The Growing Market for Precision Metal Parts for Watches in Miami

Table of Contents

1. Introduction: The Importance of Precision Metal Parts in the Watch Industry

The watch industry demands extreme precision, durability, and aesthetic appeal in every component. Whether it’s gears, casings, dials, or crowns, high-quality metal parts are essential for luxury and functional timepieces.

In Miami, a thriving hub for luxury goods and manufacturing, the demand for precision metal parts for watches is on the rise. Watchmakers and manufacturers require advanced materials such as stainless steel, titanium, and high-performance alloys to ensure longevity and precision in their timepieces.

With advancements in additive manufacturing (3D printing), the industry is shifting towards more efficient and precise production methods. Companies like Metal3DP specialize in producing high-quality metal powders and 3D-printed watch components, ensuring superior mechanical properties and flawless finishes.

2. Market Trends & Growth Potential for Watch Components in Miami

Miami serves as a strategic location for luxury watch brands, independent watchmakers, and high-end retailers. Several key trends are shaping the demand for precision metal parts in the industry:

Key Market Trends

| Trend | Impact on the Watch Industry |

|---|---|

| Luxury Watch Manufacturing Growth | Increased demand for custom and high-precision components |

| Adoption of 3D Printing | Faster prototyping and production of intricate parts |

| Sustainable Manufacturing | Shift towards eco-friendly and waste-reducing production methods |

| Customization & Personalization | Demand for unique, precision-crafted watch components |

Market Growth Potential

- The global watch market is expected to grow significantly, with luxury and smartwatches leading the way.

- Miami’s luxury sector continues to expand, making the city a hotspot for watch component suppliers.

- Advanced manufacturing technologies like Selective Electron Beam Melting (SEBM) are revolutionizing how watch parts are made.

3. Key Factors to Consider When Choosing a Precision Metal Parts Supplier

Selecting the right supplier for precision watch components is essential for ensuring quality, consistency, and efficiency in manufacturing. Here are some critical factors to consider:

1. Material Quality & Selection

A reputable supplier should offer a variety of high-performance metals, including:

- Stainless Steel (316L, 904L) – Corrosion resistance and durability

- Titanium Alloys (Ti-6Al-4V, TiNi) – Lightweight and strong

- Cobalt-Chromium (CoCrMo) – High wear resistance

2. Manufacturing Capabilities

- CNC Machining – High-precision milling for small parts

- 3D Printing (Additive Manufacturing) – Efficient production of complex geometries

- Laser Cutting & Engraving – Customization and detailing

3. Quality Control & Certifications

A supplier should adhere to ISO 9001 and AS9100 standards, ensuring stringent quality measures for metal components.

4. Customization & Prototyping Services

The ability to produce custom watch components and offer rapid prototyping is crucial for luxury watchmakers.

5. Reliability & Lead Times

Fast turnaround times and reliable delivery schedules are essential, especially for high-demand industries like watchmaking.

6. Cost-Effectiveness

While high precision comes at a cost, working with a manufacturer that provides competitive pricing without compromising quality is key.

Why Metal3DP Stands Out as a Leading Supplier

Metal3DP specializes in high-precision metal powders and additive manufacturing for industries requiring exceptional accuracy. With state-of-the-art gas atomization technology, Metal3DP produces high-quality spherical metal powders used in 3D printing for watch components.

🔗 Learn more about Metal3DP’s advanced 3D printing capabilities here.

4. Top 5 Precision Metal Parts Suppliers for Watches in Miami

Miami is home to several reputable suppliers specializing in precision metal parts for watches. These companies provide advanced manufacturing solutions, including CNC machining, laser cutting, and additive manufacturing. Below are the top five suppliers in Miami:

1. Swiss Precision Machining, Inc.

- Specializes in high-precision CNC machining for watch components.

- Offers stainless steel, titanium, and exotic alloys.

- ISO-certified, ensuring strict quality control for luxury watchmakers.

2. Miami Metal Works

- Provides custom metal fabrication and laser engraving for watch dials and casings.

