Stainless Steel Powder 17-4PH

Table of Contents

Overview

stainless steel powder 17-4ph is a precipitation hardening martensitic stainless steel that can be processed via powder metallurgy techniques for high performance applications requiring good mechanical properties, corrosion resistance and ease of fabrication.

This guide covers different types of 17-4PH powders, their characteristics, properties data, processing methods, applications, specifications, suppliers, installation and handling procedures, maintenance requirements, selection criteria for powder vendors, pros and cons of using 17-4PH powder and answers to frequently asked questions.

Types of 17-4PH Powder

stainless steel powder 17-4ph is available in different forms suitable for various powder consolidation processes:

| Type | Characteristics |

|---|---|

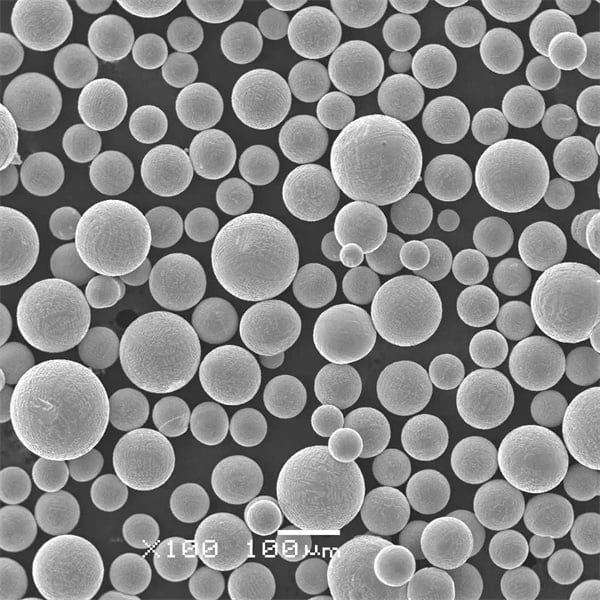

| Gas atomized | Spherical morphology, good flowability |

| Water atomized | Irregular morphology, wide size distribution |

| Plasma atomized | Very fine, spherical powder |

| Hydride-dehydride | Spongy, porous morphology |

| Carbonyl iron | High purity (+99% Fe) powder |

Gas atomized powder with smooth spherical particles allows excellent packing density and sintered properties but is relatively expensive. Water atomization is more economical but shape is less ideal. Very fine plasma atomized powders are preferred for metal injection molding. HDH and carbonyl iron powders are used for blending to achieve higher purity and improved properties.

Composition and Properties

| Property | Description |

|---|---|

| Composition | 17-4 PH stainless steel powder boasts a specific chemical makeup that grants its desirable properties. The primary element is iron (Fe), typically constituting around 73% of the powder’s weight. Chromium (Cr), a key component for corrosion resistance, ranges between 15.0 and 17.5%. Nickel (Ni) content falls within 3.0 to 5.0%, contributing to strength and toughness. Copper (Cu), another element influencing strength and machinability, is present at 3.0 to 5.0%. Manganese (Mn) (around 1.0%) enhances hardenability, while silicon (Si) (also around 1.0%) improves strength and oxidation resistance. For precipitation hardening, small amounts of Tantalum (Ta) and Niobium (Nb) (combined not exceeding 0.15%) are included. |

| Particle Characteristics | 17-4 PH powder is typically manufactured using various techniques to achieve specific particle features. A common characteristic is a spherical shape, offering several advantages in additive manufacturing processes like better flowability and packing density. Particle size distribution is another crucial aspect. Manufacturers may specify the distribution using a D-value notation. For instance, D10 indicates the diameter at which 10% of the particles are smaller and 90% are larger. Similarly, D50 represents the median particle diameter, and D90 signifies the diameter where 90% of the particles are smaller and 10% are larger. Particle size significantly impacts the final properties of the additively manufactured part. Finer powders generally result in smoother surface finishes but may be more challenging to process due to flowability issues. Conversely, coarser powders offer better flow characteristics but can lead to a rougher surface finish. |

