Metal Powder

Product Category

Maraging Steel C300 Powder

In the ever-evolving world of additive manufacturing, the quest for high-performance materials has led to the development of specialized alloys, each engineered to cater to specific industrial demands. Among these, Maraging Steel C300 Powder has emerged as a powerhouse, renowned for its exceptional strength, toughness, and resistance to corrosion.

Maraging Steel MS1 Powder

Maraging Steel MS1 Powder is a maraging steel alloy powder designed for additive manufacturing techniques like laser powder bed fusion (LPBF) and directed energy deposition (DED). As an advanced engineering material, MS1 offers distinct benefits over conventional maraging grades for powder-based AM processes. This article provides a comprehensive overview of maraging steel MS1 including its composition, key characteristics, processing methods, applications, pros/cons, and supply details.

Molybdenum Mo Powder

Molybdenum Mo Powder is an important material with wide-ranging industrial and engineering applications. This definitive guide provides detailed technical information on molybdenum powder types, composition, properties, manufacturing, pricing, suppliers, and comparisons to alternatives.

Overview of Molybdenum Mo Powder

Molybdenum is a silvery-white transition metal with the chemical symbol Mo and atomic number 42. In its elemental form, molybdenum has one of the highest melting points among pure elements at 2,623°C. Some key attributes of molybdenum powder include:

Nickel Alloy 52 Powder

Nickel Alloy 52 powder, also known as Nicrofer 5220h or 2.4631 powder, is a nickel-chromium alloy powder used for additive manufacturing and metal 3D printing applications. This alloy stands out due to its high strength properties coupled with outstanding corrosion and oxidation resistance at elevated temperatures.

Nickel Alloy 601 Powder

Before we delve into the details, let’s start with a brief overview of Nickel Alloy 601 Powder. This alloy, also known as Inconel 601, is a nickel-chromium alloy developed by Special Metals Corporation (now part of Huntington Alloys Corporation).

Nickel Alloy 718 Powder

Nickel Alloy 718 powder, also known as Inconel 718 powder, is a high-strength, corrosion-resistant nickel-chromium alloy powder.

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| Inconel 718 | 0-20μm | 1KG | 60.9 | 53-105μm | 1KG | 59 |

| 10KG | 39.8 | 10KG | 38 | |||

| 100KG | 34.5 | 100KG | 33 |

Nickel Alloy C276 Powder

Nickel Alloy C276 powder, also known as Hastelloy C276 powder, is a nickel-molybdenum-chromium alloy powder with high corrosion resistance. It has excellent resistance to a wide range of corrosive environments, especially oxidation and chloride-ion stress corrosion cracking.

Nickel Alloy HX Powder

Nickel Alloy HX powder can be used to fabricate complex net shape components using powder bed fusion additive manufacturing processes like selective laser melting (SLM) and electron beam melting (EBM). Its properties make it suitable for parts requiring high strength, heat resistance, and corrosion resistance across a range of industries like aerospace, oil & gas, automotive, and general industrial.

The alloy system allows tailoring of properties through heat treatment. Solution annealing followed by aging enables optimizing strength, ductility and crack resistance as per application requirements.

Nickel Alloy K500 Powder

Nickel Alloy K500 powder, also known as Monel K500 powder, is a nickel-copper alloy with excellent corrosion resistance and high strength. This advanced material is valued for durability across a wide range of demanding applications.

Nickel Alloy K500 stands out for its combination of high strength and exceptional resistance to many corrosive environments. Parts made from K500 powder maintain durability, dimensional stability and integrity despite exposure to sea water, salts, acids, alkalis,sour gas and crude oil.

This versatility makes the alloy suitable for oil & gas components, marine hardware, valves, fasteners, pump and impeller parts exposed to erosion, oxidation or corrosion. The fine grain structure and work hardening ability of K500 allows it to be formed into complex shapes.

Nickel Alloy X750 Powder

Nickel Alloy X750 is a precipitation-hardenable nickel-chromium alloy that offers excellent resistance to corrosion and oxidation. It is noted for retaining strength, toughness and ductility after age hardening and has remarkable high temperature strength.

X750 has good formability in the annealed condition and can be easily fabricated using standard shop forming practices. It can be readily forged or otherwise hot worked. Cold forming presents no particular problems. It also has excellent weldability.

Here is an overview of Nickel Alloy X750 powder properties and applications:

Nickel Silver Powder

Nickel silver powder refers to a special type of metal powder made from a copper alloy that contains nickel and often zinc. It gets its name from its silvery appearance, which resembles sterling silver. However, it contains no elemental silver. Nickel silver powder has become an important material across several industries due to its properties and applications.

