Product

Product Category

Inconel 740 Powder

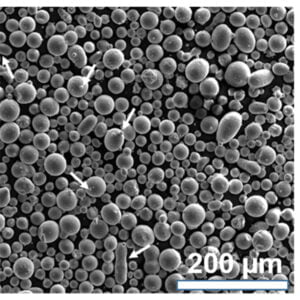

Inconel 740 is a nickel-based alloy powder used primarily in powder metallurgy applications. It has excellent high temperature strength, outstanding corrosion resistance, and good oxidation resistance.

Some key properties and characteristics of Inconel 740 powder include:

Inconel 907 Powder

Inconel 907 powder is a nickel-based superalloy designed for high-temperature applications and extreme environments. This advanced material is known for its exceptional strength, corrosion resistance, and oxidation resistance at elevated temperatures, making it suitable for various industries, including aerospace, chemical processing, and energy production.

Inconel X750 Powder

Inconel X750 Powder is a nickel-chromium alloy powder used primarily in high-temperature applications requiring corrosion and oxidation resistance. It has excellent strength, toughness, and fatigue resistance up to 1300°F (704°C). Key features include:

- High temperature strength and corrosion resistance

- Excellent oxidation resistance up to 1800°F (982°C)

K465 Alloy Powder

K465 alloy powder is a nickel-based superalloy that offers high strength and corrosion resistance at elevated temperatures. It is widely used in aerospace, power generation, and chemical processing industries.

M2 Powder

M2 is a high-speed steel powder characterized by its high hardness and wear resistance along with good toughness and compressive strength. It is widely used in metal additive manufacturing to produce durable tooling for cutting, forming and stamping applications.

Maraging Steel 250 Powder

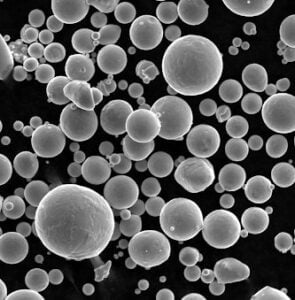

Maraging steel 250 powder is a precipitation-hardenable steel powder that can be used for 3D printing or additive manufacturing applications. It has excellent strength and toughness combined with good weldability and ductility.

Some key properties and characteristics of maraging steel 250 powder include:

Composition: Iron-nickel alloy with 18-19% nickel, 7-9% cobalt, 3-5% molybdenum, 0.6-1.2% titanium and less than 0.1% carbon

Density: 8.1 g/cc

Melting point: 1480-1525°C

Ultimate tensile strength: >250 ksi (>1723 MPa) in aged condition

Maraging Steel 300 Powder

Maraging steel 300 powder is an alloy steel powder typically containing approximately 18% nickel, 8.5% cobalt, 3% molybdenum, 0.6% titanium and trace amounts of aluminum. It is characterized by high strength and toughness along with good weldability.

Maraging Steel 350 Powder

Maraging steel 350 powder is a precipitation-hardenable, martensitic steel powder designed for additive manufacturing, especially for applications requiring high hardness and strength alongside good ductility. It is known for its ultra-high strength from a unique blend of molybdenum, cobalt, nickel, aluminum, titanium and other alloying elements.

Maraging Steel C250 Powder

Maraging Steel C250 Powder is an 18% nickel, cobalt strengthened steel (C250) alloy noted for its ultra-high strength and toughness without losing malleability. Maraging steels provide strengths 2 to 5 times higher than standard austenitic or martensitic grades via precipitation strengthening by intermetallic compounds.

Maraging Steel C300 Powder

In the ever-evolving world of additive manufacturing, the quest for high-performance materials has led to the development of specialized alloys, each engineered to cater to specific industrial demands. Among these, Maraging Steel C300 Powder has emerged as a powerhouse, renowned for its exceptional strength, toughness, and resistance to corrosion.

Maraging Steel MS1 Powder

Maraging Steel MS1 Powder is a maraging steel alloy powder designed for additive manufacturing techniques like laser powder bed fusion (LPBF) and directed energy deposition (DED). As an advanced engineering material, MS1 offers distinct benefits over conventional maraging grades for powder-based AM processes. This article provides a comprehensive overview of maraging steel MS1 including its composition, key characteristics, processing methods, applications, pros/cons, and supply details.