| Apparent Density | Apparent density refers to the mass of powder per unit volume, considering the spaces between particles. It’s a crucial parameter for powder handling and storage efficiency. For 17-4 PH powder, the apparent density typically falls around 5.0 g/cm³. This value can vary depending on the particle size distribution and packing techniques. |

| Flowability | Flowability describes how easily powder moves under its own weight or external force. It’s essential for smooth operation in additive manufacturing processes. Spherical particles generally exhibit better flowability compared to irregularly shaped ones. Additionally, particle size distribution plays a role. Powders with a wider distribution can experience flowability issues due to segregation, where larger particles tend to separate from finer ones. Manufacturers often employ flowability additives or adjust particle size distribution to optimize powder flow for specific printing processes. |

| Mechanical Properties | 17-4 PH stainless steel powder offers a unique combination of mechanical properties when processed into a solid part. In the solution annealed condition (achieved through heat treatment), the material exhibits high ductility and good machinability. However, its strength is relatively low. The true potential of 17-4 PH lies in precipitation hardening. This secondary heat treatment process allows the material to achieve high strength and hardness while maintaining good corrosion resistance. The specific values for tensile strength, yield strength, and elongation depend on the chosen heat treatment parameters. Typically, 17-4 PH parts can achieve tensile strengths exceeding 1000 MPa (145 ksi) and yield strengths exceeding 830 MPa (120 ksi). |

| Corrosion Resistance | Similar to wrought 17-4 PH stainless steel, the powder variant boasts excellent corrosion resistance. The presence of chromium provides a passive oxide layer that protects the underlying metal from corrosion. This makes 17-4 PH suitable for applications exposed to harsh environments, including saltwater, acidic, or alkaline conditions. However, it’s important to note that the surface finish of the additively manufactured part can influence its corrosion resistance. A smoother surface finish generally offers better corrosion performance. |

| Weldability | 17-4 PH stainless steel powder demonstrates good weldability using various fusion and resistance welding techniques. This allows for the creation of complex parts by joining additively manufactured components with other metallic elements. However, proper welding procedures and filler metals are crucial to maintain the integrity and properties of the weld joint. |

| Heat Treatment | Heat treatment plays a vital role in unlocking the full potential of 17-4 PH stainless steel powder. The typical process involves solution annealing, followed by precipitation hardening. Solution annealing involves heating the material to a specific temperature and holding it for a predetermined time. This dissolves copper-rich precipitates within the microstructure, making the material soft and ductile. Subsequent rapid quenching freezes this microstructure in a metastable state. Precipitation hardening involves reheating the solution-annealed material to a lower temperature and holding it for a specific time |

Applications of stainless steel powder 17-4ph

| Industry | Application | Key Considerations |

|---|---|---|

| Aerospace | Aircraft fittings and braces Turbine blades and structural components Rocket and missile parts | High strength-to-weight ratio for lightweight yet robust structures Excellent fatigue resistance for components under repeated stress Retention of mechanical properties at elevated temperatures (up to 600°F) |

| Oil & Gas | Downhole tools and equipment Valves and wellhead components Chemical processing components | Exceptional corrosion resistance against harsh downhole environments containing brine, sour gas, and CO2 – High wear resistance for parts experiencing friction and abrasion – Good machinability for post-processing and customization |

| Medical & Dental | Surgical instruments and implants Dental prosthetics and tools | Biocompatible properties for safe implantation within the body High strength and hardness for instruments requiring precise cutting and manipulation Good polishability for a smooth, hygienic surface |

| Power Generation | Nuclear reactor components Steam turbine blades Valve stems and wear rings | Excellent resistance to general and stress corrosion cracking in nuclear environments High creep resistance for components under prolonged high-temperature stress Good dimensional stability for precise operation and tight tolerances |

| Automotive & Motorsports | High-performance suspension components Gears and transmission parts Lightweight chassis components | High strength-to-weight ratio for reduced vehicle weight and improved fuel efficiency Exceptional fatigue strength for components enduring constant vibration and shock loads Good formability for complex near-net shape manufacturing |

| Consumer Goods & Electronics | Luxury watch components High-end cutlery and tools Sporting goods and equipment | Aesthetic appeal due to a bright, polished finish High strength and hardness for wear resistance and durability Good machinability for intricate and detailed designs |