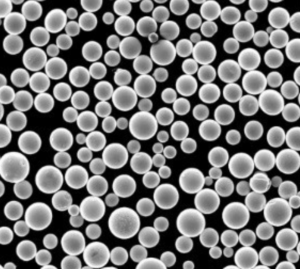

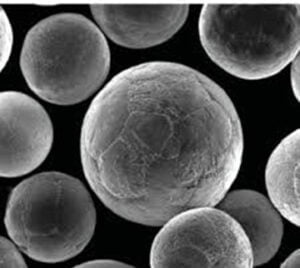

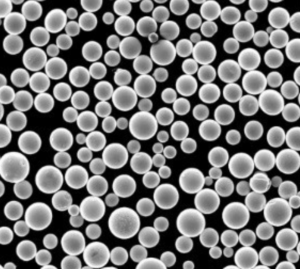

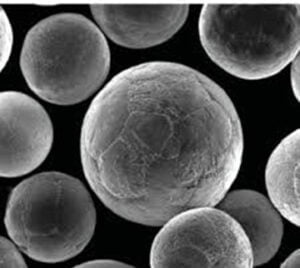

Spherical Stainless Steel Powder 15-5PH

Spherical Stainless Steel Powder 15-5PH belongs to the prestigious family of precipitation-hardening (PH) stainless steels. As the name suggests, the powder boasts a spherical shape, crucial for smooth flow and exceptional performance in additive manufacturing processes like laser beam melting (LBM) and electron beam melting (EBM).

Stainless Steel 13-8Mo Powder

Stainless steel 13-8Mo powder is a martensitic precipitation hardening stainless steel that contains approximately 13% chromium, 8% nickel, 2% molybdenum, and trace amounts of other alloying elements such as aluminum and titanium. It is known for having high strength and hardness coupled with excellent corrosion resistance.

13-8Mo powder offers a unique combination of properties and is widely used across industries like aerospace, oil and gas, chemical processing, pumps and valves, etc. Some of its key characteristics that make it suitable for these demanding applications include:

Stainless Steel 15-5PH Powder

Stainless steel 15-5PH powder is a martensitic precipitation hardening stainless steel that offers high strength, good corrosion resistance, and excellent mechanical properties. It is widely used in applications that require high hardness, strength, and corrosion resistance including aerospace, automotive, oil and gas, marine, medical, food processing and tooling industries.

Some key properties and characteristics of 15-5PH stainless steel powder include:

- High strength and hardness – Achieves high tensile strength up to 200 ksi after heat treatment

- Excellent corrosion resistance – More resistant than conventional martensitic grades

Stainless Steel 316L Powder for Metal 3D Printing

Stainless steel 316L powder is a type of stainless steel powder that contains molybdenum and has low carbon content. It is an austenitic chromium-nickel stainless steel that exhibits high strength and excellent corrosion resistance properties. 316L powder is widely used for 3D printing or additive manufacturing applications across industries such as aerospace, medical, automotive, and general manufacturing.

Stainless Steel 330 Powder

Stainless steel 330 powder is a highly alloyed austenitic stainless steel that offers excellent high temperature strength and corrosion resistance. It has good ductility and toughness even at extreme temperatures up to 1150°C. The key features of stainless steel 330 powder include:

Stainless Steel 330 Powder Key Features:

- Excellent high temperature strength up to 1150°C

- Outstanding corrosion resistance

Maraging Steel C300 Powder

In the ever-evolving world of additive manufacturing, the quest for high-performance materials has led to the development of specialized alloys, each engineered to cater to specific industrial demands. Among these, Maraging Steel C300 Powder has emerged as a powerhouse, renowned for its exceptional strength, toughness, and resistance to corrosion.

Maraging Steel MS1 Powder

Maraging Steel MS1 Powder is a maraging steel alloy powder designed for additive manufacturing techniques like laser powder bed fusion (LPBF) and directed energy deposition (DED). As an advanced engineering material, MS1 offers distinct benefits over conventional maraging grades for powder-based AM processes. This article provides a comprehensive overview of maraging steel MS1 including its composition, key characteristics, processing methods, applications, pros/cons, and supply details.

Molybdenum Mo Powder

Molybdenum Mo Powder is an important material with wide-ranging industrial and engineering applications. This definitive guide provides detailed technical information on molybdenum powder types, composition, properties, manufacturing, pricing, suppliers, and comparisons to alternatives.

Overview of Molybdenum Mo Powder

Molybdenum is a silvery-white transition metal with the chemical symbol Mo and atomic number 42. In its elemental form, molybdenum has one of the highest melting points among pure elements at 2,623°C. Some key attributes of molybdenum powder include:

Nickel Alloy 52 Powder

Nickel Alloy 52 powder, also known as Nicrofer 5220h or 2.4631 powder, is a nickel-chromium alloy powder used for additive manufacturing and metal 3D printing applications. This alloy stands out due to its high strength properties coupled with outstanding corrosion and oxidation resistance at elevated temperatures.

Nickel Alloy 601 Powder

Before we delve into the details, let’s start with a brief overview of Nickel Alloy 601 Powder. This alloy, also known as Inconel 601, is a nickel-chromium alloy developed by Special Metals Corporation (now part of Huntington Alloys Corporation).

