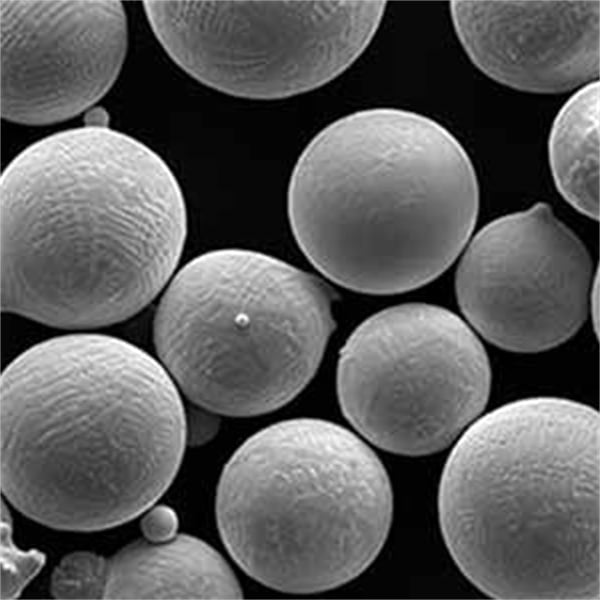

- High-purity platinum alloy powders produced using gas atomization and PREP technologies

- Custom prototyping and bulk manufacturing options available

- ISO-certified production process ensuring top-tier quality

- Global shipping and fast turnaround times

2. Immensa Additive Manufacturing

Overview:

A leading 3D printing service provider in the UAE, Immensa specializes in metal additive manufacturing, including platinum alloys for industrial and medical applications.

Key Features:

- Expertise in metal powder bed fusion

- Strong presence in the aerospace and healthcare sectors

- Offers customized solutions for industrial clients

3. Proto21 3D Printing LLC

Overview:

Proto21 is a well-known 3D printing company in Dubai, offering high-precision metal additive manufacturing services, including platinum alloys for jewelry and high-end applications.

Key Features:

- Specialized in jewelry and fashion industries

- High-resolution printing for intricate designs

- Rapid prototyping services available

4. Sinterex

Overview:

Sinterex focuses on metal 3D printing for healthcare and dental applications, utilizing biocompatible materials such as platinum alloys for medical implants.

Key Features:

- Certified for medical-grade applications

- On-demand production for the healthcare industry

- Advanced post-processing services

5. Generation 3D

Overview:

A pioneer in additive manufacturing in the UAE, Generation 3D provides customized metal printing solutions, including platinum alloys for luxury and aerospace applications.

Key Features:

- Specializes in high-end automotive and aerospace parts

- Offers precision engineering capabilities

- Utilizes state-of-the-art metal 3D printing technologies

These suppliers play a key role in Dubai’s growing 3D printing industry, catering to high-end applications requiring superior material properties.

5. Why More Businesses Are Adopting 3D-Printed Platinum Alloys

The adoption of platinum alloy 3D printing is rapidly increasing across industries. Here’s why more businesses are switching to this innovative technology:

1. Unmatched Design Flexibility

- Complex geometries that were previously impossible can now be manufactured.

- Ideal for customized jewelry, intricate medical implants, and lightweight aerospace components.

2. Cost Efficiency & Material Savings

| Cost Factor | Traditional Manufacturing | 3D Printing |

|---|---|---|

| Material Waste | High (CNC machining cuts away material) | Low (additive process uses only required material) |

| Tooling Costs | Expensive (molds and dies required) | None (direct printing from digital files) |

| Production Time | Weeks to months | Days to weeks |

3. Superior Mechanical Properties

- Platinum alloys offer outstanding strength, corrosion resistance, and biocompatibility.

- Ideal for critical applications such as medical implants and aerospace parts.

4. Faster Prototyping and Production

- Businesses can rapidly iterate designs without long lead times.

- On-demand manufacturing reduces inventory costs and waste.

5. Sustainable & Eco-Friendly Manufacturing

- Lower carbon footprint compared to traditional metalworking methods.

- Reduced material waste and energy consumption promote sustainable production.

Industries benefiting from platinum alloy 3D printing include:

- Luxury jewelry (custom, high-value designs)

- Medical devices (biocompatible implants)

- Aerospace components (lightweight, heat-resistant parts)

- Electronics (high-performance conductive parts)

By leveraging platinum alloy 3D printing, businesses can gain a competitive edge in innovation, cost reduction, and sustainability.

6. Why Choose Metal3DP for Platinum Alloy 3D Printing?

Metal3DP stands out as a trusted global supplier of high-end metal additive manufacturing solutions. Here’s why businesses prefer Metal3DP for platinum alloy 3D printing:

1. Industry-Leading Printing Technology

Metal3DP utilizes Selective Electron Beam Melting (SEBM) and Laser Powder Bed Fusion (LPBF), ensuring:

- High precision and fine details for intricate designs.

- Excellent mechanical properties for industrial applications.

2. High-Performance Platinum Alloy Powders

- Produced using advanced gas atomization & PREP technology.

- High sphericity and flowability for optimal 3D printing results.

3. Comprehensive B2B Solutions

| Feature | Benefit for Businesses |

|---|---|

| Custom Prototyping | Enables businesses to test designs before full-scale production |

| Bulk Manufacturing | Cost-effective solutions for large orders |

| Global Shipping | Quick and reliable delivery worldwide |

| Post-Processing Services | Offers polishing, heat treatment, and finishing |

4. Extensive Industry Expertise

Metal3DP specializes in high-end applications, including:

- Luxury goods & jewelry

- Medical implants & surgical tools

- Aerospace & defense components

- High-performance industrial parts

5. Certified Quality Assurance

- ISO 9001 certified for quality management.

