317L pulver

317L-pulver är ett austenitiskt rostfritt stålpulver som innehåller 18% krom, 3% molybden och 0,08% kol. Det erbjuder en utmärkt kombination av korrosionsbeständighet, hållfasthet, svetsbarhet och kostnad.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt över 317L-pulver

317L-pulver är ett austenitiskt rostfritt stålpulver som innehåller 18% krom, 3% molybden och 0,08% kol. Det erbjuder en utmärkt kombination av korrosionsbeständighet, hållfasthet, svetsbarhet och kostnad.

Viktiga egenskaper och fördelar med 317L-pulver är bl.a:

317L Pulvers egenskaper och kännetecken

| Fastigheter | Detaljer |

|---|---|

| Sammansättning | Legering Fe-18Cr-3Mo-0,08C |

| Täthet | 8,0 g/cc |

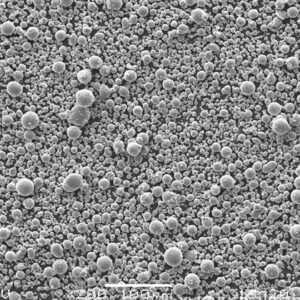

| Partikelns form | Oregelbunden, kantig |

| Storleksintervall | 10-150 mikrometer |

| Skenbar densitet | Upp till 50% av verklig densitet |

| Flytbarhet | Måttlig |

| Korrosionsbeständighet | Utmärkt i många miljöer |

| Förstärkning | Kallbearbetning och förstärkning med fast lösning |

317L-pulver används ofta inom kemisk bearbetning, marina applikationer, massa- och pappersindustrin, kärnkraftsproduktion och arkitektoniska detaljer som kräver väderbeständighet.

317L Pulversammansättning

Typisk sammansättning av 317L rostfritt stålpulver:

317L Pulversammansättning

| Element | Vikt % |

|---|---|

| Järn (Fe) | Balans |

| Krom (Cr) | 17-19% |

| Nickel (Ni) | 11-15% |

| Molybden (Mo) | 2.5-3.5% |

| Mangan (Mn) | <2% |

| Kol (C) | 0,08% max |

| Kisel (Si) | 1% max |

| Kväve (N) | 0,10% max |

| Svavel (S) | 0,03% max |

- Järn ger den ferritiska matrisen och duktiliteten

- Krom förbättrar korrosions- och oxidationsbeständigheten

- Nickel stabiliserar den austenitiska strukturen

- Molybden förbättrar ytterligare motståndskraften mot gropfrätning

- Kol, kväve och svavel kontrolleras som trampelement

Sammansättningen ger en utmärkt balans mellan korrosionsbeständighet, formbarhet, svetsbarhet och kostnad.

317L Pulver Fysikaliska egenskaper

317L Pulver Fysikaliska egenskaper

| Fastighet | Värden |

|---|---|

| Täthet | 8,0 g/cc |

| Smältpunkt | 1370-1400°C |

| Elektrisk resistivitet | 0,8 μΩ-m |

| Termisk ledningsförmåga | 16 W/mK |

| Termisk expansion | 16 x 10^-6 /K |

| Maximal driftstemperatur | 900°C |

- Hög densitet jämfört med ferritiska rostfria stål

- Bibehåller styrka och korrosionsbeständighet vid förhöjda temperaturer

- Resistiviteten är högre än för rent järn eller kolstål

- Lägre värmeledningsförmåga än kolstål

- Klarar kontinuerlig drift upp till 900°C

De fysikaliska egenskaperna gör 317L lämplig för applikationer med höga temperaturer och krav på korrosionsbeständighet.

317L pulver Mekaniska egenskaper

317L pulver Mekaniska egenskaper

| Fastighet | Värden |

|---|---|

| Draghållfasthet | 515-620 MPa |

| Sträckgräns | 205-275 MPa |

| Töjning | 40-50% |

| Hårdhet | 88-95 HRB |

| Slaghållfasthet | 100-150 J |

| Elasticitetsmodul | 190-210 GPa |

- Utmärkt kombination av styrka och duktilitet

- Kan arbetshärdas avsevärt för att öka hållfastheten

- Mycket hög seghet och slaghållfasthet

- Hållfastheten kan förbättras ytterligare genom kallbearbetning

- Hårdheten är relativt låg i glödgat tillstånd

Egenskaperna ger en utmärkt balans mellan styrka, duktilitet och seghet, vilket krävs i många korrosiva miljöer.

317L Pulver Tillämpningar

Typiska användningsområden för 317L rostfritt stålpulver är bl.a:

317L Pulver Tillämpningar

| Industri | Exempel på användningsområden |

|---|---|

| Kemisk | Tankar, ventiler, rör, pumpar |

| Petrokemisk industri | Processutrustning, slangar, ventiler |

| Marin | Propelleraxlar, fästanordningar, däcksbeslag |

| Kärnkraft | Reaktortankar, kapsling av bränsleelement |

| Arkitektonisk | Räcken, väggpaneler, tak |

Vissa specifika produktanvändningar:

- Utrustning för föroreningskontroll vid hantering av heta syror

- Kärnreaktorns inre strukturer

- Marina propelleraxlar, däcksbeslag

- Massa- och pappersindustrin Rörsystem, ventiler

- Arkitektonisk panel, takbeläggning, beklädnad

Dess utmärkta korrosionsbeständighet i kombination med god tillverkningsbarhet gör att 317L används i stor utsträckning inom krävande industrier.