Nickel Alloy 718 Powder

Nickel Alloy 718 powder, also known as Inconel 718 powder, is a high-strength, corrosion-resistant nickel-chromium alloy powder.

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| Inconel 718 | 0-20μm | 1KG | 60.9 | 53-105μm | 1KG | 59 |

| 10KG | 39.8 | 10KG | 38 | |||

| 100KG | 34.5 | 100KG | 33 |

Nickel Alloy C276 Powder

Nickel Alloy C276 powder, also known as Hastelloy C276 powder, is a nickel-molybdenum-chromium alloy powder with high corrosion resistance. It has excellent resistance to a wide range of corrosive environments, especially oxidation and chloride-ion stress corrosion cracking.

Nickel Alloy HX Powder

Nickel Alloy HX powder can be used to fabricate complex net shape components using powder bed fusion additive manufacturing processes like selective laser melting (SLM) and electron beam melting (EBM). Its properties make it suitable for parts requiring high strength, heat resistance, and corrosion resistance across a range of industries like aerospace, oil & gas, automotive, and general industrial.

The alloy system allows tailoring of properties through heat treatment. Solution annealing followed by aging enables optimizing strength, ductility and crack resistance as per application requirements.

Nickel Alloy K500 Powder

Nickel Alloy K500 powder, also known as Monel K500 powder, is a nickel-copper alloy with excellent corrosion resistance and high strength. This advanced material is valued for durability across a wide range of demanding applications.

Nickel Alloy K500 stands out for its combination of high strength and exceptional resistance to many corrosive environments. Parts made from K500 powder maintain durability, dimensional stability and integrity despite exposure to sea water, salts, acids, alkalis,sour gas and crude oil.

This versatility makes the alloy suitable for oil & gas components, marine hardware, valves, fasteners, pump and impeller parts exposed to erosion, oxidation or corrosion. The fine grain structure and work hardening ability of K500 allows it to be formed into complex shapes.

Nickel Alloy X750 Powder

Nickel Alloy X750 is a precipitation-hardenable nickel-chromium alloy that offers excellent resistance to corrosion and oxidation. It is noted for retaining strength, toughness and ductility after age hardening and has remarkable high temperature strength.

X750 has good formability in the annealed condition and can be easily fabricated using standard shop forming practices. It can be readily forged or otherwise hot worked. Cold forming presents no particular problems. It also has excellent weldability.

Here is an overview of Nickel Alloy X750 powder properties and applications:

Nickel Silver Powder

Nickel silver powder refers to a special type of metal powder made from a copper alloy that contains nickel and often zinc. It gets its name from its silvery appearance, which resembles sterling silver. However, it contains no elemental silver. Nickel silver powder has become an important material across several industries due to its properties and applications.

Spherical Stainless Steel Powder 15-5PH

Spherical Stainless Steel Powder 15-5PH belongs to the prestigious family of precipitation-hardening (PH) stainless steels. As the name suggests, the powder boasts a spherical shape, crucial for smooth flow and exceptional performance in additive manufacturing processes like laser beam melting (LBM) and electron beam melting (EBM).

Stainless Steel 13-8Mo Powder

Stainless steel 13-8Mo powder is a martensitic precipitation hardening stainless steel that contains approximately 13% chromium, 8% nickel, 2% molybdenum, and trace amounts of other alloying elements such as aluminum and titanium. It is known for having high strength and hardness coupled with excellent corrosion resistance.

13-8Mo powder offers a unique combination of properties and is widely used across industries like aerospace, oil and gas, chemical processing, pumps and valves, etc. Some of its key characteristics that make it suitable for these demanding applications include:

Stainless Steel 15-5PH Powder

Stainless steel 15-5PH powder is a martensitic precipitation hardening stainless steel that offers high strength, good corrosion resistance, and excellent mechanical properties. It is widely used in applications that require high hardness, strength, and corrosion resistance including aerospace, automotive, oil and gas, marine, medical, food processing and tooling industries.

Some key properties and characteristics of 15-5PH stainless steel powder include:

- High strength and hardness – Achieves high tensile strength up to 200 ksi after heat treatment

- Excellent corrosion resistance – More resistant than conventional martensitic grades

Stainless Steel 316L Powder for Metal 3D Printing

Stainless steel 316L powder is a type of stainless steel powder that contains molybdenum and has low carbon content. It is an austenitic chromium-nickel stainless steel that exhibits high strength and excellent corrosion resistance properties. 316L powder is widely used for 3D printing or additive manufacturing applications across industries such as aerospace, medical, automotive, and general manufacturing.

Stainless Steel 330 Powder

Stainless steel 330 powder is a highly alloyed austenitic stainless steel that offers excellent high temperature strength and corrosion resistance. It has good ductility and toughness even at extreme temperatures up to 1150°C. The key features of stainless steel 330 powder include:

Stainless Steel 330 Powder Key Features:

- Excellent high temperature strength up to 1150°C

- Outstanding corrosion resistance

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731