Stainless Steel 316L Powder

Table of Contents

Stainless steel 316L powder is a popular material choice for many applications due to its excellent corrosion resistance, mechanical properties, and biocompatibility. This guide provides a detailed overview of 316L powder, including its properties, production methods, applications, suppliers, and more.

Overview of Stainless Steel 316L Powder

Stainless steel 316L powder is a type of stainless steel alloy that contains molybdenum for enhanced corrosion resistance. The “L” refers to the low carbon content, which improves weldability.

Some key properties and characteristics of 316L powder include:

- Excellent corrosion resistance, especially against pitting and crevice corrosion

- High strength and good ductility

- Outstanding biocompatibility and suitable for medical implants

- Non-magnetic austenitic structure

- High oxidation and creep resistance at elevated temperatures

- Available in various particle sizes and morphologies

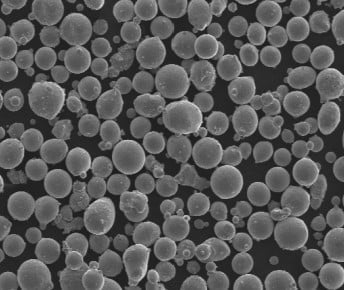

316L powder can be produced through gas atomization, water atomization, and other methods. The powder production process influences the powder characteristics like particle shape, size distribution, flowability, and more.

Here is a comparison of different 316L powder types and their typical applications:

| Powder Type | Particle Size | Morphology | Applications |

|---|---|---|---|

| Gas atomized | 15-150 μm | Spherical | Additive manufacturing, MIM |

| Water atomized | 10-300 μm | Irregular, dendritic | Metal injection molding |

| Plasma atomized | <100 μm | Spherical | Additive manufacturing |

| Electrolytic | <150 μm | Dendritic, spiky | Additive manufacturing, pressing |

| Carbonyl | <10 μm | Spherical | Powder metallurgy, pressing |

316L powder is valued for its combination of strength, corrosion resistance, and biocompatibility. Some of the major applications include:

- Additive manufacturing – Selective laser melting, direct metal laser sintering, binder jetting

- Metal injection molding – Small, complex parts like orthopedic implants

- Press and sinter – Filters, porous structures, self-lubricating bearings

- Surface coating – To improve wear and corrosion resistance

- Brazing and welding – As filler material

Here is an overview of how 316L powder is used in different manufacturing processes:

| Manufacturing Process | How 316L Powder is Used |

|---|---|

| Additive manufacturing | Powder bed is selectively melted by laser to build 3D parts |

| Metal injection molding | Powder mixed with binder, molded, then sintered |

| Press and sinter | Powder is pressed into shape and then sintered |

| Surface coating | Sprayed or fused onto surface by thermal spraying, laser cladding etc. |

| Brazing and welding | Used as filler material for joining |

The ultrafine grain structure and homogeneous consistency obtained from powders make 316L an ideal material for critical applications in aerospace, medical, chemical processing, and more.

Properties of 316L Stainless Steel Powder

| Property | Description | Impact on Usability |

|---|---|---|

| Chemical Composition | Primarily composed of iron (Fe), chromium (Cr) (16-18%), nickel (Ni) (10-12%), molybdenum (Mo) (2-3%), with minor additions of silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), nitrogen (N). Low carbon content (less than 0.03%) | The high chromium content grants excellent corrosion resistance, especially against pitting and crevice corrosion. Nickel enhances strength and ductility, while molybdenum improves resistance to localized attacks, particularly by chlorides. Low carbon minimizes the risk of carbide precipitation during welding or high-temperature processes. |

| Particle Size & Distribution | Measured in micrometers (µm), with a typical range of 15-50 µm. The distribution of particle sizes within this range is crucial. | Particle size and distribution significantly influence flowability, packing density, and the final product’s mechanical properties. Finer particles generally offer better surface finish but can be challenging to handle due to poor flowability. A well-controlled distribution with a mix of particle sizes optimizes packing and minimizes voids in the final product. |

| Apparent Density & Tap Density | Apparent density refers to the density of the powder as loosely poured. Tap density is measured after tapping the powder container to achieve a denser packing. Units are typically g/cm³. | The difference between apparent and tap density reflects powder flowability. A higher tap density relative to apparent density indicates better flow characteristics, essential for efficient powder bed creation in Additive Manufacturing processes. |