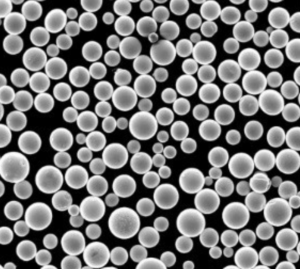

Molybdenum Mo Powder

Molybdenum Mo Powder is an important material with wide-ranging industrial and engineering applications. This definitive guide provides detailed technical information on molybdenum powder types, composition, properties, manufacturing, pricing, suppliers, and comparisons to alternatives.

Overview of Molybdenum Mo Powder

Molybdenum is a silvery-white transition metal with the chemical symbol Mo and atomic number 42. In its elemental form, molybdenum has one of the highest melting points among pure elements at 2,623°C. Some key attributes of molybdenum powder include:

Molybdenum Powder

Molybdenum powder is a refractory metal powder made from molybdenum metal. It offers high temperature strength, corrosion resistance, thermal conductivity, and lubricity.

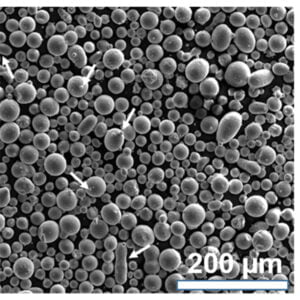

Nickel Alloy 52 Powder

Nickel Alloy 52 powder, also known as Nicrofer 5220h or 2.4631 powder, is a nickel-chromium alloy powder used for additive manufacturing and metal 3D printing applications. This alloy stands out due to its high strength properties coupled with outstanding corrosion and oxidation resistance at elevated temperatures.

Nickel Alloy 601 Powder

Before we delve into the details, let’s start with a brief overview of Nickel Alloy 601 Powder. This alloy, also known as Inconel 601, is a nickel-chromium alloy developed by Special Metals Corporation (now part of Huntington Alloys Corporation).

Nickel Alloy 718 Powder

Nickel Alloy 718 powder, also known as Inconel 718 powder, is a high-strength, corrosion-resistant nickel-chromium alloy powder.

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| Inconel 718 | 0-20μm | 1KG | 60.9 | 53-105μm | 1KG | 59 |

| 10KG | 39.8 | 10KG | 38 | |||

| 100KG | 34.5 | 100KG | 33 |

Inconel 740 Powder

Inconel 740 is a nickel-based alloy powder used primarily in powder metallurgy applications. It has excellent high temperature strength, outstanding corrosion resistance, and good oxidation resistance.

Some key properties and characteristics of Inconel 740 powder include:

Inconel 907 Powder

Inconel 907 powder is a nickel-based superalloy designed for high-temperature applications and extreme environments. This advanced material is known for its exceptional strength, corrosion resistance, and oxidation resistance at elevated temperatures, making it suitable for various industries, including aerospace, chemical processing, and energy production.

Inconel X750 Powder

Inconel X750 Powder is a nickel-chromium alloy powder used primarily in high-temperature applications requiring corrosion and oxidation resistance. It has excellent strength, toughness, and fatigue resistance up to 1300°F (704°C). Key features include:

- High temperature strength and corrosion resistance

- Excellent oxidation resistance up to 1800°F (982°C)

K465 Alloy Powder

K465 alloy powder is a nickel-based superalloy that offers high strength and corrosion resistance at elevated temperatures. It is widely used in aerospace, power generation, and chemical processing industries.

M2 Powder

M2 is a high-speed steel powder characterized by its high hardness and wear resistance along with good toughness and compressive strength. It is widely used in metal additive manufacturing to produce durable tooling for cutting, forming and stamping applications.

Maraging Steel 250 Powder

Maraging steel 250 powder is a precipitation-hardenable steel powder that can be used for 3D printing or additive manufacturing applications. It has excellent strength and toughness combined with good weldability and ductility.

