Surface Coating Materials

Table of Contents

When you think about surface coating materials, what comes to mind? Is it the shiny chrome on a car bumper, the resilient paint on a kitchen appliance, or perhaps the protective layer on a building’s exterior? Surface coating materials play a crucial role in enhancing the durability, aesthetics, and functionality of various products and structures. This article will dive deep into the world of surface coating materials, exploring their types, applications, benefits, and more. So, let’s embark on this journey and uncover everything you need to know about surface coating materials.

Overview of Surface Coating Materials

Surface coating materials are substances applied to the surface of objects to protect them from environmental damage, improve their appearance, or provide additional functionalities. These coatings can range from simple paints to complex multi-layered systems designed to withstand extreme conditions.

Types and Composition of Surface Coating Materials

Surface coating materials come in various forms, each with its unique composition and properties. Here’s a detailed look at some of the common types:

| Type | Composition | Properties | Characteristics |

|---|---|---|---|

| Powder Coatings | Thermoplastic or thermoset polymer powder | Durable, resistant to chipping | Uniform finish, eco-friendly |

| Metallic Coatings | Aluminum, zinc, or copper powders | Corrosion-resistant, reflective | High conductivity, aesthetic appeal |

| Ceramic Coatings | Oxides, carbides, nitrides | High temperature resistance | Hard, wear-resistant |

| Polymer Coatings | Epoxies, polyurethanes, silicones | Flexible, chemical-resistant | Versatile, easy application |

| Nanocoatings | Nanoparticles of various materials | Enhanced mechanical properties | Ultra-thin, superior performance |

| Organic Coatings | Natural resins, oils, and waxes | Biodegradable, renewable | Safe for food contact, eco-friendly |

Applications of Surface Coating Materials

Surface coating materials are utilized across numerous industries, each with specific requirements and applications. Here’s how they are employed in different sectors:

| Industry | Applications |

|---|---|

| Automotive | Car bodies, wheels, undercarriage protection, interior parts |

| Aerospace | Aircraft exteriors, turbine engines, structural components |

| Construction | Building facades, bridges, pipelines, flooring |

| Electronics | Circuit boards, connectors, casings |

| Marine | Ship hulls, offshore structures, underwater equipment |

| Medical | Surgical instruments, implants, diagnostic devices |

| Household Goods | Appliances, furniture, cookware |

Specifications, Sizes, Grades, and Standards

To ensure quality and performance, surface coating materials adhere to various specifications and standards. Here’s a comprehensive table showcasing some key specifications:

| Material Type | Specification | Sizes | Grades | Standards |

|---|---|---|---|---|

| Powder Coatings | ASTM D3451 | Fine powder | Industrial, commercial | ISO 9001, ISO 14001 |

| Metallic Coatings | ASTM B633 | Micron thickness | Type I, Type II, Type III | ASTM, ISO, MIL-STD |

| Ceramic Coatings | ASTM C633 | Various particle sizes | Standard, high-performance | ISO 20507, ASTM C704 |

| Polymer Coatings | ASTM D4060 | Liquid, powder | Various (based on application) | ISO 12944, ISO 14040 |

| Nanocoatings | Custom specifications | Nano-thin layers | Application-specific | ISO/TS 80004-2, ASTM E2456 |

| Organic Coatings | ASTM D2457 | Viscous liquids | Food grade, industrial | FDA, EU regulations |

Suppliers and Pricing Details

Selecting the right supplier is crucial for ensuring quality and consistency. Here’s a look at some leading suppliers and their pricing details:

| Supplier | Material Type | Price Range | Location | Contact Details |

|---|---|---|---|---|

| PPG Industries | Powder Coatings | $5 – $10 per kg | USA | www.ppg.com |

| Sherwin-Williams | Metallic Coatings | $20 – $50 per kg | Global | www.sherwin-williams.com |

| AkzoNobel | Ceramic Coatings | $30 – $70 per kg | Netherlands | www.akzonobel.com |

| BASF | Polymer Coatings | $15 – $40 per liter | Germany | www.basf.com |

| RPM International | Nanocoatings | $100 – $300 per liter | USA | www.rpminc.com |

| Axalta Coating Systems | Organic Coatings | $10 – $25 per liter | Global | www.axalta.com |

Advantages of Surface Coating Materials

Surface coating materials offer a multitude of benefits that make them indispensable in various industries. Let’s explore some of the key advantages:

Protection Against Corrosion

One of the primary functions of surface coating materials is to protect substrates from corrosion. Metals like steel and aluminum are prone to rust when exposed to moisture and oxygen. Coatings act as a barrier, preventing these elements from coming into contact with the metal surface, thus extending the lifespan of the product.

Enhanced Aesthetics

Whether it’s a vibrant color on a car or a sleek finish on an electronic gadget, coatings significantly improve the visual appeal of products. This aesthetic enhancement is not just about looks; it also plays a role in consumer satisfaction and brand perception.

Improved Durability

Coatings add an extra layer of durability to products. For instance, ceramic coatings on turbine blades in jet engines protect against extreme temperatures and wear, ensuring that the engines operate efficiently for longer periods.

