Stainless Steel and Titanium Etching in Daejeon: A Comprehensive Guide for B2B Buyers

Table of Contents

1. Introduction: Importance of Stainless Steel and Titanium Etching in Industrial Applications

Etching is a crucial manufacturing process used to create precision metal components for industries such as aerospace, medical devices, electronics, and automotive. Stainless steel and titanium are two of the most commonly etched metals due to their high strength, corrosion resistance, and durability.

Why Etching Is Essential for Industrial Manufacturing

- Precision Micropatterning – Etching allows for intricate designs without compromising material integrity.

- High Durability – Stainless steel and titanium maintain structural integrity even after etching.

- Corrosion Resistance – These metals are ideal for medical, aerospace, and harsh environmental applications.

- Lightweight & Strong – Titanium, in particular, offers an excellent strength-to-weight ratio, making it ideal for aerospace and medical implants.

Many manufacturers in Daejeon, South Korea, are now turning to advanced etching techniques to produce high-quality stainless steel and titanium components. This shift is driven by the growing demand for customized metal parts in high-tech industries.

2. Market Trends and Growth Potential for Etched Metals in South Korea

South Korea, particularly the city of Daejeon, is a hub for advanced materials and precision engineering. The market for etched stainless steel and titanium is growing rapidly due to the following factors:

Key Market Trends

| Trend | Impact on the Industry |

|---|---|

| Rising Demand for Medical Implants | Titanium etching is essential for high-precision medical implants. |

| Growth of the Semiconductor Industry | Stainless steel etching is widely used in manufacturing semiconductor components. |

| Expanding Aerospace Sector | Lightweight titanium components require precision etching for aircraft and spacecraft. |

| Increased Use of 3D Printing in Metal Manufacturing | Hybrid techniques combining 3D printing and etching are becoming more common. |

Why South Korea is a Key Player in Etching Technology

- Strong R&D Investment – Government and private sector funding drive innovation in metal processing.

- Advanced Manufacturing Infrastructure – Facilities in Daejeon specialize in high-precision etching.

- Strategic Location – Proximity to major electronics, automotive, and medical device manufacturers.

For businesses looking to source etched stainless steel and titanium components, South Korea offers high-quality, cost-effective solutions compared to Western suppliers.

3. Key Factors to Consider When Choosing an Etching Supplier in Daejeon

Choosing the right etching supplier is critical for ensuring high-quality, precision components. Here are the most important factors to consider:

1. Material Expertise

Ensure the supplier has experience working with stainless steel and titanium. These materials require specialized etching techniques.

2. Etching Techniques Used

The two main etching methods are:

- Chemical Etching – Uses acid or chemical solutions to remove material selectively.

- Laser Etching – Uses high-powered lasers for precision marking and cutting.

3. Industry Certifications

Look for suppliers with ISO 9001, AS9100 (Aerospace), or ISO 13485 (Medical) certifications. This ensures compliance with industry standards.

4. Production Capacity & Lead Time

Choose a supplier that can handle bulk orders while maintaining fast turnaround times.

5. Customization Capabilities

If you need custom designs, ensure the supplier offers CNC precision machining, CAD support, and prototyping services.

6. Cost & Pricing Structure

Compare pricing for bulk etching services. Some suppliers offer wholesale discounts for large-volume orders.

4. Top 5 Stainless Steel and Titanium Etching Suppliers in Daejeon

Daejeon is home to several high-quality metal etching suppliers specializing in stainless steel and titanium. Below are the top five companies known for their precision etching services and B2B wholesale supply.

Top Etching Suppliers in Daejeon

| Supplier Name | Key Strengths | Industries Served | Etching Methods |

|---|---|---|---|

| Daejeon Precision Metals | High-precision stainless steel etching | Medical, Aerospace, Electronics | Chemical & Laser Etching |

| Korea Metal Engraving Co. | Titanium etching for high-strength applications | Automotive, Aerospace | Chemical Etching |

| Daejeon Etching Solutions | Bulk wholesale etching services with fast lead times | Semiconductor, Industrial Machinery | Laser Etching |

| Hitech Metal Processing | Custom metal etching with CAD design support | Medical Devices, Electronics | Chemical & Laser Etching |