Some key properties and characteristics of maraging steel 250 powder include:

Composition: Iron-nickel alloy with 18-19% nickel, 7-9% cobalt, 3-5% molybdenum, 0.6-1.2% titanium and less than 0.1% carbon

Density: 8.1 g/cc

Melting point: 1480-1525°C

Ultimate tensile strength: >250 ksi (>1723 MPa) in aged condition

Maraging Steel 300 Powder

Maraging steel 300 powder is an alloy steel powder typically containing approximately 18% nickel, 8.5% cobalt, 3% molybdenum, 0.6% titanium and trace amounts of aluminum. It is characterized by high strength and toughness along with good weldability.

Maraging Steel 350 Powder

Maraging steel 350 powder is a precipitation-hardenable, martensitic steel powder designed for additive manufacturing, especially for applications requiring high hardness and strength alongside good ductility. It is known for its ultra-high strength from a unique blend of molybdenum, cobalt, nickel, aluminum, titanium and other alloying elements.

Maraging Steel C250 Powder

Maraging Steel C250 Powder is an 18% nickel, cobalt strengthened steel (C250) alloy noted for its ultra-high strength and toughness without losing malleability. Maraging steels provide strengths 2 to 5 times higher than standard austenitic or martensitic grades via precipitation strengthening by intermetallic compounds.

Maraging Steel C300 Powder

In the ever-evolving world of additive manufacturing, the quest for high-performance materials has led to the development of specialized alloys, each engineered to cater to specific industrial demands. Among these, Maraging Steel C300 Powder has emerged as a powerhouse, renowned for its exceptional strength, toughness, and resistance to corrosion.

Maraging Steel MS1 Powder

Maraging Steel MS1 Powder is a maraging steel alloy powder designed for additive manufacturing techniques like laser powder bed fusion (LPBF) and directed energy deposition (DED). As an advanced engineering material, MS1 offers distinct benefits over conventional maraging grades for powder-based AM processes. This article provides a comprehensive overview of maraging steel MS1 including its composition, key characteristics, processing methods, applications, pros/cons, and supply details.

Molybdenum Mo Powder

Molybdenum Mo Powder is an important material with wide-ranging industrial and engineering applications. This definitive guide provides detailed technical information on molybdenum powder types, composition, properties, manufacturing, pricing, suppliers, and comparisons to alternatives.

Overview of Molybdenum Mo Powder

Molybdenum is a silvery-white transition metal with the chemical symbol Mo and atomic number 42. In its elemental form, molybdenum has one of the highest melting points among pure elements at 2,623°C. Some key attributes of molybdenum powder include:

Molybdenum Powder

Molybdenum powder is a refractory metal powder made from molybdenum metal. It offers high temperature strength, corrosion resistance, thermal conductivity, and lubricity.

Nickel Alloy 52 Powder

Nickel Alloy 52 powder, also known as Nicrofer 5220h or 2.4631 powder, is a nickel-chromium alloy powder used for additive manufacturing and metal 3D printing applications. This alloy stands out due to its high strength properties coupled with outstanding corrosion and oxidation resistance at elevated temperatures.

Nickel Alloy 601 Powder

Before we delve into the details, let’s start with a brief overview of Nickel Alloy 601 Powder. This alloy, also known as Inconel 601, is a nickel-chromium alloy developed by Special Metals Corporation (now part of Huntington Alloys Corporation).

Nickel Alloy 718 Powder

Nickel Alloy 718 powder, also known as Inconel 718 powder, is a high-strength, corrosion-resistant nickel-chromium alloy powder.

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| Inconel 718 | 0-20μm | 1KG | 60.9 | 53-105μm | 1KG | 59 |

| 10KG | 39.8 | 10KG | 38 | |||

| 100KG | 34.5 | 100KG | 33 |

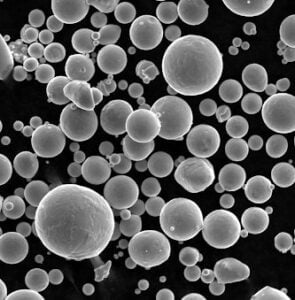

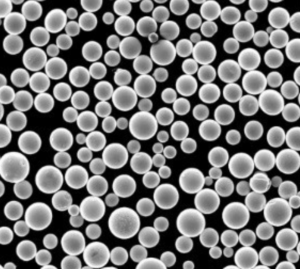

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731