Titanium Ti64ELI Powder: A Technical Overview

Table of Contents

Titanium Ti64ELI powder is an important engineering material used in various industries due to its unique properties and characteristics. This article provides a comprehensive technical overview of Titanium Ti64ELI powder covering its composition, properties, applications, specifications, pricing, advantages, and limitations.

Overview of Titanium Ti64ELI Powder

Titanium Ti64ELI powder, also known as Titanium 6Al-4V ELI powder, is a titanium alloy containing aluminum and vanadium as alloying elements. It has excellent strength-to-weight ratio, fatigue resistance, fracture toughness, and corrosion resistance. Ti64ELI powder is the extra-low interstitial variant of Ti64 with lower levels of oxygen, nitrogen, carbon, and iron.

Ti64ELI is used for additive manufacturing, metal injection molding, hot and cold isostatic pressing, and other powder metallurgy processes. It can be 3D printed into fully dense, complex parts with fine microstructures and mechanical properties comparable to wrought Ti64 products. Ti64ELI’s combination of light weight, strength, and corrosion resistance make it suitable for aerospace, medical, dental, sporting goods, automotive, and marine applications.

Some key features of Titanium Ti64ELI powder include:

- Excellent biocompatibility and osseointegration

- Ability to 3D print intricate geometries not possible with casting/machining

- Consistent composition and microstructure in 3D printed parts

- Good fatigue strength and fracture toughness

- Lower interstitial elements than Ti64 for superior ductility

- Compatibility with hot isostatic pressing (HIP) and heat treatments

- Conformance to ASTM standards for chemistry and particle size

Composition of Titanium Ti64ELI Powder

The typical chemical composition of titanium Ti64ELI powder is:

| Element | Weight % |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5-6.75% |

| Vanadium (V) | 3.5-4.5% |

| Oxygen (O) | ≤ 0.13% |

| Nitrogen (N) | ≤ 0.05% |

| Carbon (C) | ≤ 0.08% |

| Iron (Fe) | ≤ 0.25% |

The key alloying elements are aluminum and vanadium. Aluminum increases strength and decreases density. Vanadium improves strength and ductility. The low interstitial elements oxygen, nitrogen and carbon in Ti64ELI give it better ductility compared to Ti64.

Properties of Titanium Ti64ELI Powder

Titanium Ti64ELI powder has the following properties:

| Property | Value |

|---|---|

| Density | 4.43 g/cm3 |

| Melting Point | 1604-1660°C |

| Thermal Conductivity | 6.7 W/m-K |

| Electrical Resistivity | 170 μΩ-cm |

| Young’s Modulus | 114 GPa |

| Tensile Strength | 895-930 MPa |

| Yield Strength | 825-875 MPa |

| Elongation | 10-15% |

| Poisson’s Ratio | 0.32-0.34 |

| Fatigue Strength | 400 MPa |

Key highlights:

- Low density compared to steels

- Retains strength and toughness at cryogenic temperatures

- Stronger than commercially pure titanium

- Lower ductility than wrought Ti64 but sufficient for most applications

- Excellent corrosion resistance due to stable protective oxide layer

Applications of Titanium Ti64ELI Powder

| Industry | Applications | Properties Leveraged |

|---|---|---|

| Aerospace | * Engine components (fan blades, compressor discs) * Airframes (landing gear components, wing ribs) * Turbines (housings, blades) * Fasteners * Gears * Hydraulic systems (pipes, fittings) | * High strength-to-weight ratio: Reduces weight while maintaining structural integrity for improved fuel efficiency and payload capacity. * Excellent fatigue resistance: Withstands repeated stress cycles encountered during flight, enhancing component longevity. * Superior corrosion resistance: Performs well in harsh environments with high humidity and exposure to de-icing fluids. |

| Medical & Dental | * Orthopedic implants (bone plates, screws, hip replacements) * Prosthetics (knees, hips, arms) * Surgical instruments (scalpels, forceps) * Dental implants | * Biocompatibility: Safe for implantation within the body, minimizing risk of rejection. * Outstanding strength and toughness: Provides support and stability for bones and joints. * Corrosion resistance: Impedes bacterial growth and ensures implant longevity within the body. * Formability: Allows for creation of complex, patient-specific implants through additive manufacturing. |

| Automotive | * Valves (intake, exhaust) * Connecting rods * Racing car components (suspension parts, roll cages) | * High strength-to-weight ratio: Reduces weight for improved performance and handling. * Exceptional fatigue strength: Endures the high stresses experienced during driving and racing conditions. * Good heat resistance: Maintains performance in hot engine environments. * Corrosion resistance: Withstands exposure to road salts and other corrosive elements. |