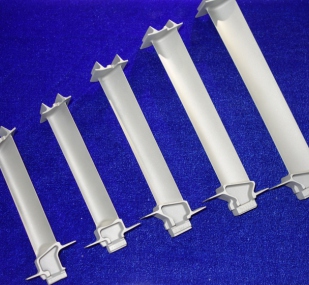

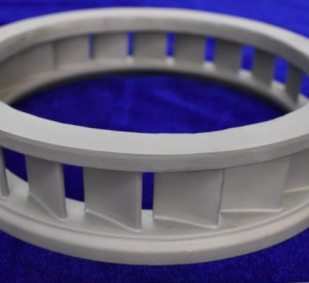

| Metal3DP | Advanced 3D printing & etching solutions for industrial applications | Aerospace, Medical, Automotive | Hybrid 3D Printing & Etching |

Each of these suppliers offers unique advantages depending on your industry requirements. However, if you need a full-service metal manufacturing solution, Metal3DP provides both additive manufacturing (3D printing) and precision etching, making it an ideal choice.

👉 Learn more about Metal3DP’s advanced metal processing capabilities: Metal 3D Printing

5. Why More Manufacturers Are Choosing Local Etching Services Over Imports

Many businesses previously relied on imported etched components from China, Japan, or the US. However, recent trends indicate a shift towards local South Korean suppliers.

Key Reasons for Choosing Local Etching Suppliers

1. Faster Lead Times

- Local Daejeon-based suppliers provide quicker turnaround times compared to overseas imports.

- No delays due to international shipping and customs clearance.

2. Cost Savings on Logistics

- Eliminates the high cost of international freight and import taxes.

- Bulk orders can be delivered faster and cheaper within South Korea.

3. Higher Quality Control

- South Korean suppliers adhere to strict manufacturing standards (ISO 9001, AS9100, etc.).

- Easier to conduct on-site inspections and quality checks.

4. Customization & Flexibility

- Local suppliers offer customized etching solutions tailored to client specifications.

- Easier collaboration on design modifications without language barriers.

5. Advanced Technology & Innovation

- Korea is a global leader in high-tech manufacturing, ensuring state-of-the-art etching solutions.

- Suppliers like Metal3DP integrate 3D printing with etching for next-gen industrial applications.

By sourcing from local etching suppliers in Daejeon, businesses can achieve higher efficiency, lower costs, and better quality control.

6. Why Choose Metal3DP for High-Quality Stainless Steel and Titanium Etching?

If you’re looking for a reliable supplier that offers cutting-edge metal processing, Metal3DP is the ideal choice.

What Makes Metal3DP Stand Out?

| Feature | Benefit |

|---|---|

| Hybrid 3D Printing & Etching | Combines additive manufacturing with precision etching for superior results. |

| Industry-Leading Expertise | Decades of experience in metal additive manufacturing and material processing. |

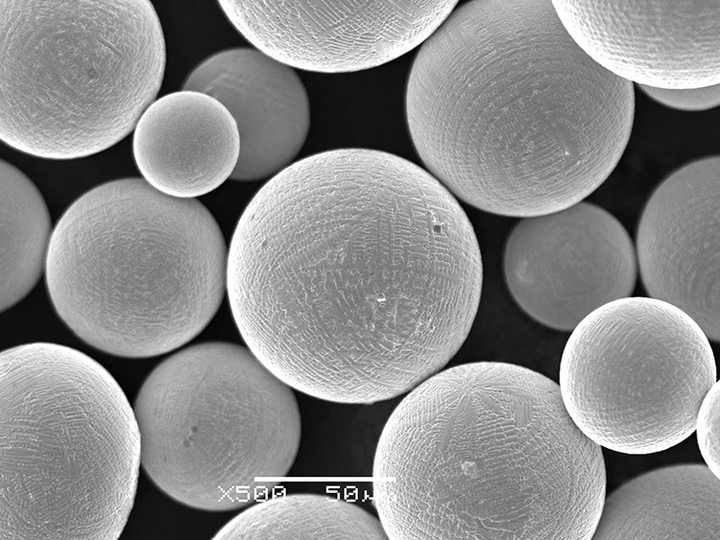

| Advanced Powder Making Technology | Produces high-quality spherical metal powders for superior etching performance. |

| High-Purity Titanium & Stainless Steel | Ensures durable, corrosion-resistant, and high-strength etched components. |

| ISO & Aerospace-Grade Certification | Meets strict industry standards for medical, aerospace, and automotive applications. |

Metal3DP’s Key Etching Capabilities

1. High-Precision Stainless Steel Etching

- Ideal for semiconductors, medical devices, and industrial components.

2. Titanium Etching for Aerospace & Medical Applications

- Produces lightweight, high-strength components with superior corrosion resistance.

