Superalloy investment casting Service

Precision Solutions for High-Performance Parts

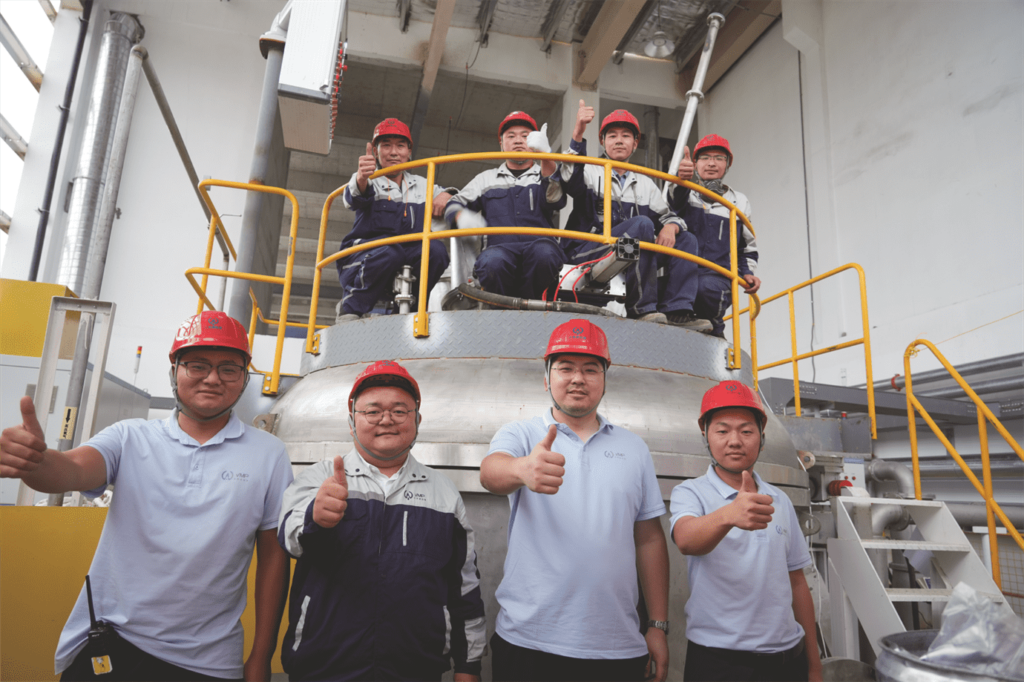

Why work with Metal 3DP

Metal3DP’s superalloy investment casting Service offers unparalleled precision, performance, and partnership for your high-performance part manufacturing needs. With Metal3DP, you benefit from state-of-the-art technology and expertise in superalloy investment casting, ensuring the highest quality and accuracy in every component. Our team of experienced professionals works closely with you to understand your unique requirements and deliver tailored solutions that exceed expectations.

Superalloy investment casting technology is commonly used for:

- Aerospace components

- Industrial gas turbines

- Automotive turbochargers

- Oil and gas equipment

aerospace

Industrial Molds

3C electronics

shipbuilding

biomedical

automobile

oil and nuclear

scientific

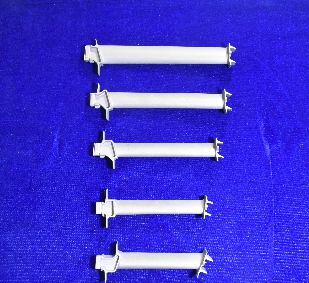

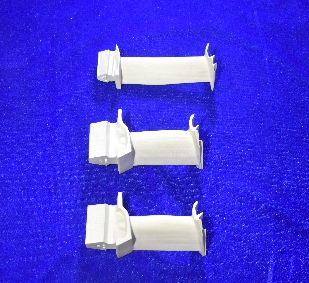

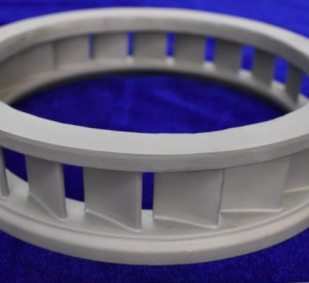

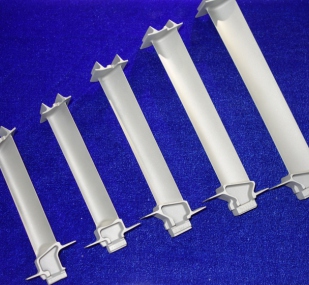

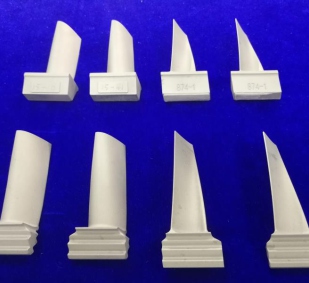

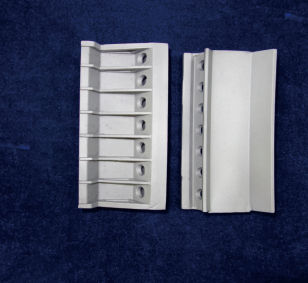

Explore the results of Superalloy investment casting

Technical Advantages

- The only company in China that integrates investment casting capabilities of superalloy, stainless steel, titanium and Ti-aluminides.

- First truly automated wax injection machine which produces 400,000 wax patterns every year.

- The only furnace in China that has both mold heater and mold vibrator functions, particularly suitable for castings with thin wall, large cross-section difference, and strict grain size requirements.

Capability

- Equiaxed Crystal/directional Parts with Maximum pouring weight of 50kg

- Equiaxed Superalloy Parts with Maximum pouring weight of 50kg

- Equiaxed stainless steel parts with maximum pouring weight of 150kg

- Equiaxed Titanium Alloy parts with maximum pouring weight of 100kg

State Of the art Equipment

Machining Services

At Metal3DP, our advanced facilities and cutting-edge equipment enable us to provide clients with a wide array of comprehensive machining services. This includes milling, turning, boring, grinding, drilling, wire cutting, and more. With continual investment in technology, Metal3DP boasts 14 top-tier high-precision 4-axis CNC machining centers, CNC gantry milling & boring machines, CNC horizontal & vertical lathes, CNC honing machines, CNC deep-hole internal grinders, and various other conventional equipment.

Surface Treatment Services

At Metal3DP, we provide a diverse range of surface treatments to optimize the performance, wear resistance, and service life of our metal components. Our offerings include:

- Shot Blasting

- Sand Blasting

- Vibration Grinding

- Electro-Galvanizing

- Pickling and Passivation

- Electropolishing

- Phosphating Treatment

- Blackening Treatment

- Brush Polishing

- Mirror Polishing

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731