| Flowability | The ease with which powder flows under its own weight. Measured using techniques like the Hall Flowmeter or Carr Index. | Good flowability allows for uniform powder spreading and minimizes segregation (separation of different particle sizes) during handling and deposition. This translates to consistent density and properties in the final product. |

| Sphericity & Morphology | Sphericity refers to how closely a particle resembles a perfect sphere. Morphology describes the overall shape of the particles (spherical, angular, irregular). | Spherical particles typically flow better and pack more densely compared to irregular shapes. However, some applications might benefit from a specific particle morphology to achieve desired surface texture or interlocking of particles. |

| Melting Point & Range | Around 1400°C (2552°F). The melting range can vary slightly depending on the specific powder composition. | The melting point is crucial for determining the appropriate processing temperatures in techniques like sintering or Additive Manufacturing. |

| Thermal Conductivity | Approximately 16 W/mK. | Thermal conductivity influences heat transfer within the powder bed during processing. This can impact factors like cooling rates, residual stresses, and the formation of undesirable phases in the final product. |

| Sintering Behavior | The ability of the powder particles to bond together during a high-temperature heating process (sintering) to form a solid object. | Sintering behavior depends on factors like particle size distribution, powder surface chemistry, and sintering parameters. Well-controlled sintering allows for densification of the powder bed, achieving the desired mechanical properties in the final product. |

| Corrosion Resistance | Inherits excellent corrosion resistance from its bulk counterpart, 316L stainless steel. Offers resistance to a wide range of environments, including oxidizing acids, reducing acids, and salt spray. | The molybdenum content in 316L powder provides superior resistance to pitting corrosion, particularly in chloride-containing environments, compared to 304L stainless steel powder. This makes it suitable for applications demanding high corrosion resistance. |

Production Methods for 316L Powder

| Method | Description | Particle Characteristics | Advantages | Disadvantages | Applications |

|---|---|---|---|---|---|

| Gas Atomization | Molten 316L steel is injected into a high-velocity inert gas stream, breaking it into fine droplets that rapidly solidify into spherical particles. | – Spherical shape – Tight size distribution (15-45 microns) – Excellent flowability – High packing density | – Consistent quality – Good for Additive Manufacturing (AM) processes like Laser Beam Melting (LBM) and Electron Beam Melting (EBM) | – High energy consumption – Potential for oxygen and nitrogen pickup | – Aerospace components (turbine blades, heat exchangers) – Medical implants (due to biocompatibility) – High-performance automotive parts |

| Water Atomization | Similar to gas atomization, but uses a high-pressure water jet to break the molten metal. | – Irregular shape with some satellites (fused particles) – Broader size distribution (10-100 microns) – Lower flowability compared to gas atomization | – More cost-effective than gas atomization – Suitable for applications where spherical shape is less critical | – Higher oxygen content due to water interaction – May require additional post-processing for AM | – Fluidized bed reactors (catalyst carriers) – Metal Injection Molding (MIM) feedstock |

| Plasma Atomization | Employs a high-temperature, high-velocity plasma torch to melt and atomize the 316L steel feedstock. | – Highly spherical shape – Tight size distribution with finer particles possible (down to 5 microns) – Excellent flowability | – Superior quality for demanding AM applications – Can achieve finer powders for intricate features | – Highest energy consumption among the three methods – Requires specialized equipment | – High-performance turbine blades – Microfluidic components – Biomedical implants requiring high surface finish |

| Mechanical Alloying | Solid elemental or pre-alloyed powders are blended and milled together in a high-energy ball mill to achieve a uniform 316L composition. | – Irregular shape with angular facets – Wide size distribution – Lower flowability | – Highly customizable for creating unique alloy compositions not achievable with other methods | – Longer processing time compared to atomization techniques – May require additional steps to improve flowability for AM | – Specialized components requiring specific material properties – Development of new alloys for AM |

| Electrolysis | An aqueous-based process where a 316L anode dissolves into the electrolyte solution, and the metal ions are deposited as powder on the cathode. | – Spherical or dendritic shapes – Wide size distribution – Can be porous | – Highly pure powders achievable – Potential for near-net shape manufacturing | – Limited production capacity – Relatively slow process | – Biomedical implants requiring high purity – Catalyst supports – Specialized applications demanding specific powder properties |