| Marine | * Propellers * Pumps * Shafts * Pipes & Fittings | * Outstanding corrosion resistance: Performs well in saltwater environments, preventing degradation and ensuring long service life. * High strength-to-weight ratio: Reduces weight of components for improved vessel stability and fuel efficiency. * Good fatigue strength: Withstands the constant stresses encountered in wave action and ocean currents. * Cavitation resistance: Maintains structural integrity when exposed to the formation and collapse of bubbles in water. |

| Chemical Processing | * Heat exchangers * Valves * Pipes for handling corrosive chemicals | * Exceptional corrosion resistance: Resists attack from a wide range of chemicals, ensuring safe and reliable operation. * High strength and toughness: Maintains structural integrity under pressure and at elevated temperatures. * Biocompatibility (in certain applications): Suitable for handling chemicals used in the production of pharmaceuticals and medical devices. |

| Sporting Goods | * Golf clubs (drivers, irons) * Bicycle frames * Tennis rackets | * High strength-to-weight ratio: Creates lightweight equipment for improved swing speed and power. * Good fatigue strength: Withstands the repeated impacts experienced during use. * Tunable stiffness: Allows for tailoring equipment to individual player preferences. * Corrosion resistance (in certain applications): Ensures equipment durability in various weather conditions. |

Specifications of Titanium Ti64ELI Powder

Titanium Ti64ELI powder is available in the following specifications:

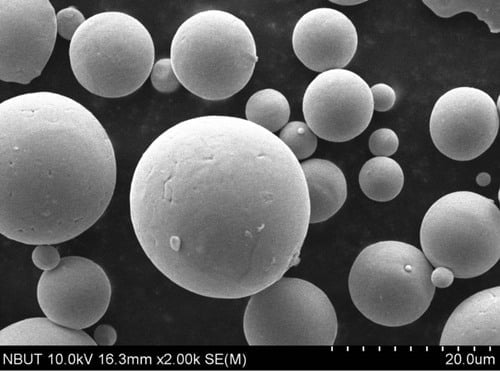

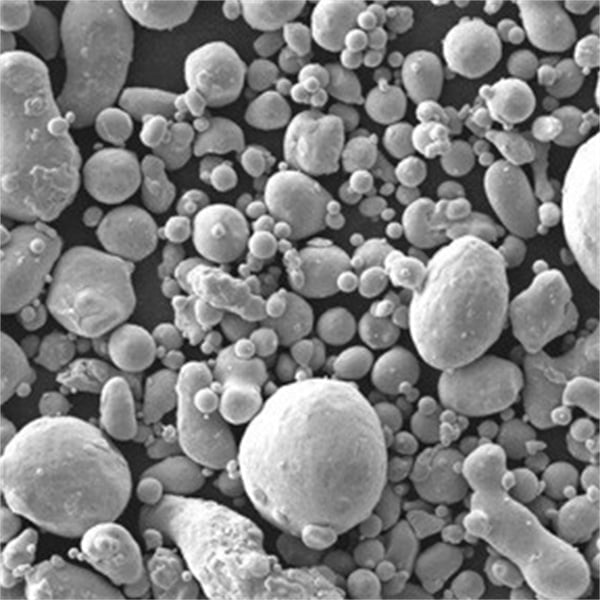

| Parameter | Details |

|---|---|

| Particle Sizes | 15-45 microns |

| Production Method | Gas atomization |

| Particle Shape | Spherical |

| Size Distribution | D10: 20 microns, D50: 35 microns, D90: 40 microns |

| Apparent Density | ~2.2 g/cc |

| Tap Density | ~3.2 g/cc |

| Flowability | Excellent |

| Standards | ASTM B348 Grade 23 |

Larger particle sizes of 63-106 microns can be custom produced based on application requirements. Finer particle sizes are available for metal injection molding feedstock.

Suppliers and Pricing of Titanium Ti64ELI Powder

Some of the major suppliers and pricing details for titanium Ti64ELI powder include:

| Supplier | Prices |

|---|---|

| AP&C | $88/kg for orders >1000 kg |

| Arcam AB | $75/kg for orders >500 kg |

| TLS Technik | €100/kg for orders >100 kg |

| LPW Technology | £70-90/kg for orders >100 kg |

| CNPC Powder | $80-100/kg for >100 kg |

Prices vary from $70-100 per kg based on order quantity, particle size distribution, and location. Small quantity and research samples can cost over $500/kg.