3. Custom Design & Prototyping Support

- Full CAD design services, allowing for customized metal parts.

4. Bulk Wholesale Orders with Competitive Pricing

- Special B2B pricing for bulk stainless steel and titanium etching.

👉 Learn more about Metal3DP’s advanced metal materials and 3D printing solutions: Product Page

7. How to Order Custom Etched Stainless Steel and Titanium Components

Sourcing high-precision etched stainless steel and titanium parts requires a well-structured approach to ensure quality, cost-effectiveness, and timely delivery. Below is a step-by-step guide on how to order etched metal components from Metal3DP and other top suppliers in Daejeon.

Step 1: Define Your Requirements

Before placing an order, ensure you have the following details:

- Material Selection – Stainless steel or titanium?

- Etching Method – Chemical etching or laser etching?

- Thickness and Dimensions – Exact measurements for your components.

- Design Specifications – CAD drawings or prototypes.

- Quantity – Bulk or small-batch production?

- Industry Standards – Any certifications required (ISO 9001, AS9100, etc.).

💡 Tip: If you need assistance with material selection or design, Metal3DP offers expert consultation for industrial applications.

Step 2: Request a Quote

Most B2B suppliers provide pricing based on factors such as:

| Factor | Impact on Pricing |

|---|---|

| Material Type | Titanium is generally more expensive than stainless steel. |

| Etching Complexity | Intricate designs may require more processing time. |

| Order Volume | Bulk orders typically receive discounted rates. |

| Surface Finish Requirements | Additional polishing or coating may increase costs. |

👉 Request a custom quote from Metal3DP: Contact Us

Step 3: Prototype and Sample Testing

Before moving to full-scale production, many suppliers offer:

- Prototype development – A small batch for approval.

- Material testing – Ensuring compliance with industry standards.

- Surface finish testing – Verifying corrosion resistance, durability, and precision.

Step 4: Bulk Production and Quality Inspection

Once the prototype is approved:

- Full-scale etching production begins.

- Quality control checks are performed (dimensional accuracy, surface finish, mechanical properties).

- Products are packaged and prepared for shipping.

📦 Shipping Options:

- Domestic delivery within South Korea.

- International shipping for global B2B buyers.

💡 Tip: Metal3DP provides bulk order discounts and high-quality assurance for stainless steel and titanium components.

8. FAQs: Common Questions About Stainless Steel and Titanium Etching

Below are some frequently asked questions about stainless steel and titanium etching for B2B buyers.

Q1: What is the difference between chemical and laser etching?

| Etching Type | Description | Best For |

|---|---|---|

| Chemical Etching | Uses acid or chemical solutions to remove material. | High-precision, complex designs, mass production. |

| Laser Etching | Uses high-powered lasers to vaporize material. | Custom markings, small-batch production, serial numbers. |

Q2: Is titanium more difficult to etch than stainless steel?

Yes, titanium is more challenging to etch due to its high strength and corrosion resistance. It requires specialized chemical solutions and controlled processing conditions.

Q3: What industries benefit the most from etched stainless steel and titanium components?

- Aerospace – Lightweight, high-strength titanium parts.

- Medical Devices – Biocompatible implants and surgical tools.

- Semiconductor & Electronics – High-precision stainless steel components.

- Automotive – Durability and corrosion-resistant metal parts.

Q4: How long does the etching process take?

- Prototyping: 1-2 weeks

- Bulk production: 3-6 weeks, depending on order size and complexity.

Q5: Can I combine 3D printing with etching for my metal components?

Yes! Metal3DP specializes in hybrid manufacturing, combining 3D metal printing and precision etching for advanced industrial applications.

👉 Learn more about Metal3DP’s printing methods: Printing Methods

9. Conclusion & Next Steps for B2B Buyers

Why Choose Metal3DP for Your Stainless Steel and Titanium Etching Needs?

If your business requires high-precision etched metal components, Metal3DP is the best choice for:

✅ Advanced hybrid manufacturing – 3D printing & etching for superior quality.

✅ High-performance metal powders – Optimized for aerospace, medical, and industrial applications.

✅ Custom solutions & bulk ordering – Competitive pricing for B2B buyers.

✅ Trusted industry expertise – Years of experience in metal additive manufacturing.

What’s Next?

🔹 Contact Metal3DP for a custom etching quote: Get a Quote

🔹 Explore our advanced metal materials: Metal 3D Printing

🔹 Learn more about our cutting-edge products: Product Catalog

Partner with Metal3DP and take your metal manufacturing to the next level!

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731