317L Pulver Specifikationer

Relevanta specifikationer och standarder:

317L Pulverstandarder

| Standard | Beskrivning |

|---|---|

| ASTM A276 | Standard för stång och profiler av rostfritt stål |

| ASTM A479 | Standard för rör av rostfritt stål |

| AMS 5524 | Glödgad stång, tråd och smide av rostfritt stål |

| ASME SA-276 | Specifikation för stång och profiler av rostfritt stål |

| AISI 630 | Standard för 17Cr-4Ni utskiljningshärdande rostfritt stål |

Dessa standarder definierar:

- Gränsvärden för kemisk sammansättning för legering 317L

- Tillåtna föroreningsnivåer som S, P

- Nödvändiga mekaniska egenskaper

- Godkända produktionsmetoder

- Protokoll för test av efterlevnad

- Korrekt förpackning, märkning och dokumentation

Genom att uppfylla certifieringskraven säkerställs att pulvret lämpar sig för de avsedda applikationerna.

317L Pulver Partikelstorlekar

317L Pulver Partikelstorleksfördelning

| Partikelstorlek | Egenskaper |

|---|---|

| 10-45 mikrometer | Ultrafin kvalitet för hög densitet och ytfinish |

| 45-150 mikrometer | Grov kvalitet ger god flytbarhet |

| 15-150 mikrometer | Standardkvalitet för pressning och sintring |

- Finare partiklar möjliggör större förtätning under sintringen

- Grovare pulver flyter bättre och fyller formhålorna jämnt

- Storleksintervallet skräddarsys utifrån de egenskaper som krävs för den slutliga detaljen

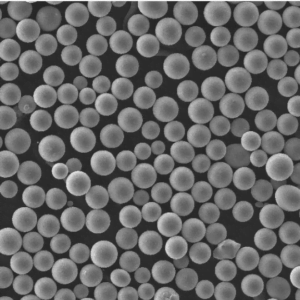

- Både gas- och vattenatomiserade pulver finns tillgängliga

Genom att kontrollera partikelstorleksfördelningen kan man optimera bearbetningsbeteendet och den slutliga detaljens prestanda.

317L Pulver skenbar densitet

317L Pulver skenbar densitet

| Skenbar densitet | Detaljer |

|---|---|

| Upp till 50% av verklig densitet | För oregelbunden pulvermorfologi |

| 4,5-5,5 g/cc typiskt | Förbättras med högre packningstäthet |

- Högre skenbar densitet förbättrar pulverflöde och kompressibilitet

- Oregelbunden morfologi begränsar maximal packningstäthet

- Värden upp till 60% är möjliga med sfäriskt pulver

- Hög skenbar densitet förbättrar pressens fyllningseffektivitet

Högre skenbar densitet leder till bättre tillverkningsproduktivitet och detaljkvalitet.

317L Pulver Produktionsmetod

317L Pulverproduktion

| Metod | Detaljer |

|---|---|

| Atomisering av gas | Inert gas under högt tryck delar upp smält metallström i fina droppar |

| Atomisering av vatten | Högtrycksvattenstråle bryter ner metall till fina partiklar |

| Induktionssmältning i vakuum | Insatsmaterial med hög renhet som smälts under vakuum |

| Flera omsmältningar | Förbättrar kemisk homogenisering |

| Siktning | Klassificerar pulver i olika partikelstorleksintervall |

- Gasatomisering ger ren, sfärisk pulvermorfologi

- Vattenförstoftning är en billigare process med oregelbundna partiklar

- Vakuumsmältning och omsmältning minimerar gasformiga föroreningar

- Efterbearbetning möjliggör anpassning av partikelstorlekar

Automatiserad produktion och sträng kvalitetskontroll resulterar i ett jämnt pulver som lämpar sig för kritiska applikationer.

317L Pulver Prissättning

317L Pulver Prissättning

| Faktor | Påverkan på priset |

|---|---|

| Renhetsgrad | Högre renhet ökar kostnaden |

| Morfologi för pulver | Sfäriskt pulver kostar mer än oregelbundet |

| Partikelstorlek | Ultrafint pulver dyrare |

| Ordervolym | Större kvantiteter har lägre pris per enhet |

| Ytterligare tjänster | Anpassning medför extra kostnader |

Indikativ prissättning

- Oregelbundet 317L-pulver: $6-10 per kg

- Sfäriskt 317L-pulver: $10-15 per kg

- Prissättning av stora volymer kan vara 30-50% lägre

Priset beror på renhet, partikelegenskaper, ordervolym och behov av kundanpassning.