Comparison Between Titanium Ti64 and Ti64ELI Powders

Here is a comparison between Ti64ELI and Ti64 titanium alloys:

| Parameter | Ti64ELI | Ti64 |

|---|---|---|

| Interstitial O, C, N | Lower | Higher |

| Ductility | Higher | Lower |

| Toughness | Better | Poor |

| Weldability | Excellent | Moderate |

| Corrosion Resistance | Comparable | Comparable |

| Strength | Comparable | Comparable |

| Cost | Higher | Lower |

| AM suitability | Excellent | Moderate |

Advantages of Ti64ELI over Ti64

| Feature | Ti64ELI | Ti64 |

|---|---|---|

| Ductility and Toughness | Superior | Lower |

| Description | Ti64ELI exhibits greater ability to deform under stress without breaking (ductility) and superior resistance to crack propagation (toughness). This makes it ideal for applications that experience impact or high stress, reducing the risk of catastrophic failure. | Description |

| Weldability | Excellent | Moderate |

| Description | Due to lower levels of interstitial elements like oxygen, nitrogen, and carbon, Ti64ELI welds with minimal cracking or brittleness. This allows for the creation of complex structures by joining multiple Ti64ELI parts while maintaining strong and reliable connections. | Description |

| Additive Manufacturing (AM) Suitability | Excellent | Moderate |

| Description | Ti64ELI’s lower interstitial content and superior ductility make it a preferred choice for 3D printing processes like powder bed fusion. This translates to a lower risk of cracking during the printing process and finished parts with better mechanical properties. | Description |

| Hydrogen Embrittlement Resistance | More Resistant | Less Resistant |

| Description | Ti64ELI’s lower interstitial content minimizes hydrogen absorption, a major cause of embrittlement (loss of ductility) in titanium alloys. This is crucial for parts exposed to hydrogen environments, such as those used in chemical processing or deep-sea applications. | Description |

| Heat Treatment Response | Can achieve higher strength levels | Lower achievable strength |

| Description | Due to its lower interstitial content, Ti64ELI can be heat treated to attain higher strength levels compared to Ti64. This allows for a wider range of mechanical properties depending on the application’s specific needs. | Description |

| Cost | Higher | Lower |

| Description | The stricter control of interstitial elements and additional processing steps involved in producing Ti64ELI lead to a higher material cost compared to Ti64. | Description |

Limitations of Ti64ELI vs Ti64

| Property | Ti64 | Ti64ELI |

|---|---|---|

| Tensile Strength (MPa) | 896-1034 | 827-965 |

| Yield Strength (MPa) | 758-903 | 703-831 |

| Elongation (%) | 10-15 | 15-20 |

| Toughness (fracture toughness) | Moderate | High |

| Weldability | Good | Excellent |

| Formability | Good | Excellent |

| Biocompatibility | Good | Excellent |

Pros and Cons of Titanium Ti64ELI Powder

| Pros | Cons |

|---|---|

| Excellent Strength-to-Weight Ratio | High Cost |

| Superior Corrosion Resistance | Reactivity at High Temperatures |

| Unlocking Complex Geometries with 3D Printing | Lower Ductility Compared to Pure Titanium |

| Biocompatible and Promotes Osseointegration | Challenges in Machining |

| Consistent Material Properties | Susceptibility to Hydrogen Embrittlement |

FAQs

Q: What is the difference between Ti64ELI and Ti64?

A: Ti64ELI has lower interstitial oxygen, nitrogen and carbon compared to Ti64. This gives Ti64ELI better ductility and fracture toughness.

Q: What are the applications of Ti64ELI powder?

A: Key applications are aerospace components, medical implants, automotive parts, and 3D printing. It is widely used in industries where high strength, low weight and corrosion resistance are required.

Q: What particle size is used for AM?

A: Particle sizes of 15-45 microns are recommended for powder bed fusion AM processes like selective laser melting (SLM) and electron beam melting (EBM).

Q: What are the advantages of Ti64ELI over stainless steel?

A: Ti64ELI has higher strength-to-weight ratio, better corrosion resistance, and superior biocompatibility compared to stainless steels. However, Ti64ELI is also more expensive.

Q: What post-processing is required on Ti64ELI AM parts?

A: AM parts may need hot isostatic pressing (HIP), heat treatments, and machining to achieve the required dimensions, surface finish, and material properties.

Q: Can Ti64ELI parts be welded for repair or joining?

A: Yes, Ti64ELI has excellent weldability. Laser welding, electron beam welding, and arc welding can be used to weld Ti64ELI parts. Proper shielding is necessary to prevent oxidation.

Conclusion

In summary, titanium Ti64ELI powder offers an excellent combination of high strength, low weight, corrosion resistance, biocompatibility, processability, and heat treatability. Its applications span aerospace, medical, automotive, chemical, and consumer sectors. With additive manufacturing, complex Ti64ELI parts can be 3D printed directly from CAD data for on-demand production of lightweight structural components. However, Ti64ELI is costlier than Ti64 and challenging to machine. Overall, Ti64ELI presents capabilities beyond the limits of conventional titanium alloys.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731