Applications of 316L Stainless Steel Powder

| Industry | Application | Properties Leveraged | Additional Notes |

|---|---|---|---|

| Medical & Dental | * Implants (knee, hip, dental) * Surgical instruments * Prosthetics | * Biocompatible (safe for body contact) * Excellent corrosion resistance * High strength * Formability for complex designs | * 316L minimizes risk of rejection and infection. * Powder allows for creation of porous structures for bone ingrowth. * Can be sterilized for safe surgical use. |

| Food Processing | * Vessels * Tubing * Valves * Fittings * Fasteners | * Superior corrosion resistance to food acids and brines * Easy to clean and maintain * Meets hygiene and safety standards | * 316L ensures food quality and prevents contamination. * Smooth surfaces minimize bacterial harborage points. * Withstands repeated cleaning cycles. |

| Marine | * Propeller shafts * Diesel engine parts * Deck equipment | * Exceptional resistance to saltwater corrosion * High mechanical strength * Durability in harsh environments | * 316L extends lifespan of critical marine components. * Maintains structural integrity under stress and heavy loads. * Performs reliably in varying temperatures. |

| Chemical & Petrochemical | * Reaction vessels * Piping systems * Valves * Pumps | * Impervious to a wide range of chemicals * High temperature resistance * Pressure tolerance | * 316L can handle aggressive chemicals without degradation. * Withstands high processing temperatures for efficient reactions. * Suitable for high-pressure environments in refineries and plants. |

| Aerospace | * Aircraft engine components * Fluid control systems * Structural parts | * High strength-to-weight ratio * Excellent mechanical properties at elevated temperatures * Corrosion resistance in challenging environments | * 316L reduces weight for improved fuel efficiency. * Maintains performance under extreme heat and pressure. * Resists corrosion from jet fuel and other aerospace fluids. |

| Automotive | * Exhaust components * Engine parts * Trim and decorative elements | * High-temperature resistance * Formability for complex shapes * Corrosion resistance for extended lifespan | * 316L can withstand hot exhaust gases without warping. * Can be formed into intricate exhaust manifolds and pipes. * Resists corrosion from road salts and harsh weather conditions. |

| Consumer Goods | * Watches * Jewelry * Cutlery * Household appliances | * Aesthetic appeal due to polished finish * High strength and wear resistance * Corrosion resistance for easy cleaning and hygiene | * 316L offers a sleek, luxurious look for high-end goods. * Utensils and appliances maintain sharpness and durability. * Easy to maintain a clean and hygienic surface. |

| Construction | * Architectural cladding * Fasteners * Railings * Hardware | * Corrosion resistance for outdoor applications * High strength and weatherability * Aesthetic appeal for modern designs | * 316L can withstand harsh weather conditions without rusting. * Maintains structural integrity and functionality over time. * Offers a sleek, contemporary look for architectural elements. |

Specifications and Standards

316L powder composition, quality, and properties are governed by various international specifications and standards.

ASTM Standards

- ASTM A240 – Standard for chromium and chromium-nickel stainless steel plate, sheet, and strip for pressure vessels and general applications. Defines composition limits and mechanical properties for 316L alloy.

- ASTM B822 – Standard test method for particle size distribution of metal powders and related compounds by light scattering. Used to characterize powder size distribution.

- ASTM F3055 – Standard specification for additive manufacturing nickel alloy powder intended for use in powder bed fusion applications. Defines stringent requirements for AM nickel alloy powder including 316L.

- ASTM F3049 – Guide for characterizing properties of metal powders used for additive manufacturing processes. Provides guidance on measuring characteristics like flow, density, morphology etc.

Other Standards

- ISO 9001 – Quality management for production of metallic powders

- ISO 13485 – Quality management for metallic powders for medical applications

- ASME Boiler and Pressure Vessel Code – Material requirements for pressure vessel applications

Reputable 316L powder suppliers have quality systems certified to ISO and ASTM standards. Lot traceability and extensive testing are maintained to ensure compliance.

316L Powder Suppliers

Some leading global suppliers of 316L stainless steel powder include:

| Company | Production Methods | Powder Types | Particle Size |

|---|---|---|---|

| Sandvik | Gas atomization | Osprey® 316L | 15-45 μm |

| LPW Technology | Gas atomization | LPW 316L | 15-63 μm |

| Carpenter | Gas atomization | Carpenter 316L | 15-150 μm |

| Höganäs | Water atomization | 316L | 10-45 μm |

| CNPC | Gas, water atomization | 316L | 10-150 μm |

| Pometon | Gas, water atomization | 316L | 10-150 μm |

| ATI | Gas atomization | 316L | 10-63 μm |

316L powder pricing depends on factors like:

- Powder quality, composition, particle size and morphology

- Production method

- Order quantity and lot size

- Level of quality control and testing

- Packaging and delivery requirements

Indicative pricing for gas atomized 316L powder is in the range of $50-100 per kg for standard orders. Custom orders with special requirements may cost more.