Specifications

Typical specifications for 17-4PH stainless steel powder include:

| Parameter | Specification |

|---|---|

| Particle size | 10 – 45 μm |

| Apparent density | 2.5 – 4 g/cc |

| Tap density | 4 – 6 g/cc |

| Hall flow rate | < 30 s/50g |

| Composition | Per ASTM A564 |

| Impurities | Low oxygen, nitrogen |

| Shape | Spherical/irregular |

| Surface area | 0.1 – 1 m2/g |

Finer powders are preferred for additive manufacturing while coarser sizes are used for press and sinter. Higher density improves powder compaction while good flow aids die filling. Purity reduces inclusions and improves corrosion resistance and mechanicals.

Design Considerations

| Design Feature | Advantage | Disadvantage | Mitigation Strategy |

|---|---|---|---|

| Wall Thickness | Promotes full densification for optimal strength Reduces internal porosity Minimizes stress concentration points | Can limit design complexity for intricate features | Maintain minimum wall thickness of 0.3-0.5 mm Utilize design for manufacturability (DFM) principles to achieve desired features with achievable wall thicknesses |

| Aspect Ratio | Enhances structural integrity by reducing stress concentrations Improves powder flow during additive manufacturing processes | High aspect ratios can lead to warping and cracking | Limit aspect ratios to a maximum of 8:1 Consider redesigning features with excessively high aspect ratios to incorporate fillets, ribs, or alternative geometries |

| Geometric Features | Wide range of design freedom achievable with additive manufacturing Allows for creation of lightweight, complex components | Internal channels and unsupported features can be challenging to fabricate | Employ design for additive manufacturing (DFM) principles to optimize geometries for printability Utilize support structures strategically during printing to prevent collapse of unsupported features Consider post-processing techniques like machining for features requiring tighter tolerances |

| Surface Roughness | Parts may exhibit inherent surface roughness due to the powder-based nature of the material | Rougher surfaces can impact tribological properties (friction and wear) | Specify desired surface finish during design phase Select appropriate post-processing techniques like polishing or bead blasting to achieve desired surface texture |

| Heat Treatment | Leverage precipitation hardening to achieve high strength and hardness | Improper heat treatment parameters can lead to distortion, warping, or reduced mechanical properties | Simulate heat treatment process virtually to optimize parameters Implement strict quality control procedures during heat treatment cycles |

| Residual Stress | Additive manufacturing processes can introduce residual stress within the component | High residual stress can lead to cracking or premature failure | Optimize printing parameters to minimize residual stress Employ stress relief heat treatments when necessary |

Processing Methods

stainless steel powder 17-4ph can be consolidated into fully dense parts using:

| Method | Details |

|---|---|

| Metal injection molding (MIM) | Binds powder into a feedstock for injection into complex molds |

| Additive manufacturing | Uses laser/e-beam to selectively melt powder layers into 3D shapes |

| Powder forging | Compacts and hot deforms powder preforms into high density parts |

| Hot isostatic pressing | Applies heat and isostatic pressure to consolidate powder |

| Press and sinter | Presses powder into a mold, then sinters for full density |

MIM provides highest precision and is ideal for complex, small components. AM offers maximum design freedom. Forging produces excellent mechanicals. HIP avoids sintering porosity. Press-sinter combines good precision and properties at lower cost.

Proper control of temperature, pressure, atmosphere, and other parameters during processing is critical to achieving desired microstructure and properties.