Functional Enhancements

Beyond protection and aesthetics, coatings can also provide functional benefits. For example, anti-reflective coatings on glass improve visibility and reduce glare, while non-stick coatings on cookware make cleaning easier.

Disadvantages of Surface Coating Materials

While surface coatings offer numerous advantages, they also come with certain drawbacks. Understanding these limitations is crucial for making informed decisions.

Cost

High-quality coatings, especially advanced types like nanocoatings and ceramic coatings, can be expensive. This cost factor can be a significant consideration for large-scale applications.

Environmental Impact

The production and application of some coatings involve chemicals that can be harmful to the environment. Although many companies are shifting towards eco-friendly options, the environmental footprint remains a concern.

Complex Application Processes

Certain coatings require specialized equipment and expertise for application. For example, applying powder coatings involves electrostatic spray deposition, which necessitates specific machinery and trained personnel.

Comparing Surface Coating Materials

When selecting a surface coating material, it’s essential to weigh the pros and cons of each type. Here’s a comparative table to help you make an informed choice:

| Material Type | Advantages | Disadvantages |

|---|---|---|

| Powder Coatings | Eco-friendly, durable, uniform finish | Requires specialized equipment |

| Metallic Coatings | High conductivity, corrosion-resistant | Can be expensive |

| Ceramic Coatings | High temperature resistance, hard | High cost, complex application |

| Polymer Coatings | Versatile, flexible, chemical-resistant | Environmental concerns |

| Nanocoatings | Superior performance, ultra-thin | Very high cost, specialized application |

| Organic Coatings | Biodegradable, renewable | Limited durability, performance |

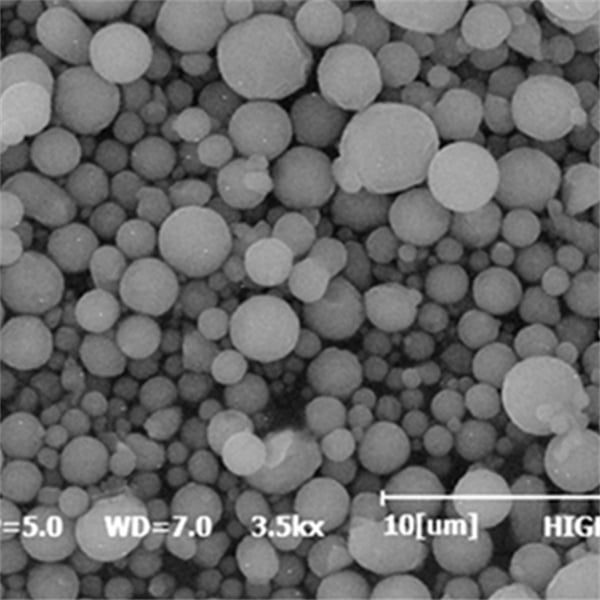

Top Metal Powder Models for Surface Coatings

Metal powders are integral to many coating processes, providing specific properties like conductivity, corrosion resistance, and aesthetic appeal. Here are ten notable metal powder models used in surface coatings:

- Aluminum 6061 Powder

- Description: A versatile aluminum alloy powder known for its excellent corrosion resistance and high strength.

- Applications: Widely used in automotive and aerospace coatings.

- Zinc Powder

- Description: A common metal powder used for its superior corrosion protection properties.

- Applications: Galvanizing steel, protective coatings for marine environments.

- Copper Powder

- Description: Offers excellent electrical conductivity and is often used in electronic coatings.

- Applications: Circuit boards, electrical connectors.

- Stainless Steel 316 Powder

- Description: Known for its corrosion resistance and strength, ideal for harsh environments.

- Applications: Medical devices, marine applications.

- Nickel Powder

- Description: Provides high-temperature resistance and corrosion protection.

- Applications: Aerospace, industrial machinery.

- Titanium Powder

- Description: Lightweight, strong, and corrosion-resistant, used in advanced applications.

- Applications: Aerospace, biomedical implants.

- Iron Powder

- Description: Economical and versatile, often used in magnetic coatings.

- Applications: Automotive parts, electronics.

- Cobalt-Chrome Powder

- Description: Offers excellent wear resistance and strength, suitable for high-stress applications.

- Applications: Medical implants, turbine engines.

- Tungsten Carbide Powder

- Description: Extremely hard and wear-resistant, used in abrasive environments.

- Applications: Cutting tools, wear-resistant coatings.

- Silver Powder

- Description: Known for its superior electrical conductivity and antimicrobial properties.

- Applications: Electronics, medical devices.