When selecting a 316L powder supplier, some key considerations include:

- Powder characteristics – particle size distribution, morphology, flowability etc. should match application needs

- Consistent quality and composition per specifications

- Reliable supply chain and logistics

- Compliance to international standards and certifications

- Technical expertise and customer service

- Pricing and minimum order quantity

Leading 316L powder manufacturers have decades of experience in producing powders tailored to AM, MIM, and other applications with stringent quality control.

Design Considerations for 316L Powder

Design Considerations for 316L Stainless Steel Powder

| Aspect | Consideration | Impact on Printed Part | Recommendations |

|---|---|---|---|

| Wall Thickness | Minimum thickness should be 0.8-1 mm | Parts with thinner walls may be weak and prone to cracking. | * Design walls at least 1 mm thick for optimal strength. * Consider using internal ribs or lattices for reinforcement in thin sections. * For parts requiring minimal wall thickness, explore alternative AM processes with higher resolution. |

| Overhangs & Angles | Sharp corners and unsupported overhangs can lead to warping and delamination. | * Minimize sharp corners by incorporating fillets and curves. * Design overhangs with angles between 30-45 degrees for better support. * Utilize strategically placed support structures during printing to prevent drooping. | |

| Surface Finish & Orientation | Powder characteristics and layer orientation can influence surface texture. | * Understand how powder size and morphology affect surface roughness. * Consider part orientation to minimize layering visibility on critical surfaces. * Post-processing techniques like polishing or bead blasting can improve surface finish. | |

| Porosity | Air pockets trapped within the part can compromise mechanical properties. | * Optimize printing parameters like laser power and scan speed to achieve high density. * Explore techniques like Hot Isostatic Pressing (HIP) to further minimize porosity. * Design internal channels or venting holes to facilitate powder removal during printing. | |

| Stress Management | Residual stresses from the printing process can lead to warping or cracking. | * Utilize support structures strategically to minimize stress concentration points. * Design features like fillets and gradual transitions to reduce stress build-up. * Consider post-printing heat treatment for stress relief annealing. | |

| Dimensional Accuracy | Powder size distribution and shrinkage during sintering can affect final dimensions. | * Account for shrinkage rates (typically around 20%) when designing the model. * Utilize design for additive manufacturing (DfAM) principles to optimize printability and minimize dimensional deviations. * Print test parts to calibrate printing parameters and ensure dimensional accuracy. | |

| Support Structures | Temporary structures needed for complex geometries can leave marks. | * Design support structures with minimal contact area to minimize removal marks. * Explore dissolvable support materials for easier post-processing. * Optimize support structure design for efficient material usage and easy removal. | |

| Powder Removal | Unremoved powder trapped inside cavities can affect functionality. | * Design internal channels or drainage holes to facilitate powder removal. * Utilize angled features and venting strategies to prevent powder entrapment. * Optimize printing parameters to minimize powder sticking and improve flowability. |

Post-Processing of 316L Parts

Post-Processing of 316L Stainless Steel Parts

| Process | Description | Benefits | Considerations |

|---|---|---|---|

| Support Removal | Removing temporary structures used during printing. | * Essential for achieving final part geometry. * Allows access to internal features. | * Selection of removal method depends on support material type (manual, mechanical, chemical dissolution). * Careful handling is required to avoid damaging the part. |

| Heat Treatment | * Stress Relief Annealing: Reduces residual stresses from printing to improve dimensional stability and prevent cracking. * Solution Annealing: Refines microstructure for enhanced mechanical properties and corrosion resistance. | * Optimizes performance and longevity of the part. * Enables conformance to specific material specifications. | * Requires precise control of temperature and time based on part geometry and desired outcome. * Rapid cooling techniques like quenching may be necessary for solution annealing. |

| Shot Peening | Bombarding the surface with small metal spheres to create a compressive stress layer. | * Improves fatigue strength and wear resistance. * Enhances resistance to stress corrosion cracking. | * Selection of shot media and blasting parameters depends on desired surface finish and depth of effect. * Excessive peening can introduce surface roughness. |

| Pickling & Passivation | Chemical cleaning process to remove surface contaminants and improve corrosion resistance. | * Essential for parts exposed to harsh environments. * Creates a passive oxide layer for enhanced corrosion protection. | * Selection of pickling and passivating solutions depends on material grade and surface condition. * Improper handling of chemicals requires appropriate safety precautions. |