- Works with luxury watch brands to create unique designs.

- Fast turnaround and local delivery services.

3. Precision Watch Parts USA

- Specializes in micro-machining and precision assembly of watch components.

- Uses high-tech EDM and CNC milling for intricate designs.

- Offers prototyping and batch production services.

4. Elite 3D Metal Printing

- Focused on additive manufacturing for watch components using metal 3D printing.

- Uses Selective Laser Melting (SLM) and Electron Beam Melting (EBM) for precise metal parts.

- Works with high-performance alloys, including Ti-6Al-4V and CoCrMo.

5. Metal3DP – Industry Leader in Metal Additive Manufacturing

- Specializes in high-quality metal powders and 3D printing for precision watch parts.

- Uses advanced Selective Electron Beam Melting (SEBM) technology for superior precision and durability.

- Provides customizable solutions for luxury watch brands and independent watchmakers.

If you are looking for a trusted supplier of high-performance metal powders and 3D-printed components, Metal3DP is your ideal partner. Learn more about Metal3DP’s products and services here.

5. Why More Watch Manufacturers Are Choosing 3D Printing for Precision Parts

The rise of 3D printing in the watch industry has transformed how precision metal parts are produced. Traditional manufacturing methods like CNC machining and casting are still widely used, but additive manufacturing provides several advantages:

Key Benefits of 3D Printing for Watch Components

| Benefit | Impact on Watch Manufacturing |

|---|---|

| High Precision & Complexity | Produces intricate designs with extreme accuracy |

| Material Efficiency | Reduces material waste compared to CNC machining |

| Customization & Prototyping | Enables rapid prototyping of custom watch parts |

| Stronger & Lightweight Parts | Advanced alloys like titanium improve durability |

| Faster Production Times | Shortens lead times for custom and bulk orders |

Applications of 3D Printing in Watch Manufacturing

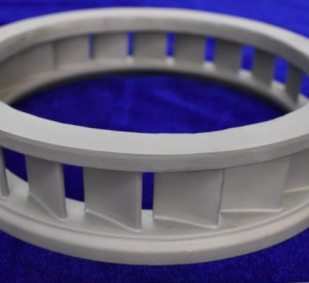

- Watch Casings & Bezels – Lightweight and durable custom designs

- Gears & Movement Parts – Precision-engineered for smooth operation

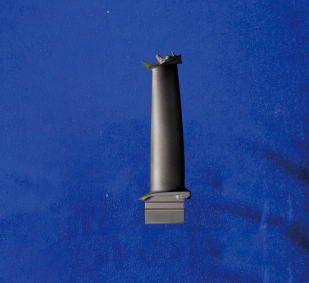

- Watch Crowns & Buckles – Customizable and aesthetically refined

Why Metal3DP’s 3D Printing Technology is Ideal for Watchmakers

Metal3DP’s advanced powder bed fusion technology ensures that metal parts have superior mechanical properties and ultra-fine surface finishes. With a wide range of metal powders, including stainless steel, titanium, and CoCrMo, we provide watchmakers with the materials they need to create high-quality timepieces.

🔗 Discover more about Metal3DP’s metal 3D printing technology here.

6. Why Choose Metal3DP as Your Precision Metal Parts Supplier

When selecting a precision metal parts supplier for watches, Metal3DP stands out due to its commitment to quality, innovation, and advanced manufacturing capabilities.

Key Reasons to Partner with Metal3DP

✅ Industry-Leading Metal Powders – High-purity, spherical powders optimized for 3D printing and traditional manufacturing.

✅ Cutting-Edge 3D Printing Technology – SEBM and SLM printing methods ensure precision and durability.

✅ Custom Manufacturing Solutions – Tailored solutions for luxury watchmakers and independent brands.

✅ Fast Lead Times & Reliable Supply Chain – Efficient production and worldwide delivery.

✅ Competitive Pricing for Bulk Orders – Cost-effective solutions for B2B buyers, distributors, and watch manufacturers.