Suppliers and Pricing

Some leading suppliers of stainless steel powder 17-4ph include:

| Supplier | Price Range |

|---|---|

| Carpenter Additive | $50 – $120 per kg |

| Sandvik Osprey | $45 – $100 per kg |

| Praxair | $40 – $90 per kg |

| Höganäs | $60 – $140 per kg |

| CNPC Powder | $30 – $70 per kg |

Prices vary based on purity, powder characteristics, production method, and purchase volume. Small quantities for R&D are more expensive while bulk orders for mass production have lower per-kg cost.

Installation and Handling

| Aspect | Description | Safety Precautions |

|---|---|---|

| Storage | Store in a cool, dry location (ideally below 25°C or 77°F) away from direct sunlight and heat sources. Maintain containers tightly sealed to prevent moisture absorption, which can affect powder flowability and lead to clumping. Consider using desiccants within the storage container for additional moisture control. | Never store 17-4PH stainless steel powder near incompatible materials such as strong acids, bases, or oxidizers. Properly label all containers with the material type, date of receipt, and lot number for easy identification and inventory control. |

| Equipment Compatibility | Ensure all processing equipment (hoppers, feeders, mixers) is constructed from compatible materials that won’t contaminate the powder. Stainless steel (304 or 316L) is a common choice due to its corrosion resistance. Regularly inspect equipment for signs of wear or damage that could compromise powder integrity. Conduct trial runs with small quantities of powder to verify equipment functionality and powder flow characteristics before full-scale production. | Implement grounding and bonding procedures to minimize the risk of electrostatic discharge (ESD) during powder handling, which can ignite dust clouds. Maintain a clean work environment to prevent contamination of the powder with foreign objects or debris. |

| Personal Protective Equipment (PPE) | Wear gloves made from a non-reactive material like nitrile or butyl rubber when handling 17-4PH stainless steel powder to prevent skin irritation or allergic reactions. Utilize safety glasses or a full-face shield to protect eyes from dust particles. When working in environments with significant dust concentrations, employ a properly fitted respirator with a P100 filter for optimal protection against airborne particles. | Wear protective clothing, such as coveralls, to minimize skin exposure to the powder. Wash hands thoroughly with soap and water after handling the powder, even if gloves are worn. Consider disposable shoe covers to prevent tracking powder throughout the work area. |

| Spills and Cleanup | Minor spills can be cleaned with a HEPA-filtered vacuum cleaner designed for metal powders. For larger spills, isolate the area and avoid creating airborne dust. Utilize wet cleaning methods with a damp cloth or mop to minimize dust generation. Dispose of collected powder waste in accordance with local regulations. Never pour powder down drains or into the environment. | Always clean up spills promptly to prevent the spread of contamination and potential safety hazards. If a significant spill occurs, evacuate the area and notify appropriate personnel for assistance. |

| Training | Implement a comprehensive training program for personnel involved in handling 17-4PH stainless steel powder. Training should cover proper handling techniques, safety procedures, emergency response protocols, and the importance of maintaining a clean work environment. | Regularly update training programs to reflect any changes in regulations, material handling procedures, or safety protocols. Maintain training records to demonstrate employee competency in handling this material. |

Operation and Maintenance

| Task | Description | Storage Considerations | Safety Precautions |

|---|---|---|---|

| Storage | |||

| – Receiving | Upon arrival, inspect the container for any signs of damage or leaks. | – Store in a cool, dry place (ideally between 10°C and 25°C) away from direct sunlight and heat sources. | – Wear gloves, safety glasses, and a dust mask when handling containers. |

| – Packaging | – Keep the container tightly sealed to prevent moisture absorption. | – Powders can be flammable or explosive under certain conditions. Implement grounding procedures when handling containers to prevent static discharge. | |

| – Segregation | Separate containers of 17-4PH powder from incompatible materials, such as strong acids, bases, and oxidizing agents. | – | – |

| Task | Description | Process Considerations | Quality Control |

|---|---|---|---|

| Handling | |||

| – Transfer | Utilize proper equipment for transferring powder, such as enclosed transfer systems or grounded scoops, to minimize dust generation. | – Avoid excessive handling, as it can degrade the powder’s flowability. | – Regularly monitor powder flow properties to ensure consistent printing performance. |