Applications and Uses of Specific Metal Powder Models

Each metal powder model has specific applications that leverage its unique properties. Here’s how some of these powders are used in various industries:

| Metal Powder Model | Primary Uses |

|---|---|

| Aluminum 6061 Powder | Automotive parts, aerospace components |

| Zinc Powder | Galvanizing steel, marine protective coatings |

| Copper Powder | Circuit boards, electrical connectors |

| Stainless Steel 316 | Medical devices, marine applications |

| Nickel Powder | Turbine blades, industrial machinery |

| Titanium Powder | Aerospace, biomedical implants |

| Iron Powder | Magnetic coatings, automotive parts |

| Cobalt-Chrome Powder | Medical implants, high-stress components |

| Tungsten Carbide | Cutting tools, wear-resistant coatings |

| Silver Powder | Electronics, medical devices |

Advantages and Limitations of Specific Metal Powder Models

Understanding the strengths and weaknesses of each metal powder model can help in selecting the right one for your application. Here’s a comparison:

| Metal Powder Model | Advantages | Limitations |

|---|---|---|

| Aluminum 6061 | Corrosion-resistant, high strength | Can be expensive |

| Zinc | Superior corrosion protection | Relatively low strength |

| Copper | Excellent conductivity | Susceptible to oxidation |

| Stainless Steel 316 | High corrosion resistance, durable | High cost |

| Nickel | High-temperature resistance | Expensive, can cause allergic reactions |

| Titanium | Lightweight, strong | Very high cost |

| Iron | Economical, versatile | Prone to rust if not coated properly |

| Cobalt-Chrome | Excellent wear resistance | High cost |

| Tungsten Carbide | Extremely hard, wear-resistant | Brittle, high cost |

| Silver | Superior conductivity, antimicrobial | Very expensive |

Technical Specifications and Standards for Metal Powders

Ensuring the quality and performance of metal powders involves adhering to specific technical specifications and standards:

| Metal Powder Model | Specification | Standards |

|---|---|---|

| Aluminum 6061 | ASTM B928 | ISO 209-1 |

| Zinc | ASTM B6 | ISO 752 |

| Copper | ASTM B170 | ISO 13307 |

| Stainless Steel 316 | ASTM A240 | ISO 5832-1 |

| Nickel | ASTM B330 | ISO 4287 |

| Titanium | ASTM B348 | ISO 5832-2 |

| Iron | ASTM A955 | ISO 10807 |

| Cobalt-Chrome | ASTM F75 | ISO 5832-4 |

| Tungsten Carbide | ASTM B777 | ISO 6158 |

| Silver | ASTM B832 | ISO 920 |

Suppliers and Pricing Details for Metal Powders

Selecting the right supplier for metal powders is crucial for quality assurance. Here’s a look at some leading suppliers and their pricing details:

| Supplier | Metal Powder Model | Price Range | Location | Contact Details |

|---|---|---|---|---|

| Höganäs AB | Aluminum 6061 | $15 – $30 per kg | Sweden | www.hoganas.com |

| American Elements | Zinc | $20 – $40 per kg | USA | www.americanelements.com |

| Makin Metal Powders | Copper | $50 – $100 per kg | UK | www.makin-metals.com |

| GKN Hoeganaes | Stainless Steel 316 | $60 – $120 per kg | USA | www.gknpm.com |

| Kennametal | Nickel | $80 – $150 per kg | Global | www.kennametal.com |

| Reading Alloys | Titanium | $150 – $300 per kg | USA | www.readingalloys.com |

| Rio Tinto Metal Powders | Iron | $5 – $10 per kg | Canada | www.riotinto.com |

| Carpenter Technology | Cobalt-Chrome | $100 – $250 per kg | USA | www.carpentertechnology.com |

| Global Tungsten & Powders | Tungsten Carbide | $200 – $400 per kg | USA | www.globaltungsten.com |

| American Elements | Silver | $300 – $600 per kg | USA | www.americanelements.com |

FAQs

Surface coating materials can be complex, and you might have several questions. Here’s an FAQ section to address some common queries:

| Question | Answer |

|---|---|

| What are surface coating materials? | Surface coating materials are substances applied to surfaces to protect, enhance appearance, or add functionality. |

| What are the types of surface coatings? | Types include powder coatings, metallic coatings, ceramic coatings, polymer coatings, nanocoatings, and organic coatings. |

| Why are coatings important? | Coatings protect against corrosion, improve aesthetics, enhance durability, and add functional benefits. |

| What are some common applications? | Applications range from automotive and aerospace to electronics, marine, medical devices, and household goods. |

| How are coatings applied? | Methods include spraying, dipping, electrostatic deposition, and thermal spraying, among others. |

| What are the advantages of nanocoatings? | Nanocoatings offer superior performance, ultra-thin application, and enhanced mechanical properties. |

| What factors affect the choice of coating? | Factors include the substrate material, environmental conditions, desired properties, and cost. |

| Can coatings be eco-friendly? | Yes, many modern coatings are designed to be eco-friendly, using less harmful chemicals and offering sustainability benefits. |

Conclusion

Surface coating materials are integral to a wide range of industries, providing essential protection, enhancing aesthetics, and delivering additional functionalities. From the gleaming finish on your car to the durable coating on a skyscraper, these materials play a pivotal role in our daily lives. By understanding the different types, applications, advantages, and limitations of surface coatings, you can make informed decisions for your projects and products.

Whether you are a manufacturer seeking to improve product durability or a consumer looking for quality finishes, surface coating materials offer solutions that meet diverse needs. With advancements in technology, the future of surface coatings promises even greater innovations and benefits.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731