As a leader in additive manufacturing, Metal3DP helps watchmakers stay ahead of the competition by providing high-quality, precision-engineered components.

🔗 Learn more about Metal3DP’s company and expertise here.

7. How to Order Precision Metal Parts for Watches in Miami

Ordering high-quality precision metal parts for watches from Metal3DP is a streamlined process designed to meet the needs of watch manufacturers, distributors, and wholesale buyers. Whether you need customized components or bulk orders, Metal3DP offers flexible solutions tailored to your business.

Step-by-Step Ordering Process

| Step | Description |

|---|---|

| Step 1: Define Your Requirements | Specify the type of watch components you need, including material selection (stainless steel, titanium, CoCrMo, etc.) and production method (CNC machining, 3D printing). |

| Step 2: Get a Quote | Contact Metal3DP with your specifications to receive a customized quotation. Bulk orders receive special pricing. |

| Step 3: Prototype Development (Optional) | If required, request a sample prototype to verify dimensions, material quality, and finishing before full production. |

| Step 4: Place Your Order | Confirm your order quantity, lead time, and shipping details. Metal3DP ensures on-time delivery to Miami and other locations worldwide. |

| Step 5: Production & Quality Control | Metal3DP follows strict quality control measures, ensuring all components meet ISO and industry standards. |

| Step 6: Final Delivery | Your precision metal parts are securely packaged and shipped using reliable logistics partners to ensure safe and timely arrival. |

Customization & Bulk Order Benefits

- Custom Engraving & Branding – Ideal for luxury watchmakers.

- Exclusive Bulk Discounts – Available for wholesale buyers.

- Flexible Manufacturing Techniques – CNC machining, Selective Electron Beam Melting (SEBM), and Selective Laser Melting (SLM).

🔗 Explore Metal3DP’s full range of products and ordering details here.

8. FAQs: Common Questions About Buying Precision Watch Components in Bulk

1. What materials are best for precision watch components?

The best materials depend on your watch design and durability requirements. Common options include:

- Stainless Steel (316L, 904L) – Corrosion-resistant and durable.

- Titanium Alloys (Ti-6Al-4V, TiNi) – Lightweight and strong.

- Cobalt-Chromium (CoCrMo) – High wear resistance for mechanical parts.

2. How does 3D printing compare to traditional machining for watch components?

- 3D printing allows for complex geometries, lightweight designs, and reduced material waste.

- Traditional CNC machining provides high precision for bulk production but can be more material-intensive.

- Hybrid manufacturing (combining both methods) is ideal for customized designs and mass production.

3. What is the typical lead time for bulk orders?

Lead times vary based on order size and material requirements:

- Standard orders: 2-4 weeks.

- Custom orders: 4-6 weeks (including prototype development).

4. Can Metal3DP supply metal powders for in-house 3D printing?

Yes! Metal3DP specializes in high-quality spherical metal powders that are optimized for laser and electron beam powder bed fusion (PBF) printing.

🔗 Learn more about Metal3DP’s advanced metal powders here.

5. Do you provide international shipping to Miami?

Yes, Metal3DP offers global shipping, ensuring reliable and timely delivery to Miami and other key watch manufacturing hubs.

9. Conclusion & Call to Action

Precision metal parts are the foundation of high-quality timepieces, and choosing the right supplier is key to maintaining excellence in watch manufacturing. Miami’s luxury watch industry continues to grow, making it essential for brands to source top-tier components from a trusted manufacturer like Metal3DP.

Why Choose Metal3DP for Your Watch Components?

✅ Industry-Leading Metal Powders & Additive Manufacturing

✅ State-of-the-Art 3D Printing Technology

✅ Customizable Watch Components for Luxury & Mechanical Timepieces

✅ Strict Quality Control with ISO Standards

✅ Reliable Bulk Ordering & International Shipping

If you are looking for precision-crafted metal parts for watches, Metal3DP is your trusted partner.

📞 Contact Metal3DP today to discuss your wholesale or custom order needs and take your watch manufacturing to the next level.

Visit Metal3DP’s official website here to get started!

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731