| – Mixing/Sieving | If necessary, use a sealed mixing system to minimize powder exposure. Sieving should be conducted in a controlled environment to prevent contamination. | – Maintain detailed records of mixing procedures and sieving parameters. | – Perform particle size analysis on a regular basis to ensure the powder meets the desired specifications. |

| – Pre-heating | For some additive manufacturing processes, pre-heating the powder bed can improve flowability and reduce moisture content. | – Follow manufacturer’s recommendations for pre-heating temperature and duration. | – Monitor and record pre-heating parameters for each build. |

| Task | Description | Process Considerations | Quality Control |

|---|---|---|---|

| Additive Manufacturing | |||

| – Build process | – Adhere to established printing parameters specific to 17-4PH powder and the chosen AM technology. | – In-situ monitoring techniques (e.g., thermal imaging, melt pool monitoring) can be used to ensure consistent build quality. | |

| – Post-processing | Heat treatment is crucial for achieving the desired mechanical properties in 17-4PH stainless steel parts. | – Follow established heat treatment protocols for 17-4PH to optimize strength and ductility. | – Perform mechanical testing (e.g., tensile testing, hardness testing) on finished parts to verify they meet the design specifications. |

| Task | Description | Inspection | Records |

|---|---|---|---|

| Quality Assurance | |||

| – Visual inspection | Conduct a thorough visual inspection of the finished part to identify any surface defects such as cracks, porosity, or delamination. | – Utilize appropriate inspection techniques based on part complexity and application requirements (e.g., X-ray, CT scan). | – Document all inspection findings, including type of defect, location, and corrective actions taken (if necessary). |

| – Dimensional inspection | Verify that the part dimensions conform to the design specifications. | – Utilize calibrated measuring instruments for accurate dimensional checks. | – Maintain records of all dimensional measurements for traceability purposes. |

Selecting stainless steel powder 17-4ph Suppliers

| Factor | Description | Key Considerations |

|---|---|---|

| Supplier Reputation | A supplier’s established track record in the metal additive manufacturing (AM) industry | Look for companies with experience supplying 17-4PH powder for AM. Research their customer testimonials and industry awards. Verify certifications like ISO 9001 (quality management) and AS9100 (aerospace quality). |

| Powder Quality | The chemical composition, particle size distribution (PSD), and flowability of the powder | Ensure the powder meets relevant material standards like ASTM International (ASTM) or Aerospace Material Specifications (AMS). Match the PSD to your specific AM technology (e.g., laser melting prefers finer powders). Prioritize good flowability for consistent printing results. |

| Quality Control Procedures | The supplier’s measures to ensure powder consistency and purity | Inquire about the supplier’s in-house powder analysis capabilities (e.g., optical emission spectrometry, laser diffraction). Seek certifications like ISO 17025 (laboratory competence). Ask about the supplier’s lot traceability system to maintain quality control. |

| Additive Manufacturing Expertise | The supplier’s understanding of AM processes and their impact on powder performance | Look for suppliers with dedicated AM teams who can advise on powder selection for your specific application. Consider suppliers who offer post-processing services like heat treatment optimization for 17-4PH. Partner with suppliers who can provide technical support and troubleshooting for AM challenges. |

| Pricing and Minimum Order Quantity (MOQ) | The cost per kilogram of powder and the minimum amount you must purchase | Compare pricing across different suppliers, considering volume discounts. Factor in shipping costs and potential import duties. Negotiate MOQs that align with your project needs. |

| Delivery Lead Time | The time it takes for the supplier to deliver the powder after your order | Consider your project timelines and potential production delays. Inquire about the supplier’s stock availability and their ability to fulfill urgent orders. Explore options for expedited shipping if necessary. |

| Customer Service | The supplier’s responsiveness and willingness to address your inquiries | Evaluate the ease of communication with the supplier’s sales and technical teams. Look for suppliers who offer dedicated account managers for ongoing support. Ensure the supplier provides clear documentation, including safety data sheets (SDS) and certificates of analysis (COA). |