| Machining & Finishing | Traditional subtractive techniques for achieving precise dimensions, tolerances, and surface finishes. | * Enables creation of features not achievable with AM. * Improves surface aesthetics and functionality. | * Requires additional machining expertise and equipment. * May introduce heat and stress that necessitate further post-processing. |

| Polishing | Mechanical or chemical methods for achieving a smooth, reflective surface. | * Enhances aesthetic appeal for decorative applications. * Improves surface hygiene for medical devices. * Reduces surface roughness for improved wear resistance. | * Selection of polishing method depends on desired level of finish. * Excessive polishing can remove material and alter part dimensions. |

| Electroplating | Depositing a thin layer of another metal onto the surface for enhanced properties. | * Improves electrical conductivity, wear resistance, or corrosion resistance. * Offers decorative finishes like chrome or gold plating. | * Requires specialized equipment and expertise for electroplating baths. * Plating thickness needs to be carefully controlled to avoid delamination. |

Common Defects in 316L Parts

| Defect | Description | Cause | Impact | Mitigation Strategies |

|---|---|---|---|---|

| Porosity | Air pockets trapped within the part during printing. | * Suboptimal laser power or scan speed. * Inadequate powder flowability. * Improper gas purging. | * Reduced mechanical strength, fatigue life, and corrosion resistance. * May create leakage paths in fluid applications. | * Optimize printing parameters for proper melting and density. * Pre-heat the powder bed to improve flow. * Utilize inert gas purging to minimize trapped air. * Consider post-processing techniques like Hot Isostatic Pressing (HIP) for further densification. |

| Lack of Fusion | Incomplete melting between adjacent powder layers. | * Insufficient laser power density. * Inconsistent powder layer thickness. * Contamination on the powder surface. | * Weak interlayer bonding, leading to potential cracking and part failure. | * Calibrate laser power and scan speed for proper melting depth. * Ensure consistent powder layer thickness through proper recoating mechanisms. * Maintain a clean powder bed free from moisture or contaminants. |

| Balloning | Molten metal accumulating into excessive beads on the top surface. | * Excessive laser power density. * Improper scan speed. * Incorrect powder size distribution. | * Rough surface finish with poor aesthetics. * Potential for spatter and process instability. | * Reduce laser power or increase scan speed to prevent overheating. * Optimize scan patterns to avoid excessive dwell time on a single area. * Utilize a more uniform powder size distribution for consistent melting behavior. |

| Cracks | Fractures in the part due to residual stresses or thermal shock. | * Rapid cooling during printing. * Insufficient stress relief post-processing. * Sharp corners or design features that concentrate stress. | * Compromised structural integrity and potential for part failure. | * Implement slower cooling rates during printing to minimize thermal gradients. * Perform stress relief annealing to reduce residual stresses. * Design features with smooth transitions and avoid sharp corners. |

| Warpage | Distortion of the part from its intended geometry. | * Uneven thermal expansion and contraction during printing. * Inadequate support structures for complex geometries. * Residual stresses locked in the part. | * Dimensional inaccuracies and potential for part malfunction. | * Optimize printing parameters to minimize thermal gradients. * Utilize strategically placed support structures for proper support during printing. * Implement stress relief annealing to reduce warping tendencies. |

| Delamination | Separation of layers within the part. | * Weak interlayer bonding due to lack of fusion. * Excessive moisture content in the powder. * Contamination on the powder bed. | * Loss of structural integrity and potential for part delamination. | * Ensure proper fusion between layers by optimizing printing parameters. * Maintain low powder moisture content through proper storage and handling. * Utilize a clean powder bed free from contaminants. |

How to Choose a 316L Powder Supplier

Here is a step-by-step guide on selecting a supplier for 316L stainless steel powder:

Step 1: Determine Application Requirements

- Consider which manufacturing process will be used – AM, MIM etc.

- Identify the critical powder properties needed like particle size, shape, purity etc.

- Consider the part specifications – mechanical properties, accuracy, surface finish etc.

Step 2: Research Potential Suppliers

- Search for leading 316L powder manufacturers with long experience

- Check capabilities – production methods, powder varieties, QC testing etc.

- Review case studies and customer reviews relevant to your application

Step 3: Evaluate Technical Capabilities

- Can they customize 316L powder to your application needs?