- Stringent quality control ensures reliable production standards.

With state-of-the-art equipment, high-quality materials, and world-class expertise, Metal3DP is the preferred partner for platinum alloy 3D printing.

7. How to Order Wholesale Platinum Alloy 3D Printing Services

Ordering wholesale platinum alloy 3D printing services requires careful planning to ensure quality, cost-effectiveness, and timely delivery. Below is a step-by-step guide to help businesses efficiently source platinum 3D printed parts.

Step 1: Define Your Requirements

Before placing an order, businesses should clarify:

- Product specifications (design complexity, dimensions, tolerances).

- Material selection (specific platinum alloy composition).

- Quantity needed (prototyping vs. large-scale production).

- Post-processing requirements (polishing, heat treatment, coating).

Step 2: Request a Quote from Metal3DP

Metal3DP offers customized quotes based on:

- Material costs (high-purity platinum alloy).

- Printing technology used (SEBM or LPBF).

- Production time and shipping (lead times and bulk discounts).

How to Request a Quote

- Visit Metal3DP’s website and navigate to the Request a Quote section.

- Upload 3D CAD files (formats like STL, STEP).

- Provide material preferences and quantity requirements.

- Specify any post-processing needs (e.g., polishing, surface finishing).

- Receive a detailed pricing breakdown within 24-48 hours.

Step 3: Prototype Development (Optional)

For new product development, businesses can:

- Order a prototype before full-scale production.

- Test mechanical properties and design accuracy.

- Make necessary adjustments before final printing.

Step 4: Bulk Production & Quality Assurance

Once the prototype is approved:

- Full-scale manufacturing begins using Metal3DP’s precision 3D printers.

- Rigorous quality control ensures dimensional accuracy and surface finish.

- ISO-certified inspection guarantees consistent product quality.

Step 5: Shipping & Logistics

Metal3DP provides:

- Worldwide shipping with secure packaging.

- Fast turnaround times for urgent orders.

- Customs documentation for international businesses.

Step 6: After-Sales Support & Reordering

- Technical support for troubleshooting and modifications.

- Reordering options with bulk discounts.

- Ongoing consultation for future projects.

By following this structured process, businesses can seamlessly order premium platinum alloy 3D printing services while optimizing costs and lead times.

8. FAQs: Common Questions About 3D-Printed Platinum Alloys

1. What industries benefit most from platinum alloy 3D printing?

Platinum alloy 3D printing is widely used in:

- Luxury jewelry (custom, intricate designs).

- Medical implants (biocompatible, corrosion-resistant materials).

- Aerospace components (heat-resistant, lightweight parts).

- Electronics (high-performance conductive applications).

2. What is the purity level of Metal3DP’s platinum alloy powders?

Metal3DP utilizes high-purity platinum alloys processed through advanced gas atomization and PREP technologies, ensuring:

- High sphericity for superior flowability.

- Minimal impurities for enhanced mechanical properties.

3. How does 3D-printed platinum compare to traditionally manufactured platinum parts?

| Feature | Traditional Manufacturing | 3D Printing |

|---|---|---|

| Complexity | Limited by machining capabilities | Can create intricate, highly detailed designs |

| Material Waste | High (CNC machining removes excess material) | Minimal (additive process uses only required material) |

| Production Time | Weeks to months | Days to weeks |

| Cost Efficiency | Expensive due to labor and waste | More cost-effective in the long run |

4. What post-processing options are available for platinum 3D-printed parts?

Metal3DP provides:

- Polishing for a smooth, high-end finish (ideal for jewelry).

- Heat treatment to enhance mechanical strength.

- Surface coatings for added durability.

5. What is the minimum order quantity for wholesale 3D printing?

Metal3DP offers flexible order quantities, with options for:

- Single prototypes for testing.

- Small-batch production for niche applications.

- Bulk orders for large-scale manufacturing.

6. How long does it take to complete a wholesale order?

Turnaround time depends on:

- Design complexity.

- Order volume.

- Post-processing requirements.

Typically, small to medium orders take 2-4 weeks, while large-scale production may take 6-8 weeks.

7. Can Metal3DP ship internationally?

Yes, Metal3DP offers global shipping, ensuring secure and timely delivery for international clients.

Businesses can contact Metal3DP for customized shipping solutions tailored to their needs.

9. Conclusion & Call to Action

Why Choose Metal3DP for Your Platinum Alloy 3D Printing Needs?

Metal3DP is a trusted global supplier of high-end metal additive manufacturing solutions, offering:

✅ Industry-leading 3D printing technology (SEBM & LPBF)

✅ High-purity platinum alloy powders for superior results

✅ Custom prototyping and bulk manufacturing options

✅ ISO-certified quality assurance for reliable production

✅ Fast turnaround times and worldwide shipping

Take Your Business to the Next Level with Platinum Alloy 3D Printing

Are you ready to integrate high-end 3D printing into your business?

- Contact Metal3DP today for a customized quote.

- Explore our advanced metal 3D printing solutions here.

- Transform your production process with cutting-edge additive manufacturing.

Empower your business with precision, efficiency, and innovation!

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731