Advantages and Limitations of 17-4PH Powder

| Advantages | Limitations |

|---|---|

| Excellent Strength & Corrosion Resistance: 17-4PH powder offers a winning combination of high strength and superior corrosion resistance. This makes it ideal for applications demanding both durability and the ability to withstand harsh environments. Compared to other stainless steel powders used in Additive Manufacturing (AM), 17-4PH finds favor for its balanced properties, making it a versatile choice across various industries. | Post-Processing Requirements: Unlike some materials used in AM, 17-4PH parts require post-processing steps like Hot Isostatic Pressing (HIP) and heat treatment to achieve their optimal mechanical properties. This adds an extra layer of complexity and cost to the manufacturing process. |

| Cost-Effective: While not the cheapest option among metal powders, 17-4PH offers a significant cost advantage compared to more exotic alloys used in AM. This makes it a more budget-friendly option for applications where exceptional performance is needed but extreme properties aren’t crucial. | Handling & Storage Challenges: Due to its fine particle size and reactive nature, 17-4PH powder requires careful handling and storage in a controlled atmosphere to prevent moisture absorption and powder degradation. This necessitates specialized equipment and handling procedures, adding to the overall cost considerations. |

| Design Freedom & Flexibility: A significant advantage of 17-4PH powder lies in its compatibility with AM technologies. This allows for the creation of complex, lightweight parts with intricate geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This design freedom opens doors for innovation and functional optimization in various applications. | Welding & Machinability: While 17-4PH offers excellent properties, it can be challenging to weld and machine due to its inherent strength and work hardening characteristics. This can pose limitations in situations where post-processing steps involving welding or machining are necessary for part assembly or final finishing. |

| Established Track Record: 17-4PH has a well-established history of successful use in various industries. This proven track record provides engineers and designers with confidence in the material’s performance and reliability. Existing data and established processing techniques for 17-4PH powder in AM contribute to a smoother development and production process. | Limited for Extreme Environments: Although 17-4PH boasts impressive strength and corrosion resistance, it might not be the optimal choice for applications in exceptionally harsh environments. For situations requiring extreme high or low temperatures, or exposure to highly aggressive chemicals, other more specialized materials might be better suited. |

FAQs

What are the typical applications for 17-4PH stainless steel powder?

17-4PH is commonly used in aerospace, oil and gas, automotive, medical, food processing, and other demanding applications requiring high strength, hardness, and corrosion resistance.

What powder characteristics are recommended for metal injection molding with 17-4PH?

For MIM, spherical powders with d50 of 8 – 15 microns and good flow properties (Hall flow rate around 20 sec/50g) are preferred to enable high powder loading in the feedstock and good mold filling.

How is corrosion resistance maximized when using 17-4PH powder?

Corrosion resistance is improved by having sufficient chromium content (>15%), low impurity levels, and a homogeneous microstructure free from precipitates. Solution annealing followed by rapid cooling helps dissolve carbides and provide the best corrosion resistance.

What is the typical 17-4PH heat treatment procedure and the purpose of each step?

17-4PH is solution annealed at 1900°F, water quenched to dissolve precipitates, conditioned at 350°F, then aged at 850°F to produce finely dispersed precipitates for optimum combination of hardness, strength and toughness.

What precautions are necessary during storage and handling of 17-4PH powder?

As a combustible metal powder, 17-4PH requires storage in a cool, dry, inert atmosphere away from oxygen and ignition sources. Proper grounding, ventilation, and PPE should be used when handling powder to prevent fire, sparks, and inhalation.

Conclusion

With its excellent balance of properties, 17-4PH stainless steel powder enables the manufacture of critical components across demanding industrial applications via efficient powder metallurgy processing methods. Proper selection and processing of 17-4PH powder combined with a heat treatment tailored to end-use requirements results in optimized performance. As processing know-how and availability continues to improve, 17-4PH will see expanded use displacing traditionally wrought and cast materials.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731