- Do they have expertise in AM, MIM or other powder technologies?

- What is their level of vertical integration and quality control?

Step 4: Assess Service Offerings

- Technical support during powder selection, application development

- Sample testing, trialling services

- Responsiveness to inquiries, lead time flexibility

Step 5: Review Certifications and Compliance

- International quality certifications – ISO 9001, ISO 13485 etc.

- Compliance to powder composition standards like ASTM

- Lot traceability, extensive testing and documentation

Step 6: Compare Pricing

- Price per kg for required particle size, quality level, quantity

- Minimum order quantity and lot size requirements

- Shipping/logistics costs

Step 7: Check Availability and Reliability

- Steady in-stock supply and ability to meet demand fluctuations

- Order tracking and monitoring, transparent lead times

- Proven on-time delivery record

Selecting a supplier with application expertise, consistent product quality, and responsive service ensures a smooth procurement experience.

How to Optimize 316L Powder for AM

Match Particle Size to AM Process

- Use 10-45 μm particles for powder bed fusion like DMLS, SLM

- Optimize size distribution – too wide can cause packing issues

- Finer 1-10 μm particles better suited for binder jetting

Achieve High Sphericity and Flowability

- Flowability directly affects powder spreading and layer uniformity

- Gas atomization produces spherical, free-flowing powders

- Test powder flow as per ASTM B213 standard

Minimize Satellite Particles

- Use sieving, classification to remove satellites and fines

- Satellites can cause agglomeration and defects

Control Composition Tolerance

- Tightly control elemental composition within ASTM specified range

- Limit impurities like O, N, C which affect properties

Reduce Porosity

- Optimize process parameters and scan patterns

- Use hot isostatic pressing to minimize porosity

- Maintain >99% density for high performance

Minimize Residual Stresses

- Optimize thermal gradients in the build process

- Use appropriate heat treatments to relieve stresses

Achieve Target Mechanical Properties

- Solution annealing and aging improves strength

- Maintain uniform properties in all build directions

Careful powder characterization, parameter optimization, and post-processing are key to achieve defect-free 316L parts using AM.

FAQ

Q: What is 316L stainless steel powder typically used for?

A: 316L powder is most widely used for additive manufacturing, metal injection molding, and press & sinter applications due to its excellent corrosion resistance combined with good mechanical properties and biocompatibility. Common applications include implants, aerospace components, automotive parts, biomedical devices, and tooling.

Q: What particle size is recommended for laser-based AM processes?

A: A particle size range of 10-45 microns is typically recommended for laser powder bed fusion processes like DMLS and SLM. Finer particles below 10 microns can cause issues with flow and spreading. Particle size distribution should also be well controlled.

Q: How does powder morphology affect properties?

A: Highly spherical, free-flowing powder is desirable for AM applications. Irregular, spiky powder is suited for press and sinter methods. Satellite particles and fines negatively impact powder flow and can create defects. Controlling powder morphology is key for optimal performance.

Q: What are some key differences between gas atomized vs water atomized 316L powder?

A: Gas atomized 316L powder has more spherical morphology and better flowability. Water atomized powder displays more irregular shapes but provides higher compressibility desired for press and sinter applications. Gas atomized powder has lower oxygen content.

Q: What post-processing methods are used on 316L AM parts?

A: Common post-processing includes heat treatment, hot isostatic pressing, surface finishing through grinding/machining, coating, and quality control testing. This helps achieve target properties, dimensional accuracy, aesthetics, and defect detection.

Q: What are some common 316L powder defects and how can they be avoided?

A: Potential defects are porosity, cracking, poor surface finish, lack of fusion, and residual stresses. Careful process parameter optimization, powder quality control, build orientation, and post-processing can minimize these defects in 316L parts.

Q: What standards apply to 316L powder for AM and other applications?

A: Key standards are ASTM F3055 for AM powders, ASTM B822 for powder characterization, ASTM A240 for alloy composition, and ISO standards for quality management. Leading 316L powder suppliers are certified to these standards.

Q: What factors determine pricing for 316L powder?

A: Main factors affecting 316L powder pricing are quality level, particle size and distribution, production method, order quantity, buyer requirements for testing/QC, packaging and delivery. More stringent needs increase pricing.

Q: How can corrosion resistance of 316L AM parts be optimized?

A: Solutions include controlling impurity levels through tight chemical composition tolerances, using hot isostatic pressing to increase density and reduce porosity, applying passivation treatments, and solution annealing to improve corrosion resistance.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731