VIGA Machines

Table of Contents

When we talk about VIGA machines, we’re diving into a world of advanced metal powder production technology that has revolutionized various industries. In this article, we’ll explore everything you need to know about VIGA machines, from an overview to detailed specifications, applications, and even a FAQ section. So, let’s get started!

Overview of VIGA Machines

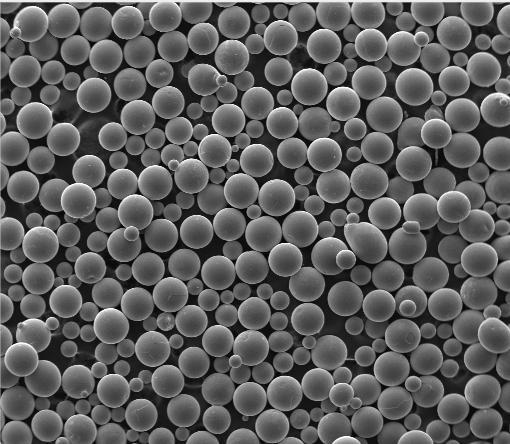

VIGA (Vacuum Inert Gas Atomization) machines are cutting-edge equipment used for producing high-quality metal powders. These powders are critical for applications in aerospace, automotive, biomedical, and additive manufacturing industries. VIGA technology stands out due to its ability to produce powders with excellent flowability, spherical shape, and controlled particle size distribution.

Key Features of VIGA Machines

- High Purity Metal Powders: VIGA machines operate in a vacuum or inert gas environment, minimizing contamination.

- Spherical Particles: Ensures excellent flowability and packing density.

- Controlled Particle Size: Adjustable atomization parameters for tailored powder characteristics.

- Wide Range of Materials: Suitable for various metals and alloys including titanium, stainless steel, and superalloys.

Types and Models of Metal Powders Produced by VIGA Machines

Here are specific metal powder models produced by VIGA machines, along with their descriptions:

| Metal Powder Model | Composition | Properties | Applications |

|---|---|---|---|

| Ti-6Al-4V | Titanium Alloy | High strength, corrosion-resistant, biocompatible | Aerospace, medical implants |

| 316L Stainless Steel | Fe-Cr-Ni-Mo Alloy | Excellent corrosion resistance, good mechanical properties | Biomedical devices, marine applications |

| IN718 | Nickel-based superalloy | High temperature strength, oxidation-resistant | Turbine blades, aerospace components |

| AlSi10Mg | Aluminum Alloy | Lightweight, good thermal properties | Automotive, aerospace |

| CoCrMo | Cobalt-Chromium-Molybdenum Alloy | High wear resistance, biocompatible | Medical implants, dental prosthetics |

| CuCrZr | Copper-Chromium-Zirconium Alloy | High electrical conductivity, good mechanical strength | Electrical components, welding electrodes |

| Maraging Steel (18Ni300) | Fe-Ni-Co-Mo-Ti Alloy | Ultra-high strength, good toughness | Tooling, high-performance gears |

| FeNiCo | Iron-Nickel-Cobalt Alloy | Magnetic properties, good mechanical strength | Magnetic components, aerospace |

| NiTi (Nitinol) | Nickel-Titanium Alloy | Shape memory, superelasticity | Medical devices, actuators |

| Hastelloy X | Nickel-Chromium-Molybdenum Alloy | High temperature strength, corrosion-resistant | Gas turbine components, chemical processing |

Applications of VIGA Machines

VIGA machines are utilized across a range of industries due to their ability to produce high-quality metal powders. Here’s a detailed look at their applications:

| Industry | Applications |

|---|---|

| Aerospace | Turbine blades, structural components, fasteners |

| Automotive | Lightweight components, engine parts |

| Biomedical | Implants, prosthetics, surgical instruments |

| Additive Manufacturing | 3D printing powders, prototyping, complex geometries |

| Energy | Turbine components, nuclear reactor parts |

| Electronics | Conductive pastes, magnetic components |

Advantages of VIGA Machines

- High Purity and Cleanliness: Operating in a vacuum or inert gas environment reduces contamination, leading to high-purity metal powders.

- Controlled Particle Size Distribution: Allows customization for specific applications, enhancing performance.

- Spherical Particles: Improves flowability and packing density, crucial for additive manufacturing.

- Versatile Material Range: Can process a variety of metals and alloys, making them suitable for diverse industries.

Disadvantages of VIGA Machines

- High Initial Cost: VIGA machines are expensive to acquire and set up.

- Complex Operation: Requires skilled operators and regular maintenance.

- Energy Intensive: The process demands significant energy, increasing operational costs.

Detailed Specifications of VIGA Machines

| Specification | Details |

|---|---|

| Material Capability | Titanium, stainless steel, nickel alloys, aluminum alloys, cobalt-chromium alloys, etc. |

| Atomization Gas | Argon, nitrogen, helium |

| Operating Pressure | Up to 150 bar |

| Particle Size Range | 10 – 200 microns |

| Production Rate | Up to 500 kg/hour |

| Vacuum Level | Up to 10^-5 mbar |

| Power Consumption | 100 – 500 kW |

| Cooling System | Water-cooled |

Comparing Pros and Cons of VIGA Machines

| Advantages | Disadvantages |

|---|---|

| High purity metal powders | High initial cost |

| Spherical particles | Complex operation |

| Controlled particle size | Energy intensive |

| Versatile material range | Requires skilled operators |

| Excellent flowability | Regular maintenance needed |

FAQ

| Question | Answer |

|---|---|

| What are VIGA machines used for? | Producing high-quality metal powders for various industries including aerospace, automotive, and biomedical. |

| How do VIGA machines work? | They use vacuum or inert gas to atomize molten metal into fine powders with spherical particles. |

| What metals can VIGA machines process? | Titanium, stainless steel, nickel alloys, aluminum alloys, and more. |

| What is the particle size range of powders produced? | Typically between 10 to 200 microns. |

| Are VIGA machines expensive? | Yes, they have a high initial cost, ranging from $900,000 to over $2,500,000. |

| What are the benefits of using VIGA machines? | High purity, controlled particle size, excellent flowability, and versatility in material processing. |

| What industries benefit from VIGA powders? | Aerospace, automotive, biomedical, additive manufacturing, energy, and electronics. |

| Can VIGA machines produce powders for 3D printing? | Yes, they are ideal for producing high-quality powders for additive manufacturing. |

| Do VIGA machines require special maintenance? | Yes, they require regular maintenance and skilled operators to ensure optimal performance. |

| What are the common atomization gases used? | Argon, nitrogen, and helium are commonly used for atomization. |

Conclusion

VIGA machines represent a pinnacle in metal powder production technology, providing high-quality powders essential for modern industries. Their ability to produce spherical, high-purity, and precisely controlled powders makes them invaluable for applications ranging from aerospace to biomedical devices. Despite their high initial cost and complexity, the benefits they offer in terms of material properties and performance are unmatched. If you’re looking to delve into high-quality metal powder production, understanding and utilizing VIGA machines can be a game-changer.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731