317L pulver leverantörer

317L pulver leverantörer

| Företag | Plats |

|---|---|

| Höganäs | Sverige |

| Sandvik | Tyskland |

| CNPC Pulver | Kina |

| Carpenter Pulverprodukter | USA |

| Erasteel | Frankrike |

| Daido stål | Japan |

Viktiga faktorer för val av leverantör:

- Pulverkvaliteter erbjuds

- Produktionskapacitet

- Partikelmorfologi och storleksintervall

- Batchanalysrapporter

- Prissättning och minsta orderkvantitet

- Tjänster för kundanpassning

- Leveranstider och tillförlitlighet

317L Pulverhantering och förvaring

317L Pulverhantering

| Rekommendation | Anledning |

|---|---|

| Använd personlig skyddsutrustning och ventilation | Undvik exponering för fina metallpartiklar |

| Säkerställ korrekt jordning | Förhindra statisk urladdning vid hantering |

| Undvik antändningskällor | Pulver kan antändas i syrehaltig atmosfär |

| Använd verktyg som inte slår gnistor | Förhindra risken för antändning |

| Följ säkerhetsprotokoll | Minskar risken för brännskador, inandning och förtäring |

| Förvaras i stabila behållare | Förhindrar kontaminering eller oxidation |

Eftersom 317L-pulver är brandfarligt bör antändnings- och explosionsrisker kontrolleras under hantering och lagring. Annars är det relativt säkert med lämpliga försiktighetsåtgärder.

Inspektion och provning av 317L-pulver

317L Pulverprovning

| Test | Detaljer |

|---|---|

| Kemisk analys | ICP och XRF verifierar sammansättningen |

| Fördelning av partikelstorlek | Laserdiffraktion bestämmer storleksfördelningen |

| Skenbar densitet | Hall-flödesmätartest enligt ASTM B212-standarden |

| Morfologi för pulver | SEM-bildtagning visar partikelns form |

| Analys av flödeshastighet | Gravitationsflöde genom specificerat munstycke |

| Förlust vid tändning | Fastställer kvarvarande fukthalt |

Strikta tester säkerställer att pulvret uppfyller kraven på kemisk renhet, partikelegenskaper, densitet, morfologi och flytbarhet enligt gällande specifikationer.

Fördelar och nackdelar med 317L-pulver

Fördelar med 317L-pulver

- Utmärkt korrosionsbeständighet i många miljöer

- Hållfasthet vid höga temperaturer och oxidationsbeständighet

- God duktilitet, seghet och svetsbarhet

- Mer kostnadseffektiva än austenitiska kvaliteter med hög nickelhalt

- Lätt formbar med hjälp av konventionella tekniker

- Kan arbetshärdas genom kall/varm bearbetning

Nackdelar med 317L-pulver

- Lägre kryphållfasthet vid höga temperaturer än vissa ferritiska kvaliteter

- Lägre hårdhet och slitstyrka än martensitiska kvaliteter

- Känslig för spänningskorrosionssprickor orsakade av klorid

- Kräver glödgning efter svetsning för att förhindra sensibilisering

- Begränsad kapacitet för kallbearbetning och formning

- Missfärgning av ytan över tid vid exponering utomhus

Jämförelse med 316L pulver

317L vs 316L Pulver av rostfritt stål

| Parameter | 317L | 316L |

|---|---|---|

| Täthet | 8,0 g/cc | 8,0 g/cc |

| Styrka | 515-620 MPa | 485-550 MPa |

| Korrosionsbeständighet | Utmärkt | Utestående |

| Motstånd mot gropfrätning | Mycket bra | Utmärkt |

| Kostnad | Låg | Hög |

| Användningsområden | Processindustri, marin | Kemisk, farmaceutisk |

- 317L ger högre hållfasthet till lägre kostnad

- 316L ger bättre motståndskraft mot gropfrätning

- 317L har god beständighet mot kloridspänningskorrosion

- 316L föredras för extremt korrosiva miljöer

- 317L lämpar sig för marina applikationer och kärnkraftsindustrin

Vanliga frågor om 317L-pulver

F: Vilka är de viktigaste användningsområdena för 317L rostfritt stålpulver?

A: Huvudapplikationer inkluderar kemisk bearbetning, petrokemisk, marin, kärnkraft, massa och papper och arkitektonisk. Det används för utrustning som tankar, ventiler, rör, pumpar, axlar och beklädnad.

F: Vilka försiktighetsåtgärder bör vidtas vid hantering av 317L-pulver?

S: Rekommenderade försiktighetsåtgärder omfattar ventilation, jordning, undvikande av antändningskällor, användning av gnistfria verktyg, skyddsutrustning, säker förvaring och kontroll av dammexponering.

F: Hur förbättrar molybden korrosionsbeständigheten hos 317L?

S: Molybden förbättrar motståndskraften mot grop- och spaltkorrosion i kloridmiljöer. Det stabiliserar den passiva film som skyddar ytan.

F: Vad är den största skillnaden mellan 304L och 317L rostfritt stålpulver?

A: 317L innehåller 3% molybden vilket ger den betydligt bättre korrosionsbeständighet jämfört med 304L, särskilt i marina och andra kloridmiljöer.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731